Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

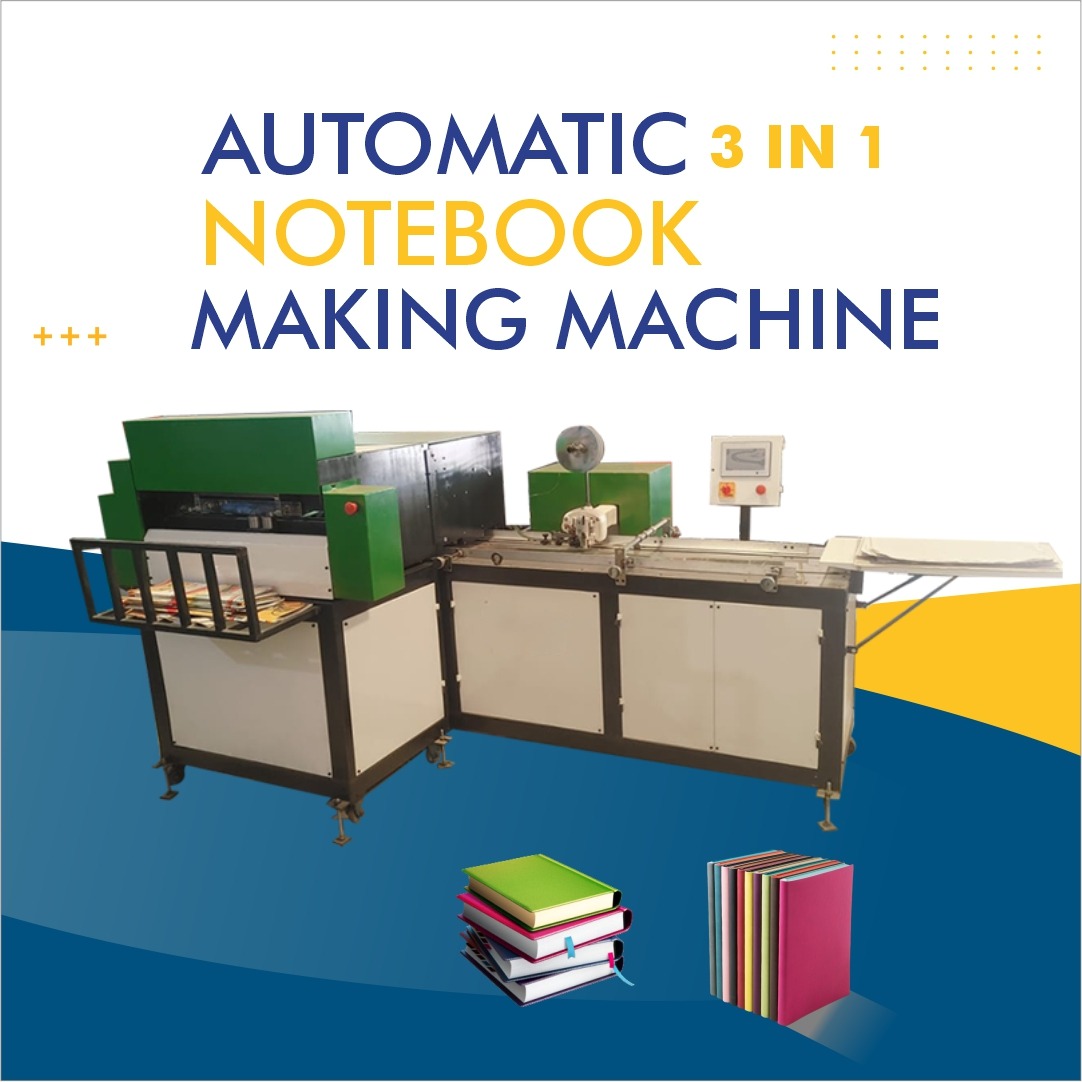

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Jajjar Haryana – Reliable Manufacturer & Dealer

Notebook Making Machine in Jajjar | Haryana

If you are planning to establish a notebook manufacturing unit or upgrade your existing stationery production line in Jajjar, Haryana, choosing the right notebook making machine is critical. Whether you want to start small with manual or semi-automatic models or scale up production with fully automatic machinery, understanding the features, capacity, and local servicing helps you make the best investment.

In this guide, you will find everything you need to know:

-

Types of notebook making machine available

-

Key features & specifications

-

Price considerations

-

Why Jajjar / Haryana is a good location

-

Maintenance & after sales support

-

How to select the right model for your production scale

We’ll repeat and reinforce important terms (synonyms) such as notebook manufacturing machine, automatic notebook making machine, notebook production equipment, notebook machinery Haryana, etc., to help SEO and clarity.

Why Choose Jajjar, Haryana for Your Notebook Machinery Base

-

Strategic location

Jajjar is well-connected by road to Delhi, industrial belts in Haryana and Rajasthan. Locating your notebook making machine business or workshop here gives you access to both raw material supply (paper, board, binding materials) and nearby markets. -

Industrial environment

Haryana has supportive infrastructure for small-scale manufacturing. Power supply, industrial permits, and connectivity are accessible for SMEs in areas around Jajjar. Local availability of skilled labor for operating notebook production equipment also helps. -

Cost advantages

Operating outside major metro areas like Delhi can reduce overheads: lower land/rent costs, lower labor costs, and perhaps easier regulatory compliance. If you plan to install a manual / semi-automatic notebook making machine here, you can benefit from local sourcing of materials and services. -

Service & maintenance

If you choose a supplier that offers service in Haryana, you can get faster turnaround time for maintenance, repairs or spare parts for your notebook manufacturing machine — a factor that reduces downtime.

Types of Notebook Making Machines

Here are the common types available in or near Haryana (including price ranges & key features):

| Type | Description | Production Capacity | Typical Price* |

|---|---|---|---|

| Manual Notebook Making Machine | Operated by hand or simple motor assistance. Ideal for low-volume or startup units. | up to ~3,000 notebooks/day (for small setups) sbsmachine.com | ~₹1-2 lakhs for basic manual setups sbsmachine.com |

| Semi-Automatic Notebook Making Machine | Some tasks automated (cutting, folding, stitching) while others need operator input. | ~3,000-5,000 pieces/day asveng.com+1 | Varies; some models ~₹2-3 lakh (SHKI Machinery example) shkimachinery.com |

| Fully Automatic Notebook Making Machine | Most operations automated: paper cutting, folding, binding, trimming. Suitable for medium-to-large scale production. | up to thousands per day (or per hour) TradeIndia+1 | Prices range higher; for example TradeIndia listing shows INR ~5.5 lakh for a fully automatic model TradeIndia |

*Prices are indicative, depending on capacity, brand & features. Always verify at purchase time.

Key Specifications to Compare

-

Production capacity: notebooks/day or per hour

-

Automation grade: manual / semi-automatic / fully automatic

-

Cutting size / sheet size: determines maximum notebook size

-

Power requirement: motor power in kW / HP

-

Build quality & material: mild steel, cast iron, stainless steel body

-

Binding type & finishing features

Selecting the Right Notebook Making Machine

When you're in Jajjar and shopping for a machine, consider the following steps and criteria to ensure you get the best fit:

-

Assess Your Production Target

Estimate how many notebooks you want to produce per day or per month. If you're servicing local schools or stationery shops, lower capacity may suffice. For regional supply or bulk orders, you may need a semi or fully automatic machine. -

Determine Machine Type

-

If you're starting with smaller volume, choose a manual notebook making machine or semi-automatic model.

-

To scale up or handle larger orders, go for automatic notebook making machine or high-capacity semi-automatic variant.

-

Consider modular or upgradeable options so you can upgrade later without complete replacement.

-

-

Budget & Return on Investment (ROI)

The machine cost is only part of the total investment. Include raw materials, labor, space, power consumption, maintenance, and downtime. Calculate ROI based on expected number of notebooks sold and your margin per notebook. -

Supplier Proximity & After-Sales Support

Verify whether the supplier can provide service or spare parts in Haryana. If the notebook machinery supplier is based far, you may incur higher shipping cost or delays. Look for brands or vendors with presence near Haryana, or willingness to deliver/maintain in Jajjar. -

Space & Utility Requirements

Ensure your workshop has enough floor area, stable power supply, appropriate ventilation, and access roads. For high-capacity machines, check electrical load (voltage / phase) and ensure compliance with local regulations. -

Quality & Safety Standards

Inspect machine build quality, safety guards, alignment precision (especially for automatic machines). A poorly aligned machine can damage materials or waste paper, increasing your cost per notebook. -

Scalability & Upgrades

See if your supplier offers modular features: e.g. add finishing station, upgrade binding capacity, add cover customization attachments. This gives you flexibility to grow your business without buying new machines from scratch.

Maintenance & Operation Tips

To ensure your notebook making machine continues to perform reliably:

-

Routine Maintenance Schedule

Clean moving parts daily (rollers, cutting blades), lubricate bearings, check alignment of cutting & stitching heads. This helps reduce wear and tear of your notebook production equipment. -

Training Operators

Skilled workers familiar with machine operation can reduce scrap, minimize downtime, and improve output quality. -

Spare Parts Stock

Maintain basic spare parts locally — blades, belts, motors. If your supplier supports Haryana service, ask for a parts kit or quick delivery option for your location. -

Calibration & Quality Checks

Conduct test runs each shift to check that notebook size, page alignment, stitching is correct. Especially for semi-automatic or automatic machines, small misalignments can lead to large material waste over time. -

Power Management

Monitor electricity usage, voltage fluctuations, or phase stability at your Jajjar workshop. A stable supply protects motor-driven equipment and reduces repair cost.

Advantages of Investing in the Right Machine

By investing wisely in a notebook making machine located in or around Jajjar, Haryana, you can gain multiple benefits:

-

Better quality output — accurate cutting, perfect binding, uniform finishing

-

Higher productivity — reduce manual labor and increase throughput per shift

-

Cost efficiency — lower per-notebook production cost through automation and reduced wastage

-

Faster turnaround — produce in-house rather than outsourcing binding or cutting

-

Competitive edge — offer customized notebook products or faster delivery to schools, offices, local businesses

Additionally, expanding production through a semi or fully automatic line gives you the capacity to supply stationery shops or distributors across Haryana and adjacent regions.

Case-Scenarios / Examples

-

Small-scale startup in Jajjar

Suppose you plan to produce 2,000 school notebooks per day for nearby schools. A semi-automatic notebook making machine with capacity ~3,000/day may serve well. Initial capital investment may be moderate, and you can scale gradually. -

Mid-scale unit with growth plans

If you plan to supply stationery stores in Rewari, Rohtak, Delhi NCR, consider a fully automatic notebook making machine with higher capacity. Though initial cost is higher, the speed and labour savings may offer better ROI within 12–18 months. -

Upgrade of existing unit

If you already have manual cutting and stitching but want to reduce labor costs or improve consistency, replacing or supplementing with semi-automatic machinery can yield productivity gains without full replacement of your infrastructure.

Conclusion

Choosing the right notebook making machine in Jajjar, Haryana requires balancing your production goals, investment capacity, and long-term service & support. Whether you go for manual, semi-automatic or fully automatic models, focusing on quality, supplier reliability, and maintenance ensures you get the best return on your investment.

If you’d like help selecting specific models, obtaining quotations, or comparing machine options for your scale (startup / midscale / full-scale), I can assist you further — just let me know your capacity requirement, budget range, and desired automation level.