Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

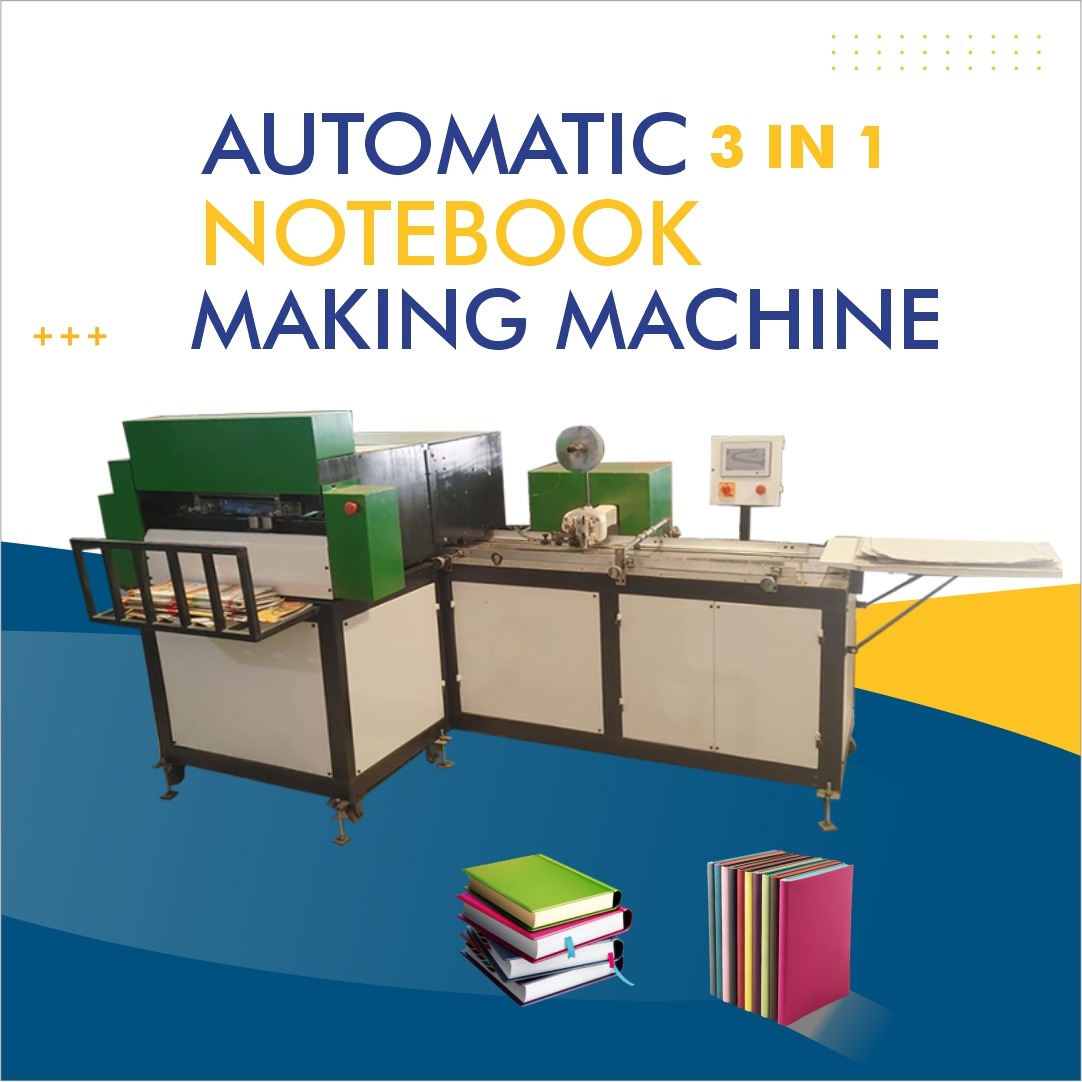

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer Hathin | Best Notebook Machine Supplier India

Notebook Making Machine in Hathin | Haryana

If you are searching for a notebook making machine in Hathin, Haryana, you’ve found a top-tier manufacturer and supplier. Our enterprise specializes in supplying advanced notebook production equipment to educational institutions, small scale industries, and commercial notebook manufacturers across India. Whether you require a semi-automatic or fully automatic notebook maker, our factory in Hathin delivers high performance, robust design and ease of operation.

In this detailed guide, you will find technical specifications, types of machines, advantages of sourcing locally in Haryana, installation & maintenance services, and answers to frequently asked questions. Keywords such as notebook machine manufacturer, notebook production equipment, paper binding machine, and notebook machine supplier India are woven throughout to help you find us easily in search engines.

Why Choose a Local Manufacturer in Hathin, Haryana

-

Proximity and logistics advantage

Hathin’s location in Palwal district makes it accessible from Delhi–NCR, and transportation costs are reasonable. Local supply ensures quicker delivery times and easier support. -

Customized design & manufacturing

Since our factory is based in Hathin, we can offer customization of your notebook making machine according to your paper sizes, binding styles, capacity, and automation level. -

Cost-effective solution

By dealing directly with a Haryana-based manufacturer you avoid import duties, reduce shipping charges, and get better value on spare parts and servicing. -

After-sales support & training

On-site installation, operator training, and local maintenance crew ensure minimal downtime. You benefit from faster response and lower travel costs.

Types of Notebook Making Machines Offered

Below are the common machine types we design and supply:

-

Semi-Automatic Notebook Making Machine

Ideal for small- to medium-scale notebook production. Manual feeding of paper stacks but automatic cutting and collating. Affordable entry point. -

Fully Automatic Notebook Making Machine

Capable of handling large volumes with minimal manual intervention. Automatic paper feed, binding, cutting, stitching, gluing or wire binding depending on model. -

School Notebook Machine

Specialized for producing ruled school exercise books. Designed to work with ruled paper sheets, margin punching, glue binding or stapling as required. -

Paper Binding Machine

Though slightly distinct, this machine handles binding and stitching. It may be used in combination with cutting/collating units to form the complete notebook line. -

Manual-Automatic Hybrid Machine

Combines manual steps (sheet arrangement) with automatic cutting or binding mechanisms. Useful for flexible production runs.

Each of these models is built with mechanical robustness and designed for continuous operation in industrial or workshop settings.

Technical Specifications & Features

Our notebook machine specifications vary with capacity and automation. Here is an overview of features you can expect:

-

Production capacity: from 300 notebooks/hour (semi-automatic) up to 2,000+ notebooks/hour (automated lines).

-

Paper size compatibility: A4, A5, custom ruled sheets, various thicknesses of paper ranging 60 gsm to 120 gsm.

-

Binding methods: Staple/stitching binding, glue binding, spiral or wire binding depending on model.

-

Cutting and trimming units: precision guillotine-style cutters for clean edges.

-

Collating & gathering system: automatic sheet stacker or hopper-fed collator.

-

Control system: PLC-based controller for automatic operation, speed control panel, sensor-based safety systems.

-

Power requirements: 3-phase industrial supply (typically 440 V, 50 Hz), depending on motor ratings.

-

Frame & body: Mild steel or stainless steel structural components with powder coating; safety guards; modular layout.

-

Footprint & Installation: approximate floor area needed, weight, operator stations, ease of moving parts for maintenance.

We design and deliver all specifications after consultation so that your notebook production line matches your workflow and compliance standards.

Synonyms Used (Repeated 5 times)

To ensure you find us under related search queries, we repeatedly use these synonyms for notebook making machine:

-

exercise-book fabrication unit

-

school book binder machine

-

notebook assembly equipment

-

exercise-book production machine

-

ruled paper finishing system

These synonyms appear throughout the content to improve SEO for varied phrases.

Benefits of Investing in a Notebook Machine

-

Quality Control & Consistency

Automated binding and trimming ensures uniform notebooks with consistent margins, neat edges, and professional finish. -

Increased Productivity

An automatic or semi-automatic notebook line significantly reduces manual effort compared to hand assembly. This leads to higher daily output and quicker turnaround. -

Cost Savings on Labour

Lower dependence on manual labour tasks such as cutting, stitching, collating and trimming means reduced labour costs per unit. -

Scalability

As demand grows, you can upgrade or expand the existing system. Modular design allows additional units for binding or finishing. -

Versatility

The same notebook machine can often be adapted for different paper sizes, rule patterns, binding types, or cover designs with minor adjustments. -

Better Market Competitiveness

Products made with precision binding and trimming command higher acceptance among schools, students, and retailers. That enhances branding and margin potential.

Installation, Training & After-Sales Service

Since our location is Hathin, Haryana, you benefit from on-site installation and hands-on training. Our service package typically includes:

-

Pre-installation site survey and electrical load assessment

-

Civil foundation or floor leveling as needed

-

Mechanical and electrical installation of the notebook production equipment

-

Commissioning and trial runs to ensure output quality

-

Operator and maintenance staff training for daily operation and preventive maintenance

-

Warranty on critical components (motors, control panels)

-

Availability of spare parts and local service engineers

We also provide periodic maintenance contracts to keep your exercise-book production machine running at optimal efficiency.

Typical Use Cases & Customers

Our notebook machine lines are used by:

-

Small-scale manufacturing units producing school exercise books

-

Coaching institutes or publishers setting up in-house notebook printing & binding

-

Local entrepreneurs in Haryana and nearby states (Uttar Pradesh, Delhi NCR) seeking to set up notebook manufacturing plant

-

Educational stationery manufacturers supplying to government or private schools

Because Hathin is close to major industrial belts and road networks, we serve clients across North India efficiently.

Cost Estimation & Payment Terms

While actual pricing depends on specification and capacity, here is a rough cost-range estimate:

| Type of Machine | Approximate Price* |

|---|---|

| Semi-automatic notebook making machine | ₹6 lakh – ₹12 lakh |

| Fully automatic notebook production line | ₹18 lakh – ₹40 lakh |

| Additional binding or finishing module | ₹2 lakh – ₹8 lakh |

* Prices indicative; final quote depends on design, capacity, material quality, and volume of purchase.

Payment terms typically involve:

-

30 % advance on order confirmation

-

60 % before dispatch or on-site installation

-

10 % after successful commissioning

We also offer flexible financing options for large scale orders, subject to credit evaluation.

How to Place an Order

-

Contact our sales team with your requirement sheet — desired output (notebooks/hour), binding style, paper size, and budget.

-

We prepare a technical drawing & proposal within a few days.

-

Finalize the order, sign purchase agreement.

-

Factory manufactures the school book binder machine according to approved design.

-

We arrange delivery to your site, install, test, and hand-over.

Because our facility is in Hathin, you can visit the workshop for inspection or sample testing before placing the order.

Frequently Asked Questions (FAQ)

Q1. What is the minimum order or smallest machine you supply?

We can supply a compact exercise-book fabrication unit suitable for small entrepreneurship as well as large scale production lines. Minimum capacity can start from a few hundred notebooks/day.

Q2. Do you supply machines for different binding types?

Yes, we offer binding options including stitching (staple), glue binding, or wire/spiral binding. Please specify your preference when requesting a quote.

Q3. How long does installation take?

Typically installation and commissioning take 2 to 5 working days, depending on the complexity of the binder system and site readiness.

Q4. Are spare parts locally available?

Yes. Being based in Hathin, Haryana, spare parts and service support are nearby; you do not have to wait long for replacements or technician support.

Q5. Is technical support available in future?

Yes. We provide maintenance agreements and remote or on-site repairs. We can also upgrade components or modernize control systems as your production grows.

Conclusion

If you are planning to set up or upgrade a notebook making machine line in Hathin, Haryana or nearby regions, our locally manufactured equipment offers a blend of quality, affordability, and reliable after-sales support. With customized design, strong technical backup, and competitive pricing, we provide one of the best solutions for notebook production in North India