Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

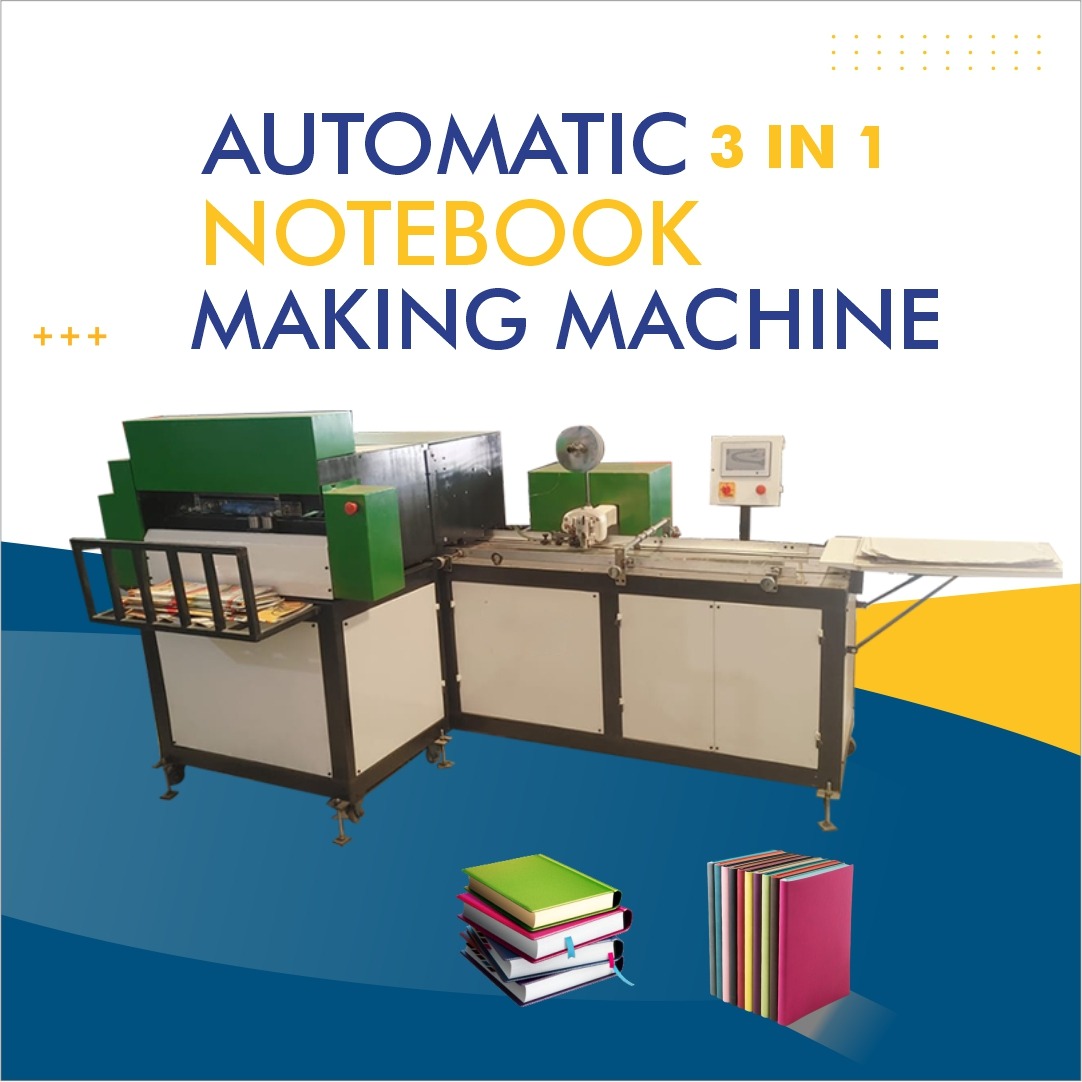

Notebook Making Machine Gohana Haryana | Manufacturing & Supply

Notebook Making Machine Gohana | Haryana

Are you planning to start or scale up a notebook production business in Gohana, Haryana? Whether you are an entrepreneur eyeing the stationery market or an existing manufacturer seeking to upgrade your equipment, investing in the right notebook making machine can make all the difference. Located in Gohana (Sonipat district), our factory/supply chain offers high-quality notebook production machines suited for local businesses across Haryana and nearby areas.

In this comprehensive guide, we walk you through everything you need to know: types of machines, benefits, features, technical specifications, local advantages of being in Gohana, considerations before purchasing, and after-sales service.

Why Gohana, Haryana is a Good Location

-

Gohana is a tehsil in Sonipat district of Haryana. Wikipedia

-

Proximity to industrial towns like Panipat, Sonipat, and Delhi NCR means good logistics connectivity for machinery and raw materials.

-

Gohana being in Haryana provides access to local labour, state-level incentives for MSMEs, and a market for stationery manufacturing in North India.

-

As stationery demand grows with schools, colleges, and offices, having machinery locally means lower freight, quicker service, and faster setup.

What is a Notebook Making Machine?

A notebook making machine refers to an integrated setup (or series of machines) used in the manufacturing of notebooks. It typically covers cutting paper sheets, ruling lines, stitching or binding, trimming edges, pressing, and finishing tasks. Depending on automation level, machinery can be manual, semi-automatic, or fully automatic. Key parts may include binding machines, ruling machines, cutting machines, edge-squaring presses, and stitching units.

These machines are essential for any stationery manufacturer that wants to produce notebooks at scale with consistent quality. The performance is judged by output capacity (notebooks per day / per hour), precision of cut / alignment, durability, power consumption, ease of maintenance, and cost of spare parts.

Types of Notebook Making Machines Offered

We supply various categories of machines depending on production capacity, automation level, and budget:

-

Manual Notebook Making Machine

-

Suitable for small scale operations or start-ups with limited investment.

-

Operated manually or with minimal electric power.

-

Lower throughput but simpler maintenance.

-

-

Semi-Automatic Notebook Making Machine

-

Balances cost with automation.

-

Some stages manual, others powered (cutting, binding).

-

Higher output than manual; ideal for medium volume production.

-

For example, one model from ASV Engineering (semi-automatic notebook machine) offers production capacity of thousands per day. asveng.com

-

-

Automatic Notebook Making Machine

-

Fully integrated workflow: cutting, ruling, stitching/binding, pressing / finishing.

-

Best for high-volume production.

-

Reduced manual intervention, greater consistency and speed.

-

-

Supporting / Auxiliary Machines

-

Paper cutting machines

-

Ruling / line-printing machines

-

Edge squaring or trimming machines

-

Binding / stitching machines

-

Hydraulic presses for pressing notebook blocks.

-

Suppliers may offer packages or full setups that include all necessary units to establish a production line.

Features & Specifications to Consider

When choosing a notebook making machine in Gohana / Haryana region, evaluate:

-

Production capacity (notebooks per hour or day)

-

Automation grade (manual / semi-automatic / automatic)

-

Size & format supported (e.g. A4, A5, custom sizes)

-

Power requirements (voltage, phase)

-

Material quality & frame construction (steel, mild steel, stainless parts)

-

Precision & finishing quality (edge trimming accuracy, alignment after binding)

-

Speed & downtime (ease of maintenance, spare parts logistics)

-

Customization options (custom ruling patterns, binding styles, thickness)

-

After-sales service, local technical support & warranty

-

Cost & return on investment, including logistics from Gohana to yours

Benefits of Buying Notebook Making Machine from Gohana Supplier

Choosing a machine supplier or manufacturer based in or near Gohana (Haryana) offers advantages:

-

Reduced transportation cost & time — local delivery within Haryana / NCR.

-

Faster installation / commissioning at your site due to proximity.

-

Better after-sales support (technicians can reach quickly).

-

Local regulatory & incentive awareness — suppliers familiar with Haryana / Sonipat environment.

-

Customization geared to local stationery market (sizes, styles common in North India).

Furthermore, being in Haryana means you can often source raw material (paper sheets, cover boards) locally, reducing your lead times and cost.

Applications & Who Should Use It

Your notebook making machine can serve:

-

Standalone Notebook Manufacturing Units in Gohana or nearby towns

-

MSMEs or Startups in stationery production

-

Schools / Educational Stationery Projects or government supply tenders

-

Contract manufacturers who produce notebooks for brands or publishers

-

Value-addition workshops that supply ruled exercise books, spiral / stitched notebooks

If you already run small-scale binding or paper cutting setups, upgrading to a semi-automatic or automatic machine can help you scale up capacity and quality.

Setting up & Workflow

Here’s a high-level overview of setting up a notebook production workflow using the machine:

-

Design / Planning

Determine sizes, ruling style, binding type, number of pages, thickness etc. -

Raw Material Procurement

Order sheets of ruled paper, cover sheet material, binding thread / staples, cover lamination if needed. -

Cutting / Trimming

Use paper cutting machine to cut to dimensions; trim edges for uniformity. -

Ruling / Printing Lines

If your machine includes ruling unit, print ruling lines or leave blank pages as needed. -

Collating

Assemble inner sheets with cover. -

Binding / Stitching

Machine binds via stitching, stapling, or glue (depending on model). Some machines support wire / thread binding. -

Pressing / Squaring

Use edge-squaring machine / hydraulic press to flatten and finish the notebook block. -

Trimming / Finishing

Remove excess edges, polish corners, ensure clean binding. -

Packaging

After production, notebooks are packaged for distribution.

Your machinery should allow you to perform most steps in an integrated fashion so throughput is maximized, rejection is minimal, and quality is consistent.

Investment & ROI Considerations

-

Estimate your initial cost: machine price + delivery + installation + operator training.

-

Consider operating cost: electricity, labour, maintenance, spare parts.

-

Estimate daily output and your selling price per notebook to compute breakeven.

-

Plan for scalability: can you add extra units or upgrade automation later?

-

Factor in after-sales service: downtime due to breakdown can affect profitability.

Working with a local supplier in Gohana means you may negotiate packages that include spare parts and maintenance plans.

After-Sales Support & Maintenance

A reputable notebook making machine supplier near Gohana should offer:

-

On-site installation & commissioning

-

Training of operators (how to run the machine, safety, routine checks)

-

Scheduled maintenance visits

-

Spare parts supply (rollers, cutting blades, binding components)

-

Technical support via phone / on-site visits

These services reduce downtime and ensure your production quality remains high.

Why Choose Our Machine / Service (Example USP Section)

(You can adapt this for your own brand / business)*

-

Built for Indian conditions: voltage, duty-cycle, operator ease.

-

Custom size support: A4 / A5 / school exercise book dimensions common in Haryana market.

-

Affordable pricing, especially for semi-automatic setups for MSMEs.

-

Fast response time for service calls in and around Sonipat / Gohana.

-

Quality assurance: rugged build, minimal maintenance, long life.

-

Capability to upgrade: add modules or extra units for binding / trimming / finishing as your business grows.

How to Order / Contact

If you are based in Gohana or nearby (Sonipat, Panipat, Rohtak), and wish to purchase or enquire about a notebook making machine, you may:

-

Request a site visit / demo in your factory or workshop.

-

Ask for product brochure / specifications sheet (capacity, automation grade, sample finishes).

-

Provide your desired notebook size, pages count, binding style, daily target production.

-

Get a quotation including machine cost + delivery + installation + support.

-

Evaluate financing options if required (bank loans / MSME support).

We can help you with all these steps — from machine selection to after-sales service in and around Gohana, Haryana.

Conclusion

Investing in a high-quality notebook making machine is a key step to scaling your stationery manufacturing business. By sourcing the machine locally (in Gohana / Sonipat region), you benefit from lower logistics cost, faster support, and better alignment with regional market needs. Whether you choose manual, semi-automatic, or fully automatic machinery, ensure you balance production capacity, quality, and long-term maintenance.