Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

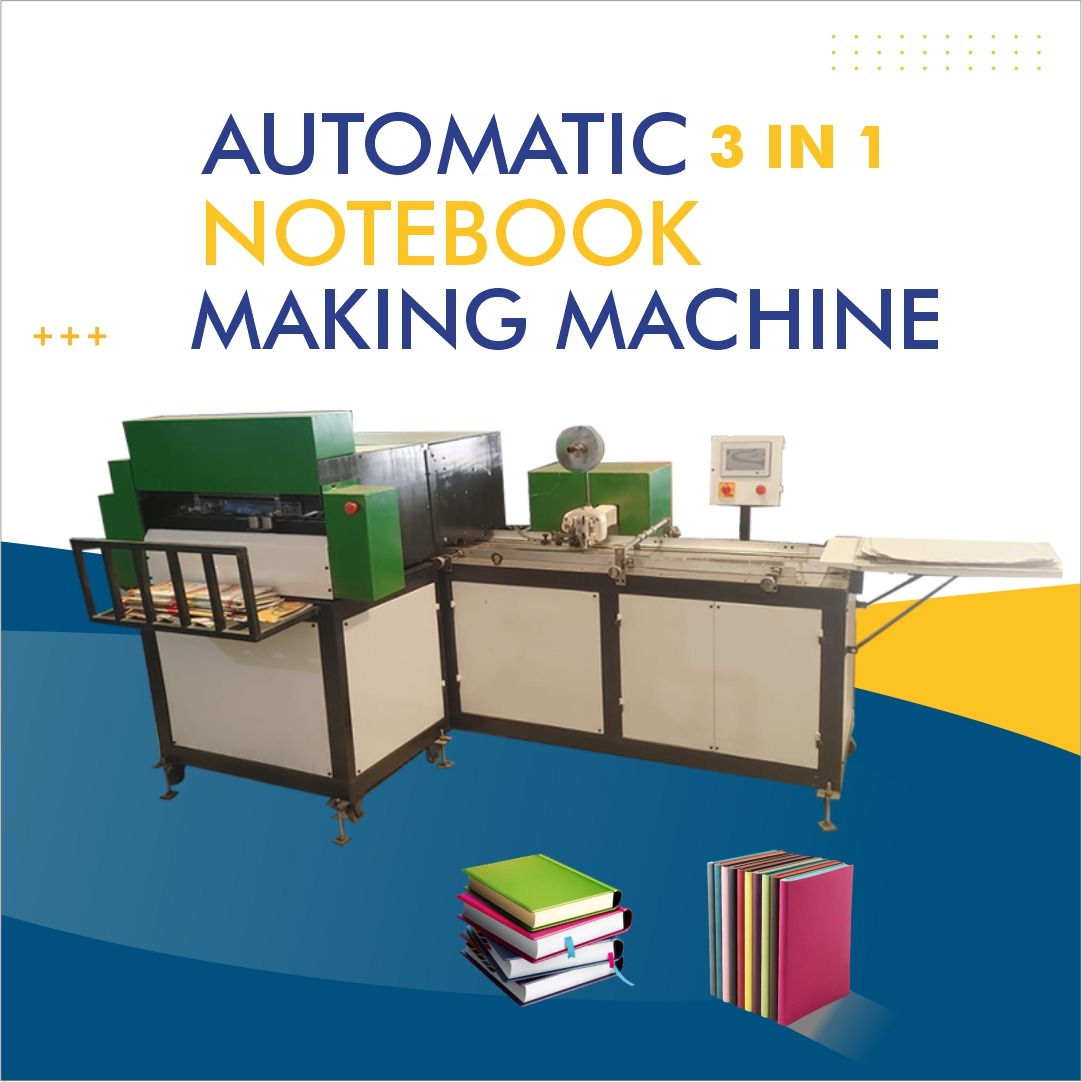

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Gharaunda Haryana | Manufacturer & Exporter

Notebook Making Machine in Gharaunda | Haryana

If you are looking to set up or scale a notebook production unit in Haryana, choosing the right notebook making machine is crucial for efficiency, quality and profitability. Based in Gharaunda, Haryana, our manufacturing facility offers robust machines designed to handle everything from manual production to high-speed automatic operations. Our notebook making machine solutions are ideal for new entrepreneurs, small-scale units, and large manufacturing operations throughout northern India.

In this detailed guide, you’ll learn about the types of notebook making machines, their features, benefits, and why selecting a machine sourced from Gharaunda gives you competitive advantage. We also discuss factors such as capacity, automation grade, maintenance, and cost.

2. Why Gharaunda, Haryana is a Strategic Location for Notebook Making Machine Manufacturing

-

Strategic proximity to major industrial hubs such as Karnal, Panipat, and Delhi.

-

Access to skilled workforce and metal-fabrication facilities.

-

Lower transportation cost for deliveries around North India.

-

Compliance with local industrial regulations and ability to cater to state incentives.

-

Easier face-to-face support, servicing and installation for customers in Haryana, Punjab, Uttarakhand, Himachal Pradesh and Delhi NCR.

Because of these location benefits, purchasing your machine from Gharaunda ensures lower logistical delays, better on-site support, and faster commissioning.

3. Types of Notebook Making Machines We Offer

We supply and manufacture different types of notebook making machine to suit varied production demands. Key categories include:

-

Manual Notebook Making Machine

-

Best for low-volume production, educational institutes, or start-ups.

-

Simple operation, lower cost, easy maintenance.

-

For example, manual notebook making machine setups in India often produce ~3,000 notebooks per day. sbsmachine.com

-

-

Semi-Automatic Notebook Making Machine

-

Partially automated functions (cutting, folding or stitching), reducing labour requirement.

-

Balanced cost and productivity. Many semi-automatic machines are available in the Indian market. asveng.com+1

-

-

Fully Automatic Notebook Making Machine

-

High throughput with minimal human intervention.

-

Suitable for large-scale manufacturing units. Indian suppliers offer models that run thousands of notebooks per day. kolkatamachineryimportexport.com+1

-

-

Custom or Hybrid Models

-

Machines combining manual / semi / automatic components tailored for special size, binding type or finishing.

-

4. Key Features & Specifications

When evaluating any notebook making machine, these are the most important features and specifications to consider:

| Feature | Why it Matters |

|---|---|

| Production Capacity | Determines how many notebooks per hour or per day. Manual machines may produce a few thousand per shift; automatic machines scale up to many thousands. |

| Automation Grade | Manual, semi-automatic or fully automatic determines labour input, speed, consistency and investment. |

| Material & Build Quality | Steel frame (mild steel or stainless steel), quality welding, precision parts affects longevity and reliability. |

| Power Requirements | Voltage, phase (single-phase / three-phase), motor rating, energy efficiency. |

| Size & Format Compatibility | Notebook sizes (A4 / A5 / custom), binding type (stitching, edge-squared, folding), thickness capacity. |

| Ease of Maintenance | Spare part availability, local servicing from Gharaunda/Haryana, alignment adjustments, training for operators. |

| Safety & Compliance | Guards, emergency stops, certification if required. Local regulatory compliance for industrial machinery in Haryana. |

| Cost & ROI | Initial investment vs expected output, cost per notebook, return on investment period. |

5. Benefits of Our Notebook Making Machine Solutions

By choosing a notebook making machine from our Gharaunda facility, you enjoy the following advantages:

-

High Durability – Designed with robust structural materials for long life under industrial use.

-

Superior Quality Finish – Accurate cutting, alignment, stitching and folding ensures notebooks are professional-grade.

-

Local Support & Service – Since you are in Haryana / nearby, our installation, operator training and spare-parts support is faster and more cost-effective.

-

Scalable Options – You can start with a manual or semi-automatic machine today and upgrade or expand to automatic systems as your business grows.

-

Competitive Pricing – Lower transportation and sourcing cost compared to importing machinery or buying from distant suppliers.

-

Energy Efficiency – Optimized for Indian power supply and duty-cycles.

6. Use Cases & Applications

Users of notebook making machines include:

-

Schools & educational stationery producers

-

Small-scale printing & binding workshops

-

Startup entrepreneurs manufacturing exercise books, diaries, registers

-

Custom notebook producers printing special designs or sizes

-

Bulk supply chains to retailers, bookstores, publishers

With the right notebook making machine, you can produce exercise notebooks, school registers, gift notebooks, and customized diaries with branded covers and finishing.

7. Choosing the Right Capacity

Here is how to select capacity based on your production needs:

| Production Goal | Recommended Machine Type |

|---|---|

| Up to 3,000 notebooks/day | Manual or low-capacity semi-automatic machine |

| 3,000–7,000 notebooks/day | Semi-automatic medium-speed machine |

| 7,000 or more notebooks/day | Fully automatic notebook making machine |

When scaling up production, you should account for working hours per shift (8 hr / 16 hr), downtime, operator availability, and waste/scrap allowances.

8. Pricing Expectations

Pricing depends on type and capacity:

-

Manual notebook making machines tend to be lowest-cost entry models. sbsmachine.com

-

Semi-automatic models cost more due to additional mechanical/electrical components. asveng.com

-

Fully automatic lines with servo control, synchronized folding & stitching command premium pricing. endurancemachinery.com

Because we fabricate locally in Gharaunda, costs related to freight, import duty, and remote servicing are minimized. We can offer competitive quotes tailored to your required spec (size, speed, automation grade).

9. Installation & After-Sales Support

We provide full lifecycle support for our notebook making machine units:

-

Site survey & Installation – We visit your location (within Haryana / NCR) to plan installation layout.

-

Training & Testing – Operator training and trial production run to ensure machine meets target output.

-

Spare Parts & Repairs – Stock of consumables and wear-parts located locally for rapid replacement.

-

Maintenance Contracts – Optional periodic maintenance service to keep machine uptime high.

-

Upgradability – Ability to upgrade parts (e.g. motor upgrade, automation module) as demand grows.

10. Why Us — Our Competitive Edge

Here are a few reasons why our notebook making machine offering is ideal:

-

Years of experience in industrial machinery production and customisation

-

Transparent specifications and reliable performance

-

Local presence in Gharaunda, Haryana ensures faster delivery and support

-

Flexible configuration: manual / semi-automatic / automatic

-

Quality assurance before delivery and commissioning

11. Frequently Asked Questions (FAQ)

Q. What is lead time for a custom notebook making machine?

A. Typically, manufacture and testing take 4 – 8 weeks depending on specifications.

Q. Can I get a sample trial run before full commissioning?

A. Yes, we run test samples at our facility in Gharaunda and share measurable output metrics.

Q. What sizes of notebooks can your machine handle?

A. Our default formats include standard sizes (A-5, B-5, custom sizes), with capacity for cover thickness and binding type adjustable per model.

Q. Do you support expansion later to higher capacity or automation?

A. Yes — many customers start with semi-automatic machines, then upgrade modules or add parallel lines.

Q. What kind of power supply is required?

A. Machines are built for Indian industrial voltage (single-phase or three-phase) depending on model; we specify exact ratings on quotation.

12. How to Order / Contact

If you want to purchase a notebook making machine from our Gharaunda, Haryana facility, here’s the typical process:

-

Share your required production capacity (no. of notebooks/day or per hour).

-

Specify notebook size, binding type and finishing options.

-

Choose automation grade: manual / semi-automatic / fully automatic.

-

We send a detailed specification sheet & quotation.

-

Upon confirmation, we schedule manufacturing, delivery & installation.

Contact us via phone or email, or visit our facility in Gharaunda for a site discussion and demo.

Conclusion

Investing in the right notebook making machine is a foundational decision for any stationery or notebook-manufacturing business. With our Gharaunda-based manufacturing, you get quality, reliability, and support tailored to your needs. Whether you are launching a small-scale production or scaling up to large output volumes, our machines deliver the performance you require. Choose us for your notebook production equipment and experience the advantages of local expertise, robust build quality, and comprehensive after-sales support in Haryana and beyond.