Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

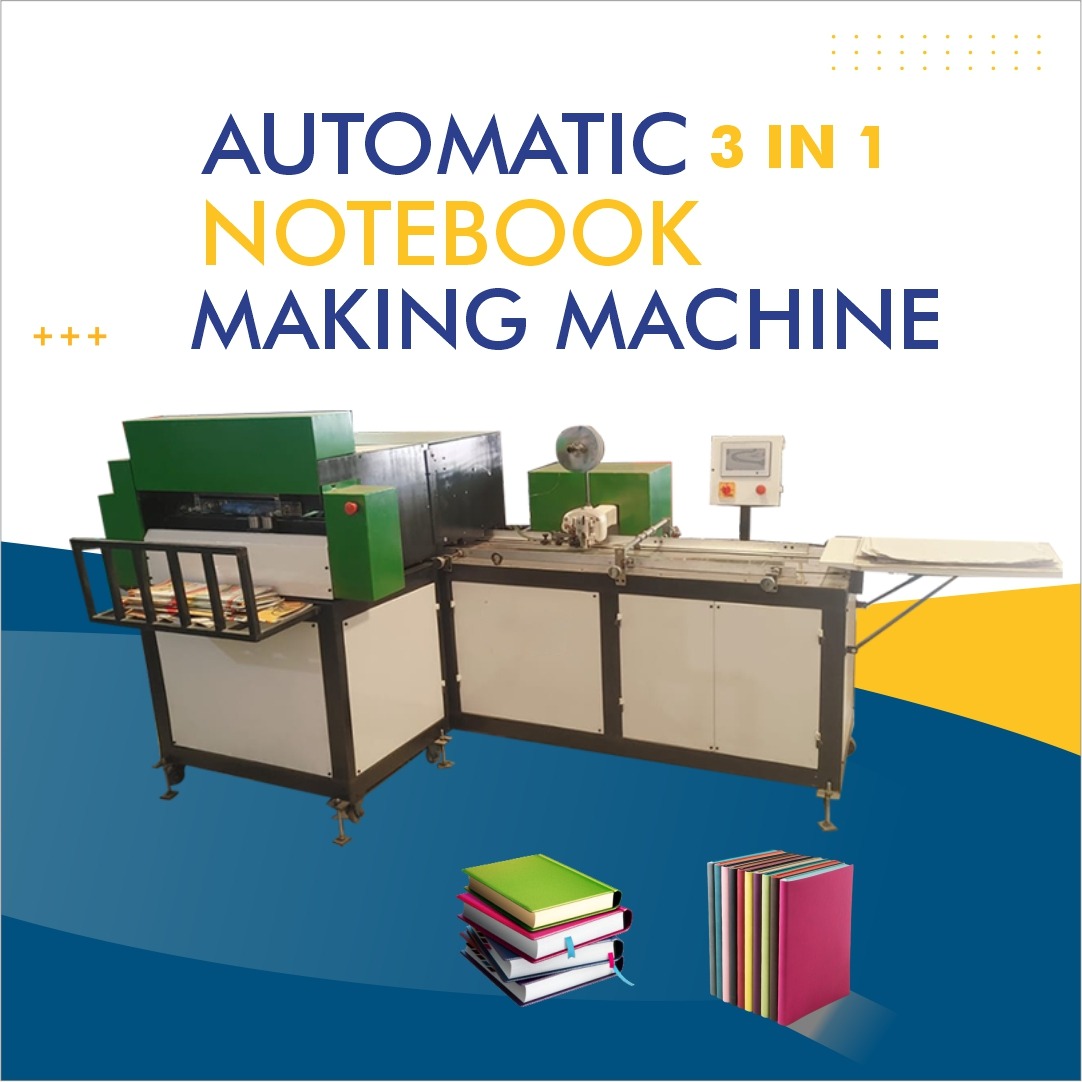

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier in Dabwali, Haryana | Precision Equipment India

Introduction

Welcome to Precision Equipment India, your trusted partner for designing, manufacturing, and supplying notebook making machines in Dabwali, Haryana. If you are looking for a high-performing notebook making machine, book-binding press or automated bookbinder system within Haryana or nearby regions such as Sirsa, Sri Ganganagar or Hisar, you’ve come to the right place. Our comprehensive range of equipment delivers exceptional output, reliable operation, and local after-sales service — ideally suited to small, medium and large scale stationery manufacturing units.

In this page you’ll find detailed information on what makes our notebook making machines special, the features, benefits, specifications, and why choosing a locally manufactured machine in Dabwali can give you an edge over imported or distant-sourced equipment.

About Us

Located in Dabwali, Haryana, we are a leading engineering and manufacturing company specializing in stationery production equipment. Our core business includes designing, fabricating, assembling, testing, and commissioning notebook production machinery for local and regional clients. Because our factory is right here in Dabwali, we can offer prompt delivery, rapid installation, training for operators, and on-site support.

We understand the technical requirements for notebook making — folding, stitching, trimming, binding and packaging. Our deep knowledge of mechanical systems, electronics and production workflows ensures that our notebook making machine (and related binding equipment) functions reliably day after day with minimal downtime.

What Is a Notebook Making Machine?

A notebook making machine is a specialized industrial system used for producing bound paper products such as notebooks. It integrates various subsystems including paper folding, gathering, stitching (or gluing), trimming edges, and pressing the covers. In automated configurations, the notebook making machine can process large volumes with consistent quality and is widely used by stationery manufacturers, schools’ suppliers, and publishers.

Synonyms or related terminology you may hear include:

-

Bookbinding machine

-

Automatic book binding machine

-

Binding press

-

Notebook binding equipment

-

Stationery binding system

These terms essentially refer to the same or highly similar machinery used to bind pages together and produce finished notebooks.

Types of Notebook Making Machines

We manufacture and supply multiple types of equipment to suit different production scales:

| Type | Description |

|---|---|

| Semi-automatic notebook making machine | Requires some manual intervention (e.g. inserting sheets) but automates trimming, binding or stitching. Ideal for medium-scale production. |

| Fully automatic notebook making machine | Capable of continuous operation with minimal human intervention. Sheets fed automatically, stitched or glued, trimmed, and ejected. Ideal for large-scale stationery factories. |

| Binding press / stitching press | A standalone binding press for hand-fed notebooks, often used in small units or storerooms. |

| Notebook production line | Integrated set of machines for collecting sheets, folding, binding, trimming, pressing, and packing. |

Our machines can be customised to your preferred page size, thickness (number of pages), binding style (thread-stitching, staples, glue), cover type, and production speed. Whether you require manual binding press or high-speed automatic bookbinding machine, we have the right solution.

Features & Benefits

When you invest in a notebook making machine from our facility in Dabwali, you get:

-

High precision components – all moving parts, trimming blades, stitching heads, are engineered to tight tolerances so your notebooks have consistent margin alignment and edge finish.

-

Robust frame and chassis – made from industrial-grade steel and treated to resist corrosion in Haryana’s climate.

-

Custom sizing – capability to handle sizes such as A4, A5, or custom dimensions.

-

Variable speed options – from low volume to high-speed automatic throughput.

-

Safety features – emergency stop buttons, guard covers, and safety interlocks to meet Indian factory safety norms.

-

Local service & spare parts – based in Dabwali, we maintain an inventory of spare parts (blades, belts, stitching heads) for prompt replacement.

-

Training & commissioning – our engineers come to your site (within Haryana or neighbouring states) for installation, calibration, operator training, and maintenance.

-

Energy-efficient drive systems – modern motors and controllers reduce electricity usage, helping you save on operating costs.

Why Choose Our Notebook Making Machine in Dabwali, Haryana

Local Proximity & Lower Lead Time

Being based in Dabwali, we are physically close to many stationery and printing units in Haryana, Punjab, Rajasthan. This proximity reduces shipping time and freight cost. It also allows you to visit the manufacturing unit or have our engineers visit your site for fast installation.

Customisation & Flexibility

Our engineers can customise the machine layout, paper size, binding style, cover material or thickness. Because we develop the product locally, modifications are easier and faster to implement compared to imported equipment.

Cost-Effectiveness

By manufacturing in Dabwali rather than importing machines from overseas, we avoid customs duties, import shipping, and currency-fluctuation costs. This makes our notebook making machines more affordable while maintaining high quality.

After-Sales Support

We provide on-site servicing, preventive maintenance, and spare-parts supply. Our response time within Haryana or adjacent districts is much faster than vendors located in distant cities.

Compliance and Safety

All electrical, mechanical and electronic components meet Indian regulatory standards. We ensure that our notebook making machine passes safety inspections, especially for use in industrial environments.

Technical Specifications Example

Here is an example specification sheet for a mid-range automatic notebook making machine:

| Parameter | Value |

|---|---|

| Maximum Sheet Size | 300 mm × 450 mm |

| Cover Size Options | From A5 to A4 |

| Maximum Page Thickness | Up to 200 pages (80 gsm sheets) |

| Throughput Speed | Up to 120 notebooks per minute (varies by size) |

| Binding Type | Thread stitching or staple or glue binding |

| Trimming Accuracy | ± 0.2 mm (edge trim) |

| Power Supply | Three-phase 415V, 50 Hz |

| Power Consumption | Approx. 5 kW under full load |

| Machine Dimensions (L × W × H) | 2000 × 1200 × 1600 mm |

| Machine Weight | Approx. 950 kg |

| Operator Interface | PLC Touchscreen or Manual Controls |

| Safety Features | Guards, emergency-stop, interlocks, overload protection |

These specifications can be tailored according to your production requirements.

How It Works (Process Workflow)

Here’s a simplified workflow of how a notebook making machine operates:

-

Sheet Feeding – Paper sheets are stacked or fed via hopper.

-

Collation / Gathering – Sheets are arranged in the correct sequence (for multiple signatures or one set).

-

Stitching or Binding – Depending on the model, the machine applies thread stitch, staples or adhesive glue to bind the sheets.

-

Edge Trimming – Trim the three edges to ensure clean, uniform appearance.

-

Pressing – A binding press may compress the bound book block to flatten it, ensure tight edges, and set glue or binding pressure.

-

Cutting / Finishing – Final trimming or bevels.

-

Ejection – Finished notebook is ejected or stacked for packaging.

-

Quality Check – Visual inspection or weight check to ensure pages are secure and aligned.

Operators control the speed, margin settings, trimming width, and binding tension via the control panel or interface. Regular maintenance includes replacing blades, lubricating moving parts, and checking tension of stitching heads or adhesive application rollers.

Applications & Clients

Our notebook making machine is suited for:

-

Small to medium stationery manufacturers producing exercise books, school notebooks, diaries.

-

Printing and binding houses looking to expand into notebook production.

-

Educational institutions or publishers planning in-house binding and printing.

-

Packaging or gift-item companies producing custom notebooks, journals or promotional gifts.

We have supplied machines to clients across Haryana, Punjab, and Rajasthan. Many users in Sirsa, Fatehabad and Hisar trust our equipment because of its reliability and local maintenance.

Pricing & Investment

The investment cost for a notebook making machine depends on the type (semi-automatic or fully automatic), binding method, production speed and custom features. Approximate price ranges include:

-

Semi-automatic binding press / bookbinding machine: INR 3 lakh to 8 lakh

-

Fully automatic notebook production line: INR 12 lakh to 25 lakh (or more depending on speed & capacity)

-

Custom modifications (size change, electrical upgrades, software interface) may add additional cost

We also offer financing options, installation charges, and warranties. Contact us with your production volume, required speed, binding style and budget, and we will provide a detailed quotation.

Maintenance & Service

To keep your notebook making machine operating smoothly:

-

Carry out scheduled preventive maintenance every 3–6 months.

-

Replace trimming blades and stitching heads as per usage.

-

Ensure operator training for safe handling.

-

Use stable power supply and surge protection.

-

Keep a log of production run hours, faults, and servicing records.

We provide maintenance contracts for customers in Dabwali, Sirsa, Hisar, and surrounding areas. Our technicians can travel on short notice for urgent repairs.

Contact & Location

If you are interested in purchasing or visiting a demo of our notebook making machine:

Precision Equipment India

Address: Industrial Area, Dabwali, Haryana – [PIN code]

Phone: +91-[your number]

Email: info@precisionequipmentindia.com

You are welcome to visit our factory in Dabwali to see the notebook making machine in action, inspect quality, and discuss custom requirements.

We also provide virtual consultation and video demonstration if you are not immediately nearby.

FAQ

Q. What minimum order quantity is required?

A. You can order a single machine or a complete production line depending on your needs. MOQ is typically one unit for standard machines. Customised production-lines may require confirmed order.

Q. How long is the warranty?

A. We offer 12 months’ warranty on mechanical and electrical components. Extended maintenance contracts are available.

Q. Can the machine handle different notebook sizes?

A. Yes, our design allows adjustment for different paper sizes and thicknesses. Customisation may incur minor additional cost.

Q. What support is available after installation?

A. We provide on-site commissioning, operator training, and after-sales service within Haryana and nearby states.

Conclusion

Choosing a notebook making machine manufacturer in Dabwali, Haryana ensures you receive high-quality, cost-effective, and locally supported equipment. Whether you are starting a new stationery business or upgrading your production capacity, our tailor-made machines, reliable service and local presence make us the ideal partner.