Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

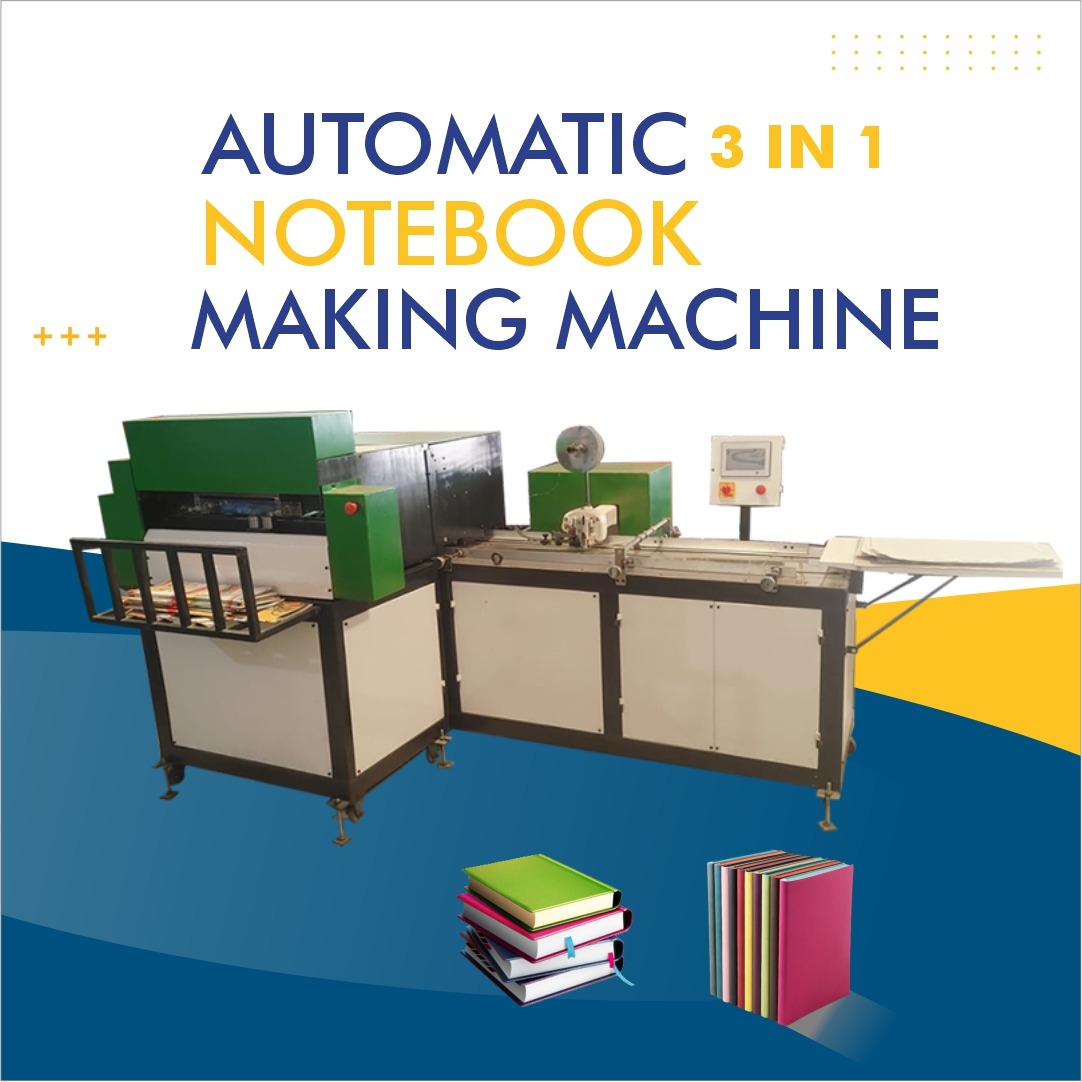

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Best Notebook Making Machine in Bawani Khera Haryana – Automatic & Semi-Automatic

Notebook Making Machine in Bawani Khera | Haryana

If you're planning to start or expand a notebook manufacturing unit in Bawani Khera (District Bhiwani), Haryana, investing in the right notebook making machine is critical. Whether you want automatic or semi-automatic equipment, the choice of machinery will directly impact your production capacity, operating costs, finish quality, and profitability. This guide will walk you through the factors to consider, types of machines, local support options near Bawani Khera, and how to evaluate suppliers.

Bawani Khera is a town in Bhiwani district of Haryana. Wikipedia Its proximity to major road networks (such as NH 148B which passes near Bawani Khera) Wikipedia gives access to logistics for raw materials and finished goods transport. Using a machine supplier that can deliver to Bawani Khera while offering after-sales support is an advantage.

Why Choose a Notebook Making Machine Near Bawani Khera

-

Reduced Freight / Logistics Cost

Procuring machinery from a local or nearby Haryana / Bhiwani area supplier reduces transportation time and cost. For heavy machinery like notebook stitching, cutting & binding equipment, this matters. -

After-Sales Support & Maintenance

Local presence (or supplier willing to visit) ensures timely maintenance, spare parts, and technical support for your notebook manufacturing line. -

Regulatory & Power Considerations

Machines installed in Bawani Khera must meet local electrical infrastructure (voltage phases, power load), and comply with any municipal or industrial regulations. Choosing a machine compliant with local conditions reduces delays during installation. -

Scalability for MSME / Startup Units

Whether you’re setting up a small scale operation or scaling operations, selecting the right model (manual / semi / fully-automatic) with provision for expansion is key.

Types of Notebook Making Machines

When searching for notebook making machine, you’ll find different categories depending on automation, capacity, binding style, finishing features etc. Here are the common types:

| Category | Description |

|---|---|

| Manual Notebook Making Machine | Requires more human intervention. Suitable for low-cost startup units. Example models like SBS NB-01. sbsmachine.com |

| Semi-Automatic Notebook Making Machine | Some operations automated (paper feeding, cutting, ruling, binding) while others manual. Balanced cost vs productivity. |

| Fully Automatic Notebook Making Machine | High-speed continuous production with minimal manual effort. Higher investment but greater output. Example offerings by ASV Engineering. asveng.com |

| Spiral / Stitch Binding Machine | Specialized modules for binding spiral notebooks or stitched notebooks as part of the production line. |

| Cutting, Ruling, Edge-Squaring & Press Machines | Complementary units that cut paper, rule pages, press / square edges, trimming or finishing of notebooks. |

Each machine type has trade-offs in price, speed (e.g. notebooks per hour), required skilled labour, power requirement, and maintenance cost.

Key Specifications to Compare

When evaluating notebooks making machines for your site in Bawani Khera, consider these technical & operational specs:

-

Production Capacity – e.g. number of notebooks per day / hour. Manual machines may produce few thousands per day; automatic ones can scale to tens of thousands.

-

Size and Format – e.g. A4, A5, number of pages, thickness of notebook, page ruling. Some machines allow variable sizes.

-

Automation Grade – manual, semi-automatic or fully automatic. Higher automation reduces manual labour but increases upfront investment.

-

Power Requirements – voltage phase (single / three phase), power consumption (kW), compliance with local electricity supply.

-

Material & Build Quality – using robust steel frames, good-quality motor parts to reduce breakdowns.

-

Support & Spare Parts – availability of local support / spare parts in Haryana / Bhiwani vicinity.

-

Cost & Return on Investment (ROI) – upfront cost vs expected sale of notebooks, labour cost savings, maintenance cost.

-

Footprint & Layout – physical space required in your factory / workshop.

Suppliers & Manufacturers Near Haryana / Bhiwani Region

While there may not be a manufacturer exactly in Bawani Khera, there are suppliers in Haryana / nearby regions who cater to notebook making machinery. Some examples:

-

Food Mart Agro is listed as a supplier of notebook making machines in Haryana. foodmartagro.com

-

ASV Engineering offers a range of semi-automatic and automatic notebook making machines. asveng.com

-

SBS Machines offers manual notebook making machine full setups. sbsmachine.com

-

Manufacturers in Hisar / Sector-14 also list notebook making machine manufacturing options. Justdial

When approaching them, you can ask for machines to be delivered & installed at Bawani Khera, transportation cost, commissioning time, warranty terms, training for your staff, and after-sales backup.

Step-by-Step Guide to Procuring a Notebook Making Machine

-

Define Your Production Goal

Estimate monthly production quantity, target notebook formats and quality. E.g. “I want to produce 5000 notebooks per day of A4 ruled pages with stitched binding.” -

Shortlist Machine Types

Based on your goal, decide if you want manual / semiautomatic / fully automatic. Compare quotes from suppliers like Food Mart Agro, ASV, SBS etc. -

Visit / Inspect Demo Machines

Ask for site visits or videos of machines working in real production. Check quality of cuts, binding strength, aesthetics (page alignment, trimming). -

Check Local Installation & Power Compliance

Confirm that the machine can run properly with the electricity infrastructure in Bawani Khera (voltage, phase). Also check if you need any clearances or local municipality inspections. -

Negotiate Terms

Price, delivery time, installation charges, training cost, spare parts availability, maintenance contract, warranty period. -

Plan for Raw Material & Storage

Paper sheets, cover boards, ruling inks, binding wires or staples. You may need pre-cut paper sizes, storage area close to your machinery footprint. -

Train Your Workforce

Operator training is usually provided by supplier; ensure sufficient handling staff, maintenance schedule. -

Quality & Compliance

Ensure your notebooks meet local standards for stationery (page ruling, margins etc.), and check packaging, labeling or branding for your notebooks once ready.

Advantages & Challenges

Advantages

-

Local presence in Bawani Khera / nearby Haryana reduces downtime for breakdowns.

-

Ability to supply educational institutions, schools in Bhiwani district, or nearby towns using your notebooks.

-

Growing stationery demand upstream in India, especially for school / college supplies.

Challenges

-

Large capital investment for fully automatic machinery.

-

Need for consistent raw material supply (paper quality, ruling inks etc.).

-

Skilled labour & maintenance skills must be developed locally.

-

Ensuring power supply stability (voltage fluctuations) in semi-rural areas.

Case Example (Hypothetical)

Suppose you are planning a small scale notebook production unit in Bawani Khera:

-

You buy a semi-automatic notebook making machine with capacity 3,000 notebooks per day.

-

Machine cost (example model) = ₹ 3,00,000 (approx) from a supplier in Haryana.

-

Raw material cost per notebook = ₹ 5; you sell each notebook for ₹ 15 in local market.

-

Your monthly production (25 working days) = 3,000 × 25 = 75,000 notebooks.

-

Revenue = 75,000 × ₹ 15 = ₹ 11,25,000.

-

Material cost = 75,000 × ₹ 5 = ₹ 3,75,000.

-

Labor, packaging & power cost say ₹ 1,00,000 monthly.

-

Gross margin ~ ₹ 11,25,000 − (3,75,000 + 1,00,000 + depreciation of machine etc.). If depreciation / maintenance is ₹ 50,000 monthly, net before other overhead ~ ₹ 11,25,000 − ₹ 5,25,000 = ₹ 6,00,000.

This simplified example shows potential for good returns if you manage market demand, sales & quality.

Recommendations & Best Practices

-

Always ask supplier if the machine can be calibrated for multiple notebook sizes (A4, A5 etc.).

-

Request preventive maintenance schedule & spare parts list.

-

Consider modular expansion — add cutting / edge-press / stitching modules later as your business grows.

-

Ensure good infrastructure (flooring, lighting, ventilation) in your workshop in Bawani Khera.

-

Obtain any required licensing or registration for stationery / manufacturing under local Haryana / Bhiwani civic norms.

Conclusion

If your goal is to establish or expand a profitable notebook manufacturing operation in Bawani Khera, Haryana, selecting the right notebook making machine is foundational. Whether you pick a manual, semi-automatic or full-automatic model, you should evaluate production capacity, cost, automation level, and local servicing. Suppliers in nearby Haryana such as Food Mart Agro, ASV Engineering, SBS Machines etc., can support your needs. With proper planning — from machine installation to raw material supply to sales planning — you can build a sustainable stationery business serving local schools, colleges and retailers.