Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

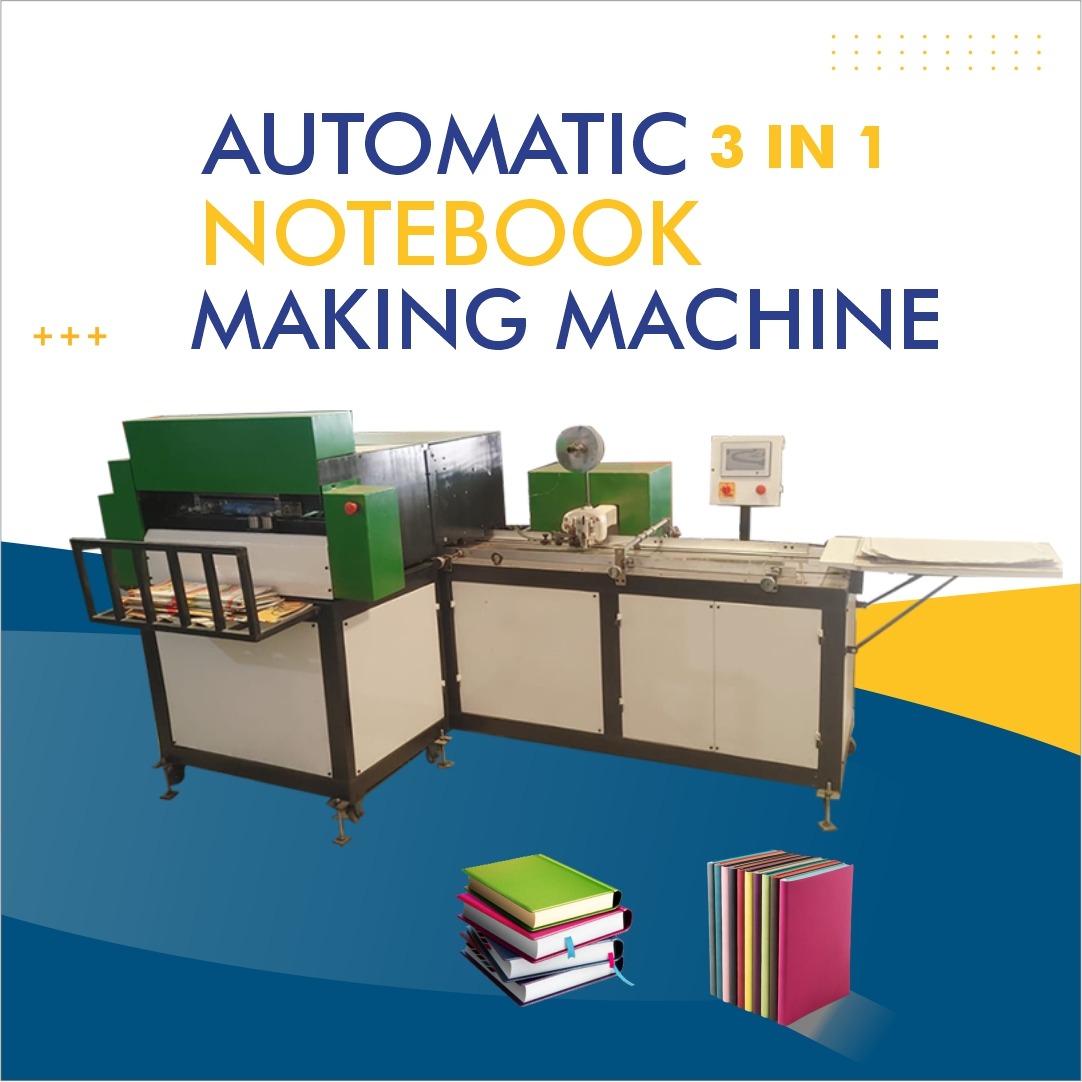

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier Assandh | High Efficiency Binding Machine Haryana

Notebook Making Machine in Assandh | Haryana

Assandh, a town in Karnal district of Haryana, is increasingly becoming a hub for stationery manufacturing and allied industries. Wikipedia For entrepreneurs planning to set up a notebook production unit in this region, selecting the right notebook making machine is central to success. Whether you are looking for automatic, semi-automatic, or manual notebook production equipment, this guide will help you understand how to choose the best machine, what features matter, cost considerations, and the benefits of locating your manufacturing in Assandh / Haryana.

In this article, you will find detailed information about types of notebook making machines, how they affect productivity, what technical specifications to watch out for, and why Assandh / Haryana is a good place to locate mobile production or a full-scale notebook manufacturing line.

Why Choose Assandh, Haryana for Your Notebook Production Unit

-

Strategic Location

Located in Karnal district, Assandh enjoys proximity to major highways and good road connectivity in Haryana. Being in the state gives access to raw materials, labour, and important markets like Delhi-NCR. -

Growing Stationery / Manufacturing Activity

There are existing notebook manufacturers, stationery wholesalers, and binding businesses around Assandh and nearby areas. Justdial+1 That creates an ecosystem for procurement of paper, binding materials, and ancillary services (printing, packaging, finishing). -

Cost Advantages

Operating in Haryana (rather than major metro regions) often brings lower land and labour costs. This can reduce your capital expenditure and operating overheads, especially for a semi-automatic or manual notebook making setup. -

Access to Suppliers and Machinery Dealers

Haryana has listings of notebook making machine suppliers and dealers in nearby districts (e.g. Hisar, Sirsa). Justdial+1 That means spare parts, maintenance, or sourcing second-hand or new machinery is feasible.

Types of Notebook Making Machines & Their Features

Below are the common types of notebook making & binding machines you would consider for your unit:

| Type | Description | When to Use It |

|---|---|---|

| Fully Automatic Notebook Making Machine | This machine automates cutting, stitching / binding, trimming, folding, etc. Requires minimal manual intervention. Higher throughput. | Good for medium / large-scale production; you plan to produce large volumes of notebooks daily. |

| Semi-Automatic Notebook Making Machine | Some operations are automated (e.g. stitching/folding) but cutting, feeding or trimming may need manual steps. | Suitable for growing businesses that want to reduce manual labour without full automation. |

| Manual or Low-Cost Notebook Binder | Basic binding, stitching or folding done with manual feed or with minimal automation. Cheaper investment, slower throughput. | Best for small-scale operations, prototype production, startups with low capital. |

| Spiral Binding / Wire Binding Machine | Useful if you plan to offer spiral-bound notebooks rather than stitched binding. | Can be integrated as a binding module in your notebook production line. |

Some machines also offer cutting, perforation, cover pasting, trimming, & edge-squaring capabilities. When selecting a machine, watch for parameters such as speed (sheets per minute), binding thickness (number of pages), paper sizes supported, power requirements, maintenance support, and after-sales service.

Specification Considerations

When you choose a notebook making machine, consider:

-

Output / Capacity: How many notebooks per hour or per shift? Higher capacity machines justify higher cost only if you have demand.

-

Binding Style Capability: Stitched binding, saddle stitch, centre stitch, spiral binding. If you want variety (school notebooks, registers, composition books), you may need multiple binding options or modular attachments.

-

Precision & Quality: Machines with servo motors, accurate stitch alignment, trimming precision will reduce wastage (paper misalignment, trimming error).

-

Paper Size & Thickness: Your machine should accommodate standard sizes (A4, A5, exercise book sizes), margin sheets, cover stock thickness.

-

Automation Level & Labour Requirement: Fully automatic vs semi-automatic trade-offs in capital vs labour cost.

-

Power / Utility Requirements: Single phase or three phase electricity; local infrastructure in Assandh / Haryana; backup supply if needed.

-

Spare Parts & Maintenance Support: Machines purchased from suppliers in or near Haryana will reduce downtime and logistics costs.

-

Cost and ROI: Estimate your total investment (machine cost + shipping + installation + training) vs expected revenue per notebook, production volume, and payback period.

Cost & Pricing Examples

To give you a rough idea of pricing, here are a few data points:

-

A fully automatic notebook making machine listed in Sirsa, Haryana has prices ranging around ₹ 9,50,000 to ₹ 11,50,000 for certain models. Justdial

-

Another listing on TradeIndia shows a fully automatic machine from Shki Industries in Faridabad (Haryana) at approx ₹ 5,50,000. TradeIndia

-

Semi-automatic or manual machines cost significantly less, though will have lower speed or require manual input.

These prices do not include shipping, installation, or any custom attachments. You will need to request quotes from suppliers. Also factor in import/duty (if parts are imported), and local transport to Assandh.

Setting Up a Notebook Production Line in Assandh

Here’s a suggested workflow for a small to medium notebook manufacturing unit:

-

Procurement of Raw Material

-

Paper sheets (ruled / plain / graph)

-

Cover boards or cover stock

-

Binding wire / stitching staples (if applicable)

-

Packaging (plastic wrap / film / carton)

-

-

Machine Layout & Utilities

-

Space allocated for cutting & trimming machine

-

Binding machine / stitching / folding station

-

Cover pasting / finishing section

-

Quality check area

-

Storage for raw / finished notebooks

-

-

Labour Staffing

-

One or two operators per machine (depending on automation level)

-

Helper staff for feeding paper, stacking finished notebooks, packaging

-

-

Quality Control & Testing

-

Test for binding strength, trimming accuracy, edge squaring

-

Ensure consistency in page alignment, margin prints

-

-

Packaging & Dispatch

-

Bundle notebooks in packs (e.g. 10 / 20 / 50)

-

Labeling, wrapping, palletizing for dispatch

-

-

Marketing & Business Channels

-

Local schools, stationery shops in Haryana / nearby states

-

Bulk orders for colleges / institutions

-

Tie-ups with stationery wholesalers around Karnal / Assandh

-

Advantages of Investing in the Right Machine

-

Improved Productivity: With a good notebook making machine, your throughput can drastically increase, reducing labour cost per unit.

-

Consistent Quality: Automated trimming, binding and finishing reduce defects, wastage, and rework.

-

Flexibility: Many modern machines allow you to switch sizes (A5 / A4 etc.), thicknesses, binding styles — helping you diversify your product line (exercise books, registers, practical notebooks etc.).

-

Scalability: As demand grows, you can add modules / upgrade your machine rather than replace the entire setup.

-

Competitive Pricing: Lower unit cost enables you to offer competitive prices to schools or institutions, helping you grow market share in Haryana / northern India.

Challenges & Mitigation Strategies

| Challenge | Suggested Mitigation |

|---|---|

| Power fluctuations or interruptions in rural / semi-urban industrial area | Install voltage stabilizers or UPS; schedule production during stable hours |

| Import delays or custom parts | Choose suppliers who maintain stock locally or within nearby districts like Hisar / Sirsa |

| Skilled operator training | Get training support from the machine supplier; hire staff with some mechanical / electrical experience |

| Raw material quality inconsistency | Build relationship with reliable paper stock suppliers; test material before large runs |

How to Choose Your Supplier & Next Steps

-

Identify credible machine suppliers in or near Haryana. Ask them for demo videos, factory visits, sample production runs.

-

Check references — other notebook manufacturers in Karnal / Haryana using similar machines. Visit if possible.

-

Request multiple quotes for the same specification (automatic vs semi-automatic) including freight, installation & training.

-

Plan your capacity & forecast demand — estimate how many notebooks monthly or yearly you expect to sell; ensure the chosen machine supports that throughput.

-

Secure working capital & permits — local municipal approvals, electricity connection, GST registration, environmental compliance (if any).

Conclusion

If you are planning to launch or expand a notebook manufacturing business in Assandh, Haryana, investing in the right notebook making machine is a critical decision. By selecting an appropriate model — whether fully automatic, semi-automatic or manual — you can optimize your costs, improve quality, expand capacity, and serve the growing stationery market across Haryana and nearby states.

Carefully assess your production goals, compare supplier offers, evaluate maintenance support and power / utility requirements. With the competitive advantages that Haryana offers (lower overheads, proximity to markets, existing stationery manufacturing presence), you have the potential to build a successful, scalable notebook production unit.