Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

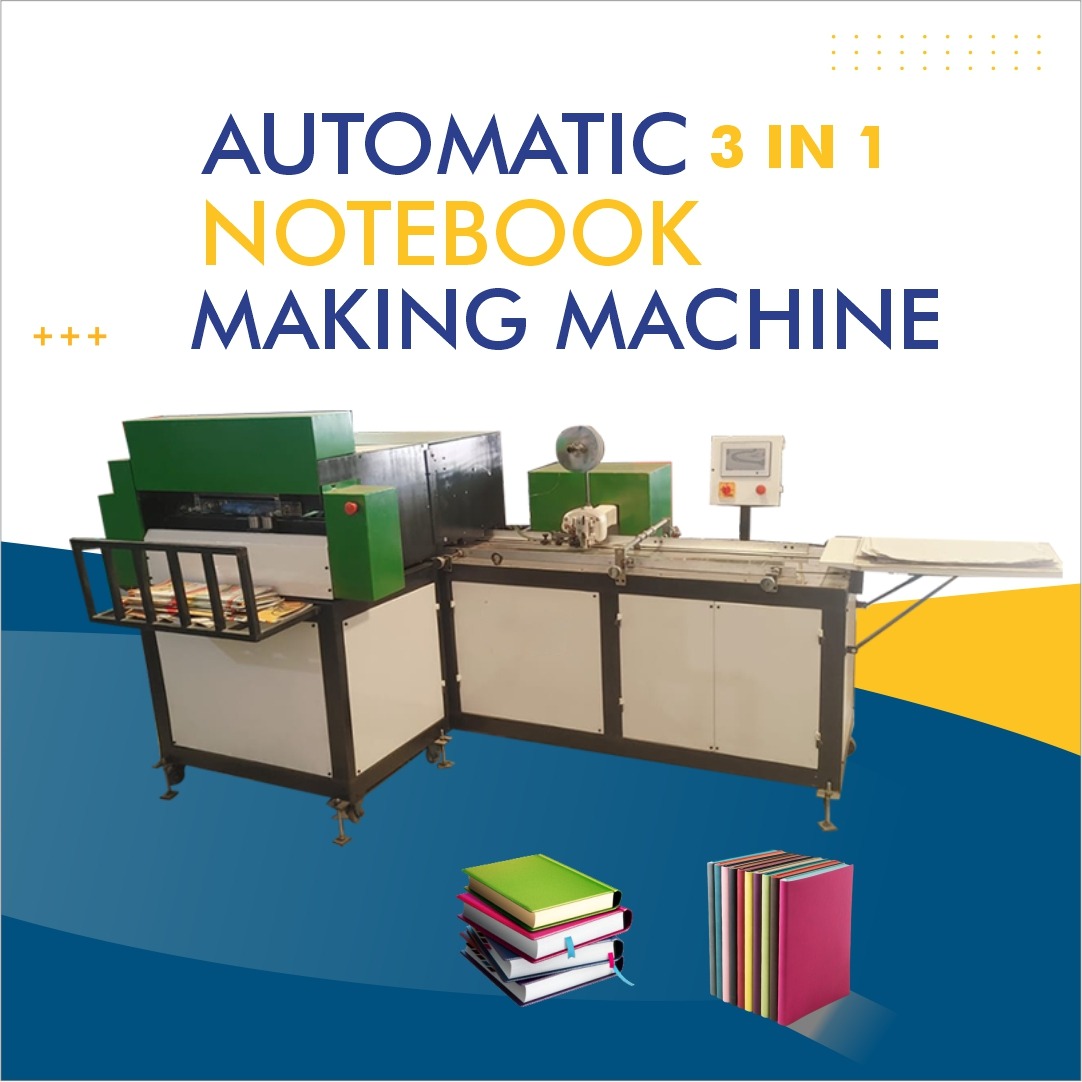

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Bahadurgarh Haryana | Leading Manufacturer & Supplier

Notebook Making Machine in Bahadurgarh | Haryana

Bahadurgarh, Haryana is rapidly emerging as a hub for industrial manufacturing in the national capital region. Nestled on the outskirts of Delhi, Bahadurgarh offers strategic advantages such as proximity to raw material suppliers, skilled labor, and excellent logistics. For businesses looking to invest in notebook making machine systems, this locale provides the perfect blend of cost efficiency and accessibility.

A notebook making machine manufacturer based in Bahadurgarh Haryana can deliver turnkey solutions for notebook production lines tailored to your scale of operation – from small batch to large-scale manufacturing. Whether you require an automatic notebook machine or a semi-automatic setup, local suppliers can provide design, installation, and after‐sales support.

2. Why Choose Bahadurgarh for Your Notebook Production Equipment

Strategic Location

-

Situated conveniently near major highways and rail links, Bahadurgarh reduces your transportation time and cost for both raw materials like paper boards and finished notebooks.

-

Proximity to Delhi NCR offers access to a broad customer base as well as sourcing opportunities for components, motors, and ancillary systems.

Skilled Workforce & Industrial Ecosystem

-

The industrial clusters around Bahadurgarh include engineering workshops, machine-tool fabricators, and assembly shops. Manufacturers of notebook making machine leverage this ecosystem to build custom jigs, spare parts, and upgrades effectively.

-

Local technicians are often accustomed to working with precision engineering needed for high-speed production lines.

Cost Efficiency

-

Operation and maintenance costs such as land rent, utilities, and labor tend to be lower compared to locations within the city.

-

Reduced travel time for installation and servicing means rapid turnaround for maintenance or retrofitting.

3. Types of Notebook Making Machines

When planning a notebook manufacturing setup, it helps to understand the types of machines available. Local notebook making machine manufacturers in Bahadurgarh offer a variety of equipment types adapted to different production needs:

-

Manual Notebook Making Machine

-

Ideal for artisans or small setups producing limited volumes.

-

Operated with human input for paper alignment, stitching/binding, trimming, and counting.

-

-

Semi‐Automatic Notebook Machine

-

Partly automated operations such as feeding, stitching or gluing, and trimming.

-

Offers a balance between labor cost savings and capital investment.

-

-

Fully Automatic Notebook Making Machine

-

Complete automation for high-volume production.

-

Features may include automatic paper feeding, binding (stitched or glued), trimming, stacking, numbering, and packaging.

-

Electronic control systems, PLCs, safety interlocks, and sensors to ensure consistent quality.

-

-

Spiral & Wire-O Notebook Making Equipment

-

Specialized machines to punch and bind spiral wire notebooks.

-

Often integrated with punching stations and coil insertion modules.

-

-

Customized Notebook Production Equipment

-

Custom-built machines to meet unusual formats or special binding styles.

-

Adjustable for sheet sizes, cover thicknesses, or decorative binding features.

-

Whether your operation requires an automatic notebook machine or a custom solution, the manufacturers in Bahadurgarh Haryana can provide tailored designs integrated into your production line.

4. Key Features to Look for in Notebook Making Machines

To maximize return on investment and ensure consistent quality, consider the following features when selecting a notebook production equipment supplier:

Speed & Throughput

-

How many notebooks per minute/hour can the machine produce? High-speed machines are ideal for scaling up production.

-

Throughput should match your demand forecasts while allowing room for future scaling.

Precision & Alignment

-

Accurate feeding, binding alignment, and trimming are critical for professional-grade finished notebooks.

-

Quality control systems to detect misalignment or defective binding.

Flexibility & Size Range

-

The ability to accommodate various sizes (A4, A5, custom sizes), cover materials (paperboard, cardboard), and binding styles (stitched, glued, spiral).

Automation & Controls

-

PLC or microcontroller-based controls for sequence timing, error detection, and operator interface.

-

Safety interlocks, emergency stops, and user training modules included.

Material Handling & Changeover Time

-

Quick changeover capability when shifting from one notebook format to another.

-

Efficient stacking and unloading mechanisms to reduce labor requirements.

Maintenance & Spare Parts Availability

-

Local availability of spare parts and consumables reduces downtime.

-

After-sales service and preventive maintenance contracts offered by your notebook making machine manufacturer.

Energy Efficiency & Compliance

-

Machines designed to meet electrical safety and industry regulations.

-

Lower power consumption while maintaining performance.

5. Applications & Business Use Cases

A well-chosen notebook making machine can serve varied business needs. Following are applications and use cases for manufacturers based around Bahadurgarh Haryana:

-

Educational Stationery Manufacturers producing ruled notebooks, drawing books, and exercise pads for schools and colleges.

-

Corporate Branding companies needing customized notebooks for corporate gifting.

-

Packaging & Print Houses that extend into value-added stationery by adding bound notebooks to their product line.

-

Startup Entrepreneurs launching branded journals, diaries, or specialty notebooks.

-

Contract Manufacturing customers seeking to outsource batch production using your equipment.

These business segments benefit from investing in reliable notebook making machine solutions that deliver consistent quality while controlling overhead.

6. How to Select the Right Manufacturer in Bahadurgarh Haryana

When evaluating vendors in Bahadurgarh for notebook making machine procurement, consider the following steps:

-

Review Technical Specifications

-

Request machine specification sheets: size ranges, speed, binding type, electrical rating, safety certifications.

-

Compare options for manual, semi-automatic, or fully automatic models.

-

-

Inspect Demonstrations

-

Ask for a live demonstration or video at the manufacturer’s facility.

-

Confirm the actual speed, accuracy, and reliability under full production load.

-

-

Check After-Sales Support

-

Ensure availability of spare parts locally.

-

Confirm whether the vendor offers installation, commissioning, and maintenance training.

-

-

Assess Costs & Financing

-

Obtain detailed quotes including shipping, installation, training, and warranty.

-

Consider financing options or government incentives for manufacturing equipment.

-

-

Verify Customization Options

-

Ensure the manufacturer can adjust specifications—such as notebook size, cover thickness, or binding style—as per your requirements.

-

Confirm possibility of future upgrades, such as increased speed modules or additional binding options.

-

-

Evaluate Quality & Certifications

-

Ask about quality control standards followed by the vendor—ISO certifications or internal QC practices.

-

Confirm that materials and finishes meet industry requirements.

-

By following these steps, you can more reliably choose a reputable notebook making machine manufacturer in Bahadurgarh Haryana to meet your production goals.

7. Cost Factors & ROI Considerations

Investing in a notebook making machine involves more than just the upfront cost. To project return on investment (ROI), examine the following:

-

Capital Expenditure (CapEx): Base machine price, installation charges, site preparation, and any customization fees.

-

Operating Expenses (OpEx): Labor, consumables (thread, glue, binding wire), energy consumption, maintenance & spare parts.

-

Production Yield: Number of usable notebooks produced per hour, factoring in rejects and downtime.

-

Market Rate: Selling price per notebook, expected volume, and margins after raw material costs.

-

Uptime & Throughput: Reliable uptime with minimal breakdowns improves cost-per-unit. A high-speed or automatic notebook machine usually lowers per-unit cost by increasing output.

-

Payback Period: Estimate how long it will take to recover CapEx based on net profit per notebook batch.

Manufacturers in Bahadurgarh Haryana often help clients run sample runs to estimate realistic throughput and profitability before final purchase. This hands-on approach helps you forecast when your industrial notebook maker will pay for itself.

8. Maintenance, Service & Training

Once your notebook making machine is installed, ongoing support is vital for sustainable production. Local vendors in Bahadurgarh offer the following services:

-

Installation & Commissioning at your site with qualified engineers.

-

Operator Training to ensure staff understand controls, safety, and maintenance procedures.

-

Preventive Maintenance Contracts to periodically service motors, belts, sensors, and binding heads.

-

Spare-parts Supply for consumables such as threading materials, cutting blades, and electrical components.

-

Remote Diagnostics / Upgrades when newer modules become available.

Having reliable local maintenance options reduces downtime and improves overall productivity of the notebook production equipment over its lifetime.

9. Case Study & Success Example

Consider a stationery manufacturer based in Bahadurgarh that expanded its notebook output by installing a fully automatic notebook making machine. Before the upgrade, they were facing slow throughput and high defect rates due to manual binding. After commissioning a high-speed automatic system, they achieved:

-

A capacity increase of over 3000 notebooks per day.

-

Reduction in binding defects by 40 %.

-

Lower labour cost per unit and faster turnaround for large orders.

-

Quick payback within 18 months due to higher production volume and lower per-unit cost.

Such success stories showcase the value of investing in the right automatic notebook machine from a local supplier in Bahadurgarh Haryana.

10. Summary & Call to Action

Bahadurgarh, Haryana offers a strategic and cost-effective location to source notebook making machine solutions. Whether you require a manual, semi-automatic, or fully automatic notebook maker, manufacturers here can provide the right design, engineering, and service support.

Evaluate vendors based on technical specifications, service quality, customization capability, and after-sales support. Factor in both capital and operating expenses to ensure you select a machine that maximizes productivity while delivering a strong return on investment.

If you are planning to launch or upgrade your notebook production line, consider contacting one of the leading notebook making machine manufacturer in Bahadurgarh Haryana for a quotation and site visit.

Get in touch today to discuss your production requirements, preferred binding style, desired throughput, and budget. Let us help you identify the best notebook production equipment tailored for your business growth.