Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

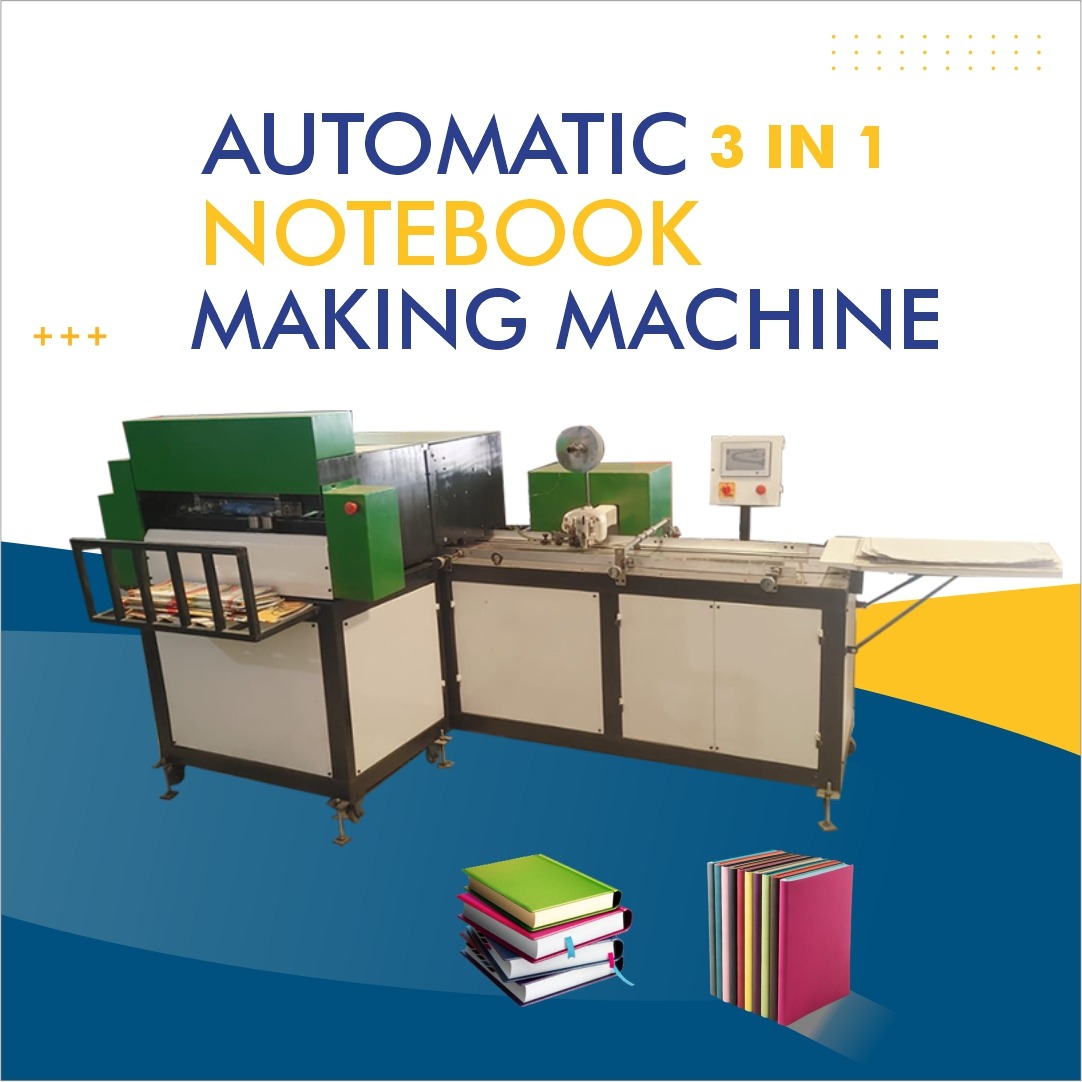

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Talaja Gujarat | High Quality Machines

Notebook Making Machine in Talaja | Gujarat

If you are planning to start or scale up a notebook manufacturing unit in Talaja, Gujarat, selecting the right notebook making machine is critical. Whether you need a fully automatic system or a semi-automatic solution, your choice of machine will determine the production speed, consistency, cost of maintenance, and ultimately your product’s quality.

Talaja (in Bhavnagar district) is increasingly emerging as a hub for light engineering and fabrication. Companies from nearby areas supply industrial machinery, and with good infrastructure, it’s an advantageous location for manufacturing.Wikipedia+1

This page explores everything you should know about notebook making machines in Talaja, Gujarat — from types, features, benefits, to choosing a reliable manufacturer.

Why Talaja, Gujarat is an Advantageous Location

-

Proximity to Industrial Base: Talaja is in Bhavnagar district, which is already recognised for machinery fabricators and manufacturing workshops.Justdial

-

Lower Overheads: Compared to large industrial cities, setting up fabrication or assembly near Talaja may reduce land, labour and logistics costs.

-

Access to Suppliers & Skilled Labour: Nearby areas like Ahmedabad, Rajkot and Bhavnagar have accessory firms, suppliers for sheet-metal works, electrical parts, control panels etc., which helps in procurement.

-

Regulatory & Transport Advantage: Being in Gujarat, with good road connectivity and industrial policy incentives, you may benefit from local government schemes for MSMEs or engineering-units.

All these make Talaja a strategic place for manufacturing or assembling notebook making machines for regional customers (within Gujarat or beyond).

Types of Notebook Making Machines

When you search for a notebook making machine, you will encounter different types depending on automation level, binding style, speed and product size. Key categories include:

-

Manual Notebook Making Machine

-

Basic model where the operator does many steps by hand or partially assisted by the machine.

-

Lower capital cost, suitable for small-scale production or startups.

-

Example: manual notebook making machine listed under Ahmedabad supplier.TradeIndia

-

-

Semi-Automatic Notebook Making Machine

-

Some operations are mechanised (e.g. cutting, stitching), while others require manual feed or supervision.

-

Offers better speed than manual; moderate investment.

-

E.g. Semi Automatic Notebook Making Machine from Tony Machinery in Gujarat.tonymachinery.in

-

-

Automatic / Fully Automatic Notebook Making Machine

-

Majority of steps automated: cutting sheets, folding, stitching, binding, trimming, stamping etc.

-

Designed for higher volumes, consistent quality, minimal manual intervention.

-

Ideal when you scale your production or serve business clients (schools, stationery distributors).

-

-

Specialty Machines

-

Machines designed for specific binding styles — spiral binding, wire stitching, soft/hard covers.

-

Machines tailored for different sizes or custom notebook formats.

-

May include feeder systems, computerized controls, safety guards, sensors etc.

-

Understanding which type fits your business helps you specify machine speed (units/hour), binding capacity, paper thickness it can handle, power consumption, and maintenance requirements.

Key Specifications & Features to Consider

When evaluating suppliers or planning to procure a notebook making machine in Talaja, observe the following features:

| Specification | Importance |

|---|---|

| Production Speed | How many notebooks per hour/day—affects your output capacity. |

| Binding Type | Wire binding, spiral binding, stitched binding, glue binding etc. Choose based on your product style. |

| Sheet Size & Thickness | The machine should support the paper size (A4, A5, custom) and cover material thickness. |

| Automation Features | Sensors, automatic feeders, trimming mechanisms reduce error and labour. |

| Power Requirements | Voltage, motor capacity, energy consumption (important for local grid conditions). |

| Build Quality & Materials | Durable frame, corrosion-resistant parts, reliable motors for long life. |

| After-sales service & Spares | Local availability of spare parts, ability of the manufacturer to service the machine on-site. |

| Flexibility / Customisation | Custom branding, adjustable margins, capacity to upgrade modules in future. |

| Compliance & Safety | Guards, emergency stops, safety interlocks, certifications if required. |

These features ensure that the notebook making machine performs reliably and delivers consistent product quality.

Local Manufacturers & Suppliers Near Talaja

Although Talaja itself may not yet host many listed notebook makers, nearby cities such as Ahmedabad have multiple notebook making machine suppliers.Justdial+1

Some examples:

-

Ahmedabad-based Manufacturers: Several firms in Ahmedabad supply notebook making machines (manual, semi-automatic, fully automatic).Justdial

-

Tony Machinery, Gujarat: Offers semi-automatic notebook making machines.tonymachinery.in

-

TradeIndia Listings: Manual notebook making machine listed under Ahmedabad supplier.TradeIndia

If you establish or partner with a local engineering / fabrication unit in Talaja, you can potentially reduce lead time and transportation cost by sourcing components locally and doing final assembly in Talaja.

Additionally, you may approach general machine / industrial engineering firms in Talaja that fabricate sheet-metal components, frames, or do welding & machining, and ask them to collaborate or customise a notebook making machine design.

How to Choose the Right Vendor

When selecting a vendor for your notebook making machine in or near Talaja, follow these steps:

-

Define Your Output Requirements

Estimate how many notebooks you wish to produce daily / monthly. Decide your binding style, paper size and finishing quality. -

Request Multiple Quotes

Solicit proposals from several machine makers (e.g. firm in Ahmedabad, or regional vendors). Compare costs, delivery time, installation, and warranty. -

Evaluate Samples / Demos

Ask for demo videos, working prototypes, or visit their factory if possible. Check the machine’s build quality, ease of operation, accuracy and speed. -

Check Local Support & Spares

Prefer manufacturers who can supply spare parts quickly in Gujarat, or provide on-site servicing. This reduces downtime in your production line. -

Negotiate Customisation

If you need a custom notebook size or binding style, discuss whether the machine can be adjusted or modularly modified (e.g. adjustable cutter, binding head). -

Warranty & Maintenance Terms

Clarify warranty period, after-sales maintenance charges, installation support. Also find out training for operators. -

Compliance & Safety

Ensure the machine meets required safety norms; guards, emergency stop switches, electrical safety compliance (local electrical inspector approval etc.).

Benefits of Having a Notebook Making Machine in Talaja

Owning or having local access to a notebook making machine near Talaja offers multiple advantages for your business:

-

Faster turnaround: Reduced shipping time for machine parts & less transportation cost.

-

Better control: Being local allows you to customise more easily, do immediate servicing, adjust settings locally.

-

Lower costs: Lower logistics & easier access to local labour / technicians.

-

Scalability: You can expand production gradually, upgrade to more automated versions as demand grows.

-

Competitive Edge: Having reliable in-house machinery reduces dependency on external job work; ensures timely deliveries and consistent quality.

These benefits can help you offer competitive prices to your customers (e.g. stationery shops, schools or corporate clients) while maintaining margin and quality.

Challenges & Mitigation

Of course acquiring a notebook making machine also involves challenges:

-

Initial Capital Investment: Even semi-automatic or manual machines may require significant upfront cost. Plan your finance accordingly.

-

Operator Training: Your staff / operator must learn to run and maintain the machine safely and efficiently.

-

Maintenance & Downtime: Mechanical components will need periodic maintenance; prepare for potential downtime by keeping spare parts.

-

Quality Control: Especially in binding, alignment, trimming—you must ensure consistent quality, or risk rejects or customer complaints.

To mitigate these:

-

Build a preventive maintenance schedule.

-

Maintain buffer stock of critical spares.

-

Provide training documentation or operator manual.

-

Set up quality checks at various stages (cutting, folding, binding).

-

Keep in touch with your machine vendor for updates, firmware / control adjustments, or retrofits.

Cost Estimates & ROI

While exact prices will depend on type (manual vs semi-automatic vs automatic), speed, custom features and vendor, you can expect the following rough estimates:

-

Manual machines: lower cost, possibly in the range of ₹ 75,000 or more for an entry-level unit.Justdial+1

-

Semi-automatic machines: mid-range cost depending on binding heads, motor strength, sheet capacity, etc.

-

Fully automatic machines: highest cost, but faster throughput, better finish quality, and long term returns.

Your Return on Investment (ROI) will depend on how many notebooks you produce monthly, your margin on each unit, and your annual maintenance cost. If you produce regularly with good utilization (say > 70% capacity), a well-chosen machine can pay for itself within 12–36 months.

Action Plan: Setting Up Notebook Production in Talaja

Here is a sample step-by-step action plan if you want to start notebook production / upgrade your machine in Talaja:

-

Market Research

Understand demand in local schools, stationery shops, corporate gift houses around Bhavnagar / Gujarat. Decide types of notebooks (plain-ruled, customised covers, spiral / wire binding etc.). -

Capacity Planning

Estimate required daily output and select machine type accordingly (manual / semi-automatic / automatic). -

Vendor Contact & Shortlisting

Reach out to machine makers (e.g. Ahmedabad / nearby Gujarat firms), obtain quotations and compare. Ask for references of other customers. -

Site Preparation

Allocate workshop space, ensure required electricity (voltage & phase), floor strength, ventilation, operator safety infrastructure. -

Procurement & Installation

Finalise order for machine, arrange delivery to Talaja, oversee installation & commissioning, conduct trial runs. -

Training & Quality Setup

Train operators, document process flows (cutting → folding → stitching / binding → trimming / finishing). Set up quality checks. -

Launch & Monitoring

Start production, monitor yield, maintenance logs, scrap rate, operator efficiency. Periodically review machine performance and plan upgrades. -

Scale Up

Once initial volumes are stable, explore upgrading to higher-capacity or more automated binding heads, or adding finishing features (UV-coating of covers, printing module etc.).

Conclusion

A well-chosen notebook making machine can be the backbone of a successful stationery or notebook manufacturing business. Talaja, Gujarat offers strategic advantage due to its industrial proximity, lower costs, and potential for custom engineering collaboration. By choosing the right type of machine (manual, semi-automatic or fully automatic), considering key specifications (speed, quality, flexibility, serviceability), and working with a reliable vendor, you can build an efficient, scalable production line.

If you need help shortlisting vendors, obtaining quotations or designing a customised notebook making machine for Talaja, I can assist further.