Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

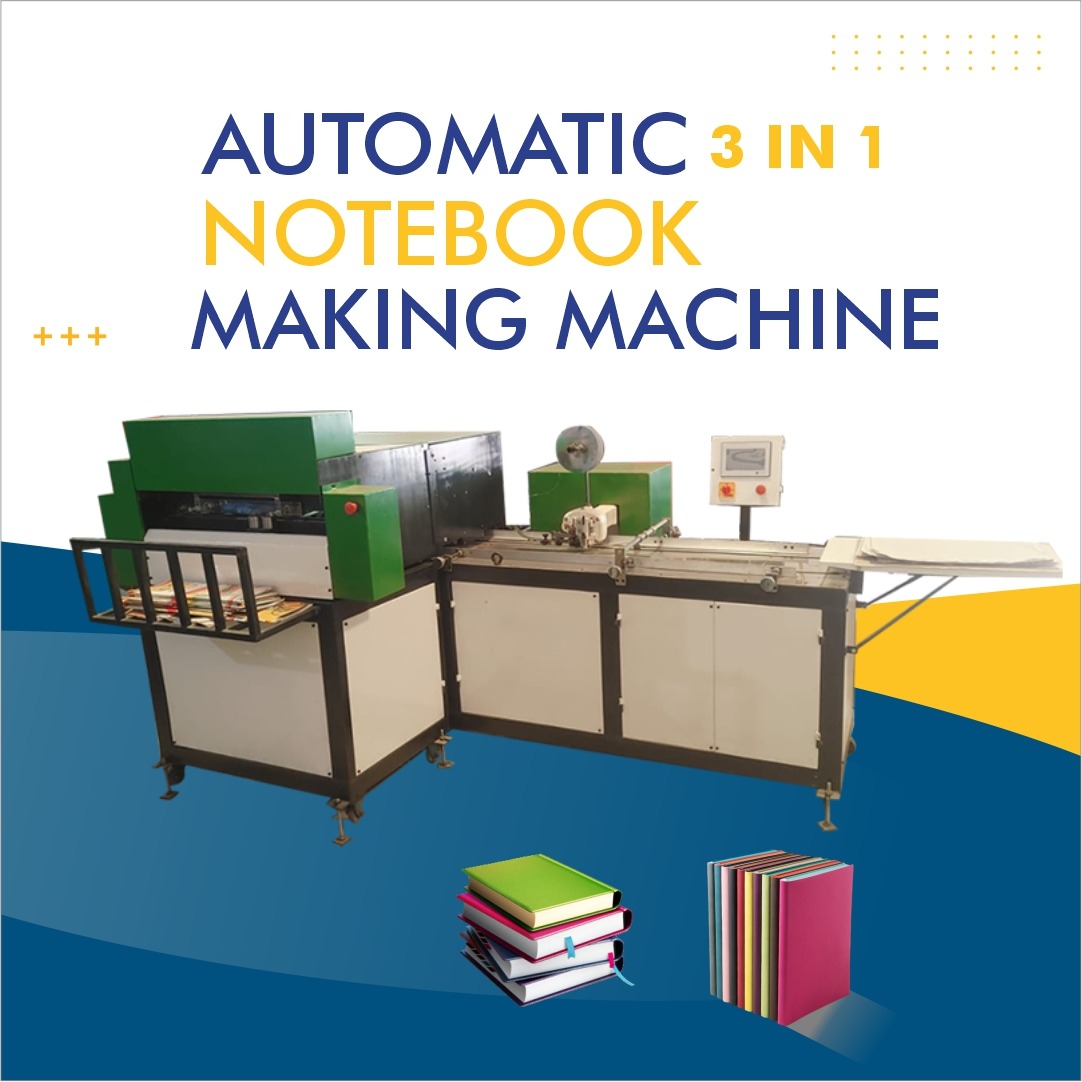

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Surat, Gujarat | Best Manufacturer & Supplier

Notebook Making Machine in Surat | Gujarat

Surat, Gujarat is emerging as a strong base for industrial machinery for stationery manufacturing. If you are looking to start or upgrade your notebook production unit, choosing the right notebook making machine is critical. Whether you want a fully automatic system, a semi-automatic setup or a manual-plus-automation hybrid, Surat has multiple suppliers and manufacturers.

This article will serve as a comprehensive SEO-optimized guide to notebook making machines in Surat, covering types of machines, features, selection criteria, benefits of sourcing locally, and a buyer’s checklist.

Why Choose a Notebook Making Machine in Surat, Gujarat

-

Local availability & support: With many wholesalers and manufacturers located in Katargam, Udhna, Ring Road, and other industrial areas of Surat, you can get faster turnaround for service, spare parts, and technical assistance Justdial+1

-

Cost advantage: Procuring machinery locally reduces shipping and import duties. You may also negotiate better pricing when dealing with regional vendors.

-

Customization & flexibility: Local machine makers often offer customization — size adjustments, binding style modifications, or capacity scaling — to suit your notebook specification.

-

Proximity to raw material & workforce: Surat is a commercial and industrial city where stationery materials (paper, card stock, binding wires) and technical labor are easily accessible.

These advantages make sourcing a notebook making machine in Surat not only practical but often more economical and efficient than importing a foreign machine or relying on distant suppliers.

Types of Notebook Making Machines

When you search for a notebook making machine in Surat, you’ll encounter various types. Each has its own use-case, cost, and output capacity:

-

Fully Automatic Notebook Making Machine

-

Automates the entire process: paper cutting, inner page collating, cover pasting, binding (spiral or stitched) and trimming.

-

Ideal for large-volume production lines.

-

Example: Automatic Notebook Making Machine listed in Surat on Aajjo site aajjo.com

-

Higher investment, but reduces manual labor costs and increases output consistency.

-

-

Semi-Automatic Notebook Making Machine

-

Some manual intervention; certain stations automated.

-

Balanced cost vs. output; suitable for small-to-medium businesses.

-

Offers flexibility to switch between production runs and modifications.

-

-

Manual / Mechanical Binding Aids & Hybrid Machines

-

Some functions manual (binding or trimming), others automated.

-

Lower upfront cost; more suitable for customized or low-volume notebook runs.

-

-

Binding Machine / Paper-Cutting Module / Collating Module

-

Sometimes you may only need a binding unit or a cutting / trimming unit rather than a full machine.

-

Suppliers often offer modules or retrofit units for existing lines.

-

Each category is suited for different scales: startup manufacturers, mid-level stationery producers, or large scale industrial production. Ensure you choose the type that fits your business volume, budget, and growth plan.

Key Features to Evaluate

When assessing notebook making machines in Surat or Gujarat, consider the following features:

| Feature | Why It Matters |

|---|---|

| Production Capacity | Number of notebooks per hour / per shift. Ensure it meets your target. |

| Sheet Size Range | Capability to handle various page sizes (e.g. A4, custom sizes), thickness of the notebook. |

| Binding Type | Spiral / Wire-o binding, stitched binding, glue binding. Machines differ in binding mechanism. |

| Automation Level | Fully automatic reduces labor; semi-automatic offers control; manual/hybrid is cheaper but slower. |

| Electrical & Safety Standards | Compliance with Indian safety norms, proper guarding, reliable motors, local serviceability. |

| Material Compatibility | Ability to work with various paper thicknesses, cover stock, or eco-friendly/recycled paper. |

| Brand & After-Sales Service | Local supplier reputation, ability to provide spare parts, maintenance, and training. |

| Cost & ROI | Initial investment vs. savings in labour / wastage over time. Evaluate return on investment period. |

Additional factors such as energy consumption, footprint of machine, noise levels, and ease of operation (user interface) also influence the purchase decision.

Leading Suppliers & Manufacturers Around Surat

Here are examples of suppliers / listings of notebook making machines in Surat / Gujarat:

-

Tejoplast Jyoti Brothers – listed as a notebook making machine manufacturer in Surat. tejoplast.in

-

Aajjo / National Industries listing for an automatic notebook making machine in Surat. aajjo.com

-

Wholesalers in Katargam, Surat: there are multiple notebook making machine wholesalers in Katargam area. Justdial

-

Laghu Udyog – providing notebook making machines in Gujarat including Surat & Ahmedabad. laghuudyogbharat.com

-

Food Mart Agro – offers high-speed automatic notebook making machines in Gujarat. foodmartagro.com

You can approach these suppliers to compare quotations, specifications, and after-sales support.

Benefits of Investing in a Quality Notebook Making Machine

Investing in a reliable notebook making machine brings multiple long-term advantages:

-

Higher productivity – Machines with good throughput help meet larger orders consistently.

-

Better quality control – Uniform cutting, binding, and finishing improve product quality and reduce rejects.

-

Reduced labor costs – Automation reduces manual effort, training time, and dependency on skilled manual labor.

-

Scalability – As your business grows, a well-chosen machine can scale production without needing frequent replacement.

-

Competitive advantage – Faster delivery, better finishing, and lower cost-per-unit can help you win contracts or scale B2B / B2C notebook sales.

-

Sustainability & compliance – Some modern machines support eco-friendly paper types, energy-efficient motors, and safer working conditions.

How to Choose the Right Machine for Your Business

Here’s a step-by-step checklist to ensure you pick the correct notebook making machine:

-

Define your production goals

Estimate monthly / yearly volume targets (e.g. 500,000 notebooks per year) and understand quality standards required (cover paper, binding strength, finishing). -

Determine formats & variants

Do you plan multiple sizes? Variable thickness? Spiral binding vs stitched? Custom designs? This affects the choice of model. -

Visit local suppliers & see live demos

In Surat, contact manufacturers in Katargam or Udhna to see machine performance on sample runs. -

Request technical specifications

Ask for throughput (notebooks/hr), size range, power consumption, maintenance schedule, spare part availability, warranty. -

Compare costs

Compare price quotations and total cost of ownership — installation, training, maintenance, electricity, downtime losses. -

Check after-sales & support availability

Ensure supplier has proven service records in Gujarat / Surat. Local proximity helps reduce downtime. -

Plan for future growth

Choose a machine that can handle moderate expansion (e.g. increase thickness or shift to automatic operation later). -

Compliance & Safety

Ensure electrical safety certifications, emergency stop systems, and proper guarding. For commercial/industrial installation, check local regulations.

Challenges and Mitigation

Even with good planning, you may face some common challenges when procuring a notebook making machine in Surat:

-

Downtime due to spare parts unavailability

→ Mitigation: choose supplier who stocks spares locally or offers timely delivery. -

Technical training of staff

→ Mitigation: arrange onsite training during installation; request operator manual; choose simple user-interface models. -

Variations in raw material quality

→ Mitigation: ensure machine tolerances are sufficient for standard deviations in paper thickness or cover board stiffness. -

Electric / Power Fluctuations

→ Mitigation: use stabilizers, check voltage requirements, request protection features with machine supplier. -

Changes in order patterns (size changes, special finishes)

→ Mitigation: buy modular or flexible machines that can handle different notebook variants.

Recognizing these in advance helps you incorporate flexibility into your business planning.

Conclusion

If you’re planning to set up or upgrade a notebook manufacturing line in Surat, Gujarat, selecting the right notebook making machine is vital for productivity, quality, and cost-efficiency. Use the local industrial ecosystem to your advantage by sourcing from Surat-based manufacturers / wholesalers; evaluate machine types, features, and support thoroughly; and plan with growth & maintenance in mind.