Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

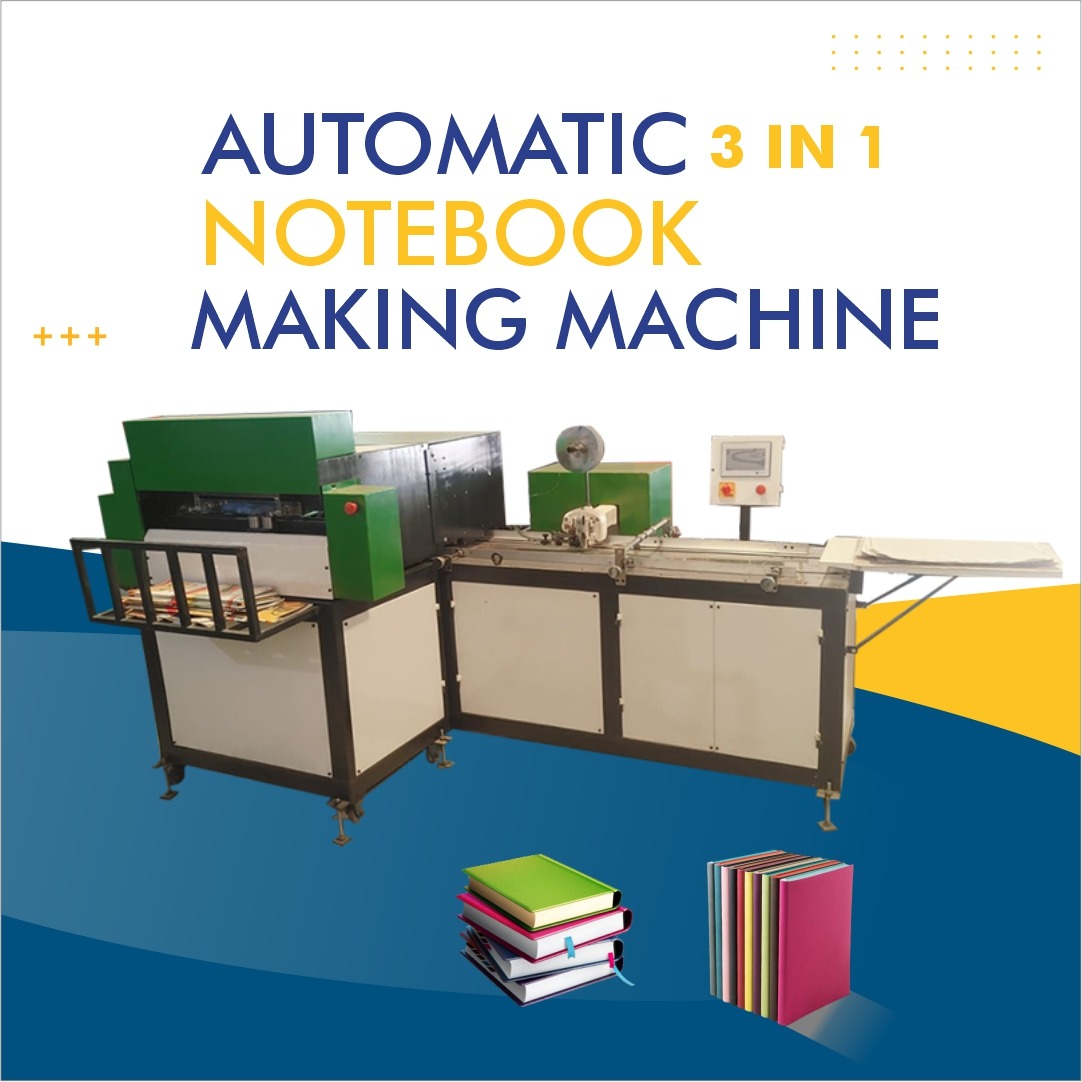

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Santrampur, Gujarat | Quality & Durable Machines

Notebook Making Machine in Santrampur | Gujarat

If you are in search of a dependable notebook making machine supplier in Gujarat, particularly around Santrampur, you’ve come to the right place. Our company specializes in designing, manufacturing, and supplying high-performance notebook making machines that meet the standards of educational stationery producers, small manufacturers, and industrial users. Whether you are starting a new production line or upgrading existing equipment, our machines are tailored for reliability, efficiency and cost-effectiveness.

In this article we’ll cover everything you need to know about notebook making machines: from types, features and benefits to local advantages of choosing a Santrampur-based manufacturer. You’ll also see case uses, specifications, maintenance tips, and how to choose the best machine for your production capacity.

What Is a Notebook Making Machine?

A notebook making machine is a mechanical system designed to automate the production of notebooks from raw paper, cover stock, binding materials, and finishing components. It includes processes such as sheet collating, cutting, folding, stitching or spiral binding (depending on type), trimming and packing. A notebook binding machine is part of that system, responsible for securely joining inner sheets and cover.

These machines eliminate manual labour, reduce waste, increase precision, and enable higher throughput. They can be manual-assisted or fully automatic notebook maker lines depending on your budget and required output.

Types of Notebook Making Machines

Here are some common categories:

-

Manual/semi-automated notebook making machine

Suitable for small-scale producers or startups. Some processes remain manual (e.g. feeding sheets, binding), but core functions such as trimming and cutting may be mechanised. -

Automatic notebook making machine

A fully automated production line, capable of collating sheets, binding (stitching, spiral binding or perfect binding), trimming edges, punching holes, embossing or foiling covers, and stacking finished notebooks. Ideal for medium to large output. -

Notebook binding machine

Standalone machine focused on stitching, stapling or comb/spiral binding. It can be integrated or used separately in a binding department. -

Cut-edge trimming and finishing equipment

After stitching or binding, notebooks often require trimming three edges for a clean finish. This trimming equipment may be separate or built-in. -

School notebook production line

Complete turnkey line for manufacturing school notebooks with printed covers, ruled inner sheets, cover lamination or embossing, edge trimming, binding and packing.

Why Choose Santrampur, Gujarat as Your Source?

There are several strategic and practical advantages to manufacturing or sourcing your notebook making machine from Santrampur, Gujarat:

-

Local manufacturing hub: Gujarat has a strong industrial and mechanical fabrication base, enabling access to skilled technicians, sheet-metal workshops, electrical controls and custom fabrication. Being based in Santrampur allows shorter lead times and local support.

-

Cost-advantage in sourcing materials: Raw steel, electrical components, and hydraulic parts are more affordable in Gujarat due to efficient supply chain and lower freight cost compared to remote import or out-of-state vendors.

-

Customization support: A local manufacturer in Santrampur can better understand your operational context—power supply, sheet size norms, local labour practices—and can provide tailored modifications to the automatic notebook maker to suit your school notebook production line.

-

Service & maintenance: For equipment in Gujarat (or nearby states like Maharashtra, Rajasthan), having the manufacturer nearby means you can get faster service visits, part replacements or preventive maintenance schedules with minimal delay.

-

Compliance with local regulations: Machines built locally can more easily comply with regional electrical safety standards, power supply norms and VAT/sales tax registration in Gujarat.

Key Components & Features

When evaluating or designing a notebook making machine, consider the following features:

-

Production capacity (notebooks per hour / per day)

-

Sheet size compatibility (A4, A5, custom ruled sizes)

-

Binding method (stitch-sewn, stapling, perfect binding, comb/spiral binding)

-

Trimming accuracy (edge trimming to ± 0.5 mm or better)

-

Automation level (manual feed, semi-automatic, fully automatic)

-

Control system (PLC or micro-controller-based operation, touch-panel interface)

-

Safety features (guards, emergency stop, CE or BIS compliance)

-

Energy consumption and electrical ratings suitable for Gujarat’s grid (e.g. 415 V, 50 Hz three-phase).

-

Durability & maintenance ease (readily available spare parts, modular design).

-

Material input & waste handling (paper sheet feeder, scrap collection, offcuts disposal).

Technical Specifications — Sample Model

| Feature | Specification |

|---|---|

| Capacity | Up to 1,200 notebooks per hour |

| Sheet Size | Up to 8.5″ × 11″ or custom sizes |

| Pages per notebook | 20-200 ruled pages |

| Binding Type | Double-stitching (wire staple), optional perfect binding attachment |

| Trimming | 3-side trimming with automatic waste ejection |

| Control Panel | PLC with HMI touch screen |

| Power | 3-phase 415 V, 50 Hz (customizable for single-phase small units) |

| Machine Footprint | 3.5 m × 1.2 m × 1.8 m (L × W × H) |

| Weight | Approx. 900 kg |

| Material Handling | Automatic sheet collator; stacking and packing station |

These specifications can be modified based on your required production rate, page-count range, and binding style. Custom machines may include cover printing module, embossing, lamination, foil stamping, or serial numbering.

Applications & Use Cases

-

School Notebook Manufacturers

Companies that manufacture school exercise books and ruled notebooks can use these machines to scale up output while maintaining quality and cost efficiency. -

Stationery Exporters

Exporters catering to overseas markets require consistent finishing quality. An automated notebook maker helps meet uniform binding strength and tight tolerances. -

Printing Houses Adding Value-Addition

A printing press may wish to add notebook-making in-house rather than outsource final binding and finishing—thus controlling turnaround time and margins. -

Small Packaging & Custom Gifts

Boutique brands or corporate gifting operations might use smaller-scale notebook making machines for customized notebooks with logo printing, embossing or special cover materials. -

Educational Institutions / NGOs

Large NGOs or educational trusts producing in-house learning material or notebooks for schools may invest in their own binding line for cost control.

Advantages of Owning Your Own Machine

-

Lower Operating Cost: Once the capital expenditure is covered, the marginal cost per notebook drops significantly compared to outsourcing binding.

-

Better Quality Control: In-house binding ensures alignment, trimming precision and binding strength according to your standards.

-

Faster Turnaround Time: No dependency on third-party binders means you can respond rapidly to bulk orders or make on-demand print runs.

-

Scalability: You can start with semi-automatic equipment and upgrade later to full automation as production grows.

-

Return on Investment (ROI): With proper utilisation, the investment can pay for itself within months, depending on order volume, cost savings per notebook, and machine uptime.

Purchasing & Customization Guide

To ensure you select the right notebook making machine for your operation, follow these steps:

-

Define your production targets

Estimate daily or monthly notebook output, number of pages per notebook, dimensions. -

Select binding type & finishing style

Decide whether you need stitched binding, embossed covers, trimming tolerance, cover thickness, etc. -

Choose automation level

If you are operating at high volume, an automatic notebook maker is justified; otherwise semi-automatic may give better ROI at smaller scale. -

Request technical proposal

Ask prospective suppliers for detailed drawings, electrical specifications, control logic diagrams, maintenance schedule, warranty terms. -

Visit the workshop / site demo

For a local manufacturer in Santrampur, visit their factory to observe a prototype or sample run. Inspect build quality, sheet alignment, safety guards and ease of operator interface. -

Negotiate after-sales service & spare parts plan

Ensure you have access to replacement staples, cutting blades, motor servicing and preventive maintenance support locally in Gujarat. -

Plan installation & commissioning

The supplier should assist with installation, calibration, trial runs, and operator-training before handover.

Maintenance & Safety Recommendations

Proper maintenance is key to uninterrupted production:

-

Schedule regular cleaning of trimming blades and lubricate moving parts monthly.

-

Inspect electrical cabinets for loose wiring, dust and heat build-up.

-

Ensure emergency stop buttons and safety guards are functional and regularly tested.

-

Keep consumables such as binding wire, consumable blades and electrical fuses in stock.

-

Train operators in safe loading of sheets, handling of paper dust and scrap disposal.

-

Use downtime logs to monitor faults and downtime causes; improve preventive schedule.

Cost & ROI Estimation

While costs vary widely depending on automation level, binding style and customisation, a rough estimate for an automatic notebook making machine in Gujarat may range from ₹5 lakhs to ₹25 lakhs (or more for high-capacity/advanced finishing modules).

Based on production of e.g. 50,000 notebooks per month, savings achieved by eliminating third-party binding may recover initial investment in 12-18 months.

Factors influencing ROI:

-

Cost per outsourced unit (transport + binding labor)

-

Downtime percentages and maintenance costs

-

Electricity & labor costs in Gujarat

-

Volume growth and machine utilisation rate

Why Our Machine Stands Out

-

Designed and manufactured locally in Santrampur, Gujarat, with hands-on supervision.

-

Modular design allows you to begin with basic capabilities (collating, binding, trimming) and upgrade later (embossing, foiling, lamination).

-

We offer custom sizes to suit local school norms and custom formats.

-

Excellent after-sales commitment with local service team within Gujarat.

-

Competitive pricing compared to national or imported machines, without compromising quality or durability.

How to Order / Contact

If you are ready to explore or purchase a notebook making machine in Santrampur, Gujarat:

-

Send us your specifications: notebook size (height × width), page-count per notebook, binding type, daily output target.

-

Request a quotation specifying delivery timeline, installation, commissioning and training.

-

We can arrange a site visit to your facility or invite you to our workshop in Santrampur for a demo run.

-

We provide warranty, spare-parts kit and preventive-maintenance schedule for all machines supplied in Gujarat and nearby regions.

Conclusion

Investing in a quality notebook making machine is a strategic decision for any stationery manufacturer or printing house wanting to increase capacity, improve precision and reduce long-term cost. By sourcing from a reputed local manufacturer in Santrampur, Gujarat, you can benefit from customization flexibility, faster support turnaround and local cost advantages. Whether you’re launching a new school-notebook line or expanding existing production, selecting the right machine with proper features and service support is critical for success.

If you would like more details—such as technical drawing, sample video, detailed price-breakup or spare-parts list—feel free to get in touch. We are ready to assist you from Santrampur, Gujarat to set up your notebook production line smoothly and efficiently.