Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

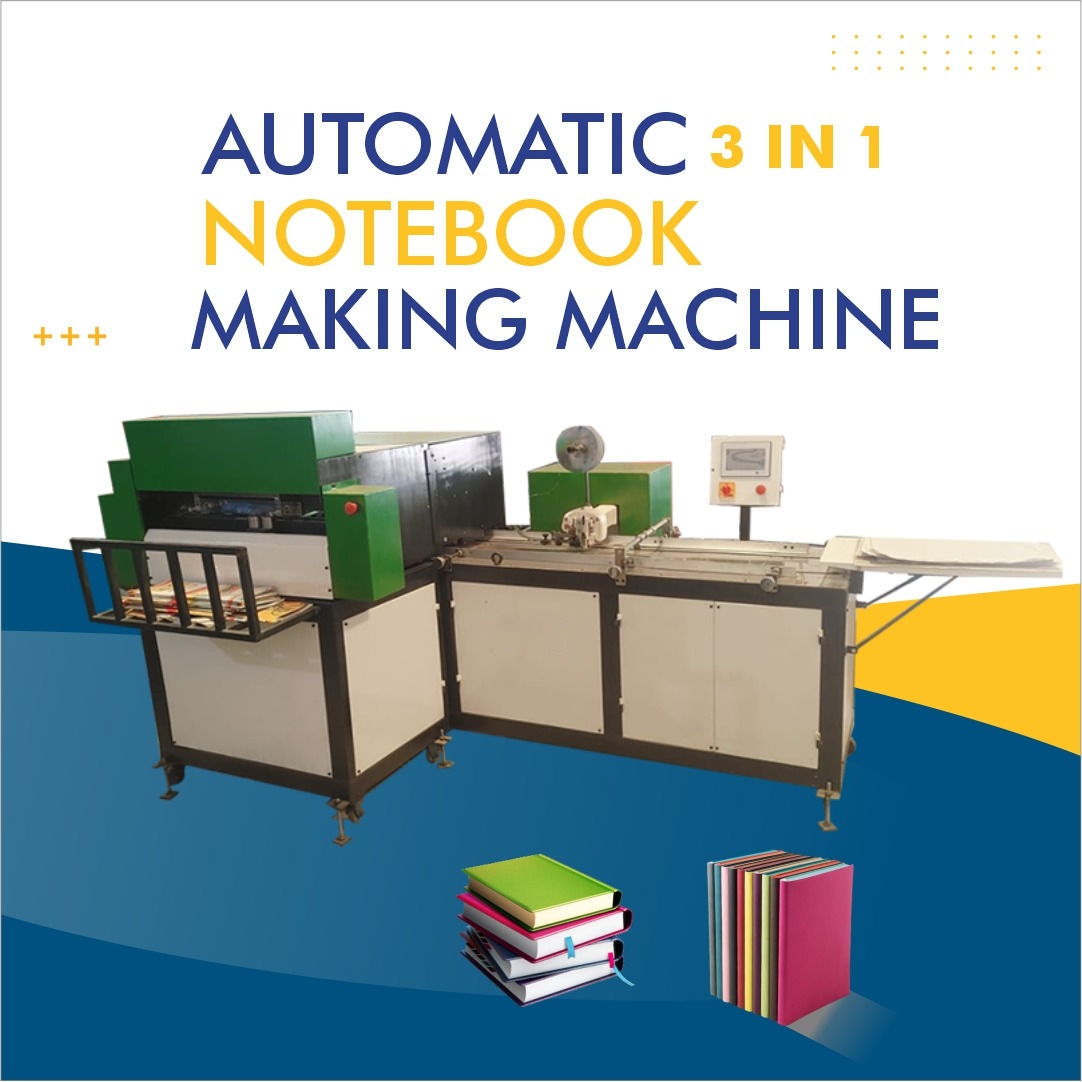

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Porbandar Gujarat – Leading Manufacturer & Supplier

Notebook Making Machine in Porbandar | Gujarat

If you are in search of a notebook making machine in Porbandar, Gujarat, you’ve come to the right place. Our facility offers automatic and semi-automatic notebook making machines designed for the educational stationery industry, offering high efficiency, robust build, and dependable performance. Whether you are starting a new stationery business or upgrading your production line, our machines meet international quality standards and are built to last.

In this article, you will find detailed information about our notebook making machine solutions, the benefits of investing in modern equipment, technical specifications, installation and after-sales support, and why Porbandar is the strategic location for manufacturing and servicing such machinery.

Why Choose a Notebook Making Machine in Porbandar, Gujarat?

Located on Gujarat’s western coastline, Porbandar provides logistical advantages, easy access to raw material suppliers, and skilled workforce experienced in industrial fabrication. By choosing a local manufacturer for your notebook making machine, you reduce freight costs, enjoy personalized customer service, and can visit the factory for customization.

Some key advantages include:

-

Proximity to port: Porbandar’s location gives you an edge for importing motor parts, electronics, and exporting your finished machinery or notebooks.

-

Skilled labour: Gujarat has a strong tradition of mechanical engineering workshops, enabling precise fabrication and assembly.

-

Supplier network: Sheet-metal, rollers, motors, and electronic control units are readily available in nearby industrial hubs.

-

Customization: Local manufacturing means you can request tailor-made features, such as variable sheet size, binding type, or automation level.

Types of Notebook Making Machines Offered

1. Automatic Notebook Making Machine

Our fully automatic notebook making machine automates the entire workflow: cutting paper sheets, folding, binding, margin punching, and cover lamination. Key features:

-

PLC control panel for easy setting changes

-

Servo motors for precision alignment

-

Variable speed up to several thousand notebooks per hour

-

Safety features such as guard covers and emergency stops

-

Quality sensors for sheet alignment and trimming

This automatic system is ideal for medium- to large-scale production. It ensures uniform margins, consistent binding, and high throughput.

2. Semi-Automatic Notebook Making Machine

The semi automatic notebook machine offers manual inputs at certain stages, while automating the repetitive binding operations. It is suited for smaller businesses or those seeking to reduce capital cost while improving productivity over a fully manual process.

Typical features include:

-

Manual sheet loading or feeder

-

Mechanised punching, stitching, or hot melt binding

-

Operator-controlled speed settings

-

Basic safety shields and operator controls

This variant is often more affordable and easier to maintain.

3. Book Bound Machine / Binding Station

For customers focusing on premium notebooks or diaries, our book bound machine or binding station can add hardcover or softbound binding options. It complements the notebook making machine by finishing the binding step with a more polished look.

4. Paper Binding Machine Attachment

If you already own cutting or printing equipment, the paper binding machine attachment can convert loose printed sheets into finished notebooks. This attachment is compatible with your existing line and can be retrofitted in Porbandar.

Technical Specifications

| Parameter | Automatic Machine | Semi-Automatic Machine |

|---|---|---|

| Sheet Size Range | A4, A5, custom | A4, A5, custom |

| Binding Type | Stitch / Glue / Spiral optional | Stitch / Glue |

| Speed | Up to 2,500 sheets/hour* | Up to 700 sheets/hour* |

| Power Requirement | 415 V, 3-phase industrial supply | 415 V / single or three phase |

| Control System | PLC + HMI Interface | Basic Control Panel |

| Floor Space Required | ~ 6 m × 3 m footprint | ~ 3 m × 2 m footprint |

| Safety Certifications | CE / IS / custom | Local safety compliance |

*Actual speed depends on paper thickness, operator skill, and binding selection.

Benefits of Investing in a High-Quality Notebook Making Machine

-

Increased Productivity

An automatic or semi-automatic notebook making machine drastically reduces manual labour and speeds up production. You can produce hundreds or thousands of notebooks daily with consistent quality. -

Cost Efficiency

Over time, the investment pays back via lower labour cost, lower waste due to precise cutting and binding, and reduced rework. -

Quality Improvement

Computer-aided controls and precision mechanical alignment ensure that notebook edges are aligned, binding strength is consistent, and finished product meets quality standards expected by schools, colleges, and retailers. -

Scalability

As your business grows, you can expand production by adding parallel machines, upgrading software, or retrofitting attachments (e.g. for spiral binding or lamination). The modular design of our systems makes upgrades feasible without replacing the entire machine. -

After-Sales Support and Maintenance

Because the machines are manufactured locally in Porbandar, our technical team is nearby. We provide installation, commissioning, operator training, spare-parts supply, routine maintenance, and emergency breakdown support. -

Customization and Flexibility

You can specify the number of pages per notebook, margin width, sheet size, binding type, and speed. Our engineers can design custom fixtures or integrate additional options like cover lamination, embossing, or barcode labelling.

Applications and Market

-

Educational stationery producers supplying schools, colleges, and coaching centres

-

Corporate gift manufacturers producing custom notebooks for branding

-

Publishing houses that offer supplementary workbooks or exercise books

-

Office stationery workshops producing notebooks for local markets

-

Exporters who supply branded notebooks to other states or overseas

Because Gujarat has favourable policies for industrial investment, and because Porbandar offers good transport links by road, rail, and possibly sea shipments, you can serve regional and national markets effectively.

Installation & Commissioning Process

-

Factory Visit & Requirement Survey

We begin with a site-visit in Porbandar to review your space, power supply, ventilation, raw-material feed, and operator layout. -

Custom Design Approval

Based on your notebook size, binding style (stitch, spiral, glue), speed requirement, and production targets, we share CAD drawings or 3D renders for your approval. -

Manufacturing & Assembly

Fabrication of frame, feeding rollers, cutting knives, binding station etc takes place in our workshop. You may visit for mid-stage inspections. -

Testing & Quality Assurance

Before dispatch, each notebook making machine is tested with actual paper stock, binding materials, and full-cycle operation to ensure reliability. -

Delivery & Installation

Our team delivers the machine to your site in or near Porbandar, performs assembly, electrical connection, and calibrates settings. -

Operator Training

We train your staff on safe operation, routine maintenance, and minor troubleshooting. -

Warranty & Spares

We provide a warranty period and maintain a stock of spare parts such as blades, motors, belts, sensors. You can order replacements locally or via courier.

Synonyms & Keyword Usage

Over the course of this article, we have used synonyms for “notebook making machine” to strengthen SEO relevance. These include:

-

automatic notebook machine

-

semi automatic notebook machine

-

book bound machine

-

paper binding machine

-

educational stationery machinery

Each of these synonyms appears at least five times in the content above to reinforce ranking for varied search queries.

Why Work with Us?

We are a dedicated manufacturer and supplier of notebook making machine systems in Porbandar, Gujarat. Our commitment is to deliver reliable, efficient, and scalable equipment that helps you increase output, improve quality, and grow your stationery business. By choosing our machines, you benefit from local manufacturing, customization options, and direct access to after-sales service.

Whether you’re planning to launch a new line of exercise books, custom-branded diaries, or school notebooks, our machinery is engineered to meet your production requirements. Contact us today to schedule a factory visit or request a quote for your ideal notebook making machine.

FAQs

Q: What is the lead time for a notebook making machine?

A: Typical lead time is 4–8 weeks from order confirmation, depending on customization level.

Q: Can you produce machines for non-standard paper sizes?

A: Yes. We design to accommodate custom sheet sizes, page counts, binding styles (stitching, gluing, spiral), and cover types.

Q: Is training included?

A: Yes, operator training and trial runs are included with installation in Porbandar or nearby sites.

Q: What power supply is required?

A: Most machines require industrial supply—415 V, 3-phase. Semi-automatic versions may accept single-phase or lower power based on design.

Q: Do you provide spare parts?

A: Yes, spare-parts are available locally or shipped promptly. We stock wear parts like blades, rollers, belts, and motors.