Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

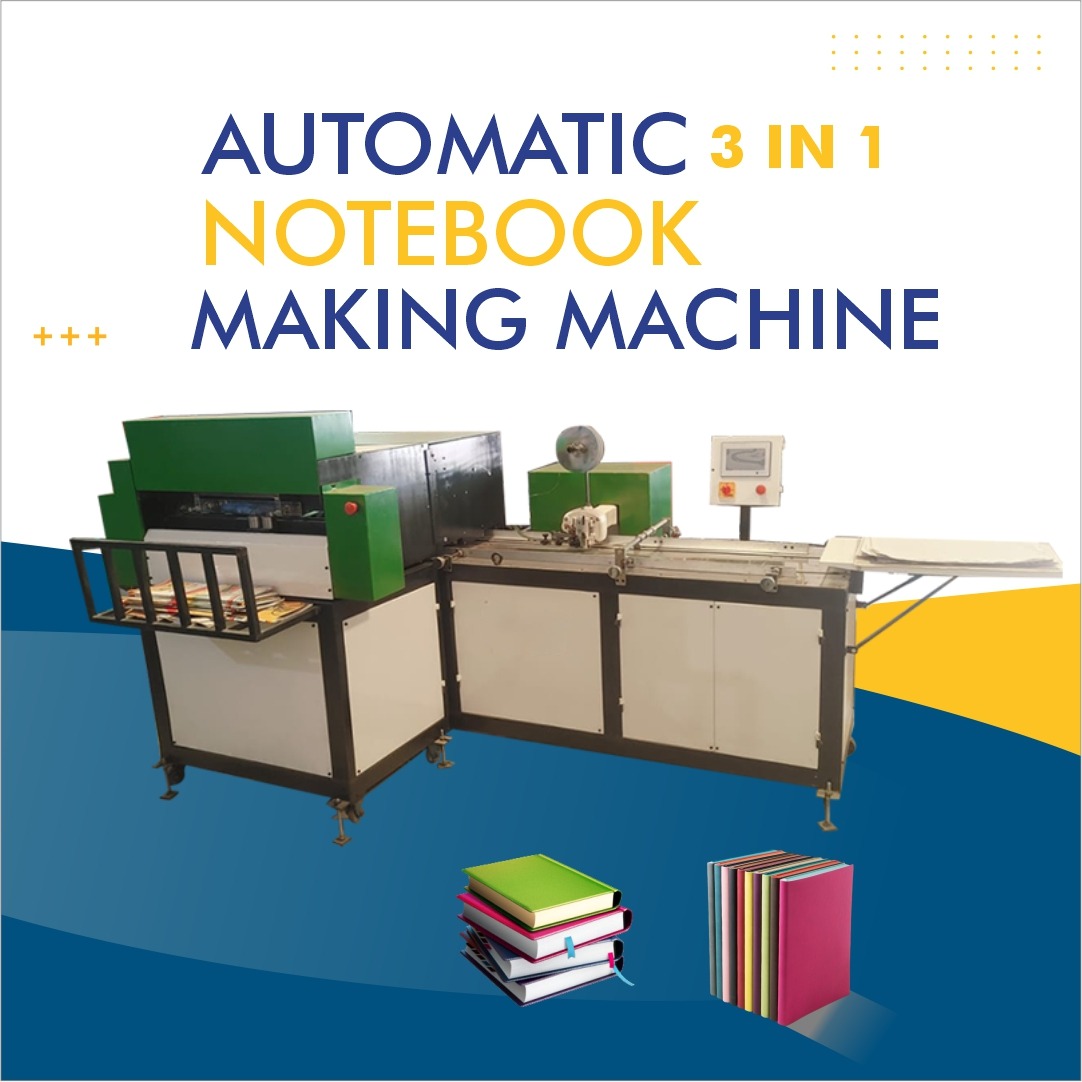

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machines in Navsari Gujarat | Reliable Output & Competitive Price

Notebook Making Machines in Navsari | Gujarat

If you are searching for a notebook making machine in Navsari, Gujarat, you’ve come to the right place. Whether you are a small-scale stationery producer or an industrial paper converter, choosing the right notebook production equipment can dramatically boost both quality and output. At [Your Company Name], we specialize in designing, manufacturing, installing, and supporting high-precision notebook making machines that meet the rigorous demands of the Indian stationery market.

In this article, you will learn about:

-

Why Navsari is a strategic location for notebook machinery manufacturing

-

The features and benefits of our notebook making machines

-

Technical specifications and customization options

-

Applications and use cases

-

Installation, training, after-sales service

-

How to choose the right notebook machine for your operation

We also highlight why our company stands out as a trusted notebook machine manufacturer in Gujarat and across India.

Why Navsari, Gujarat is a Strategic Location

Navsari is an emerging industrial hub in southern Gujarat with good connectivity to major road and rail networks, and relatively lower operational cost compared to metropolitan centres. This makes it an ideal place to set up manufacturing or sourcing of industrial equipment.

-

Proximity to ports (such as Hazira or Diamond Harbour via road networks) helps in the movement of raw material (paper reels / boards) and exporting finished machines or components.

-

Skilled labor and engineering workshops in Gujarat are capable of precision metal fabrication, electrical wiring, and control system integration.

-

Competitive labor cost, favorable local industrial policy, and availability of local vendors for electrical components, sheet-metal fabrication, gear components, and drive systems.

-

Being in Gujarat gives you access to a large stationery market across western India (Maharashtra, Rajasthan, Madhya Pradesh, etc.), reducing transportation time and cost for buyers.

Thus, locating your notebook machinery supplier in Navsari can help you benefit from reduced logistics cost, faster service, and better collaboration for custom manufacturing.

What is a Notebook Making Machine

A notebook making machine is specialized industrial equipment that automates multiple processes involved in producing a notebook. These generally include:

-

Paper cutting / trimming

-

Folding (if applicable for inner sections or signatures)

-

Binding (spiral binding, glue binding, case binding, staple binding etc.)

-

Cover insertion and finishing

-

Numbering or embossing (optional)

-

Stacking, packaging, and final inspection

Modern notebook machines are often automatic or semi-automatic. They combine mechanical, pneumatic, electrical and computer control (PLC / HMI) systems to ensure consistent sheet alignment, binding quality, cutting precision, and output speed.

Depending on your requirement, a notebook making machine may produce single-signature notebooks (plain sheets folded and staple-bound), multi-signature stitched booklets, or hardcover notebooks. The machine may include inline trimming, cover gluing, and trimming of edges to give a clean finish.

We also offer supporting equipment such as paper cutting and folding machine, stapling / stitching / perfect binding unit, and packing or shrink-wrapping systems to complement the main notebook machine.

Key Features & Specifications

Below are some of the standard and customizable features you can expect when sourcing a notebook making machine in Navsari:

-

Production Speed: e.g. 100–500 notebooks per hour (depending on size, binding type, number of pages)

-

Paper Size Range: A5, A4, custom sizes

-

Page Count Range: From 16 pages up to 200 pages (or more, by special design)

-

Binding Type: Staple / stitch binding, glue binding, wire/spiral binding

-

Motor Power & Automation: Automatic feed, PLC-controlled operations, touchscreen HMI; servo-driven feed systems for accurate registration.

-

Cutting Tolerance: ±0.5 mm or better, depending on knife blade or guillotine design.

-

Material Handling: Paper feed magazine, stacker for finished notebooks, reject tray for defects.

-

Safety Features: Emergency stop buttons, guard covers, safety interlocks.

-

Frame & Build: Heavy steel frame to reduce vibration, precision aluminum guides or stainless components for longevity.

-

Optional Accessories: Edge embossing, numbering, foil stamping station, barcode sticker labelling station, shrink wrapper.

-

Power Supply: 3-phase electrical supply (custom voltage as per Indian standard), energy-efficient motors & drives.

Custom orders may include integration with upstream paper cutting tables or downstream packaging systems, or even semi-robotic material handling.

Benefits of Investing in a High-Quality Notebook Machine

1. Increased Productivity

Automation replaces manual labor for repetitive tasks like folding, trimming and binding. Your output rises significantly while maintaining consistency in page alignment and binding precision.

2. Reduced Waste & Rework

Precise cutting and binding systems reduce misalignment, misprints or misfolded pages. This lowers paper waste, reduces material cost, and improves overall product yield.

3. Better Product Quality

Reliable binding and trimming lead to cleaner edges, uniform spine alignment, and professional finishing. High-quality notebooks fetch better rates in wholesale or retail markets.

4. Scalability & Customization

Modern notebook making machines can be reconfigured for different sizes, cover types, and binding styles. This allows you flexibility to produce a variety of notebooks without investing in separate lines.

5. After-Sales Support & Maintenance

Since your supplier is based in Navsari / Gujarat, turnaround for service parts, maintenance or upgrades is faster. You benefit from local support for preventive maintenance and troubleshooting.

Applications / Use Cases

You can use the notebook production machine for a wide range of stationery manufacturing or printing / packaging applications:

-

School and college notebooks (ruled / plain / graph)

-

Diaries, organizers, planners

-

Notebooks for corporate gifting

-

Hardcover or softcover books (if machine supports case binding)

-

Custom branded notebooks for printing houses or promotional agencies

-

Export quality notebooks for overseas clients

Small and medium stationery manufacturing units in Gujarat and neighbouring states can upgrade from manual binding to semi-automatic or fully automatic notebook manufacturing. Printing houses can bundle this equipment with pre-printed signatures.

How to Choose the Right Notebook Making Machine

When comparing different notebook machines or suppliers, consider the following checklist:

-

Output Capacity & Speed – Match machine throughput with your production target.

-

Binding Style & Flexibility – Ensure the machine supports your required binding types (stitch, glue, spiral).

-

Automation Level – Manual, semi-automatic or fully automatic; PLC / touchscreen interface; servo drives.

-

Footprint & Layout – Evaluate floor space available in your factory.

-

Power Consumption – Efficient motor / drive systems and energy rating to reduce operating cost.

-

Spare Parts & Service – Local availability of blades, motors, electronics; preventive maintenance plan.

-

Customisable Features – Size adjustment (for different notebook formats), special finishing stations (embossing or numbering).

-

Price & Return on Investment (ROI) – Calculate total cost including installation, commissioning, and amortize over expected notebook output.

Before purchase, request a sample run, inspect a working demonstration, and check testimonials from existing customers in Gujarat or beyond.

Our Company’s Offering in Navsari

At [Your Company Name], based near Navsari, Gujarat, we offer customized notebook machine solutions tailored to your operational needs:

-

Custom Design & Manufacture

We can design a notebook making machine as per your required sheet size, binding style, speed and automation preferences. -

Installation & Training

Our technicians will install the machine on your site, calibrate settings for your paper type and binding specifications, and train your staff for optimal operation. -

After-Sales Service & Support

We offer local maintenance, periodic servicing, and quick availability of replacement components (knives, belts, magnetic sensors, control modules). -

Competitive Pricing & Local Presence

Because our workshop is located in Gujarat, you benefit from lower shipping costs, shorter lead time, and more personalized coordination compared to distant out-of-state or imported machinery. -

Upgrades & Retrofitting

If you already own older binding or cutting machines, we can retrofit modern control panels or add modules for higher automation and safety features. -

Compliance & Safety

Our machines meet Indian safety standards and use reliable electrical components. We ensure safe operation under industrial conditions.

We proudly serve stationery manufacturers across Gujarat (Surat, Vadodara, Ahmedabad), as well as clients in Maharashtra and other neighbouring states.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for manufacturing a notebook making machine?

A: Depending on the complexity, automation level, and customization, it typically takes 6 to 12 weeks from order confirmation to factory delivery, plus installation and commissioning.

Q: Can your machine handle different formats (A4, A5, custom)?

A: Yes. We design adjustable feed and cutting stations so you can switch between formats with minimal setup time.

Q: What binding types do you support?

A: We support staple/stitch binding, glue binding, and optional spiral / wire binding modules on request.

Q: What power supply is required?

A: Standard 3-phase industrial power supply (400 V, 50 Hz) is used. We provide detailed electrical specification along with the machine documentation.

Q: How do I maintain sharp knives or cutting blades?

A: We supply hardened-steel blades and recommend periodic sharpening or replacement. Our maintenance contract includes on-site blade servicing.

Q: Do you provide financing or leasing options?

A: We can help you connect with financial partners who support capital equipment loans for manufacturers in Gujarat.

Conclusion

Investing in a reliable notebook making machine is a strategic decision if you aim to expand or modernize your stationery manufacturing business. Choosing a local manufacturer in Navsari, Gujarat gives you the benefits of lower lead time, easier service access, and potential cost advantages.