Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

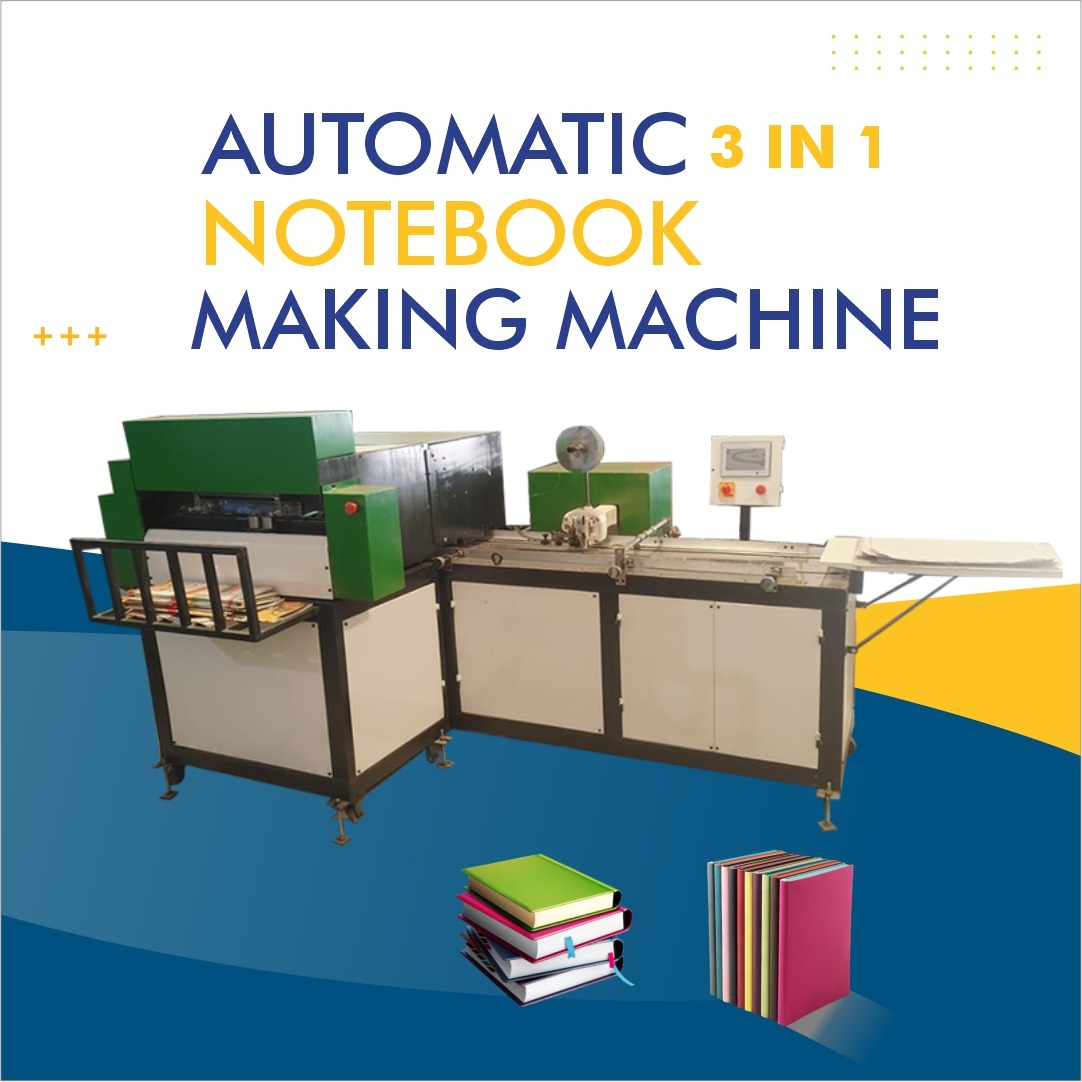

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Modasa Gujarat | High Quality Machinery

Notebook Making Machine in Modasa | Gujarat

Modasa, a growing industrial town in the Aravalli district of Gujarat, has emerged as a strategic location for manufacturing and machinery production. Wikipedia+1 Among the many industries there, the production and supply of notebook making machines is gaining importance for stationery manufacturers across Gujarat and nearby states. In this article, we explore the features, benefits, types, and why you should consider a notebook making machine manufacturer based in Modasa.

If you are looking to establish or upgrade a notebook production line, choosing a reliable notebook making machine in Modasa, Gujarat offers benefits such as lower logistics cost, localized support, and faster turnaround times.

About Modasa, Gujarat & Advantages

-

Modasa is the district headquarters of Aravalli district in Gujarat. Wikipedia+1

-

Being part of a growing industrial zone, it offers good transport connectivity within Gujarat, and proximity to supply of materials such as paper, binding material, and labor.

-

Local access to skilled workforce and regional manufacturing support helps reduce maintenance delays and downtime.

-

Setting up machinery or sourcing machines from Modasa, Gujarat helps you leverage regional incentives and reduced overhead costs compared to distant suppliers.

Therefore, sourcing your notebook making machine from a manufacturer based in Modasa can deliver better overall value for your investment.

What is a Notebook Making Machine?

A notebook making machine is specialized industrial equipment used to assemble, cut, bind, fold, and package notebooks. Depending on your production volume, quality requirements, and budget, such machines can be:

-

Automatic notebook making machine – high-speed, minimal manual intervention

-

Semi-automatic notebook making machine – some automated processes, some manual steps

-

Manual notebook making machine – mostly manual operation, suitable for small-scale or startup operations

These machines perform functions such as:

-

Cutting paper sheets to required size

-

Stacking pages and cover sheets

-

Binding (e.g. spiral coil binding or stapling)

-

Trimming edges

-

Folding or pressing

-

Packaging or bundling finished notebooks

They help ensure consistency in quality, save labor, increase throughput, and reduce wastage.

Types of Notebook Making Machines Offered

Here are typical categories:

-

Manual Notebook Making Machine

-

Best suited for small-scale production

-

Operator handles stacking, binding and trimming steps

-

Lower cost of investment

-

Example product listed for manual type costs around INR 1,30,000. TradeIndia

-

-

Semi-Automatic Notebook Making Machine

-

Some steps automated (e.g. trimming or cutting), others manual

-

Balanced cost versus productivity

-

Suitable when production volumes are moderate

-

-

Fully Automatic Notebook Making Machine

-

End-to-end automation — cutting, binding, trimming, stacking

-

High throughput (hundreds to thousands of notebooks per hour)

-

Lower labor cost per unit, higher investment

-

For example, one model produces up to 650 pcs/hr or 1000 pcs/hr in Gujarat region. guptamachinary.com

-

-

Customized or Spiral Notebook Making Machine

-

Some machines are adapted for spiral binding or specific formats

-

Useful if your notebooks use coil binding rather than staple or glue binding

-

-

Spare parts, after-sales support & tooling

-

Local manufacturer can supply spare cutters, blades, motors

-

On-site servicing and breakdown support

-

Key Features to Evaluate

When selecting a notebook making machine in Modasa, Gujarat, consider these specifications:

-

Production capacity (notebooks per hour)

-

Automation level (manual / semi-automatic / automatic)

-

Power consumption & voltage

-

Sizes supported (e.g. A4, A5, custom dimensions)

-

Thickness of notebooks (number of pages / cover material)

-

Binding type (staple, glue, coil / spiral)

-

Material of construction (steel body, quality frame & safety features)

-

Maintenance & after-sales support

-

Cost vs ROI (investment payback based on production volume)

A local manufacturer in Modasa can help you tune these features for Gujarat market conditions, such as available electricity, labor cost & delivery time.

Benefits of Choosing Local Manufacturer in Modasa

Choosing a supplier/manufacturer based in Modasa, Gujarat offers several advantages:

-

Reduced logistics & transportation cost

-

Faster delivery & installation

-

Customization to local standards

-

Proximity for maintenance, spare-parts and technical support

-

Better coordination for upgrades or retrofits

-

Knowledge of local regulatory & safety compliance

-

Potential for regional grants / government support for industrial machinery in Gujarat

This gives you a competitive edge vs importing machinery from distant locations.

Typical Applications & Industries

Notebook making machines located in Modasa (or supplied from Modasa) find uses in:

-

Local stationery manufacturers producing exercise books, drawing books, school notebooks

-

Printing houses that add binding & finishing lines

-

Educational stationery brands distributing within Gujarat or neighbouring states

-

Small business startups entering into notebook manufacturing

-

Industrial units expanding their finishing & binding capacity

These machines help these applications meet quality benchmarks at scale, reduce defects, and maintain consistent output.

Price Range & Investment Estimate

While actual cost depends on specification, automation level, and capacity, you can expect:

-

Manual models in the range of ~ INR 1,00,000 to ₹1,50,000

-

Semi-automatic machines higher, depending on features

-

Fully automatic higher capacity machines may cost several lakhs of rupees (e.g. models listed online show rates in lakhs for higher speed machines). guptamachinary.com

-

Additional costs for shipping, installation, power-connection & training

When planning investment, calculate production volume, running hours per day, margin per notebook, and pay-back period.

How to Choose the Right Machine

Here are steps you can follow:

-

Assess your production needs

-

How many notebooks per day? What sizes? What binding type?

-

-

Choose automation level

-

If you expect growth, fully automatic or semi-automatic may be better

-

For low volume or pilot scale, manual might suffice

-

-

Verify machine specifications

-

Confirm capacity, speed, accuracy, safety standards

-

-

Request demo or site visit

-

Visit manufacturer in Modasa (if facility available)

-

See live performance & quality of finish

-

-

Compute total cost of ownership

-

Include electricity, maintenance, spare parts, downtime

-

-

Check after-sales & maintenance

-

Warranty terms, local service team, spare parts availability

-

Why Opt for Us (Hypothetical Manufacturer Profile)

Let’s assume you're representing a notebook machine manufacturer based in Modasa. You can highlight:

-

Decades of experience designing & building notebook making machine

-

Capability to build custom sizes & formats (spiral binding / staple binding)

-

On-site installation & commissioning in Gujarat towns

-

Spare-parts & servicing teams stationed nearby

-

Focus on energy-efficient motors and durable components

-

Competitive pricing vs distant suppliers, with faster turnaround

Conclusion

If you’re planning a stationery manufacturing setup or upgrading your finishing line in Gujarat, a notebook making machine sourced from a reliable Modasa-based manufacturer can offer you strong value. You benefit from localized support, customization, competitive cost, and good quality control. Assess your production volume, choose the right automation level, and partner with a manufacturer who understands your product dimensions, binding requirements and maintenance needs.

Get in touch with local engineers and suppliers in Modasa, verify machine demos, compare quotations, and select a machine that aligns with your budget & production targets. By doing so, you’ll maximize efficiency, maintain consistent quality, and reduce operational downtime.