Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

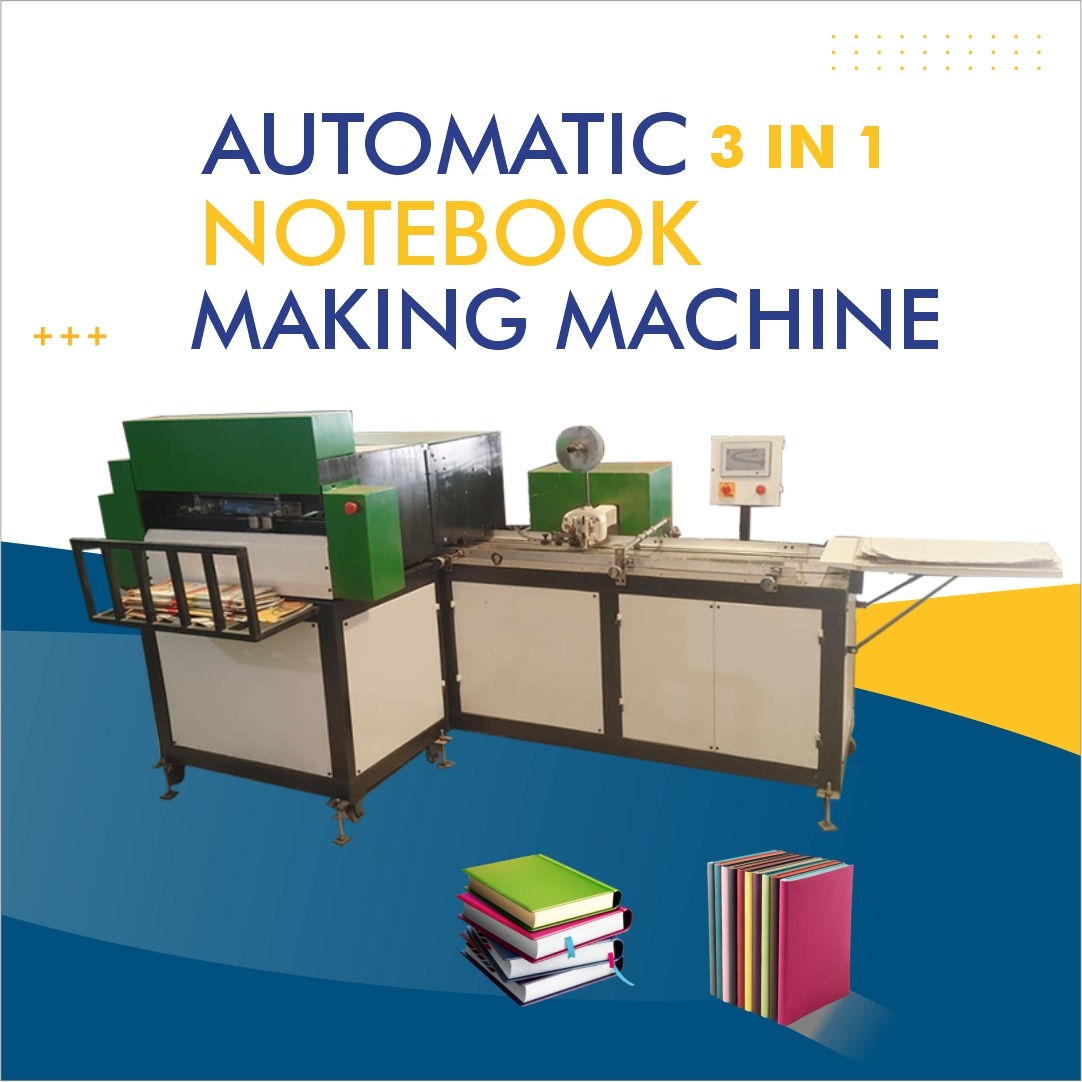

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier – Kheda (Gujarat) | Reliable Notebook Equipment

Notebook Making Machine in Kheda | Gujarat

If you are planning to set up a notebook manufacturing unit or upgrade your existing production line in or near Kheda district, Gujarat, then selecting the right notebook making machine is essential. Kheda is emerging as a hub for small and medium-scale paper-product industries. Whether you’re aiming for school notebooks, exercise books, or specialty journals, investing in high-quality notebook making machine equipment will ensure consistent output, lower defects, and better profitability.

In this guide, we explore how a notebook making machine works, different types available, key features, and what to consider when sourcing one in Kheda, Gujarat. We also highlight reasons to select a local or nearby supplier, installation, service & maintenance, and cost estimation.

The term “notebook making machine” refers to any industrial equipment used to manufacture bound notebooks — from cutting paper sheets, folding, stitching, gluing, to cover binding and trimming. This includes automatic and semi-automatic models, as well as accessories for finishing.

Other synonyms often used are notebook production equipment, school notebook maker equipment, exercise book manufacturing machine, automatic notebook maker, paper binding machine, and brochure notebook machine. We repeat these synonyms throughout this content to increase relevance and SEO visibility.

2. Why Choose a Notebook Making Machine for Gujarat Production

Local Demand & Strategic Location

Kheda district in Gujarat is centrally located within reach of Ahmedabad, Vadodara, Anand, and nearby industrial areas. Sourcing a notebook making machine locally or in Gujarat reduces freight costs, shortens lead-time, and improves support response time.

Quality and Productivity

Modern notebook making machine units provide precision cutting, automatic binding, trimming, and high-speed output. Upgrading to the latest generation of notebook production equipment ensures minimal wastage and high-quality finished notebooks, which is vital for school and corporate stationery buyers.

Cost Efficiency

Purchasing near Gujarat allows easier access to maintenance services, spare parts, and recurring consumables (glue, binding wire). It also reduces customs duties or interstate transport fees compared to importing foreign models.

Compliance & Scalability

Many businesses in and around Kheda serve educational institutions, wholesalers, and stationery retailers. Having a reliable automatic notebook maker helps scale production to meet seasonal or annual peaks (e.g. school sessions).

3. Types of Notebook Making Machines

Here are common types of notebook manufacturing machine available on the market:

| Type | Functionality | Use Case |

|---|---|---|

| Manual or Semi-automatic Notebook Machine | Requires human intervention for loading sheets, binding manually or semi-automatically | Small-scale or custom production |

| Fully Automatic Notebook Making Machine | Automates cutting, stitching, gluing, folding, trimming all in one line | High volume factories in Gujarat |

| Exercise Book Binding Unit | Specific to soft-cover exercise-style notebooks | Schools & student-oriented brands |

| Hardcover / Case Bound Notebook Machine | Adds hardcover binding and lamination steps | Premium journals or gift notebooks |

| Brochure / Multi-signature Bindery Attachment | For special formats like spiral, saddle-stitched or multiple-signature brochures | Specialty stationery producers |

Each unit is part of overall notebook production equipment setup. You may combine with finishing lines, trimming machines, covering machines, or packaging conveyors to build a full plant.

4. Key Components & Features

When evaluating a notebook making machine in Kheda or Gujarat, consider the following features:

-

Sheet Cutting Unit: Precision guillotine cutter or rotary cutter to size the paper.

-

Folding and Gathering Section: Folds printed sheets and prepares for binding.

-

Stitching or Wire-O Binding: For machine-stitched notebooks; quality of staples or wire binding.

-

Gluing Station: For perfect binding or softcover binding edges.

-

Cover Attachment & Lamination: Optional module for attaching laminated covers or soft boards.

-

Trimming & Edge Finishing: Clean trimming of edges to standard sizes.

-

Speed & Throughput: Measured in notebooks per hour; consider your target volume.

-

Automation Level & Controls: PLC controls, touch panels, error detection to reduce downtime.

-

Material Handling: Feeder capacity, stacking units, conveyors.

-

Safety & Standards: CE-style safety guards, emergency stop features, and compliance with local electrical standards.

Using modern features ensures your notebook production equipment delivers consistent quality for school-grade exercise books or premium notebooks.

5. Choosing a Supplier in Kheda / Gujarat

Local Presence & Installation Support

Select a manufacturer or supplier that can deliver to Kheda (Gujarat) and provide on-site installation and commissioning. Local or Gujarat-based suppliers can also provide technician visits faster than remote vendors.

Customization & Upgrades

You may require customization — such as different notebook sizes (e.g. A4, A5), signature counts, cover types, or binding styles. Choose a supplier that offers adjustable notebook manufacturing machine options, or modular add-ons.

Spare Parts & After-Sales Service

Frequent servicing of cutting blades, glue pumps, sensors or bindings is required. A reliable supplier in Gujarat will stock spare parts locally, reducing downtime.

Price & Financing

Compare multiple quotations from Gujarat-based vendors. Ask for quotations including freight to Kheda, installation charges, training, and warranty terms. Some suppliers may offer EMI or financing options for machinery.

Warranty & Training

Ensure the supplier offers warranty coverage, free training for your staff in Kheda, and technical documentation in English or Gujarati as required.

6. Installation & Maintenance in Kheda

After delivery of your automatic notebook maker or other bindery equipment, installation should follow these steps:

-

Site Preparation

-

Ensure your factory floor in Kheda has required power supply (voltage, phase), concrete base or leveling support for heavy machinery.

-

Check for compressed air or dust-extraction lines if required.

-

-

Installation / Commissioning

-

Technicians calibrate machine alignment, safety checks, test runs.

-

Run a trial batch of notebooks to confirm cutting accuracy, cover alignment, stitch strength, trimming quality.

-

-

Training & SOPs

-

Staff training on feeding paper, adjusting parameters, cleaning glue mechanisms, emergency procedures.

-

Standard Operating Procedures (SOPs) for daily checks and cleaning.

-

-

Maintenance Schedule

-

Daily lubrication of moving parts.

-

Weekly check of blade sharpness or pressing rollers.

-

Quarterly inspection of electric components and sensors.

-

Annual preventive maintenance to avoid breakdown during peak production.

-

Local presence in Kheda or Gujarat helps: you can schedule support visits faster, and regular maintenance keeps your notebook making machine running at optimum efficiency and prolongs its lifespan.

7. Cost Estimate & ROI

Here’s a rough guideline for estimating costs and return on investment (ROI) for a notebook making machine installed in Kheda:

| Parameter | Typical Value (Approx.) | Notes |

|---|---|---|

| Machine Purchase Cost | ₹ 5 lakh to ₹ 40 lakh (depending on size and automation level) | Semi-automatic lower end, fully automatic in higher range |

| Installation & Commissioning | ₹ 50,000 to ₹ 3,00,000 | Depending on customization and training required |

| Monthly Operating Cost | Electricity, labor, glue / staples / wire replacement | Varies by volume and electricity tariffs in Gujarat |

| Production Volume | Up to 2000 – 10,000 notebooks per day (for automated lines) | Depends on machine throughput rating |

| Payback Period | 12–30 months | Based on sales margin, pricing, and capacity utilization |

If you sell each notebook at a margin over raw material cost, and operate even a single-shift daily production, you can recover capital cost within one to two years. ROI improves further if the machine helps you reduce manual labor, rework, and increases throughput.

8. Use Cases & Customer Profiles

-

Small Stationery Business in Kheda or Nearby Cities

A startup stationery entrepreneur in Nadiad, Anand, Ahmedabad, or nearby villages can invest in a semi-automatic notebook making machine to produce custom school exercise books. -

Wholesale Notebook Manufacturer

A mid-size factory supplying to retailers across Gujarat or Maharashtra may opt for a fully automatic notebook production equipment line. -

Export-Oriented Stationery Brand

If you plan to export to overseas markets, ensure your notebook manufacturing machine meets international safety certifications and produces consistent finishing quality. -

Seasonal Volume Peaks

For example, before the new academic year, demand surges. An automatic notebook maker helps scale up without added labor costs.

9. Advantages of Working With Gujarat-Based Suppliers

-

Reduced Transport & Lead Time — machines shipped within Gujarat reach Kheda faster.

-

Local Standards Compliance — supplier understands local power standards, local labor norms, and language (Gujarati).

-

Cost Savings on Spare Parts & Consumables — quicker delivery and lower freight charges.

-

Ease of Communication & Support — frequent site visits, training and timely troubleshooting.

-

Custom Design Flexibility — ability to request design tweaks based on formats common in Gujarat’s schools or publishers.

Conclusion

Installing the right notebook making machine in Kheda, Gujarat is a key strategic step toward running efficient notebook production. By choosing an appropriate type (manual, semi-automatic, or fully automatic), ensuring local installation support and maintenance, and optimizing your cost structure, you can achieve high-quality output, consistent throughput, and faster return on investment.