Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

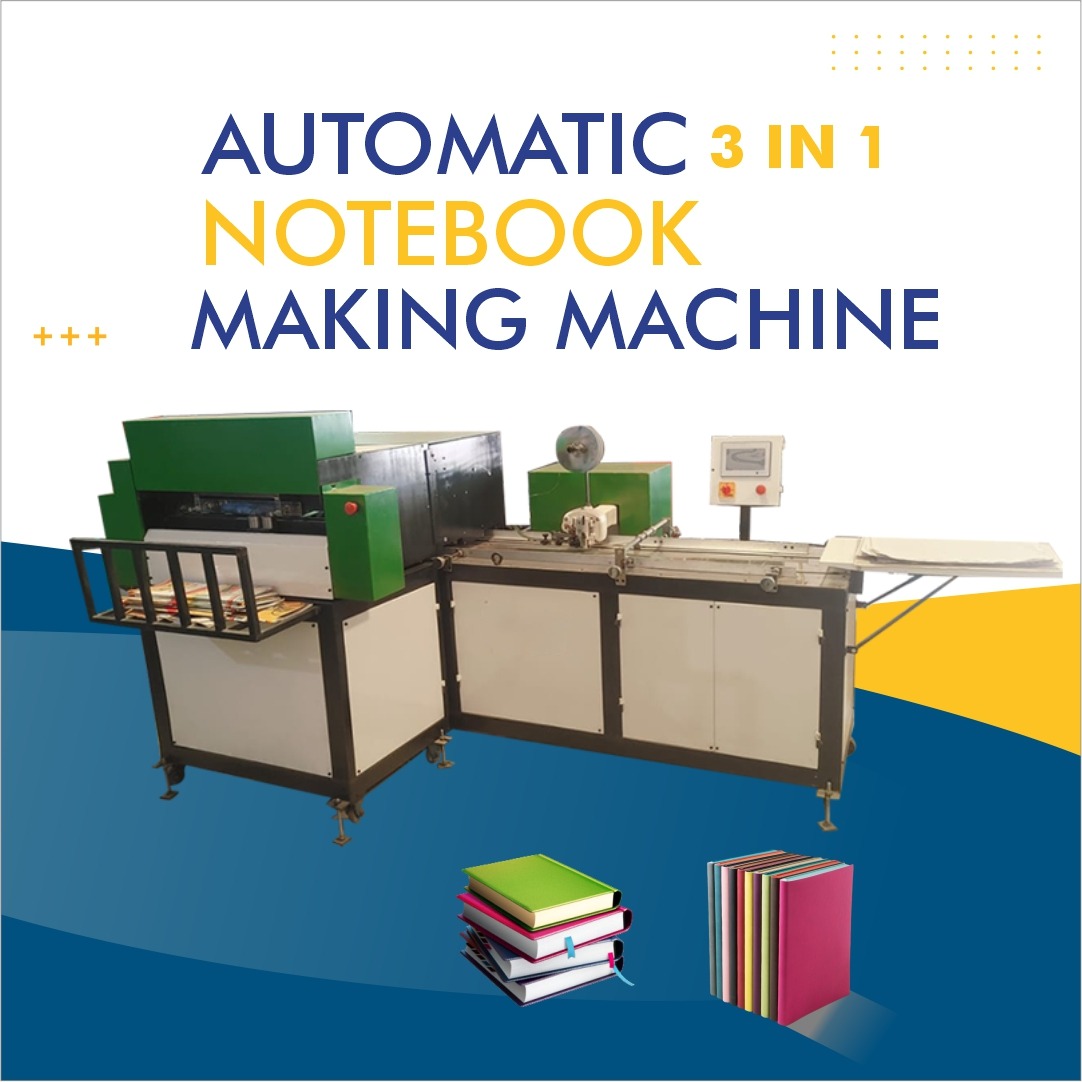

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

“State-of-the-Art Notebook Making Machine Supplier in Khambhat, Gujarat”

Notebook Making Machine Supplier in Khambhat | Gujarat

Khambhat, Gujarat is emerging as a manufacturing hub for stationery and paper-product equipment. If you are looking for a notebook making machine in Khambhat, Gujarat, you’ve come to the right place. Our company specializes in designing, manufacturing, and supplying top-quality notebook making machines suitable for small to industrial-scale production. Whether your need is for binding, cutting, embossing or custom finishing, we deliver turnkey solutions to meet your production targets.

In this article, you will learn about the features, benefits, types, installation, maintenance, and buying considerations for notebook making machines in Khambhat, Gujarat. We also cover synonyms and related terms such as notebook manufacturing equipment, binding machinery, paper pressing machine, automatic binding system, and school notebook production line.

2. Why Choose Khambhat for Notebook Making Machinery?

-

Strategic Location: Khambhat is well-connected to major transportation networks in Gujarat. Its proximity to raw-material suppliers (paper mills, binding supplies) makes it ideal for stationery machinery manufacturing.

-

Skilled Workforce: Gujarat has a long tradition of engineering workshops and small-scale machine fabrication. You can find experienced technicians for designing, fabricating, and servicing notebook production systems.

-

Cost-Effective Production: Local manufacturing offers lower logistics cost compared with importing machines. Labour rates and material procurement are competitive in this region.

-

Custom Solutions: Many clients require non-standard sizes or additional features (embossing, perforation, customized covers). A Khambhat-based supplier can provide custom modifications faster than distant manufacturers.

-

After-Sales Support & Maintenance: Proximity means you can get faster on-site service for notebook manufacturing equipment, reducing downtime and improving ROI.

3. Key Types of Notebook Making Machines

Below are some common types of machines used in notebook production:

-

Cutting & Trimming Machines

Used to cut paper sheets to desired sizes with precision. Quality cutting reduces paper wastage. -

Binding Equipment

Includes spiral/wire binding, glue binding or stitched binding units. An automatic binding system streamlines the finishing process. -

Cover Lamination & Embossing Machines

For aesthetic finishing, these machines laminate covers, emboss logos or text, and provide premium touch. -

Paper Pressing Machine

After binding, pressing machines flatten the notebook spine or compress the stack to ensure uniformity. -

Hole-Punching / Perforation Units

Create punched holes in sheets prior to binding (especially for ring bound or spiral bound notebooks). -

School Notebook Production Line

An integrated line combining cutting, collating pages, binding, pressing, trimming, and packaging — ideal for high-volume notebook manufacture.

Each of these is part of the broader category of notebook manufacturing equipment, and we can supply all variants or full production lines.

4. Features & Specifications You Should Look For

When selecting a notebook making machine in Khambhat or anywhere else, consider the following features:

-

Production Capacity: How many notebooks per hour/day? Choose machines rated for your volume (e.g. 2000, 5000, 10,000 notebooks/day).

-

Sheet Size Compatibility: Standard sizes (A4, A5, custom). Adjustable cutting and binding width.

-

Automation Level: Manual, semi-automatic or fully automatic systems. Higher automation reduces labor cost.

-

Binding Type: Spiral, glue, stitch binding or hard-cover binding. For example, glue-binding units require heating elements and adhesive systems.

-

Precision & Quality: Accurate cutting, aligned punching holes, consistent binding depth. Helps reduce rejects.

-

Power & Energy Consumption: Energy-efficient motors and drives reduce operating cost.

-

User Safety & Compliance: Guards, emergency stop buttons, wiring standards according to Indian regulations.

-

Maintenance & Spare Parts Availability: Choose a supplier who stocks spare parts locally in Gujarat so your downtime is minimal.

When you purchase notebook manufacturing equipment from a local supplier in Khambhat Gujarat, you can inspect the machine in person, request factory acceptance test (FAT), and ensure it meets your technical requirements.

5. How Our Notebook Making Machine Serves Your Business

Our machines offer the following benefits:

-

High throughput with reliable uptime: State-of-the-art components ensure your notebook making operations run smoothly, day after day.

-

Consistency & Quality: Accurate binding and trimming reduce wastage. Your finished notebooks look professional and uniform.

-

Scalability: Start with a semi-automatic configuration; upgrade to fully automatic school notebook production line when your orders grow.

-

Energy efficiency: Designs optimized for lower power consumption reduce cost per unit.

-

Local support in Gujarat: Our service and maintenance teams are based near Khambhat. You get fast response for onsite servicing of paper pressing machine or binding units.

-

Customization options: From custom cover embossing units to specific sheet size formats, we tailor the machine to your requirements.

In short, investing in our notebook making machine means better productivity, lower cost per piece, and a strong competitive edge in the stationery market.

6. Installation & Commissioning in Khambhat

When you order from us, here’s our typical process:

-

Requirement Analysis

We discuss your production volumes, notebook sizes, binding type, and automation preferences. -

Design Approval & Quotation

Based on discussion, we provide technical drawings and cost estimate. -

Manufacturing & Factory Testing

The machine is manufactured in our Gujarat facility, tested internally under working loads. -

Delivery & Installation

Our team delivers and installs the machine at your workshop in Khambhat or nearby location. -

Commissioning & Training

We run a trial production (“factory acceptance test”) on-site and train your staff in operation and basic maintenance. -

After-Sales Support

Regular maintenance contracts, prompt spare-part supply, and on-site servicing of your automatic binding system, paper pressing machine, or other units.

7. Maintenance & Troubleshooting Tips

To maintain optimal performance of your notebook making machine:

-

Schedule routine cleaning and lubrication of moving parts.

-

Replace cutting blades periodically to maintain crisp edges.

-

Check motors and drives for overheating.

-

Monitor alignment of punching and binding modules.

-

Ensure safety guards are in place, especially during punching / embossing operations.

-

Maintain inventory of critical spare parts (belts, blades, heating elements, sensors).

-

Keep firmware/software updates up to date (if your machine uses digital controls).

If you face any issue with your notebook manufacturing equipment, our technical support team in Gujarat can provide remote assistance or visit your site in Khambhat for faster resolution.

8. Cost & Return on Investment (ROI)

Factors that influence cost:

-

Automation level (manual vs automatic)

-

Size and specification (number of binding heads, cutting width, motor capacity)

-

Additional features (embossing, lamination, perforation)

-

Volume capacity and throughput

-

Shipping or installation charges (though local delivery from Gujarat reduces them)

Typical ROI calculations for a school-notebook production line in Khambhat might include:

-

Initial investment recovered in 12-24 months if you run the machine at high utilization.

-

Savings in labour cost through automation.

-

Reduced wastage (better precision in trimming/cutting).

-

Faster turnaround for customer orders leading to more business.

We can help you model the exact ROI based on your expected production volumes and binding types.

9. Case Study: Local Notebook Producer in Gujarat

One of our clients near Khambhat installed a school notebook production line comprising cutting, binding, pressing, trimming, and packaging units. After installation, they increased output by 70% and reduced reject rate by 40%. The business was able to serve additional local school orders within shorter delivery time. They recovered their investment within 18 months.

Their satisfaction with our notebook making machine and accompanying automatic binding system encouraged them to expand capacity further with a second unit six months later.

10. How to Choose Your Supplier

When selecting a supplier for your notebook making machine or notebook manufacturing equipment in Khambhat Gujarat, consider:

-

Reputation and years of experience in stationery-machinery manufacturing.

-

Availability of local references / site-visits to other customers.

-

Quality of components (motors, sensors, PLC / control systems).

-

Compliance to Indian safety standards.

-

Warranty terms, maintenance contracts, availability of spare parts in Gujarat.

-

Customization flexibility for sizes, binding types, and finishing options.

-

Training and support services including remote or on-site troubleshooting.

Choosing a trustworthy supplier ensures you don’t just buy a machine — you gain a partner in your notebook manufacturing journey.

11. Conclusion

If you are planning to establish or upgrade your notebook production facility in Khambhat, Gujarat, investing in the right notebook making machine can transform your operation. With local design, installation, and support, you benefit from reduced cost, faster turnaround, and higher quality output.

Contact us today to discuss your requirements — whether it's a standalone binding or punching unit, a full school notebook production line, or a customized paper pressing machine — we will deliver a solution that suits your budget and scale.