Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

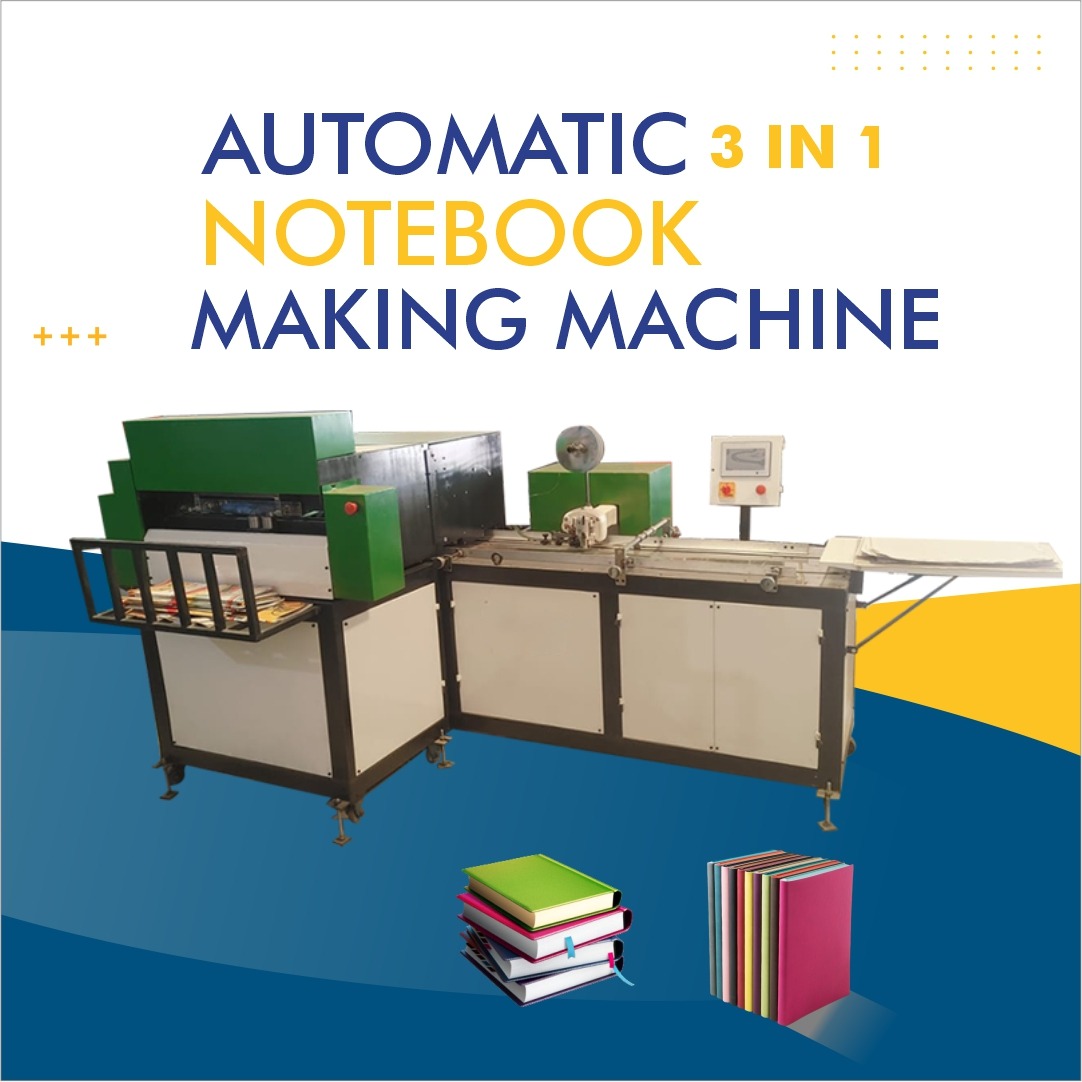

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Jasdan Gujarat | High-Quality Notebook Machinery

Notebook Making Machine in Jasdan | Gujarat

Jasdan, Gujarat is emerging as a hub for small and medium scale industrial manufacturing. Among its growing sectors is stationery production — especially machines used for making notebooks. If you are looking for a notebook making machine in Jasdan or the surrounding region, you need technical excellence, reliable after-sales support, and cost-effective pricing. This article explores why selecting the right machine matters, different types of notebook making machines, features to evaluate, and how to choose a supplier in Jasdan, Gujarat.

Why Choose a Notebook Making Machine from Jasdan, Gujarat?

-

Local availability and support: Machines based in or near Jasdan offer shorter lead times, easier transportation, lower shipping cost, and easier servicing.

-

Cost efficiency: Local manufacturing reduces import duties and logistics overhead; Indian-made notebook manufacturing equipment tends to be more affordable yet customizable to your production size.

-

Customization and upgrades: A supplier in Gujarat can better adapt the automatic notebook making machine to your required paper sizes, binding types, and speed output.

-

After-sales service: Proximity ensures quicker service visits, spare parts supply, and training for your staff when using a paper binding machine or spiral notebook machine.

Types of Notebook Making Machines

Your production needs will determine which type of notebook production machine is most suitable:

-

Automatic Notebook Making Machine

These fully-automated systems cut, stack, bind, trim, and package notebooks with minimal manual input. Ideal for medium to high-volume manufacturing and consistent quality. -

Manual or Semi-Automatic Notebook Maker

For lower production volumes or tighter budgets, manual or semi-automatic machines allow you greater control over individual steps, such as binding or trimming. These are typically less costly, easier to maintain, and suitable for smaller enterprises. -

Spiral Notebook Machine

Designed specifically for spiral-bound notebooks, this kind of spiral notebook machine punches holes, inserts spiral binding, and trims edges. If your product line includes spiral versions, such machinery is essential. -

Paper Binding Machine

Generic binding equipment that works for various types of notebooks — perfect for hard-binding, soft-binding or glue-binding processes. This is often used in conjunction with trimming or cutting units. -

Notebook Manufacturing Machine for Custom Sizes

If you require non-standard formats, such as A5 mini notebooks or bespoke promotional formats, make sure your supplier can adjust cutting dies, binding jaws, glue settings and trimming parameters.

Key Features to Evaluate

When you assess any notebook making machine, consider these critical attributes:

-

Production Speed and Capacity: How many notebooks per hour or per shift? Higher output is essential for scaling business.

-

Paper Size Range: Ability to handle various formats (e.g. A4, A5, custom sizes).

-

Binding Type Supported: Stapled, glue-bound, spiral-bound, or stitched.

-

Accuracy & Finish Quality: Clean trimming, uniform alignment, smooth binding edges.

-

Automation Level: Automatic vs semi-automatic vs manual.

-

Build Quality & Durability: Use of industrial-grade motors, durable cutting knives, steel frames.

-

Safety & Compliance: Safety guards, electrical norms, and operator safety features.

-

Maintenance & Spare Parts: Availability of spare parts locally in Gujarat ensures less downtime.

-

Ease of Use: Operator control panels, changeover speed between sizes, training requirements.

-

After-Sales Support: Local presence means faster response for repairs or calibration — especially important for notebook manufacturing equipment.

How to Choose the Right Supplier in Jasdan, Gujarat

Selecting the right manufacturer for your notebook production machine is as important as the machine itself. Here are steps you should follow:

-

Check Local Manufacturers

Search for notebook making machine manufacturers or suppliers in Jasdan, Rajkot district, or within Gujarat. Visit their workshops if possible to evaluate machine performance directly. -

Review Client References

Ask for existing customers using their notebook production machine. See real-world output, check reliability over months of operation, and audit maintenance history. -

Request Demonstrations or Test Runs

A supplier should demonstrate cutting, binding, and trimming using your paper type, size, and binding style. This helps you assess finish quality and throughput. -

Compare Cost vs Features

Cheaper machines may lack key features or heavier duty components. Compare offers not just on purchase price, but the long-term value: expected lifespan, energy consumption, and productivity per rupee invested. -

Customization & Upgradability

Ensure that the notebook manufacturing machine can be adjusted for new formats or higher speeds in future. Discuss modular upgrades such as automatic feeding, additional trimming units, or digital interface options. -

Warranty, Maintenance Contract & Spare Parts

Confirm warranty period, availability of spare parts in Jasdan / Rajkot / Ahmedabad region, and whether maintenance contracts are offered. -

Energy Efficiency & Compliance

Machines should adhere to Indian power standards, energy-efficient motors, and safety standards (such as electrical safety, operator shielding, etc.). -

Training & Documentation

A supplier should provide user manuals, operational training for your staff, and maintenance schedules. This reduces downtime and ensures consistent quality.

Use Cases & Applications

Here are some practical scenarios where a notebook making machine adds value:

-

School stationery factories producing thousands of notebooks daily for local markets.

-

Promotional notebook producers fulfilling corporate orders with custom sizes, logos, and binding styles.

-

Custom stationery businesses that wish to offer spiral-bound or premium bound notebooks for wedding planners or corporate gifting.

-

Small-scale export preparation, where notebooks manufactured in Gujarat are branded and shipped overseas; high-quality binding and finishing are essential for competitiveness.

Benefits of Investing in a Quality Notebook Making Machine

-

Higher Productivity: Automated sheet feeding, binding and trimming reduces manual labor and speeds up throughput.

-

Improved Consistency: Uniform alignment and trimming reduces rework and improves product quality.

-

Cost Savings Over Time: Though initial investment may be higher, operational cost per notebook drops with scale — especially important for high-volume orders.

-

Scalability: As demand increases, you can upgrade or add modules to your notebook manufacturing equipment without buying entirely new machinery.

-

Competitive Advantage: Superior finish, reduced turnaround time, and reliable output help you compete with imported stationery or large-brand manufacturers.

Challenges & Considerations

While the benefits are significant, there are also challenges to be aware of:

-

Initial Capital Investment: Even semi-automatic or manual notebook makers require investment; positive ROI depends on consistent order flow.

-

Training & Skilled Operators: Operator learning curves for high-speed equipment — mistakes in alignment, cutting or binding may cause wastage.

-

Maintenance Downtime: Mechanical parts (blades, binding jaws) may wear; local service support is vital.

-

Power Supply Stability: In some industrial areas, power fluctuations in Gujarat may affect electrical systems; voltage stabilisers or backup may be necessary.

-

Material Quality: Paper thickness, moisture, binding wire quality all affect machine performance and waste rates. Ensure raw materials meet specification consistently.

Synonyms Usage for SEO Impact

To improve search engine relevance, this article includes synonyms like notebook manufacturing machine, book binding machine, paper notebook machine, notebook manufacturing equipment, manual notebook maker. These terms help diversify how your business can rank for related searches — for example "book binding machine Gujarat" or "manual notebook maker Jasdan". Use them throughout your website page or product listing for stronger SEO.

Pricing & Lead Time (Estimated for Jasdan Suppliers)

While exact pricing depends on features, size and automation level, here are indicative cost ranges for Gujarat-based notebook making machines:

| Type | Estimated Cost (INR) | Lead Time |

|---|---|---|

| Manual / Semi-Automatic Notebook Maker | ₹ 80,000 – ₹ 4,00,000 | 2–4 weeks |

| Semi-Automatic Binding & Trimming Combo | ₹ 4,00,000 – ₹ 10,00,000 | 4–8 weeks |

| Fully Automatic Notebook Making Machine | ₹ 10,00,000 – ₹ 25,00,000+ | 8–16 weeks |

These are rough estimates. Always request a formal quotation and confirm shipping, installation, and training charges.

Installation & Training Tips

-

Ensure your factory floor has level concrete foundation and adequate space for machine footprint plus operator access.

-

Confirm electrical supply (voltage, phase, power draw), and provide required wiring & safety disconnectors.

-

Organise operator training during commissioning so staff become proficient in changeover between different notebook sizes.

-

Prepare a maintenance schedule: lubrication, cleaning of cutting blades, alignment check monthly or quarterly.

Maintenance & Spare Parts in Gujarat

Having your notebook machine installed in or near Jasdan means spare parts like cutting blades, binding jaws, motors or electronic controls can often be sourced locally — either from the manufacturer or allied suppliers in Rajkot / Ahmedabad. This reduces downtime compared to imported or remote suppliers. If your supplier offers a formal maintenance contract, it is advisable to include regular check-ups, preventive maintenance visits, and availability of consumables.

Sustainability & Environmental Aspects

Increasingly, stationery manufacturers must consider sustainable practices. A good notebook production machine should:

-

Minimise paper waste through precision trimming.

-

Support recycled paper stock, which may require stronger motors or blades.

-

Optimize energy consumption with efficient motors and standby modes.

-

Reduce noise and dust emissions in the factory environment.

Conclusion

If you want to invest in a notebook making machine in Jasdan, Gujarat, selecting the right model and a reliable local supplier is critical. Prioritise automation level, capacity, binding styles, local service support, maintenance, and upgrade options. With careful planning and due diligence, you can establish a productive, cost-effective notebook manufacturing facility that meets your quality expectations and scales with your business growth.