Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

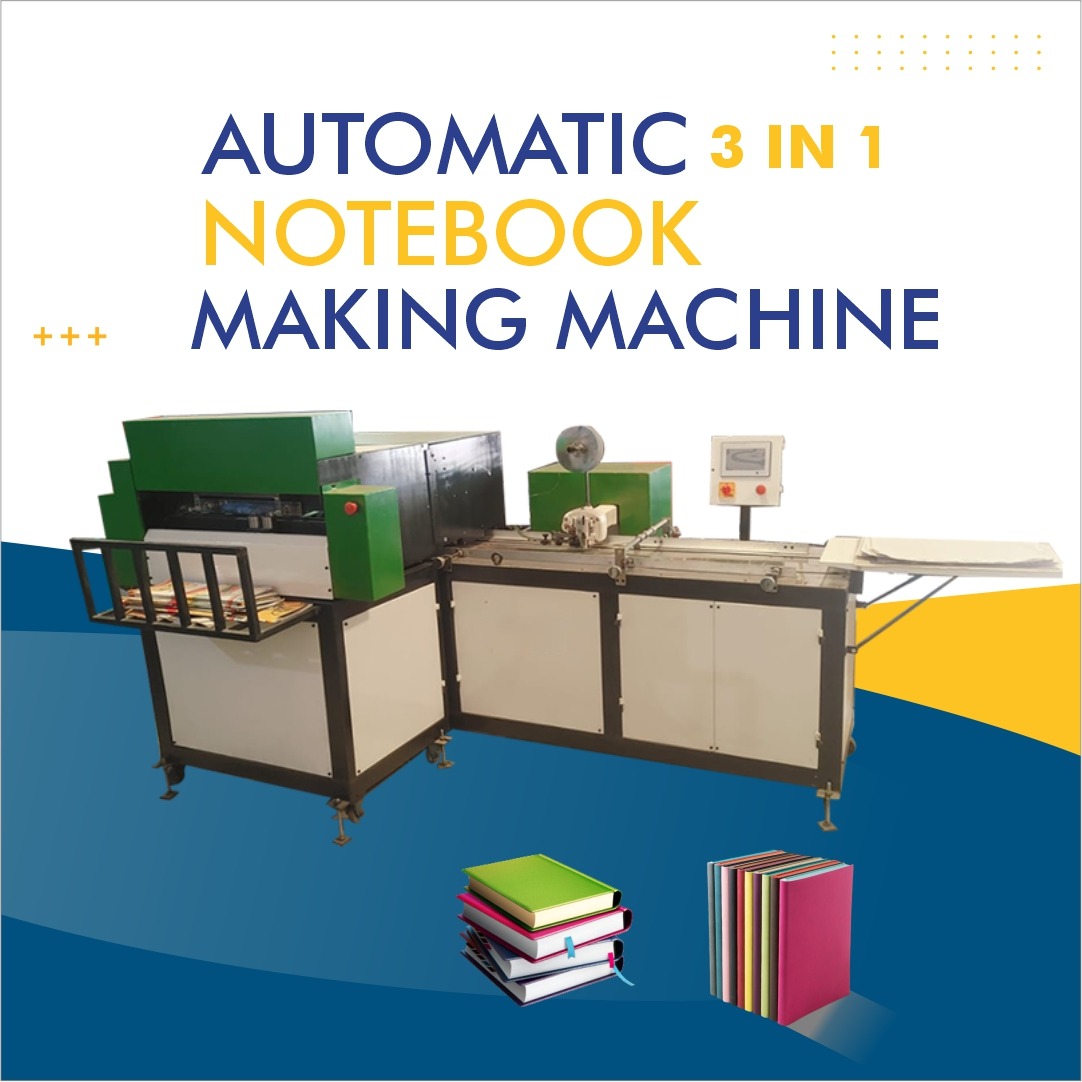

Notebook Making Machine Manufacturer in Jamjodhpur Gujarat | Buy Notebook Making Machine

Notebook Making Machine in Jamjodhpur | Gujarat

If you are searching for a notebook making machine in Jamjodhpur, Gujarat, you've come to the right place. Whether you run a stationery manufacturing business, school supplies unit or industrial printing facility, you need reliable equipment that delivers consistent quality at high speed. Our notebook making machine is designed to meet the highest standards of precision, efficiency and durability.

We manufacture and supply both automatic and semi-automatic versions tailored to your production volume, space constraints, and budget. With local service support in Jamjodhpur, Gujarat, you can ensure minimal downtime and optimal performance.

In this detailed guide, you’ll discover the benefits, features, specifications, installation, maintenance, and purchasing tips for the best notebook making machine available in Gujarat.

2. Why Choose a Notebook Making Machine from Jamjodhpur, Gujarat?

-

Local manufacturing & support: Being based in Gujarat means faster delivery times and local technical assistance.

-

Quality assurance: Machines built using industrial-grade components for long life and precision.

-

Customization: You can select specifications such as sheet size, binding style, speed (sheets per minute), power requirements, and automation level.

-

Cost-effectiveness: Manufacturing overheads are lower than imports and you save on transport & duties.

-

After-sales service: Maintenance crew available locally to service binding rollers, motor drives, and control panels.

When you choose the notebook making machine from a Gujarat manufacturer, you invest in strong local support and excellent reliability.

3. Types of Notebook Making Machine

Automatic Notebook Making Machine

An automatic notebook machine handles almost every part of the process — sheet feeding, folding, stapling or binding, trimming, and stacking. This type is ideal for high-volume operations. It saves labour, increases output, and ensures uniform quality.

Semi-Automatic Notebook Making Machine

A semi-automatic notebook maker requires manual feeding or intervention at one or more stages but reduces manual labour significantly compared to fully manual methods. It’s suitable for small to medium manufacturers in Gujarat.

Manual/Low-capacity Machines

These are basic binding or cutting machines that assist in part of the process. While not usually called “notebook making machines” in the automated sense, they may complement your main production line.

4. Key Features to Look For

When you evaluate a notebook making machine, consider these critical features:

-

Speed & Throughput

Measure how many sheets or notebooks the machine can produce per hour or minute. Higher throughput means better ROI if you run high-demand production. -

Sheet Size Compatibility

Your machine must accept the standard sheet sizes used in your notebooks. Options may include A4, A5, customised formats common in India. Adjustable sheet feeders and guides help flexibility. -

Binding Type & Folding Mechanism

Choose binding methods such as saddle-stitching, stapling, glue binding or spiral binding. Folding wheels or creasing systems should be precise to avoid misalignments. -

Cutting & Trimming Accuracy

Precise cutters (e.g. guillotine blades) or trimmers ensure clean edges without ragged pages. -

Control & Automation

Modern machines include PLC or microcontroller-based control panels, programmable speeds, sensors to detect paper jams, and safety guards. -

Power Consumption & Motor Type

Check whether the machine runs on single-phase or three-phase power. Motor brand (e.g. servo, gear motors), energy efficiency, and voltage compatibility with local supply are important. -

Material Compatibility & Thickness

Supports sheet weights typical in notebooks (for example, 70-80 GSM paper, card board covers) and binding materials like wire, glue, staples, thread. -

Footprint & Installation Requirements

Your factory floor space, ventilation, power supply, loading and unloading zones should guide machine dimension and layout. -

Durability & Build Quality

Machines built with welded steel frames, quality bearings, standard fasteners and protective coatings resist wear in humid or dusty conditions. -

Maintenance & Parts Availability

Ensure that consumable parts — blades, rollers, belts, staples — are affordable and readily available.

5. Applications & Benefits

A high-quality notebook making machine brings many benefits to manufacturers in Gujarat and beyond:

-

Increased production speed and capacity

-

Uniform binding and trimming quality

-

Reduced human error and rework

-

Lower labour cost per unit

-

Ability to scale production quickly

-

Competitive pricing for finished notebooks

-

Enhanced product consistency that attracts bulk buyers (schools, offices, export orders)

Applications include: school notebook production, corporate gift notebooks, promotional pads, customised company-branded note-pads, spiral notebooks, and notepads.

6. Technical Specifications (Example Configuration)

Below is a sample technical specification for an automatic notebook making machine suitable for mid-level capacity units in Jamjodhpur:

| Parameter | Typical Specification |

|---|---|

| Production speed | 200–300 notebooks per hour |

| Paper size range | A4, A5, custom up to 300 mm × 400 mm |

| Binding method | Staple binding or glue binding |

| Motor power | 3 HP three-phase or equivalent servo motor |

| Cutting tolerance | ±1 mm trimming accuracy |

| Machine dimensions (L×W×H) | Approx. 2.5 m × 1.2 m × 1.6 m |

| Control system | PLC based with HMI panel and safety features |

| Material thickness | Suitable for 70–100 GSM paper and covers up to 300 gsm board |

| Power supply | 415 V, 50 Hz, 3-phase |

| Automation level | Fully automatic with minimal manual intervention |

These specifications can be varied according to your order and production goals.

7. Installation & Commissioning in Jamjodhpur, Gujarat

When you place an order for a notebook making machine manufactured in Gujarat, the installation process generally includes the following steps:

-

Site preparation — power supply, floor leveling, ventilation, and safety zones.

-

Delivery and placement of machine frame.

-

Calibration of feeders, alignment of binding and trimming units.

-

Trial runs using your actual paper stock to validate quality.

-

Operator training to run and maintain the machine.

-

Warranty and after-sales orientation, including spare part kit handover.

Local presence in Gujarat means the setup period is shorter and support staff can visit your premises in Jamjodhpur or nearby districts (Rajkot, Junagadh, Morbi, etc.) swiftly.

8. Maintenance Tips

To ensure long life and consistent performance:

-

Keep cutting blades sharp and serviced periodically.

-

Lubricate moving parts like guides, rollers, hinges.

-

Regularly clean dust, paper fragments and stray staples.

-

Monitor motor health – overheating, unusual noises or vibration.

-

Replace worn belts, rollers or bearings before they affect precision.

-

Keep a log book of usage hours, maintenance actions and quality checks.

9. How to Choose a Supplier in Gujarat

When evaluating potential suppliers of notebook making machines in Jamjodhpur or Gujarat:

-

Request real performance data (e.g. output per hour, rejection rate).

-

Check for case-studies or customer references.

-

Ask for a demonstration (in-house or video) before purchase.

-

Compare warranty period, spare parts availability, and servicing terms.

-

Evaluate price versus long-term operating cost, not just initial investment.

A reliable supplier will provide you with design drawings, technical documentation (parts list, wiring diagram), and customization options.

10. Cost & ROI

The cost of a notebook making machine depends on:

-

Automation level (fully automatic vs semi-automatic)

-

Speed and throughput capacity

-

Size and complexity of binding/cutting modules

-

Local customizations for Gujarat trade norms (voltage, safety compliance)

-

Shipping and installation charge (often lower for Gujarat-based manufacture)

However, the return on investment can be rapid if your unit runs continuously and sells notebooks in bulk (schools, colleges, corporate clients). Reduced labour cost, minimal rework and higher output ensure payback within months if production is scaled properly.

11. Frequently Asked Questions (FAQs)

Q. Can I get spare parts locally near Jamjodhpur?

Yes — since the manufacturer is in Gujarat, spare parts such as blades, belts, and electrical components are stocked or available quickly.

Q. What is the lead time for manufacturing a custom notebook making machine?

Lead time depends on customization, but typical turnaround may range from 4 to 8 weeks for non-standard specs.

Q. Do you offer training and supervision during production start-up?

Yes, installation includes operator training and commissioning support by technicians on location in Gujarat.

Q. Is power backup required?

A stable three-phase supply is preferred. For regions with unstable electricity, you may consider a backup or voltage stabiliser; you should discuss this while finalising your machine design.

Q. Can I upgrade document size or speed later?

Some semi-automatic models allow modular upgrades. Fully custom machines may be scaled by adjusting feeders or switching motor power. Speak with your supplier for upgrade options.

12. Conclusion

Investing in a quality notebook making machine in Jamjodhpur, Gujarat is a smart decision for any manufacturer looking to expand capacity, improve product quality, and reduce operational costs. With the right machine specification, local support and regular maintenance, your stationery manufacturing business can scale efficiently.

Get in touch today to discuss your requirements — speed, binding type, paper sizes, and budget — and we will help you configure the perfect notebook making machine for your facility.