Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

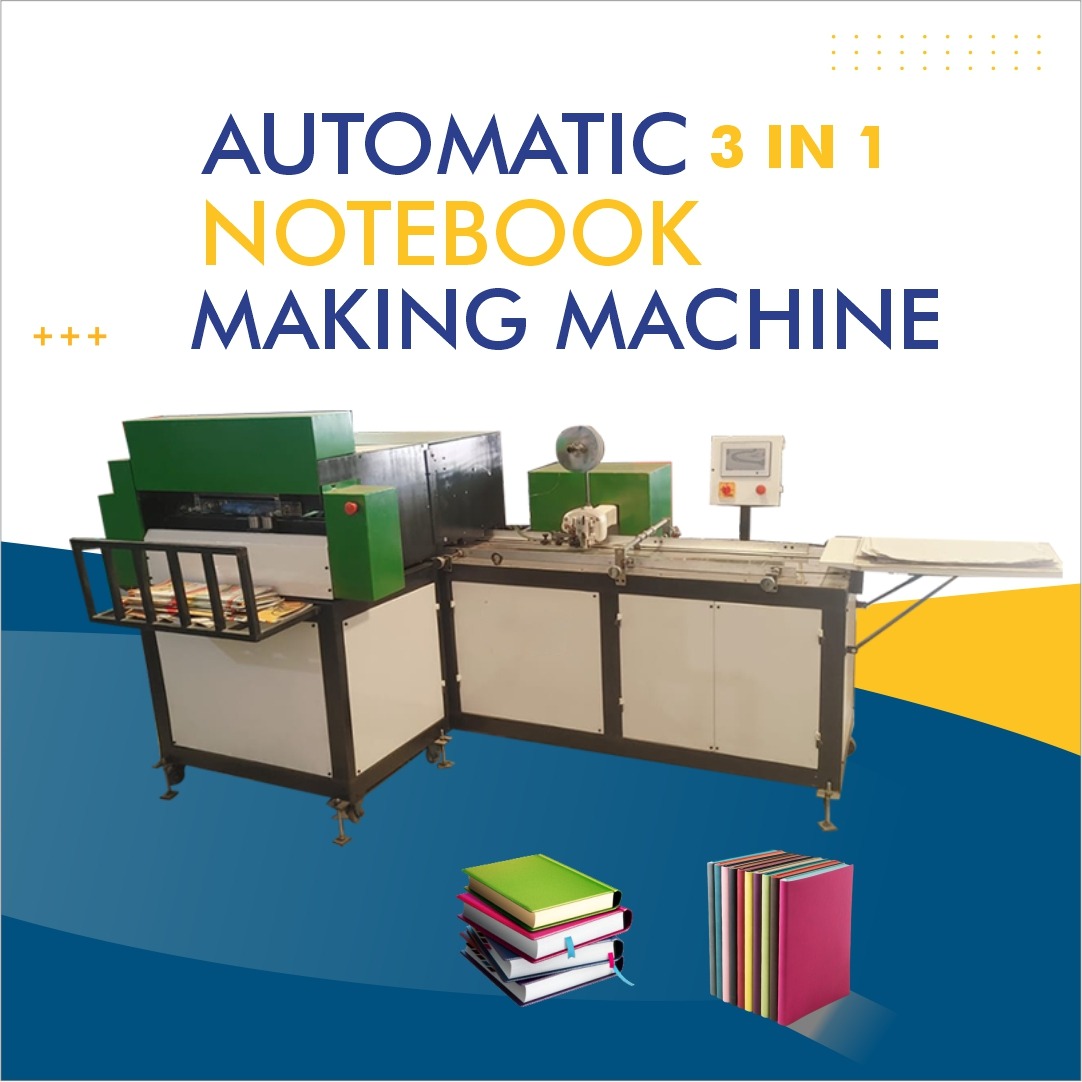

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Anklav Gujarat | High-Quality Paper Machinery

Notebook Making Machine in Anklav | Gujarat

Anklav, Gujarat has emerged as a growing centre for small and medium-scale manufacturing units including paper and stationery production. Among these, providers of notebook making machine are gaining importance. If you are looking for a robust notebook making machine in Anklav, Gujarat, this guide will help you understand product variants, specifications, buying tips, and local supplier advantages.

In this article you will read about:

-

What is a notebook making machine

-

Types of machines available

-

Key specifications you should check

-

Why purchasing from Anklav, Gujarat is advantageous

-

Installation, maintenance and after-sales support

-

Pricing trends and lead time

-

Frequently asked questions

We will also repeat synonyms and related phrases – automatic notebook machine, stationery production equipment, paper machinery Gujarat, school notebook equipment, to help SEO reach.

What is a Notebook Making Machine?

A notebook making machine is an industrial equipment designed to produce notebooks at scale. It automates multiple production stages — cutting paper, folding, binding, stitching or gluing, trimming, pressing, and finishing the notebook edges. Some are manual-assist while others are fully automatic systems.

A fully automatic or semi-automatic notebook making machine will handle sheet cutting, inner-sheet alignment, binding (stapling or stitching), edge cutting, cover pasting, and trimming. These machines are part of the broader set of paper machinery used in stationery manufacturing.

Synonyms and related terms: automatic notebook machine, school notebook equipment, stationery production equipment, notebook production system.

Types of Notebook Making Machines

Depending on your production scale and budget, you may choose among several types:

-

Manual or Semi-automatic Notebook Making Machine

-

Suitable for small workshop setups or start-ups.

-

Requires more human intervention in feeding, binding or cutting stages.

-

Lower output per hour compared to automatic types.

-

-

Automatic Notebook Making Machine

-

High-speed production, minimal manual labor.

-

Integrated feeding, stitching (or gluing), trimming, and counting.

-

Ideal for medium to large scale manufacturing units.

-

Requires higher capital investment but lower per-unit labour cost.

-

-

Spiral Notebook Machine

-

Specialised for spiral binding style notebooks.

-

Includes wire-spiralling or plastic-spiralling station.

-

Additional trimming and cover insertion stations.

-

-

College / School Notebook Machine

-

Designed to produce ruled-page notebooks as per school or college standards.

-

May feature ruled paper imprinting, perforation, or stamping units.

-

Used widely by stationery factories producing school kits.

-

-

Customized Notebook Making Machine

-

Tailored for specific cover sizes, binding styles, or production rate.

-

Custom software or control panels for automation level.

-

Flexible for changing notebook formats or sizes.

-

-

Compact Portable Notebook Machine

-

Smaller footprint version, suited for workshops with limited space.

-

Lower production rate, but suits local or small-volume demand.

-

Key Specifications to Compare

When evaluating a notebook making machine, consider the following technical parameters:

| Parameter | Why It Matters |

|---|---|

| Production Speed (notebooks per hour) | Determines throughput and capacity. Faster machines yield higher output. |

| Size Range | Maximum sheet size and minimum finished notebook size. Flexibility in notebook formats. |

| Binding Method | Stitching / stapling / gluing / spiral binding. Choose as per product design. |

| Automation Level | Manual, semi-automatic or fully automatic; affects labour cost and consistency. |

| Accuracy & Tolerance | Precision in trimming and cutting ensures professional finish. |

| Durability & Robustness | Quality of motor, frame, wear-parts. Impacts maintenance and downtime. |

| Power Consumption | Efficiency in electricity usage. Important for operating cost. |

| Control System | PLC or microcontroller panel; ease of operation affects training requirement. |

| Safety Features | Guards, sensors, emergency stops; essential for worker safety. |

| After-sales Support & Spare Parts | Proximity to supplier (e.g. Anklav or Gujarat) reduces downtime when spare parts needed. |

| Price & Warranty | Initial investment, warranty period, service contracts. |

Advantages of Buying from Anklav, Gujarat

-

Local Presence & Reduced Lead Time

Suppliers based in or near Anklav or neighboring districts can deliver more quickly, handle installation on site, and provide faster servicing. -

Lower Freight Costs

Proximity to your factory reduces logistics cost for bulky machinery. -

Regional Expertise

Manufacturers in Gujarat are aware of regional power supply norms, safety regulations, and typical notebook formats used by local educational boards or stationery markets. -

Customization Availability

Local machine builders are more amenable to customization for sizes, binding types, and output rates if your unit is nearby in Anklav or Gujarat. -

After-Sales & Maintenance Support

Closer location means quicker response for maintenance visits, spare part supply, and technical guidance. -

Regulatory Compliance

Gujarat-based machinery providers may already follow Indian standards (BIS / CE / ISO norms) which simplifies certification and compliance for your manufacturing unit.

Installation, Commissioning & Maintenance

-

Site Preparation

Ensure the workshop in Anklav is ready with correct floor strength, leveled foundation, electrical connections (voltage stability, phase supply), ventilation, lighting. -

Commissioning

Once the notebook making machine is delivered, the supplier should run initial trials to verify output speed, alignment precision, and safety features. -

Training

Operator training is essential. A supplier near Anklav can send engineers for hands-on training at your site. -

Routine Maintenance

Includes lubrication of moving parts, calibration of cutting and trimming units, inspection of bindings and belts. Maintenance contracts may be available with your Gujarat-based supplier. -

Spare-Parts Availability

Wearable parts like blades, stitching heads, cutters, feed rollers must be kept in stock. If you source locally in Gujarat, spare-part delays will be minimal.

Pricing Trends & Lead Time

-

Entry level semi-automatic notebook machine may cost significantly less than a fully automatic system.

-

Fully automatic or high-capacity machines incur higher initial capital cost, but deliver faster ROI through labor savings and consistency.

-

Lead time for custom-built or modified machines can range from a few weeks to a few months, depending on design modifications, supplier workload, and shipping readiness.

-

Suppliers based in Gujarat or Anklav often have more flexible turnaround times compared to importing equipment from distant states or countries.

To get a reliable cost estimate, contact multiple notebook making machine suppliers around Gujarat, request quotations including shipping, installation, training, and warranty.

Choosing the Right Supplier

When you shortlist a notebook making machine provider in Anklav, Gujarat or nearby:

-

Check past client references and visited installations.

-

Inspect demonstration of similar machine types.

-

Ask for videos or factory visits, if possible.

-

Verify that the supplier offers support for your machine layout, same sheet size, binding style, and desired capacity.

-

Ensure the supplier provides documentation (manuals, safety certificates) and guarantees performance levels (e.g. speed, reject rate, downtime).

Frequently Asked Questions (FAQ)

Q. Can I upgrade a semi-automatic machine later to fully automatic?

Yes — many machine builders allow modular upgrades (e.g. add automatic feeder or trimming unit) depending on the design. Ask your Gujarat supplier about upgrade paths.

Q. What is typical output for a mid-capacity automatic notebook machine?

Output depends on size and binding method, but many automatic machines deliver several hundred to over one thousand finished notebooks per hour under optimized operation.

Q. Do I need special power connections in Anklav?

Your workshop may require three-phase power supply and voltage stabilisers. A local supplier in Gujarat will guide you about local electrical infrastructure.

Q. What maintenance schedule is ideal?

Daily, weekly and monthly routines: lubrication daily, monthly calibration checks, quarterly service by technician. A supplier in Gujarat may offer annual maintenance contracts.

Q. Can the notebook machine produce different sizes in same model?

Yes, many machines allow adjustable trimming width, adjustable feed guides. Ask about range of sizes (e.g. A4, ruled notebook sizes) when specifying your machine.

Q. Are spare parts readily available?

If purchased from a Gujarat-based supplier or manufacturer near Anklav, spare parts are likely to be available locally, reducing downtime compared to imported spares.

Conclusion

If you are planning to set up or upgrade a notebook manufacturing line in Anklav, Gujarat, choosing the right notebook making machine is critical for your productivity, quality, and cost-effectiveness. Evaluate the specifications carefully — speed, binding type, automation level, power, maintenance support — and prefer a supplier with local presence for better service, faster lead time, and customization flexibility.

To proceed, ask for quotations from machine builders in Gujarat or around Anklav. Share your required notebook size, desired output rate (notebooks per hour), binding style (stitching, spiral, glued), and automation preferences. Discuss installation and after-sales agreements to ensure smooth commissioning and long-term reliability of your notebook making machine.

Anklav, Gujarat has emerged as a growing centre for small and medium-scale manufacturing units including paper and stationery production. Among these, providers of notebook making machine are gaining importance. If you are looking for a robust notebook making machine in Anklav, Gujarat, this guide will help you understand product variants, specifications, buying tips, and local supplier advantages.

In this article you will read about:

-

What is a notebook making machine

-

Types of machines available

-

Key specifications you should check

-

Why purchasing from Anklav, Gujarat is advantageous

-

Installation, maintenance and after-sales support

-

Pricing trends and lead time

-

Frequently asked questions

We will also repeat synonyms and related phrases – automatic notebook machine, stationery production equipment, paper machinery Gujarat, school notebook equipment, to help SEO reach.

What is a Notebook Making Machine?

A notebook making machine is an industrial equipment designed to produce notebooks at scale. It automates multiple production stages — cutting paper, folding, binding, stitching or gluing, trimming, pressing, and finishing the notebook edges. Some are manual-assist while others are fully automatic systems.

A fully automatic or semi-automatic notebook making machine will handle sheet cutting, inner-sheet alignment, binding (stapling or stitching), edge cutting, cover pasting, and trimming. These machines are part of the broader set of paper machinery used in stationery manufacturing.

Synonyms and related terms: automatic notebook machine, school notebook equipment, stationery production equipment, notebook production system.

Types of Notebook Making Machines

Depending on your production scale and budget, you may choose among several types:

-

Manual or Semi-automatic Notebook Making Machine

-

Suitable for small workshop setups or start-ups.

-

Requires more human intervention in feeding, binding or cutting stages.

-

Lower output per hour compared to automatic types.

-

-

Automatic Notebook Making Machine

-

High-speed production, minimal manual labor.

-

Integrated feeding, stitching (or gluing), trimming, and counting.

-

Ideal for medium to large scale manufacturing units.

-

Requires higher capital investment but lower per-unit labour cost.

-

-

Spiral Notebook Machine

-

Specialised for spiral binding style notebooks.

-

Includes wire-spiralling or plastic-spiralling station.

-

Additional trimming and cover insertion stations.

-

-

College / School Notebook Machine

-

Designed to produce ruled-page notebooks as per school or college standards.

-

May feature ruled paper imprinting, perforation, or stamping units.

-

Used widely by stationery factories producing school kits.

-

-

Customized Notebook Making Machine

-

Tailored for specific cover sizes, binding styles, or production rate.

-

Custom software or control panels for automation level.

-

Flexible for changing notebook formats or sizes.

-

-

Compact Portable Notebook Machine

-

Smaller footprint version, suited for workshops with limited space.

-

Lower production rate, but suits local or small-volume demand.

-

Key Specifications to Compare

When evaluating a notebook making machine, consider the following technical parameters:

| Parameter | Why It Matters |

|---|---|

| Production Speed (notebooks per hour) | Determines throughput and capacity. Faster machines yield higher output. |

| Size Range | Maximum sheet size and minimum finished notebook size. Flexibility in notebook formats. |

| Binding Method | Stitching / stapling / gluing / spiral binding. Choose as per product design. |

| Automation Level | Manual, semi-automatic or fully automatic; affects labour cost and consistency. |

| Accuracy & Tolerance | Precision in trimming and cutting ensures professional finish. |

| Durability & Robustness | Quality of motor, frame, wear-parts. Impacts maintenance and downtime. |

| Power Consumption | Efficiency in electricity usage. Important for operating cost. |

| Control System | PLC or microcontroller panel; ease of operation affects training requirement. |

| Safety Features | Guards, sensors, emergency stops; essential for worker safety. |

| After-sales Support & Spare Parts | Proximity to supplier (e.g. Anklav or Gujarat) reduces downtime when spare parts needed. |

| Price & Warranty | Initial investment, warranty period, service contracts. |

Advantages of Buying from Anklav, Gujarat

-

Local Presence & Reduced Lead Time

Suppliers based in or near Anklav or neighboring districts can deliver more quickly, handle installation on site, and provide faster servicing. -

Lower Freight Costs

Proximity to your factory reduces logistics cost for bulky machinery. -

Regional Expertise

Manufacturers in Gujarat are aware of regional power supply norms, safety regulations, and typical notebook formats used by local educational boards or stationery markets. -

Customization Availability

Local machine builders are more amenable to customization for sizes, binding types, and output rates if your unit is nearby in Anklav or Gujarat. -

After-Sales & Maintenance Support

Closer location means quicker response for maintenance visits, spare part supply, and technical guidance. -

Regulatory Compliance

Gujarat-based machinery providers may already follow Indian standards (BIS / CE / ISO norms) which simplifies certification and compliance for your manufacturing unit.

Installation, Commissioning & Maintenance

-

Site Preparation

Ensure the workshop in Anklav is ready with correct floor strength, leveled foundation, electrical connections (voltage stability, phase supply), ventilation, lighting. -

Commissioning

Once the notebook making machine is delivered, the supplier should run initial trials to verify output speed, alignment precision, and safety features. -

Training

Operator training is essential. A supplier near Anklav can send engineers for hands-on training at your site. -

Routine Maintenance

Includes lubrication of moving parts, calibration of cutting and trimming units, inspection of bindings and belts. Maintenance contracts may be available with your Gujarat-based supplier. -

Spare-Parts Availability

Wearable parts like blades, stitching heads, cutters, feed rollers must be kept in stock. If you source locally in Gujarat, spare-part delays will be minimal.

Pricing Trends & Lead Time

-

Entry level semi-automatic notebook machine may cost significantly less than a fully automatic system.

-

Fully automatic or high-capacity machines incur higher initial capital cost, but deliver faster ROI through labor savings and consistency.

-

Lead time for custom-built or modified machines can range from a few weeks to a few months, depending on design modifications, supplier workload, and shipping readiness.

-

Suppliers based in Gujarat or Anklav often have more flexible turnaround times compared to importing equipment from distant states or countries.

To get a reliable cost estimate, contact multiple notebook making machine suppliers around Gujarat, request quotations including shipping, installation, training, and warranty.

Choosing the Right Supplier

When you shortlist a notebook making machine provider in Anklav, Gujarat or nearby:

-

Check past client references and visited installations.

-

Inspect demonstration of similar machine types.

-

Ask for videos or factory visits, if possible.

-

Verify that the supplier offers support for your machine layout, same sheet size, binding style, and desired capacity.

-

Ensure the supplier provides documentation (manuals, safety certificates) and guarantees performance levels (e.g. speed, reject rate, downtime).

Frequently Asked Questions (FAQ)

Q. Can I upgrade a semi-automatic machine later to fully automatic?

Yes — many machine builders allow modular upgrades (e.g. add automatic feeder or trimming unit) depending on the design. Ask your Gujarat supplier about upgrade paths.

Q. What is typical output for a mid-capacity automatic notebook machine?

Output depends on size and binding method, but many automatic machines deliver several hundred to over one thousand finished notebooks per hour under optimized operation.

Q. Do I need special power connections in Anklav?

Your workshop may require three-phase power supply and voltage stabilisers. A local supplier in Gujarat will guide you about local electrical infrastructure.

Q. What maintenance schedule is ideal?

Daily, weekly and monthly routines: lubrication daily, monthly calibration checks, quarterly service by technician. A supplier in Gujarat may offer annual maintenance contracts.

Q. Can the notebook machine produce different sizes in same model?

Yes, many machines allow adjustable trimming width, adjustable feed guides. Ask about range of sizes (e.g. A4, ruled notebook sizes) when specifying your machine.

Q. Are spare parts readily available?

If purchased from a Gujarat-based supplier or manufacturer near Anklav, spare parts are likely to be available locally, reducing downtime compared to imported spares.

Conclusion

If you are planning to set up or upgrade a notebook manufacturing line in Anklav, Gujarat, choosing the right notebook making machine is critical for your productivity, quality, and cost-effectiveness. Evaluate the specifications carefully — speed, binding type, automation level, power, maintenance support — and prefer a supplier with local presence for better service, faster lead time, and customization flexibility.

To proceed, ask for quotations from machine builders in Gujarat or around Anklav. Share your required notebook size, desired output rate (notebooks per hour), binding style (stitching, spiral, glued), and automation preferences. Discuss installation and after-sales agreements to ensure smooth commissioning and long-term reliability of your notebook making machine.