Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

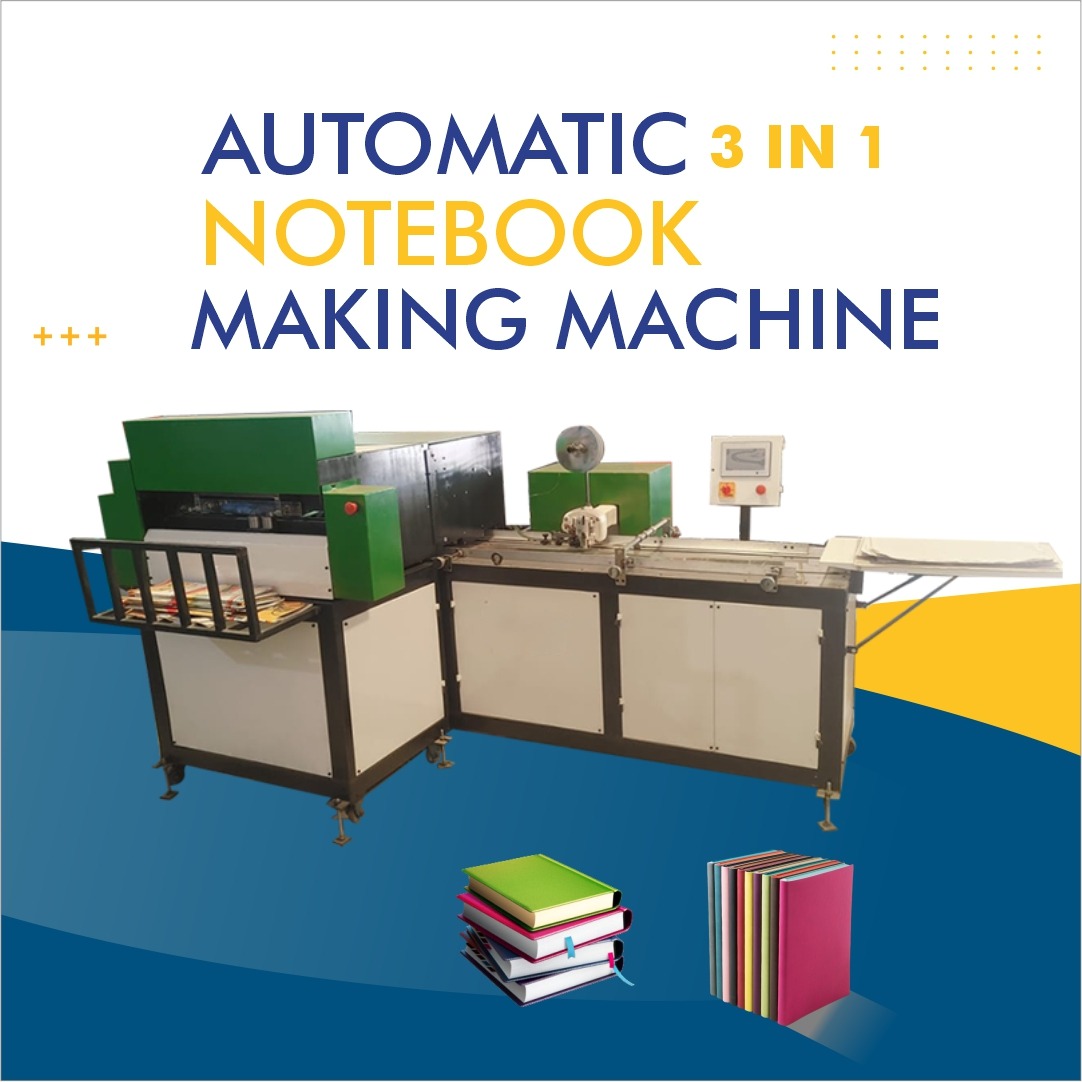

Notebook Making Machine Ahmedabad | Top Manufacturer Gujarat

Notebook Making Machine Ahmedabad | Gujarat

Ahmedabad, Gujarat is rapidly emerging as a major industrial hub specializing in paper and stationery machinery. Among the key players in the market is the notebook making machine segment. Whether you require automatic notebook binding equipment for large–scale production or semi-automatic machines for smaller workshops, finding the right manufacturer in Ahmedabad ensures you benefit from local support, lower transport costs, and quicker turnaround.

This article provides a comprehensive guide to notebook making machines available in Ahmedabad, Gujarat — their features, benefits, technical specifications, and what to consider when purchasing. We will also highlight related machinery alternatives, installation tips, and maintenance advice.

What Is a Notebook Making Machine?

A notebook making machine is specialized industrial equipment designed to automate the notebook production process. Depending on the design, it may handle one or more tasks such as paper cutting, page alignment, binding (stitching, gluing or spiral binding), cover folding, trimming, and packaging.

There are various types of notebook manufacturing equipment:

-

Automatic notebook machine — capable of end-to-end processing with minimal manual intervention

-

Semi-automatic notebook maker — requiring some manual steps but providing significant automation for binding or trimming

-

Portable or small-scale models — suitable for small workshops or start-ups

Synonyms for notebook making machine include notebook production setup, notebook assembly equipment, exercise book line, paper binding machine, and spiral binding machine line. These terms are often used interchangeably in marketing and equipment literature.

Why Choose Ahmedabad, Gujarat for Notebook Manufacturing Equipment

Local Manufacturing Hub

Ahmedabad is well-known for its thriving manufacturing sector. The city offers access to skilled labour, steel fabrication workshops, and proximity to ports for importing raw materials. If you are selecting a notebook making machine, buying from a local supplier in Gujarat can reduce lead times, offer easier servicing, and allow you to inspect machines before shipping.

Cost-Effectiveness

By sourcing your notebook production setup locally, you avoid high import duties, lower shipping costs, and often receive customised features at lower cost compared to imported machines. Local vendors in Ahmedabad often understand the Indian market and can tailor specifications (sheet sizes, paper weight, speed) accordingly.

After-Sales Support & Spare Parts

Ahmedabad-based suppliers generally provide prompt after-sales service, spare parts delivery, and technical support. Downtime is critical in notebook production; ensuring your notebook making machine is maintained quickly is vital to uninterrupted workflow.

Regulatory & Environmental Compliance

Machines manufactured in Gujarat tend to comply with Indian safety and electrical standards. If you are targeting domestic production, this reduces the approvals required compared to importing foreign machinery.

Types of Notebook Making Machines Available

Here are common variants you may find in Ahmedabad:

| Machine Type | Description | Ideal For |

|---|---|---|

| Fully Automatic Notebook Machine | Integrated unit combining feeding, cutting, binding, trimming, and packaging | Large-scale production (school books, office notebooks) |

| Semi-Automatic Notebook Binding Machine | Manual feeding or binding steps, with automated trimming or cutting | Small to medium-size workshops |

| Spiral Binding or Wire-O Binding Line | Specifically designed for spiral or wire binding rather than stitched binding | Specialty or customised notebooks |

| Cover Laminating & Folding Module | Can be added to binders to fold and press covers | Premium or hardcover style notebooks |

| Ream Break-Down & Paper Stacker Module | Part of upstream paper-handling | Bulk paper feed into notebook line |

Each machine may support different paper sizes (A4, A5, custom), number of sheets per notebook, binding style (staple-stitched, thread-sewn, glued), trimming options (three-knife trimming, side trimming), and production speeds (notebooks per minute or hour).

Key Features to Look for in a Notebook Making Machine

When evaluating a notebook manufacturing equipment purchase, consider the following:

-

Production Speed & Capacity

Evaluate how many notebooks per hour or minute the machine can produce. For example, an automatic notebook machine may produce 100–500 notebooks per hour, depending on configuration. -

Binding Method

Choose stitching (stapling), thread sewing, or adhesive binding. Thread sewing offers durability; staples are cost-effective; glue binding is ideal for softcover notebooks. -

Paper Sizes & Formats

Ensure the machine supports required formats — e.g. A4, A5, custom sizes, single or folded signatures. Flexible adjustment is useful if you plan to produce multiple formats. -

Automation Level

Fully automatic lines reduce manual labor but cost more initially. Semi-automatic models offer flexibility and lower capital expenditure for smaller shops. -

Durability & Build Quality

Since notebook making involves precision alignment, trimming blades, and mechanical wear, the machine should be built using industrial-grade components and robust frame. -

Safety Features & Compliance

Emergency stop buttons, guards around moving parts, electrical safety, and CE/ ISI-equivalent specifications should be considered. -

Ease of Maintenance & Spare Parts Availability

Local access in Ahmedabad or Gujarat is a plus. Modular design for ease of servicing is desirable. -

Power & Energy Consumption

Efficient motors, variable-frequency drives (VFDs), and judicious electrical design reduce operating cost. -

Optional Add-Ons & Customization

Add-ons like cover laminating, embossing, numbering, punching, or customised trimming can increase product value.

Typical Specifications

An example specification sheet for a medium-scale automatic notebook making machine may include:

-

Max Sheet Size: 297 × 210 mm (A4) or custom

-

Min Sheet Size: 148 × 210 mm (A5)

-

Binding Style: Staple stitching (3 staples), or thread sewing

-

Production Speed: Up to 300 notebooks/hour

-

Max Thickness per Notebook: 20 mm

-

Power Supply: Three-phase, 415 V, 50 Hz

-

Trimming Style: Top, bottom, side trimming with adjustable knives

-

Machine Footprint: 6 m × 1.5 m

-

Control Panel: PLC touch screen interface

-

Material Feed: Automatic feeder and stacker

These parameters will vary as per the model and manufacturer’s custom requirement. Always ask current vendors in Ahmedabad for their latest spec sheet tailored to your product dimensions.

Major Benefits of Investing in High-Quality Equipment

-

Improved Efficiency — Automation reduces manual labor time and increases throughput.

-

Consistent Quality — Uniform alignment, trimming and binding ensure every notebook is identical.

-

Lower Defect Rate — Precision trimming and binding reduce rejects and waste.

-

Better Aesthetics — Clean edges, consistent binding and professional finish.

-

Scalability — As your business grows, you can upgrade or expand your notebook production setup rather than starting from scratch.

-

Cost Savings Over Time — Despite high upfront investment, lower labor cost and reduced waste lead to better return on investment over months or years.

How to Select the Right Supplier in Ahmedabad

When you begin the process of buying a notebook making machine in Ahmedabad or Gujarat, follow these steps:

-

Shortlist Local Manufacturers & Dealers

Visit local industrial belts such as GIDC Naroda, Changodar or Vatva to verify the units physically. Check their prior installations and ask for video demos of the automatic notebook machine in operation. -

Request Detailed Quotations

Compare quotations that specify all modules — feeder, stitching or glue module, trimming section, control panel, safety features, and installation service. -

Visit Existing Installations

Ask for references: businesses in Gujarat already using their notebook manufacturing equipment should be visited to check output, service reliability, and spare-parts availability. -

Negotiate Training & Commissioning

Ensure the supplier provides onsite installation, employee training, and after-sales service for at least one operating cycle. -

Evaluate Warranty & Spare Parts Support

Confirm how long the warranty period is, how fast they can ship replacement cutters, blades, or electronic modules within Gujarat or nearby states. -

Plan for Future Upgrades

Confirm that the machine can be upgraded later with modules such as numbering, embossing, laminating, or enhanced binding styles without a full replacement. -

Financial & Regulatory Compliance

Check if you require GST invoices, local certifications, and whether funding or subsidy schemes for machinery manufacturing are applicable in Gujarat.

Maintenance Tips for Notebook Making Machines

To ensure best performance and longevity of your notebook production setup:

-

Daily Cleaning — Remove paper dust, trimmed scraps, and inspect moving parts.

-

Periodic Lubrication — Apply lubricants to mechanical joints, trimming rails, and binding arms as recommended by manufacturer.

-

Blade Sharpening or Replacement — Trimming knives lose sharpness; schedule replacements to maintain clean edges.

-

Calibration & Alignment Checks — Periodically check alignment of feeder rollers, trimming blades, and binding module to avoid misaligned notebooks.

-

Software Updates — If the machine uses PLC or firmware-based control panel, ensure updates are performed as required by manufacturer.

-

Operator Training — Well-trained staff reduce error rates and downtime from jams or misfeeds.

-

Spare Parts Inventory — Keep critical spares such as sensors, belts, motor drives, and electrical fuses in stock to minimise downtime.

Case Study: Small-Scale Notebook Production in Gujarat

Consider a startup stationery firm in Ahmedabad that invested in a semi-automatic notebook maker. They required production of exercise books for local schools in Gujarat. After installing the machine and training two operators, their output rose from manual binding to 200 notebooks/hour. The project paid off within 9 months due to increased capacity and reduced labor cost. They later upgraded with a trimming module to improve margins.

This illustrates how even a moderately automated notebook making machine can transform small-scale stationery manufacturing in Gujarat.

Pricing & Lead Time

Pricing for notebook machines depends on the level of automation, speed, binding method, and optional modules. Typical investment range may vary from ₹5 lakh for a basic semi-automatic line to ₹20 lakh or more for a fully automatic bound-trim line with operator interface and safety features. Lead time from ordering to delivery could range from 4 to 12 weeks, depending on customisation, fabrication workload at Ahmedabad-based factories, and installation scheduling.

You should obtain multiple quotations from Gujarat-area vendors and compare them not just on initial price but on life-cycle cost, energy consumption, spare-parts availability, and local service rating.

Conclusion

A notebook making machine is a central investment for any stationery production business. For businesses in Ahmedabad, Gujarat, sourcing your notebook manufacturing equipment locally delivers advantages in cost, support, and customisation. Whether you choose fully automatic or semi-automatic models, always examine technical features, production speed, binding method, warranty and after-sales service.

For best results, shortlist reputable suppliers in Ahmedabad industrial zones, ask for demonstrations, and build a plan for maintenance and future upgrades. With the right notebook production setup, you can scale your business, improve quality, and achieve lower unit cost per notebook — making your stationery enterprise competitive not only in Gujarat but across India.