Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

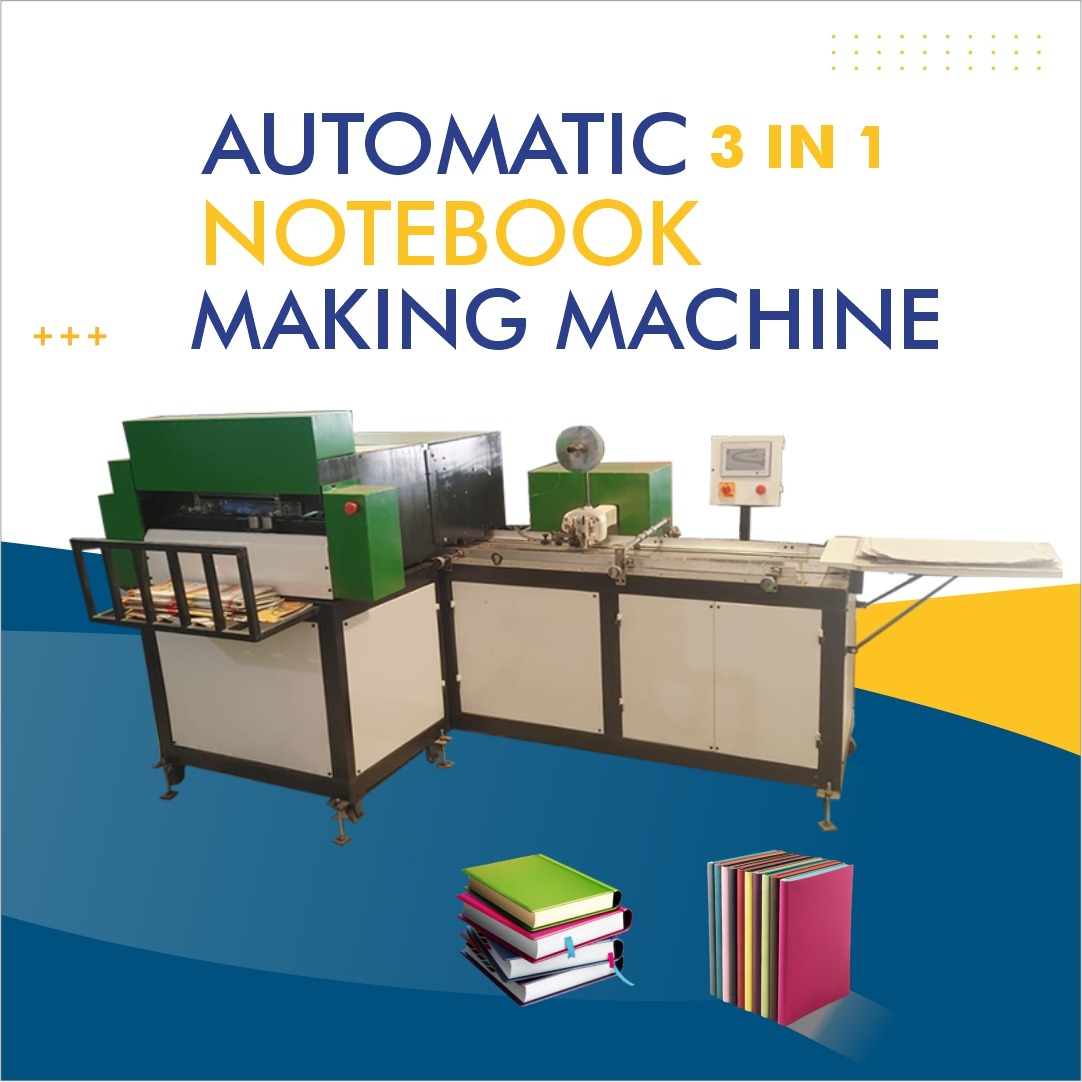

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier in Wankener, Gujarat | High-Quality Production Equipment

Notebook Making Machine Supplier in Wankener | Gujarat

Wankener, Gujarat is fast establishing itself as a manufacturing hub for stationery production. Among the most sought-after pieces of industrial equipment in the region is the notebook making machine. If you are planning to set up or expand a notebook factory, school supply business, or stationery manufacturing unit nearby, you need reliable, high-quality notebook making machine supplier and services.

In this article, you will find detailed information about types, features, advantages, maintenance, and buying guidance for notebook making machines in Wankener, Gujarat.

Why Choose Wankener, Gujarat for Notebook Manufacturing

Wankener offers advantageous logistics, proximity to raw‐material suppliers (paper mills, binding material providers), and access to skilled labor. Additionally, the local industrial policy supports small and medium-scale machinery units. Choosing a notebook making machine based here enables low lead-time, local service support, and easier procurement of spare parts.

Because demand for notebooks—for schools, offices and corporate gifting—remains steady, investment in notebook production equipment in Gujarat promises long-term returns. Local presence of a machine supplier ensures you get installation, training, and on-site servicing quickly.

What Is a Notebook Making Machine?

A notebook making machine is an industrial equipment system used to assemble paper signatures or plain sheets into a bound notebook. It typically involves several modules: paper feeding/collation, cutting and trimming, stitching or gluing, binding, casing or lamination, and finishing. Modern models may include automated features such as servo motors, programmable logic controllers (PLC), in-line trimming, and quality inspection sensors.

Synonyms you may see while searching include booklet machine, paper binding machine, composition book machine, stationery fabrication machine, or simply binding equipment. These terms broadly refer to machines capable of assembling, binding, and finishing pages into notebooks or similar bound formats.

Types of Notebook Making Machines Available in Wankener

Depending on your production volume, budget, and automation level, you can choose from various notebook making machines:

-

Semi-Automatic Notebook Making Machine

-

Ideal for small-scale production

-

Requires partial manual effort (e.g. manual feed of paper stacks)

-

Lower investment, easier maintenance

-

Suitable for startups or small stationery shops

-

-

Fully Automatic Notebook Making Machine

-

High-volume production lines with minimal manual intervention

-

Integrated modules for feeding, cutting, binding, trimming, batching, and stacking

-

Faster throughput and consistent quality

-

Ideal for factory setup in Gujarat catering to bulk orders

-

-

Stitching / Saddle-Stitch Notebook Machine

-

Uses wire staples through the fold or spine

-

Suitable for thinner notebooks or booklets

-

Often combined with trimming and folding units

-

-

Perfect-Binding / Gluing Notebook Machine

-

Uses adhesive binding for thick notebooks or soft covers

-

Incorporates glue application, pressing, and trimming

-

More durable spine, suitable for premium stationery

-

-

Custom / Modular Notebook Production Lines

-

Modules can be added or removed (e.g. lamination, embossing, numbering)

-

Designed to your specifications for size, thickness, bespoke binding

-

Each option is part of the wider paper binding machine industry. Choosing the right type depends on your run length, quality standards, and capital budget.

Key Features to Look For

When evaluating a notebook making machine supplier in Wankener Gujarat, consider these critical features:

-

Sheet feeding capacity and speed — Higher speed reduces cycle time

-

Cutting and trimming precision — Clean margins and consistent size

-

Binding quality and durability — Either stitching strength or adhesive bond

-

Control systems & automation level — PLC controls, touch panels, variable speed drives

-

Format flexibility — Ability to handle multiple notebook sizes (e.g. A4, A5, square, custom)

-

Spare parts availability — Local supply ensures minimum downtime

-

Electrical & power requirements — Compatibility with Gujarat industrial grid or 3-phase supply

-

Safety standards & certifications — Compliance with Indian industrial safety norms

Also evaluate vendor services: installation, training, preventive maintenance, and after-sales support.

Benefits of Buying Local in Gujarat

-

Reduced Transportation Cost and Time

Buying your notebook making machine locally (in or near Wankener) reduces freight charges, reduces delivery delays, and simplifies customs or interstate paperwork. -

Faster Service & Maintenance

A local stationery fabrication machine vendor or technician can respond more quickly in case of breakdowns, thus reducing downtime. -

Customisation for Local Demand

A supplier in Gujarat can offer custom modifications suitable for Indian paper sizes, local regulations, or climatic conditions (humidity, dust). -

Better Understanding of Regulations

Local manufacturers or suppliers are more familiar with GST, state policies, and industrial norms.

How to Select a Reliable Notebook Making Machine Supplier

To ensure you choose the right supplier in Wankener or nearby Gujarat, follow this checklist:

| Checklist Item | Importance |

|---|---|

| Supplier Reputation & References | Visit existing setups; get user feedback |

| Production Capacity & Machine Specifications | Ensure output matches your business targets |

| Warranty & Spare Parts Guarantee | Seek spares locally stocked |

| After-Sales Service & Training | On-site commissioning support matters |

| Total Cost of Ownership | Consider electricity usage, downtime cost, consumables |

| Scalability | Ability to upgrade (for example, to add modules later) |

Make sure you inspect a live demo or prototype before final purchase.

Installation & Maintenance

Proper installation and regular maintenance extend the life of your composition book machine. Key practices include:

-

Levelled foundation and alignment of mechanical units

-

Electrical grounding and safety check as per local norms

-

Lubrication schedules for moving parts

-

Periodic calibration of cutting blades and trimming guides

-

Preventive maintenance contract with the supplier

-

Training of your in-house operators on cleaning, troubleshooting and emergency procedures

Routine checks can avoid major breakdowns; keeping logs helps fulfil warranty conditions.

Cost & ROI Expectations

When you weigh the cost of procurement and operation of an automatic notebook making machine, you should consider:

-

Up-front capital cost (machine purchase, installation, civil work)

-

Operating expenses (power consumption, labor, binding consumables like staples, glue)

-

Production yield and scrap rate (piece rejects due to mis-alignment or poor trimming)

-

Maintenance downtime rate

-

Sale price per notebook and anticipated monthly volume

For example, if a machine produces 5,000 notebooks per day, and your margin per notebook is ₹2, your monthly revenue may reach ₹300,000 (assuming 25 working days). After accounting for operating expenses and loan amortization, the payback period could be under 2 years depending on machine cost.

Case Studies / Success Stories

Suppose a stationery manufacturer near Wankener installed a heavy-duty binding machine line with fully automatic features. They upgraded from manual binding to high-speed automatic production. As a result, their production capacity doubled, and rejection rate dropped by 70%. They recouped the investment in less than 18 months and expanded to supply notebooks to schools across Gujarat and neighbouring states.

Although names are fictional here, this kind of success is realistic if you choose the right notebook production equipment and partner with a responsive local supplier.

FAQs

Q: Can the machine handle different sizes of notebooks?

A: Yes. Most modern machines support variable formats (A4, A5, customized sizes) through adjustable guides. You can change trimming settings or folder modules as needed.

Q: What is the maintenance frequency?

A: Daily cleaning and weekly lubrication; major inspection every 3 to 6 months. Some suppliers also provide preventive maintenance contracts for annual overhauls.

Q: What types of binding are available?

A: Both stitching (wire staples) and adhesive (glue binding) are available. Some models support hybrid binding modes.

Q: How long is the warranty?

A: Warranty period varies by supplier; typically 12 months on mechanical parts, with optional extended cover for electrical components.

Q: Do I need trained operators?

A: Yes. Proper training ensures longevity and safe operation. Many suppliers include installation & operator training in their service package.

Conclusion

If you’re planning to source a notebook making machine in Wankener, Gujarat, you should evaluate your production goals, required automation level, and budget. Whether you require a semi-automatic or fully automatic setup, whether you prefer stapled or glued binding, local suppliers can offer you tailored solutions.

Using this guide and the keyword-rich details above should help you shortlist the right notebook making machine supplier and equipment for your stationery manufacturing venture.

To get started, request detailed quotations from suppliers near Wankener, ask for live demos, verify technical performance, and negotiate maintenance and training packages. With the right investment and maintenance plan, your notebook production line can be efficient, scalable, and profitable for years to come.