Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

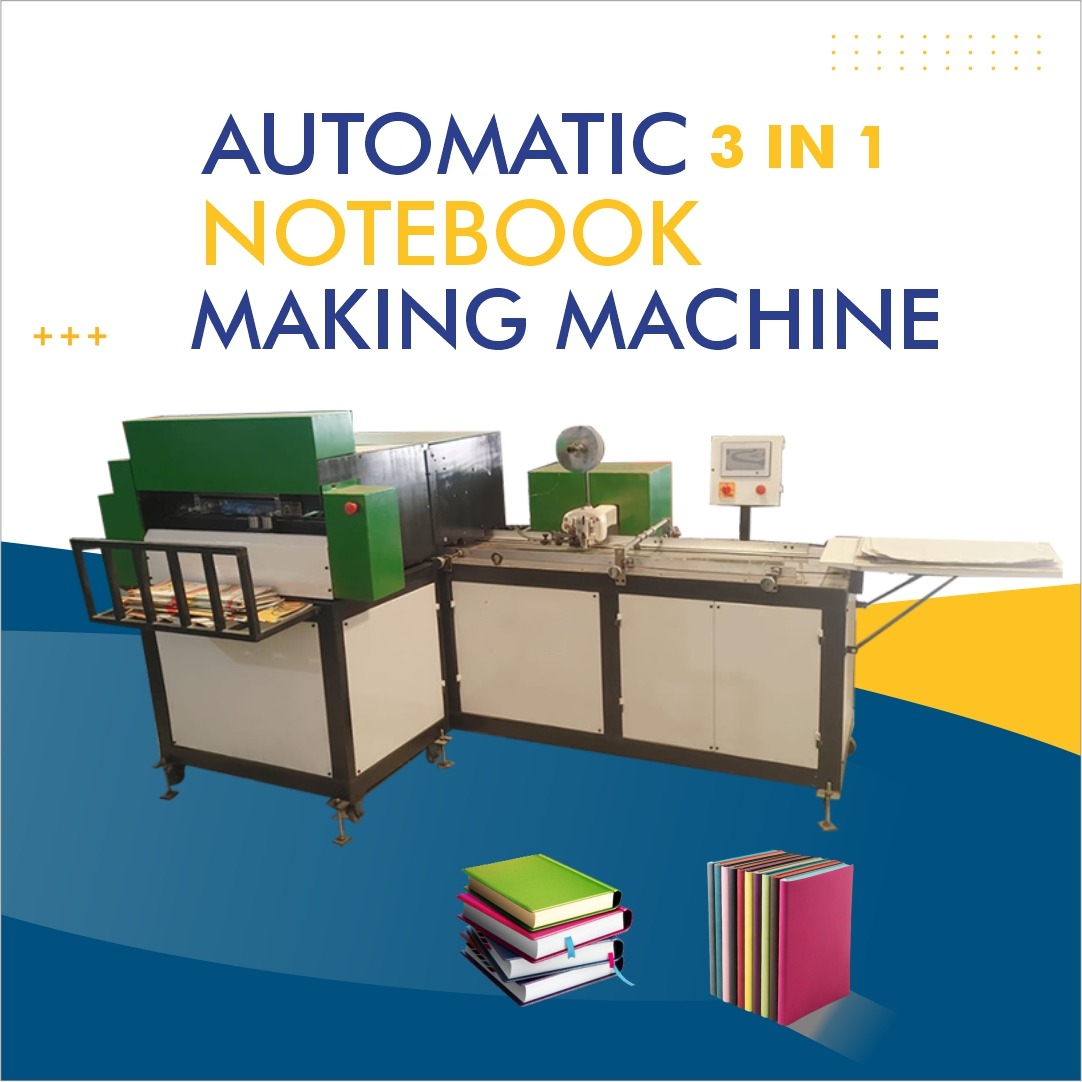

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Rajkot Gujarat | Manufacturer & Supplier

Notebook Making Machine in Rajkot | Gujarat

When you are seeking the best notebook making machine in Rajkot, Gujarat, you want cutting-edge technology, reliable service, and a manufacturer who understands local needs. Whether you are launching a small-scale stationery business or expanding your production capacity for large-scale school notebooks, choosing the right machine is crucial. In this guide, we cover everything — from machine types and technical specifications to installation, maintenance, and why Rajkot is a preferred location for notebook manufacturing machinery.

This comprehensive overview will help you evaluate your investment, compare suppliers, and ensure you get the right notebook manufacturing machine for your production goals.

Why Choose Rajkot, Gujarat for Your Machine Supplier?

-

Industrial Hub: Rajkot is one of the emerging industrial cities in Gujarat, offering easy access to suppliers, logistics, and engineering resources.

-

Cost Advantages: Local manufacturing helps reduce transport cost, import duties, and lead time compared to sourcing from far-off regions.

-

After-Sales Support: Proximity allows faster technician dispatch, spare-parts supply, and maintenance visits for your book binding machine.

-

Customisation: Manufacturers in Rajkot often provide custom configurations suited to your paper size, binding type, volume, and budget.

Types of Notebook Machines & Their Uses

Here are the common types of equipment you might need for a full production line:

| Machine Type | Purpose |

|---|---|

| Notebook Making Machine | Converts paper sheets into finished bound notebooks; includes cutting, folding, stitching or gluing, and trimming operations. |

| Notebook Manufacturing Machine | A broader term covering additional ancillary machines such as cover printing, embossing, or packaging. |

| Book Binding Machine | Used to bind loose sheets together — either by stitching, sewing, perfect binding or spiral wires. Can be part of the notebook line. |

| Paper Processing Machine | Machines that cut, perforate, or prepare raw paper sheets before binding. Useful in pre-press stages. |

| Writing Pad Making Machine | Similar to notebook machines but often configured for unbound pad stacks or glue-bound writing pads. |

Each of these plays a role in different stages of notebook production, from raw paper stock handling to final trimming and quality control.

Technical Specifications to Consider

When evaluating a notebook making machine, pay attention to:

-

Sheet size capacity (e.g. A4, A5, custom sizes)

-

Sheet thickness range (gsm – grams per square meter)

-

Production speed (notebooks per minute or hour)

-

Binding method (stitching, glue binding, spiral binding, perfect binding)

-

Automation level (semi-automatic vs fully automatic)

-

Power consumption

-

Footprint / space required

-

Material compatibility (paper types, cover card stock, printed or blank pages)

-

Safety features (emergency stop, guards)

-

Ease of maintenance and local spare parts availability

For example, a high-speed notebook manufacturing machine might produce hundreds or thousands of notebooks per hour. Meanwhile, a smaller-scale writing pad making machine may suit a startup stationery business.

Features & Benefits

Efficiency & Throughput

Modern machines in Rajkot are equipped with servo drives, PLC control, and high precision sensors — enabling consistent quality at high speeds. Whether you choose a fully automated line or semi-automated modules, these solutions boost throughput while minimising wastage.

Customisable Binding Options

You can choose between stitched binding (corner stitch or side stitch), perfect glue binding, or spiral binding. For instance, a book binding machine module allows you to switch binding types without major retooling.

Energy & Cost Savings

Local manufacturing and Indian-made components help reduce energy consumption and cost. Optimised electrical design ensures safer operation and lower running expenses.

Scalability

You can start with a smaller configuration today and upgrade modules later — e.g. adding cover printing pre-press, trimming units, or packaging conveyors to scale your production line.

Maintenance & Support

Proximity to the manufacturer in Rajkot ensures quick access to technical staff, spare parts, and periodic servicing — helping you avoid costly production downtime.

Compliance & Safety

Machines manufactured locally adhere to Indian safety standards, such as IS standards and electrical compliance. You can request safety interlocks, protective enclosures, and operator training at installation.

Typical Applications

Your notebook making machine line can serve many segments:

-

School notebooks & exercise books

-

Writing pads & notepads

-

Diaries & planners

-

Promotional notebooks for businesses

-

Customized notebooks (branded covers, special paper)

Whether you're supplying stationery stores in Gujarat or exporting across India, you can adjust your line according to packaging, size, and binding style. A paper processing machine upstream ensures accurate cutting, perforation, or hole-punching as required.

How to Choose the Right Supplier / Manufacturer in Rajkot

When selecting a manufacturer of notebook making or notebook manufacturing machines in Gujarat, consider:

-

Experience & Portfolio

Ask for case studies of other clients, sample production capacity, and sample notebooks produced by their machines. -

Technical Support & After-Sales Services

Confirm availability of engineers locally in Rajkot for installation, training, and troubleshooting. -

Turnkey Solutions

Some suppliers deliver end-to-end lines — from raw paper feeding modules, trimming, binding, to packaging conveyor. -

Customization & Upgradability

Ensure the design allows you to upgrade speed modules or add new binding types later. -

Warranty & Spare Parts

Review warranties, availability of spare components like stitching wires, glue units, knife blades, control boards etc. -

Cost & Payment Terms

Get clear quotations including freight (within Gujarat / India), local taxes (GST), installation costs and commissioning.

Case Study / Example Scenario

Suppose you wish to set up a medium-scale notebook production setup in Rajkot producing 2,000 A4 school notebooks per hour with stitched binding. Your line could include:

-

A feeder & cutter module to trim raw paper sheets to size

-

A stitching / binding module (corner or side stitch)

-

A trimming and pressing module for final finishing

-

Inspection table & packaging conveyor

You might invest in a book binding machine unit with adjustable stitch depth, and integrate a conveyor for quality check. With such a notebook making machine line, your operational cost drops compared to outsourcing except for maintenance staff, energy, and consumables.

Over six months of operation, the high throughput reduces cost per unit, and you can gradually upgrade to a writing pad making machine accessory for a sister business unit producing writing pads.

Installation & Training

Once you purchase your machine from a Rajkot-based manufacturer:

-

The supplier arranges delivery and installation on your factory floor (subject to floor strength and utilities).

-

Technicians commission the line and calibrate settings such as speed, sheet size tolerances, and binding tension.

-

Training is provided to your operators, with standard operating procedures, preventive maintenance schedule, and safety briefings.

-

Periodic service visits may be arranged under maintenance contracts to ensure optimum efficiency of your paper processing machine and Reduce downtime.

Maintenance & Operation Tips

To ensure long service life and smooth performance of your notebook manufacturing line:

-

Keep documentation (manuals, electrical diagrams, spare-parts list).

-

Establish a preventive maintenance schedule (lubrication, alignment checks, wire tension calibration, control-panel cleaning).

-

Use high-quality consumables (stitching wire, glue) recommended by the manufacturer.

-

Monitor machine output for defects (mis-cuts, mis-binding, loose covers) and adjust settings accordingly.

-

Ensure safety guards are functional and operators follow safety protocols.

Cost Estimates & Payback

While prices vary depending on capacity, automation level and features, a mid-capacity notebook making machine line in Rajkot might cost significantly less than imported equivalents due to local manufacturing. The payback period depends on your production volume — higher utilisation leads to faster ROI. You can ask your supplier for a detailed break-even analysis based on your expected order volume, labour cost, and material cost in Gujarat.

Why Our Machines Stand Out (Suggested USP Section)

If you are a manufacturer in Rajkot, you could emphasise:

-

Precision engineering with local component sourcing

-

Modular design allowing future upgrades (e.g. from stitched to glue binding)

-

Strong after-sales support across Gujarat and neighbouring states

-

Competitive pricing with transparent quotations including GST and logistics

-

Custom configuration for special paper sizes, cover styles or binding methods

Conclusion

Investing in a high-quality notebook making machine in Rajkot, Gujarat gives you a competitive advantage in cost, service, and customisation. Whether for school notebooks, writing pads, or promotional books, you can choose a line tailored to your production needs. With the right supplier, you benefit from local support, scalability, and fast turnaround times.

If you’re ready to explore specific models, request quotations, or arrange a site visit in Rajkot, feel free to contact us today. We’ll help you select the ideal notebook manufacturing machine, binders, and paper processing equipment to match your operation’s goals and budget.