Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

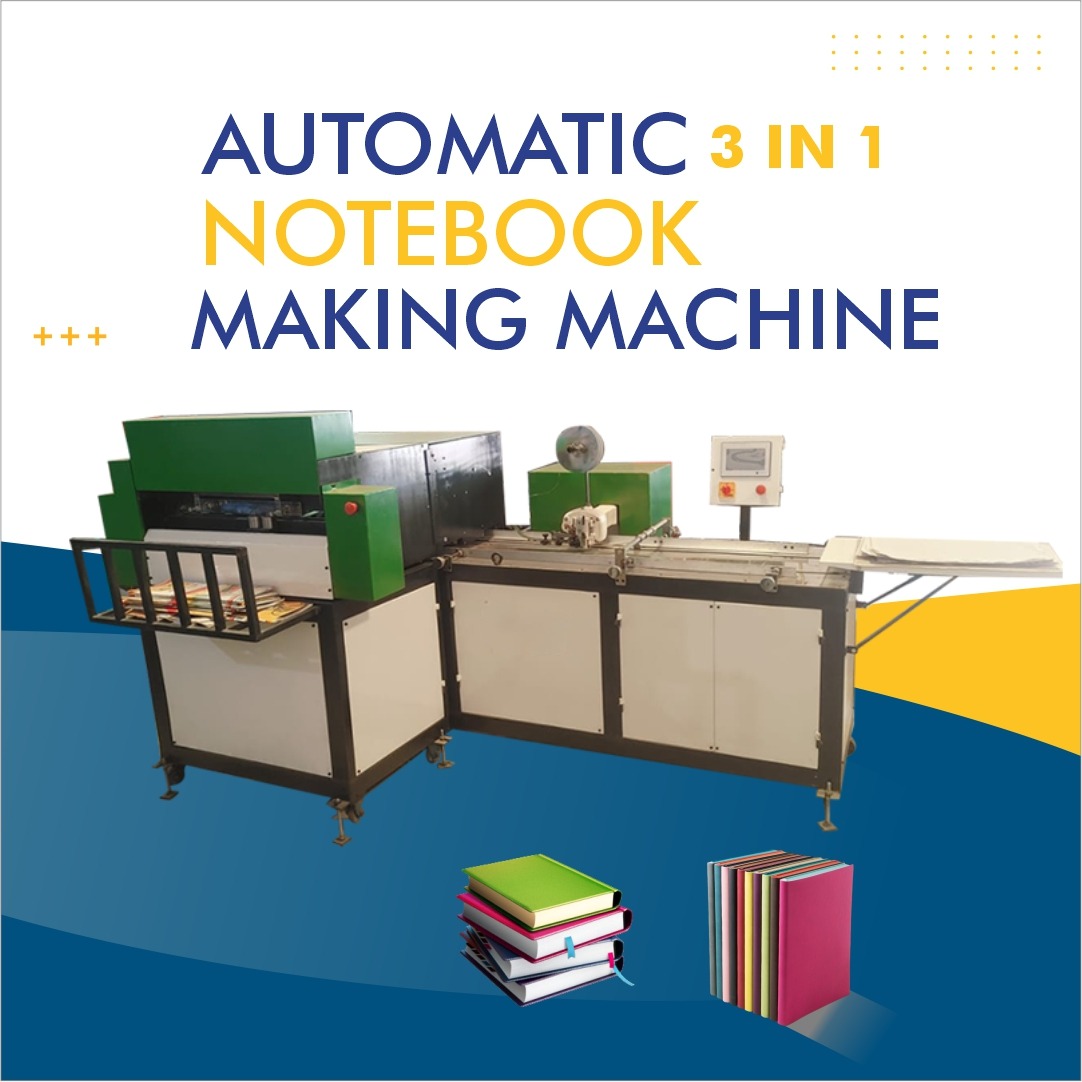

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Kalol Gujarat – High-Speed Notebook Production Equipment

Notebook Making Machine Manufacturer in Kalol | Gujarat

In today’s fast-paced paper and stationery manufacturing sector, investing in reliable and high-efficiency machinery is key to scaling operations and maintaining product quality. If you are searching for a notebook making machine in Kalol, Gujarat—a hub for industrial manufacturing—you’ll want to partner with a manufacturer that offers advanced technology, durability, and local support. This guide covers everything you need to know about selecting, installing, and maintaining notebook production equipment to streamline production and maximize ROI.

1. Why Choose Kalol, Gujarat for Notebook Machinery?

Industrial Infrastructure & Accessibility

Kalol, Gujarat is well-positioned within a strong manufacturing ecosystem, offering excellent transport links, skilled labor, and proximity to raw materials. Choosing a notebook making machine supplier in Kalol means you benefit from reduced logistics cost, faster delivery times, and access to servicing and spare parts locally.

Reputation & Local Expertise

Several trusted engineering firms in Kalol specialize in sheet-fed paper processing and binding equipment. They understand Indian paper grades, power-supply conditions, and production norms. This local expertise helps ensure your notebook production machine is optimized for your material specifications and production volumes.

Cost Advantage

Operating within Gujarat typically offers lower overall costs in terms of taxes, labor, and supply chain access compared to importing machines. You get more economical procurement, installation, and maintenance of your notebook manufacturing equipment.

2. Types of Notebook Making Machines

When exploring notebook production equipment, it's useful to understand the different types and their applications:

-

Automatic Notebook Making Machine

Fully automated machinery that feeds paper, prints/lines pages, binds (staple, glue, or spiral bind), trims edges, and stacks finished notebooks. Ideal for high-volume manufacturers. -

Semi-automatic Notebook Production Machine

Requires manual feed or partial intervention. More affordable entry-point for mid-sized operations. -

Spiral Notebook Machine

Specifically designed to manufacture spiral-bound notebooks, incorporating coil insertion, punching, binding, and trimming. -

Stapled / Stitch-bound Notebook Machine

Uses stapling or wire-stitch binding instead of spiral. Suitable for school exercise books, diaries, and similar formats. -

Glue-bound / Perfect-bound Notebook Equipment

For notebooks with glued spines rather than bindings. Often used for diaries, planners, or premium journals.

By assessing your production capacity, binding type, speed, and paper size, you can choose the right notebook manufacturing machine that fits your business.

3. Key Features to Look For

When selecting a notebook making machine, consider the following specifications and features:

| Feature | Why It Matters |

|---|---|

| Production Speed (books per hour) | Determines throughput capacity and ability to meet deadlines. |

| Paper Size & Thickness Handling | Ability to work with A4, A5, custom sizes, different GSM paper. |

| Binding Type Compatibility | Can the machine handle spiral coils, staples, or glue binding? |

| Automation Levels | More automation reduces manual labor, lowers error rate, and improves consistency. |

| Precision & Trim Quality | Clean edges, accurate punching alignment, professional finish. |

| Energy Efficiency | Efficient motors and drive systems reduce electricity consumption. |

| Ease of Maintenance | Availability of spare parts, local support staff, and downtime minimisation. |

| Safety & Compliance | Guards, emergency stops, compliance with industrial standards in India. |

Ensure your supplier provides detailed technical documentation, layout drawings, and test videos before purchase.

4. Benefits of Investing in a Modern Notebook Production Machine

Increased Productivity

Automated notebook making machines significantly increase output by reducing manual handling and error rates. The improved cycle time means you can produce more units per shift.

Cost Savings

Over time, automation reduces labor costs, reduces wastage of paper and supplies, and improves consistency. This leads to lower per-unit cost of the finished notebook.

Quality & Consistency

Precision binding, consistent trimming, and stable operation deliver a professional final product that meets higher standards demanded by schools, corporates, and exports.

Scalability & Flexibility

With modular or upgradeable systems, you can expand the capacity or add features (e.g. digital printing, customized covers, variable page counts) as your business grows.

Competitive Advantage

Having your own notebook manufacturing equipment ensures you respond quickly to market demands, reduce dependency on external suppliers, and maintain better quality control.

5. How to Choose the Right Supplier in Kalol, Gujarat

Here are the practical steps to identify the best manufacturer of notebook making machines:

-

Facility Visit

Inspect their production plant in or near Kalol. Verify manufacturing quality, check machinery they already supply, and assess on-site testing capabilities. -

Technical Specifications & Customization

Request a detailed specification sheet for the machine—production speed, power consumption, dimension footprint, and precision tolerances. Ask whether the design can be customized (sheet sizes, binding type, margin adjustments, digitized controls). -

After-Sales Support & Spare Parts

Ensure that spare parts, technical service engineers, and maintenance consultancy are available locally or within manageable travel distance (e.g. within Gujarat / nearby states). -

Warranty & Training

Verify the warranty period, on-site installation, operator training, and trial production support provided by the manufacturer. -

References & Testimonials

Ask for client feedback, case studies from other stationery manufacturers in India that use your target machine. -

Compliance & Safety Standards

Ensure that the machinery conforms to Indian electrical safety norms, industrial machine directives, and workplace safety regulations.

6. Application Examples & Case Study

Example Scenario:

You run a medium-scale stationery production unit in Gujarat producing school notebooks in A4 and A5 sizes. You require a semi-automatic or fully automatic notebook production machine capable of 1,000–2,000 notebooks per hour, handling grammages from 70 GSM to 120 GSM paper, with spiral binding and trimming.

You approach a Kalol-based manufacturer. They propose an automatic notebook making machine with the following:

-

Dual feeder for cover sheet and inner pages

-

High-speed punching station with adjustable margins

-

Spiral-binding coil inserter

-

Edge trimmer with waste-collection hood

-

Output stacking conveyor

-

HMI panel with speed control & diagnostics

-

Local power-supply compatibility (400 V, 50 Hz, three-phase)

-

Maintenance training at your site and one year of warranty for mechanical parts

After commissioning, your factory increases production by 45%, sheet waste drops by 15%, and labor cost falls by 20%—leading to a payback period of under 18 months.

Similar case studies are often available from manufacturers in Kalol who supply to stationery companies across Gujarat and neighbouring states.

7. Maintenance & Operational Best Practices

To get the best out of your notebook production machine:

-

Schedule regular preventive maintenance (lubrication, alignment check, belt condition).

-

Train operators in basic troubleshooting (paper jams, mis-alignment, coil feed issues).

-

Keep an inventory of critical spare parts (punching dies, cutting blades, drive belts).

-

Monitor production data: downtime hours, rejects, cycle speed variation.

-

Rotate paper suppliers to ensure consistent paper quality and minimize machine stress.

-

Operate machine within specified limits—don’t exceed maximum sheet thickness or overrun speed—to avoid wear and tear.

Proper maintenance ensures longevity, reliability, and consistent product quality from your notebook making machine.

8. Investment & Financial Considerations

When budgeting for a notebook making machine, factor in:

-

Capital cost of the machine (may vary significantly based on automation level).

-

Shipping / installation costs (even local factory delivery charges, foundation or anchoring work).

-

Electrical upgrade (if three-phase power or voltage stabilization is needed).

-

Operator training and any software / control panel licensing.

-

Consumables (coils, staples, glue, trimming blades) and expected lifetime.

-

Financing options (bank loan, leasing equipment).

-

Depreciation and tax benefits under Indian regulations (e.g. investment allowance under plant & machinery for manufacturing units).

By calculating return on investment (ROI) using projected increase in throughput, savings in labor, and reduction in scrap, you can justify the acquisition to stakeholders.

9. Future Trends & Upgrades

The stationery machinery market is evolving. Consider these emerging features:

-

Digital Integration & IoT Monitoring – Sensors for overheat, vibration, or fault detection with remote alerts.

-

Servo-Motor Drives – More precise control and faster changeover between formats.

-

Variable-Format Production – Adjust different sized notebooks on the fly without major manual setup.

-

Eco-friendly Operation – Energy-efficient motors, reduced noise, and better waste management for paper scraps.

-

Hybrid Printing-Binding Lines – Integrated inkjet or offset printing followed by binding and finishing in one continuous flow.

Selecting a manufacturer in Kalol, Gujarat who is ready to support such upgrades can future-proof your investment.

Conclusion

Choosing the right notebook making machine for your business is a critical decision that impacts productivity, cost-efficiency, and product quality. By partnering with a manufacturer in Kalol, Gujarat, you benefit from local industrial infrastructure, proximity to suppliers, and responsive after-sales support.

Assess your production requirements—speed, binding type, paper size, budget—and evaluate candidate suppliers based on technical specs, customization options, and service network. Maintain your equipment with preventive care and plan for future upgrades to stay competitive.

If you are ready to invest in a notebook production machine, or want to explore options such as spiral notebook equipment, automatic binding lines, or commercial notebook machinery, let me know. I can help you identify reputed manufacturers in Kalol or provide comparative quotes.