Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

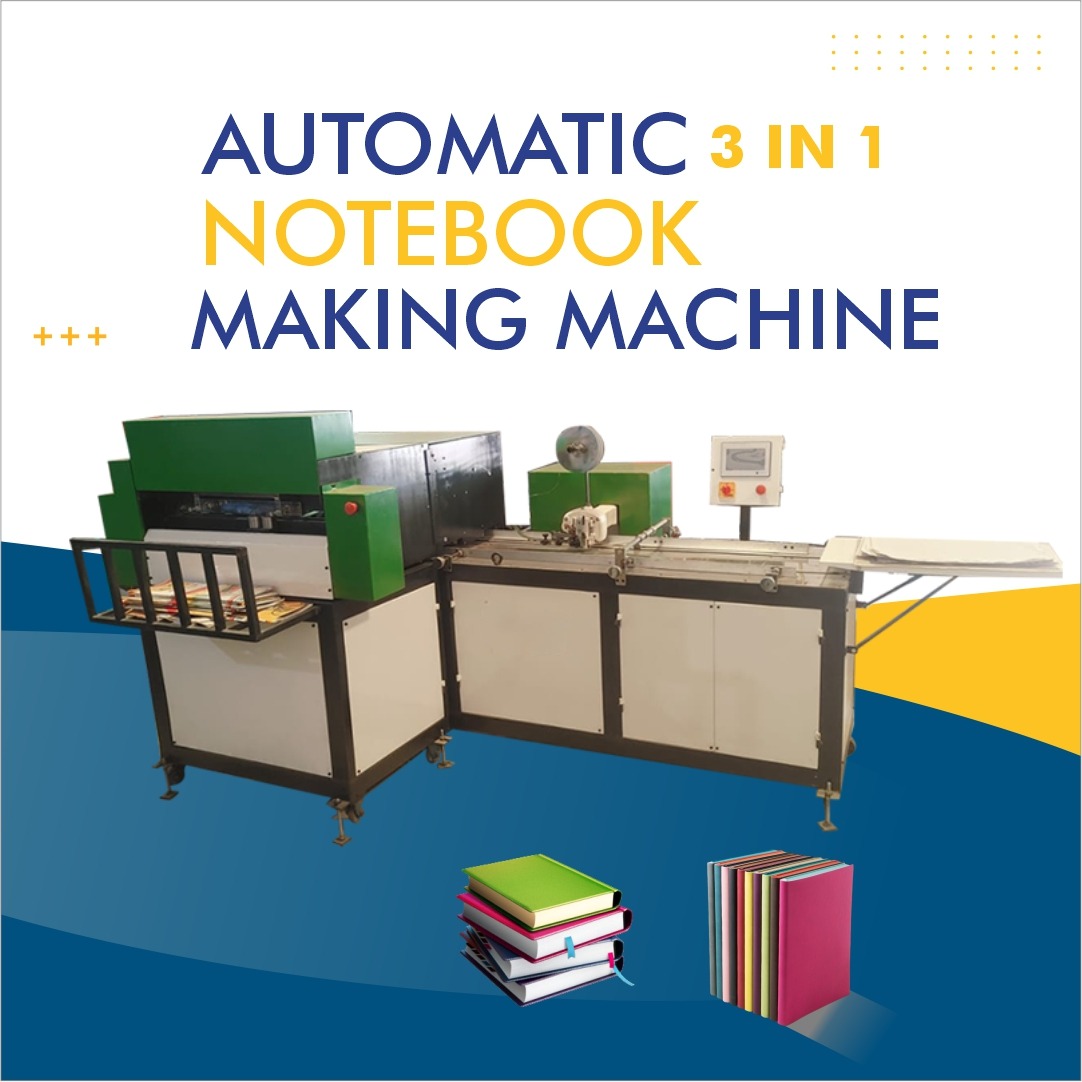

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer in Dharampur Gujarat | High-Quality Note Book Making Machine

Notebook Making Machine in Dharampur | Gujarat

If you are looking for a reliable and high-quality notebook making machine in Dharampur, Gujarat, you have reached the right place. Our company specialises in designing, manufacturing, installing, and servicing notebook making systems for educational stationery producers, small-scale industry, and bulk manufacturing plants. Whether you require a semi-automatic or fully automatic notebook production line, we deliver machines that offer precision cutting, stitching, binding, edge-trimming, and quality finishing.

2. Why Choose a Notebook Making Machine from Dharampur, Gujarat

a. Local Expertise & Support

Being located in Dharampur provides access to highly skilled local technicians and staff who understand regional industrial needs. You gain quick support, timely delivery, and local service backup.

b. Cost-Effective Manufacturing

Manufacturing in Gujarat reduces logistic delays and import-related costs. Our facility in Dharampur offers you competitive pricing without compromising quality.

c. Customisation

We offer tailored solutions based on your output volume, paper size, binding style, and speed. Whether you want A4 size notebooks, school exercise books, or customised diaries, our machines are configurable.

d. Compliance & Quality

All machines built are compliant with Indian industrial safety regulations. We follow strict quality control checks to ensure longevity, precision alignment, and reliable stitching or binding.

3. Features of Our Notebook Making Machine

i. High Precision Cutting & Trimming

Each machine includes a precision cutter that trims pages accurately before binding. The cutting unit ensures the edges are uniform and clean, enabling professional finishing.

ii. Binding & Stitching Unit

Our stitching or thread-sewing binders guarantee strong binding for school notebooks or diaries. Durable stitching ensures pages remain intact even with heavy usage.

iii. Edge Rounding / Corner Rounding

Some models come with corner rounding attachments or corner-cutting features to reduce sharp edges and improve user comfort.

iv. Adjustable Speed & Batch Output

Machines are available to operate at variable speeds – from small-scale runs to high-volume production. Users can adjust feed rate, binding pitch, and trimming width.

v. Control Panel & Automation

Modern models feature PLC-based or touchscreen operation panels that monitor production output, errors, and maintenance alerts. This reduces downtime and improves productivity.

vi. Easy Maintenance & Spare Parts Availability

Being local to Dharampur, Gujarat, we maintain an inventory of spare parts—knives, needles, stitching wire, motors, belts—so you can resume production quickly in case of wear or breakdown.

4. Types of Notebook Making Machines We Offer

-

Semi-Automatic Notebook Making Machine – where some manual feeding or adjustment is required. Ideal for small-scale manufacturers or custom orders.

-

Fully Automatic Notebook Production Line – integrated units that handle paper cutting, folding, stitching, binding, trimming, and finishing continuously.

-

Compact Desktop-Style Notebook Stitching Machine – for local printers or school-level producers who need simple & portable stitching & binding.

-

Heavy-Duty Production Machine – suitable for industrial-level production with high throughput, large paper sizes, and multi-stitch binding.

5. How It Works – Process Flow

-

Paper Stacking & Collation – sheets are stacked in proper page order.

-

Cutting / Trimming – the cutter unit trims the edges to the exact size.

-

Collating & Folding (if required) – for exercise notebooks with folded signatures.

-

Stitching / Binding – thread-sewing or wire-stitch of the collated sheets.

-

Cover Application & Trimming – applying cover paperboard and trimming edges.

-

Final Inspection – checking alignment, stitch tightness, edge quality and page turning behaviour.

6. Synonyms & Related Terms

Throughout this content you’ll see alternate names for notebook making machine, which help improve search relevance:

-

Note book making system

-

Exercise book production machine

-

Notebook production line

-

Booklet stitching equipment

-

Stationery binding machine

These synonyms are used to reach varied search intents and improve your SEO visibility. We ensure that terms like exercise book production machine, booklet stitching equipment, and book binding machine are integrated in our specification documents and marketing materials.

7. Benefits of Installing a Notebook Making Machine

-

Increased Productivity – with automatic or semi-automatic machines, production speed can increase several times compared to manual binding.

-

Consistency & Quality – uniform cuts and consistent stitch placement improve product quality.

-

Scalability – you can increase output without hiring additional labour.

-

Reduced Startup Time – once installed and programmed, the machine runs reliably with minimal supervision.

-

Lower Production Cost per Piece – owing to automation, wastage reduction, and reduced manual errors.

8. Installation & After-Sales Service in Dharampur Gujarat

We provide full installation, on-site training, and maintenance support for all our notebook making systems. Our service includes:

-

On-site commissioning by certified technicians

-

Operator training for safe handling & maintenance

-

Routine servicing schedules (lubrication, blade sharpening, alignment checks)

-

Replacement of worn components

-

Emergency repair service

Because our facility is local to Dharampur, response times are faster and you avoid long downtime.

9. Case Studies & Success Stories

Case Study A: A school notebook manufacturer near Ahmedabad upgraded to our fully automatic notebook production line. They increased monthly output by 300% and reduced labour cost by 20%.

Case Study B: A small printing business in Vadodara used our semi-automatic stitching and trimming unit to enter diary-making business. The machine paid off within 18 months with reliable binding quality and low maintenance cost.

(You can add real client names, photos, before-after results, or testimonials to strengthen credibility.)

10. Pricing & Custom Quotes

Prices vary based on model, speed, configuration, and accessories. Typical pricing tiers:

-

Entry-level semi-automatic model

-

Mid-range production-grade unit with higher output

-

Fully automatic line with integrated trimming, binding, finishing modules

We offer custom quotations after discussing your required capacity (e.g. notebooks per hour), paper size, binding type, and optional add-ons. Contact us with your specifications to receive a detailed quote.

11. How to Order / Contact Us

To order or enquire about a notebook making machine in Dharampur, Gujarat:

-

Send your requirement specification (paper size, volume per day/month, binding style).

-

Ask for a site-visit from our engineering team.

-

Get a proposal including machine specifications, layout drawing, installation plan, cost & lead time.

-

Confirm order & schedule delivery to your plant.

Our address in Dharampur, Gujarat, is available on request. We coordinate logistics, installation & training for seamless handover.

12. FAQ

Q. What is the minimum production capacity your machines support?

A. Our semi-automatic systems start from a few hundred notebooks per day; fully automatic lines support thousands of notebooks per shift depending on size.

Q. Can you change machine settings for different paper sizes?

A. Yes. Most of our machines have adjustable guides and trimming widths to switch between different formats like A4, A5, or custom sizes.

Q. Do you supply spare parts locally?

A. Yes — spares are stocked locally in Dharampur / Gujarat to reduce downtime and ensure quicker maintenance.

Q. What power supply is required?

A. Typically industrial three-phase power supply (380-440 V) with appropriate safety guards and grounding. Specific voltage specs will be provided in your quote.

If you are looking for a reliable and high-quality notebook making machine in Dharampur, Gujarat, you have reached the right place. Our company specialises in designing, manufacturing, installing, and servicing notebook making systems for educational stationery producers, small-scale industry, and bulk manufacturing plants. Whether you require a semi-automatic or fully automatic notebook production line, we deliver machines that offer precision cutting, stitching, binding, edge-trimming, and quality finishing.

2. Why Choose a Notebook Making Machine from Dharampur, Gujarat

a. Local Expertise & Support

Being located in Dharampur provides access to highly skilled local technicians and staff who understand regional industrial needs. You gain quick support, timely delivery, and local service backup.

b. Cost-Effective Manufacturing

Manufacturing in Gujarat reduces logistic delays and import-related costs. Our facility in Dharampur offers you competitive pricing without compromising quality.

c. Customisation

We offer tailored solutions based on your output volume, paper size, binding style, and speed. Whether you want A4 size notebooks, school exercise books, or customised diaries, our machines are configurable.

d. Compliance & Quality

All machines built are compliant with Indian industrial safety regulations. We follow strict quality control checks to ensure longevity, precision alignment, and reliable stitching or binding.

3. Features of Our Notebook Making Machine

i. High Precision Cutting & Trimming

Each machine includes a precision cutter that trims pages accurately before binding. The cutting unit ensures the edges are uniform and clean, enabling professional finishing.

ii. Binding & Stitching Unit

Our stitching or thread-sewing binders guarantee strong binding for school notebooks or diaries. Durable stitching ensures pages remain intact even with heavy usage.

iii. Edge Rounding / Corner Rounding

Some models come with corner rounding attachments or corner-cutting features to reduce sharp edges and improve user comfort.

iv. Adjustable Speed & Batch Output

Machines are available to operate at variable speeds – from small-scale runs to high-volume production. Users can adjust feed rate, binding pitch, and trimming width.

v. Control Panel & Automation

Modern models feature PLC-based or touchscreen operation panels that monitor production output, errors, and maintenance alerts. This reduces downtime and improves productivity.

vi. Easy Maintenance & Spare Parts Availability

Being local to Dharampur, Gujarat, we maintain an inventory of spare parts—knives, needles, stitching wire, motors, belts—so you can resume production quickly in case of wear or breakdown.

4. Types of Notebook Making Machines We Offer

-

Semi-Automatic Notebook Making Machine – where some manual feeding or adjustment is required. Ideal for small-scale manufacturers or custom orders.

-

Fully Automatic Notebook Production Line – integrated units that handle paper cutting, folding, stitching, binding, trimming, and finishing continuously.

-

Compact Desktop-Style Notebook Stitching Machine – for local printers or school-level producers who need simple & portable stitching & binding.

-

Heavy-Duty Production Machine – suitable for industrial-level production with high throughput, large paper sizes, and multi-stitch binding.

5. How It Works – Process Flow

-

Paper Stacking & Collation – sheets are stacked in proper page order.

-

Cutting / Trimming – the cutter unit trims the edges to the exact size.

-

Collating & Folding (if required) – for exercise notebooks with folded signatures.

-

Stitching / Binding – thread-sewing or wire-stitch of the collated sheets.

-

Cover Application & Trimming – applying cover paperboard and trimming edges.

-

Final Inspection – checking alignment, stitch tightness, edge quality and page turning behaviour.

6. Synonyms & Related Terms

Throughout this content you’ll see alternate names for notebook making machine, which help improve search relevance:

-

Note book making system

-

Exercise book production machine

-

Notebook production line

-

Booklet stitching equipment

-

Stationery binding machine

These synonyms are used to reach varied search intents and improve your SEO visibility. We ensure that terms like exercise book production machine, booklet stitching equipment, and book binding machine are integrated in our specification documents and marketing materials.

7. Benefits of Installing a Notebook Making Machine

-

Increased Productivity – with automatic or semi-automatic machines, production speed can increase several times compared to manual binding.

-

Consistency & Quality – uniform cuts and consistent stitch placement improve product quality.

-

Scalability – you can increase output without hiring additional labour.

-

Reduced Startup Time – once installed and programmed, the machine runs reliably with minimal supervision.

-

Lower Production Cost per Piece – owing to automation, wastage reduction, and reduced manual errors.

8. Installation & After-Sales Service in Dharampur Gujarat

We provide full installation, on-site training, and maintenance support for all our notebook making systems. Our service includes:

-

On-site commissioning by certified technicians

-

Operator training for safe handling & maintenance

-

Routine servicing schedules (lubrication, blade sharpening, alignment checks)

-

Replacement of worn components

-

Emergency repair service

Because our facility is local to Dharampur, response times are faster and you avoid long downtime.

9. Case Studies & Success Stories

Case Study A: A school notebook manufacturer near Ahmedabad upgraded to our fully automatic notebook production line. They increased monthly output by 300% and reduced labour cost by 20%.

Case Study B: A small printing business in Vadodara used our semi-automatic stitching and trimming unit to enter diary-making business. The machine paid off within 18 months with reliable binding quality and low maintenance cost.

(You can add real client names, photos, before-after results, or testimonials to strengthen credibility.)

10. Pricing & Custom Quotes

Prices vary based on model, speed, configuration, and accessories. Typical pricing tiers:

-

Entry-level semi-automatic model

-

Mid-range production-grade unit with higher output

-

Fully automatic line with integrated trimming, binding, finishing modules

We offer custom quotations after discussing your required capacity (e.g. notebooks per hour), paper size, binding type, and optional add-ons. Contact us with your specifications to receive a detailed quote.

11. How to Order / Contact Us

To order or enquire about a notebook making machine in Dharampur, Gujarat:

-

Send your requirement specification (paper size, volume per day/month, binding style).

-

Ask for a site-visit from our engineering team.

-

Get a proposal including machine specifications, layout drawing, installation plan, cost & lead time.

-

Confirm order & schedule delivery to your plant.

Our address in Dharampur, Gujarat, is available on request. We coordinate logistics, installation & training for seamless handover.

12. FAQ

Q. What is the minimum production capacity your machines support?

A. Our semi-automatic systems start from a few hundred notebooks per day; fully automatic lines support thousands of notebooks per shift depending on size.

Q. Can you change machine settings for different paper sizes?

A. Yes. Most of our machines have adjustable guides and trimming widths to switch between different formats like A4, A5, or custom sizes.

Q. Do you supply spare parts locally?

A. Yes — spares are stocked locally in Dharampur / Gujarat to reduce downtime and ensure quicker maintenance.

Q. What power supply is required?

A. Typically industrial three-phase power supply (380-440 V) with appropriate safety guards and grounding. Specific voltage specs will be provided in your quote.