Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

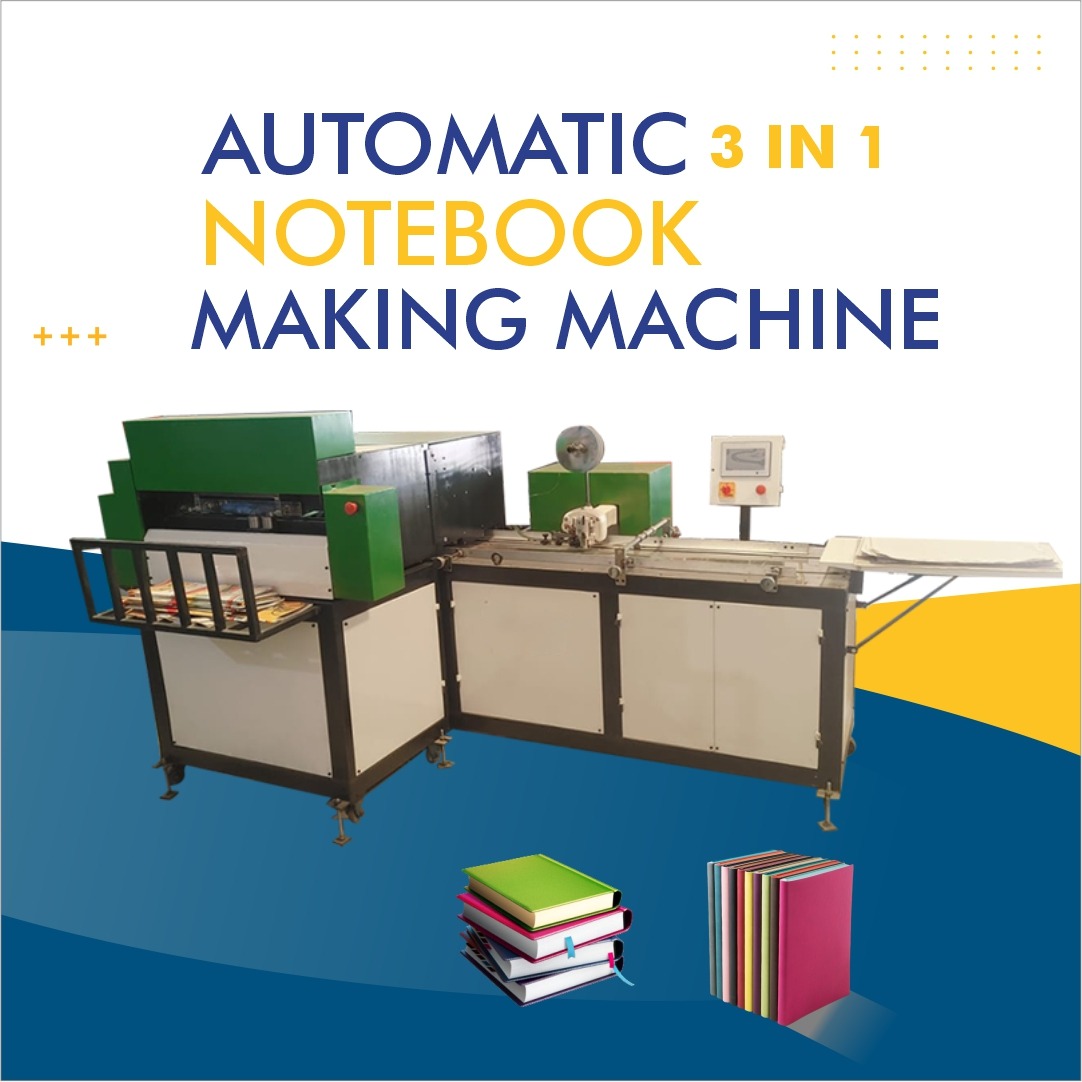

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier Bharuch | High Efficiency Binder & Cutter Systems

Notebook Making Machine Supplier Bharuch |Gujarat

If you are seeking to set up or upgrade a notebook production line in Bharuch, Gujarat, choosing the right notebook making machine can make all the difference in terms of product quality, production speed, and long-term reliability. This article will guide you through everything you need to know: from the types of machinery, the technical specifications to look for, to how to find a trustworthy supplier or manufacturer locally.

In today’s competitive stationery industry, optimizing through automation and precise engineering is essential. Whether you're starting a small boutique notebook brand or scaling up to supply schools and offices nationwide, having a high-performance notebook making machine is a core investment.

Why Choose Bharuch, Gujarat for Notebook Making Machine Suppliers

-

Industrial Infrastructure: Bharuch district is part of the broader Gujarat industrial belt. Being close to ports, highways, and strong logistics, it offers a strategic location for manufacturing and distribution across India.

-

Local Support & Maintenance: By choosing a supplier in Bharuch, you benefit from shorter response times for installation, training, repair, and spare parts.

-

Cost-Effective Manufacturing: Local machinery makers in Gujarat often offer competitive pricing without compromising on build quality, thanks to local sourcing of components and lower overheads.

-

Customization & Flexibility: Many engineers and machine-shops in Bharuch or nearby (Vadodara, Surat, Ankleshwar) are willing to design custom notebook production machines to suit your specific format, binding style, or production volume.

Types of Notebook Making Machines & Their Functions

Below are the main categories of machines you might require for a full-fledged notebook making line:

-

Paper Cutting Machine

This cuts the input paper sheets (inner sheets and covers) to the correct size. Key features include blade type, cutting length, safety features, and accuracy. A robust paper cutting machine ensures that all internal pages align perfectly before binding. -

Paper Folding Machine

Once the sheet size is right, folding (for some types of notebooks) may be required. For example, signature fold styles (for stitched binding or staple binding) use folding machines that deliver consistent creases, reducing manual labor. -

Edge-Trimming & Chamfering Machine

After binding, trims or edge finishing may be required to make the notebook look neat. Edge-trimmers are often integrated into binding systems. -

Binding Machine (Stitch / Staple / Spiral)

This is the heart of the operation. You can choose:-

Saddle stitch binding machines – staples the centre fold of signatures.

-

Spiral binding/coil binding equipment – for rings or coils.

-

Thread sewing or perfect-binding machines – for premium notebooks.

-

-

Hot-Melt Glue Binding Machine / PUR Binding

For softcover binding with glued spine, a hot-melt glue binder or PUR (polyurethane reactive) binder may be used. This is ideal for thicker notebooks or premium finish. -

Cover Laminating / Binding Presses

Machines that press the covers or apply lamination coatings may follow the binding step. They improve durability and finishing quality. -

Automatic Counting, Numbering & Packaging Machines

Advanced notebook production lines may include automatic numbering or labeling machines, and packaging systems that bundle notebooks in sets. -

Quality Inspection & Reject-Sorting Systems

To maintain quality, systems that detect mis-aligned pages, crooked binding or loose staples help reduce rework.

To build a fully integrated production setup, you might combine several of these into a workflow.

Technical Specifications to Consider

When you evaluate a notebook production machine, keep the following in mind:

-

Production Capacity: How many notebooks per hour or per minute? For example, a binding machine might deliver 200–500 notebooks/hour, depending on size.

-

Size Range & Custom Formats: Maximum sheet size, minimum size, cover thickness, spine width, etc. Can the machine handle different formats — A4, A5, custom designs?

-

Automation Level: Semi-automatic vs fully automatic. Automatic feeders reduce manual handling, which improves speed and consistency.

-

Power Consumption & Energy Efficiency: Especially important for longer daily operation.

-

Safety Features & Compliance: Emergency stops, guarding, and compliance with local electrical and labor safety standards.

-

Changeover Time: Time taken to switch from one format to another (e.g. from A4 spiral notebook to A5 stapled format). Lower changeover time increases flexibility.

-

Build Materials & Durability: Construction material (steel frame, alloy parts), quality of motor & bearings.

-

Maintenance & Spare Parts Availability: Critical to check whether the supplier stocks spare components locally in Bharuch or nearby.

-

Software / Digital Interface: Some modern machines offer computerized job setups or digital counters to track production, which helps with quality control and efficiency.

How to Select the Right Supplier in Bharuch

Here’s a step-by-step approach to choosing a good supplier or manufacturer near Bharuch:

| Step | What to Check |

|---|---|

| 1. Portfolio & Client References | Ask for videos, case studies or live demos of their notebook production machine in action. |

| 2. After-Sales Service | Ensure they provide installation, training, and maintenance service in Bharuch or nearby. |

| 3. Customisation Capability | Check if they can modify dimensions, binding type, or integrate additional modules (e.g. numbering, packaging). |

| 4. Warranty & Spare-Parts | How long is the warranty, and how quickly can you get replacement parts locally? |

| 5. Compliance & Safety | Confirm the machine meets Indian standards for electrical safety and labour regulation. |

| 6. Price vs Quality Trade-off | Request detailed quotations with specs. Sometimes lower initial price can lead to higher downtime or lower precision. |

To shortlist suppliers, you can search online for “notebook making machine manufacturer Gujarat” or “stationery machinery Ahmedabad / Vadodara / Bharuch”. Visit their workshops if possible.

Benefits of Investing in an Automated Notebook Making Machine

-

Increased Output: Automated machines can produce many more notebooks per hour compared to manual assembly. That supports larger production runs and helps meet bulk orders.

-

Consistent Quality: Automation reduces human error — precise cuts, uniform binding, proper alignment. That increases customer satisfaction and reduces returns.

-

Lower Labour Costs: Once installed, fewer manual operators are needed. Over time, labour cost savings help offset the machine investment.

-

Scalability: As demand increases (e.g. school season peaks), you can scale up production without major overhauls.

-

Competitive Edge: Having modern machinery helps you compete with low-cost imported or foreign-supplied stationery by offering faster turnaround, better finish, and potential for customisation (e.g. branded covers).

Case Study: (Hypothetical) Notebook Factory Setup in Bharuch

Imagine you are establishing a mid-scale notebook unit near Bharuch with the following parameters:

-

Production target: 1,000 notebooks/day (mix of A4 ruled spiral, A5 stapled softcover)

-

Shift time: 8 hours/day

-

Format mix: 70 % spiral, 30 % staple bound

You might require:

-

One paper cutting machine with capacity of 2,000 sheets/hour

-

One spiral binding machine with output of 300 notebooks/hour

-

One saddle-stitch stapling / binding machine for smaller A5 format

-

One packing & numbering module

By sourcing locally in Bharuch, you might save on transport & installation costs compared to importing. Local engineers can adjust conveyor speed and binding roller pressure based on paper thickness variations in Gujarat’s humid climate. Suppliers may even tailor the design to run on 415 V three-phase supply common in Gujarat industrial zones.

Over a year, you benefit from faster fulfilment, fewer rejects, and can accommodate rush orders (for example, during school registration season).

Common Challenges & Solutions

| Challenge | Possible Solution |

|---|---|

| Paper misalignment during binding | Use precision registration guides and regular calibration; supplier should provide calibration service. |

| Variation in paper quality due to humidity | Choose machines with adjustable pressure rollers; regular maintenance and training. |

| Spare-part downtime | Negotiate spare-parts inventory consignment at Bharuch site. |

| Changeover delay between formats | Ask for quick-change fixture kits, memory-based machine presets (if digital interface). |

| Operator training | Supplier should provide on-site training sessions and operation manuals in local language. |

Maintenance, Upgrades & Long-Term Reliability

After installation, ensuring uptime is critical. Here are best practices for maintaining your notebook production line:

-

Scheduled preventive maintenance monthly/quarterly (lubrication, belt tensioning, blade sharpening).

-

Backup of critical electrical components (PLC controllers, sensors).

-

Periodic inspection of binding heads, motor integrity, and alignment.

-

Software / interface updates if digital controls are provided.

-

Plan for scalability: you may upgrade from semi-automatic to fully automatic feeding modules, or add packaging automation in the future.

Consider long-term relationships with your machine-builder in Bharuch: negotiate extended maintenance contracts, parts-replacement agreements, and upgrade paths.

Local Regulations & Power Considerations in Gujarat

Since you plan to operate in Bharuch, keep in mind these regional factors:

-

Electric Power Supply: Industrial establishments normally have 3-phase electric supply. Verify voltage stability and factor in any back-up or surge-protection needs.

-

Factory Licensing & Pollution Norms: Depending on the site, you may need to comply with Gujarat factory regulations, labour laws, and ensure minimal noise & dust (especially paper dust).

-

Fire Safety: Binding machines often heat up (hot-melt gluing); ensure fire-safe installation, vents, fire extinguishers, and compliance with local fire-department norms.

-

Labour Welfare: Provide training & safety gear to operators; document SOPs (standard operating procedures) as required by Gujarat state labour authorities.

How to Get Started

-

Specification Outline: Prepare a requirement sheet — formats, volumes, binding types, budget, space available.

-

Request for Quote (RFQ): Contact 2–3 manufacturers or machine-builders in or near Bharuch; share your spec sheet.

-

Visit Demo: Ask for a demonstration or video of similar installations. Evaluate the precision, noise level, ease of maintenance.

-

Negotiate Contract Terms: Price, delivery time, installation, training, support period, warranty, spare parts.

-

Install & Commission: Ensure on-site commissioning. Train your team. Run a trial batch. Monitor rejects and fine-tune calibration.

-

Review Performance: After one production month, calculate throughput, downtime, maintenance cost; decide if you’ll upgrade or scale further.

Conclusion

Choosing the right notebook making machine in Bharuch, Gujarat involves evaluating multiple factors — machine capability, automation level, supplier reliability, and long-term support. By opting for a local or regional supplier with proven experience, you gain advantages in cost, customisation, and service.

Whether you’re building a new production line or upgrading existing equipment, a carefully selected notebook production system will help you deliver consistent, high-quality stationery products, meet deadlines, and scale your business efficiently.