Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

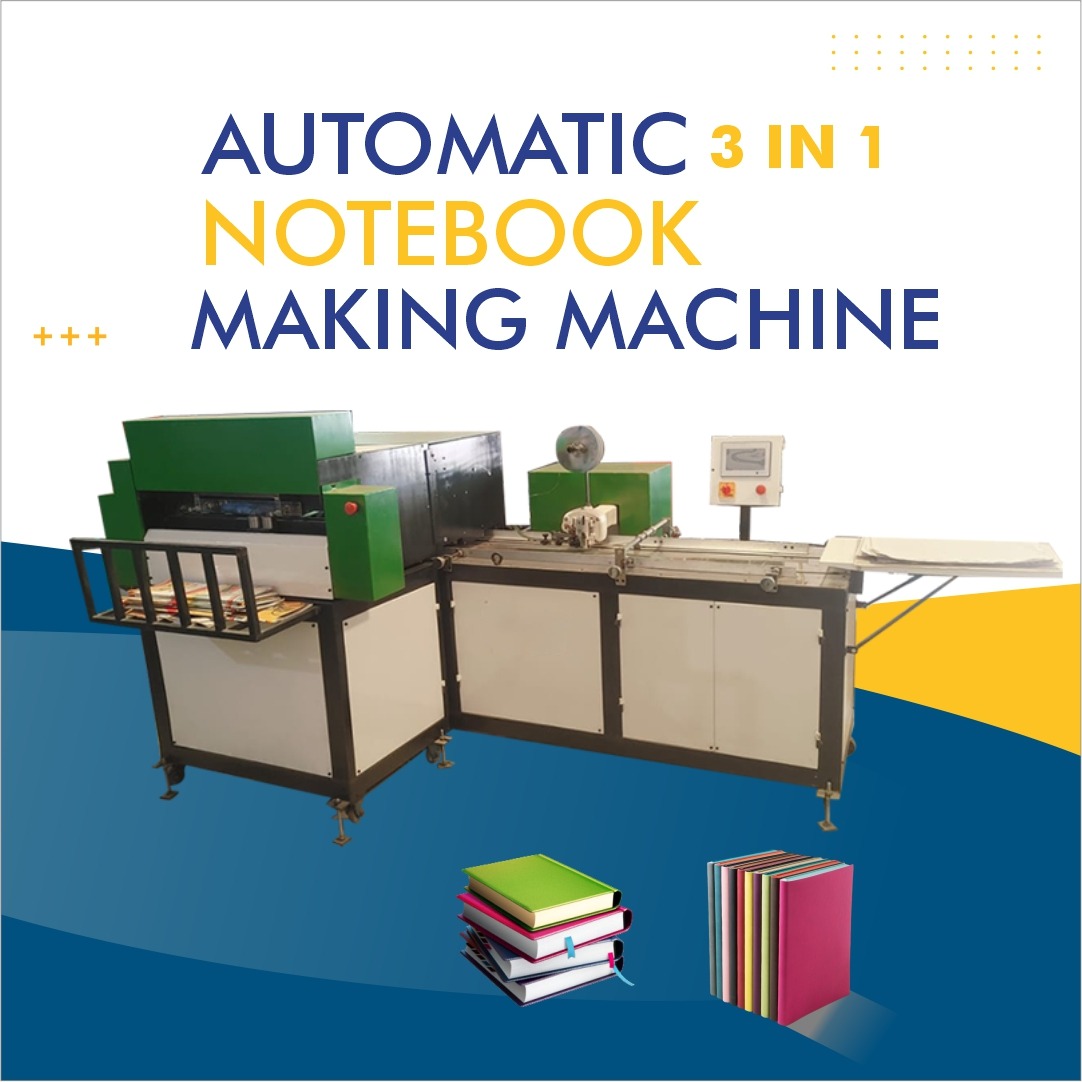

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine – Vodlemol Cacora Goa | Precision Equipment for Bulk Production

Notebook Making Machine Vodlemol Cacora | Goa

Vodlemol Cacora Goa is fast becoming a hub for precision machinery manufacturing, especially in the notebook industry. If you are searching for a reliable notebook making machine provider in Goa, our facility at Vodlemol Cacora offers end-to-end solutions — from cutting and stitching pages to binding and finishing the covers. Our expertise in notebook production equipment ensures you can launch or scale your stationery business with high quality output.

In this detailed overview, you will learn about our capabilities, the features of our machines, and why our location in Vodlemol Cacora Goa gives you an edge in cost, logistics, and service.

2. Why Choose Vodlemol Cacora Goa for Notebook Machinery

Strategic Location

Our facility is located in Vodlemol Cacora, Goa — offering logistical advantages for coastal shipping as well as domestic distribution across Maharashtra, Karnataka, and southern India.

Skilled Workforce & Custom Engineering

At Vodlemol Cacora, we combine qualified mechanical engineers and local skilled labor to deliver customized exercise book maker lines. We can alter speed, sheet size, binding style, and materials to suit your production workflow.

Compliance & Quality Standards

We design our equipment to meet international safety and quality standards. Our clients benefit from robust build quality and after-sales support, making our journal binder machine lines both durable and reliable.

3. What We Offer: Notebook Making Machine / Production Line

Our notebook production equipment is modular and scalable. Some of the primary components include:

-

Paper cutting & trimming unit: Precision guillotine cutters for trimming edges to exact dimensions.

-

Page collating / stitching unit: Automatic collating arms and sewing or stitching heads to assemble pages.

-

Punching / perforation station: For ring binding or punched notebooks.

-

Cover feeding & gluing station: For perfect binding or case-bound covers.

-

Pressing & finishing module: For smoothing, flattening, and finishing edges.

-

Control panel & PLC interface: For speed control, error detection, and monitoring uptime/downtime.

These modules form a complete bulk notebook manufacturing line capable of producing hundreds to thousands of notebooks per hour, depending on size and binding style.

4. Synonyms & Variants: Understanding Your Machinery Options

In order to help you find the right equipment, note that “notebook making machine” may also be referred to as:

-

Exercise book maker – equipment specifically tuned for student-size bound exercise books.

-

Journal binder machine – tailored for premium or hardcover journals.

-

Note binder system – a broader term involving binding and finishing.

-

Paper binding system – the subsystem that binds pages and cover.

-

Automated binder equipment – emphasizing automation and production speed.

We strive to ensure each variant is well-supported at our Vodlemol Cacora facility, so whether you need an automated binder equipment line or a manual-hybrid note binder system, we can deliver.

5. Technical Specifications & Customization

To meet the diverse preferences of stationery manufacturers, our machines include:

-

Production speed: up to 600 notebooks per hour for A4 or A5 formats (configurable).

-

Binding style options: staple / stitched binding, glue-binding, spiral or wire-binding, ring-binding (via punch).

-

Sheet size range: Standard A4, A5, B5 or custom dimensions.

-

Material thickness capacity: up to 200 gsm paper; cover board up to 300 gsm.

-

Interface: PLC touch-screen panel, with preset programs for page count, stitch count, and production run tracking.

-

Power supply: Compatible with Indian industrial standards (380 VAC, three-phase), with optional generator compatibility.

-

Safety features: Emergency stop switches, safety guards, overload protection.

Customization services include:

-

Adapting the machine footprint to your factory layout in Vodlemol Cacora Goa.

-

Integrating ancillary systems (e.g. packaging conveyor, shrink-wrap station).

-

Training your operators on machine setup, maintenance, and troubleshooting.

6. Applications & Use Cases

Our notebook making machine lines serve various industries and product types:

-

School stationery manufacturers producing exercise books in bulk for academic markets.

-

Corporate gifting firms offering promotional notebooks with custom branding.

-

Custom‐printed journals and diaries for retailers or event merchandise.

-

Publishing houses needing in-house binding capacity for small print runs.

By integrating our bulk notebook manufacturing solutions, you reduce reliance on outsourcing, cut lead times, and improve per-unit margins while maintaining consistent quality.

7. Installation, Support & After-Sales in Goa Region

Because our facility is in Vodlemol Cacora Goa:

-

We provide site survey and installation support at your factory location.

-

Local parts inventory reduces downtime — common spares such as blades, belts, sewing heads are stored regionally.

-

Training and maintenance contracts are available for nearby customers in Goa, Karnataka, and Maharashtra.

-

Remote diagnostics via PLC interface so we can guide your technical team in real time.

8. Cost & Investment Considerations

When evaluating your ROI on a journal binder machine or exercise book maker, key cost drivers include:

-

Machine base price (depends on configuration and speed).

-

Shipping & customs duties (local transport within Goa is competitive due to our proximity to ports).

-

Installation & commissioning charges.

-

Operator training and maintenance contract fees.

-

Energy consumption (we optimize for efficiency to lower your electricity cost).

Compared with imported equipment, sourcing locally from Vodlemol Cacora Goa often yields lower lead time, lower shipping costs, and faster service access.

9. How to Procure / Next Steps

To begin the procurement process:

-

Contact our sales team with your specifications – page count, size, binding style, capacity per hour.

-

We’ll prepare a proposal including layout drawings, equipment cost, and installation timeline.

-

On-site survey at your factory location to verify utilities, space, and workflow.

-

Sign off on final design; place purchase order.

-

Machine delivery, installation, testing, operator training, and handover.

-

Post-installation support: warranty period, preventive maintenance, spare-parts supply.

We recommend early engagement to allow up to 8-10 weeks for manufacturing customization, followed by another 2-4 weeks for installation and commissioning.

10. Why Our Solutions Lead the Market

-

High Reliability: Engineered for minimal downtime and long service life.

-

Scalability: You can upgrade or expand later with add-on modules (e.g. automatic cover feeder, shrink wrap station).

-

Local Presence: Being based in Vodlemol Cacora Goa means faster response times and lower service overhead.

-

Tailored Designs: Unlike off-the-shelf imports, our designs consider your factory layout, binding style preferences, and production volumes.

-

Value for Money: Competitive pricing, flexible payment terms, and lower lifecycle cost compared to fully imported alternatives.

Conclusion

If you are planning to start or upgrade your notebook manufacturing unit in Goa or southern India, our notebook making machine lines at Vodlemol Cacora are ideal. With full customization, installation support, and local after-sales service, we help you achieve high-speed, high-quality notebook production equipment solutions.

Reach out today to discuss your production capacity goals, binding preferences, and site constraints — and let us design a tailor-made line that delivers consistent output, quality, and profitability.