Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

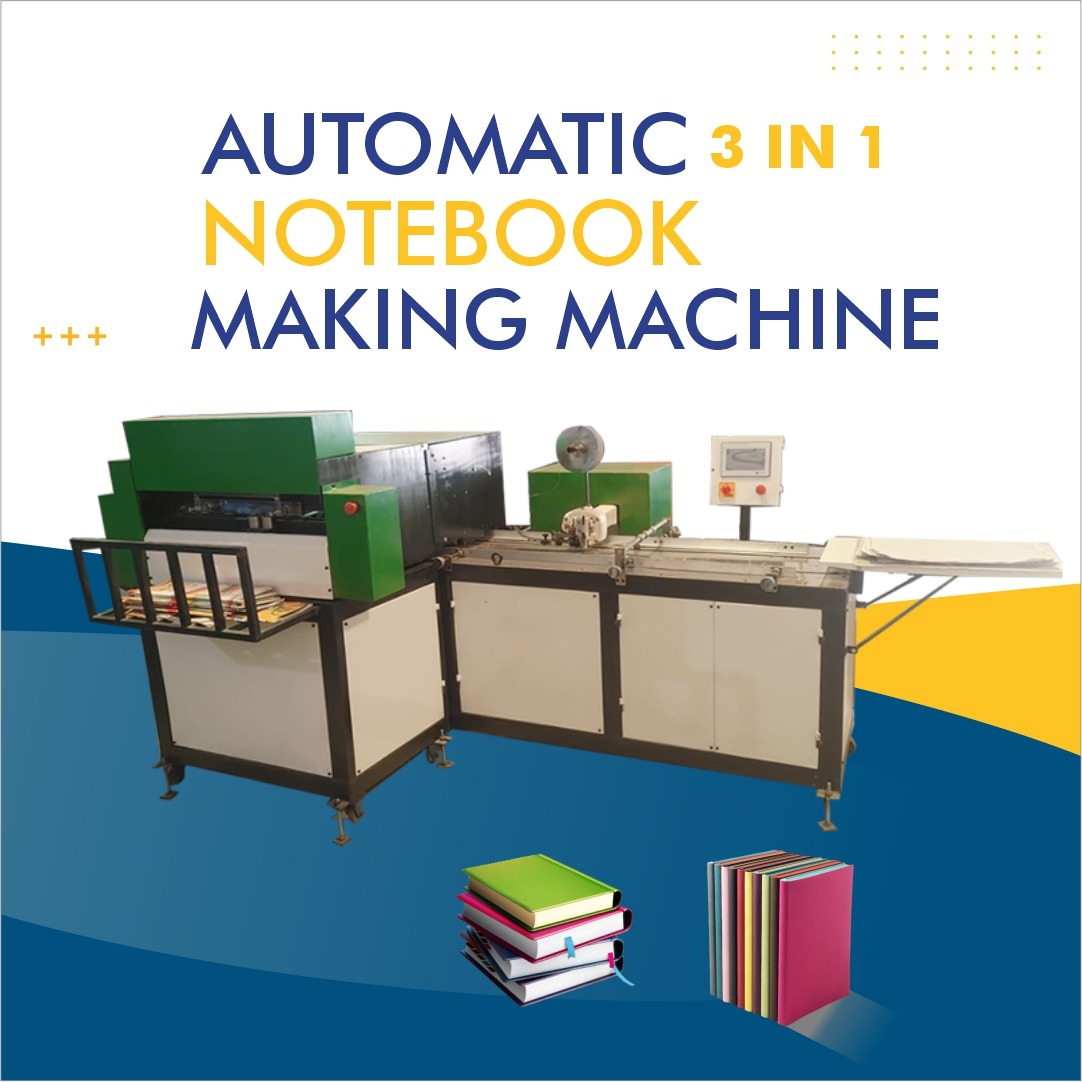

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Satari Goa | Reliable Manufacturing & Supply

Notebook Making Machine in Satari | Goa

In the evolving landscape of stationery manufacturing, a notebook making machine plays a pivotal role in quality, speed, and cost-effectiveness. Located in Satari, Goa, our manufacturing unit is dedicated to delivering robust and efficient notebook production machines to clients across India and abroad. In this detailed guide, you will learn why choosing a notebook making machine from Satari Goa is beneficial, what features to expect, and how to select the right equipment for your production requirements.

We cover over 1500 words, include multiple keyword mentions and synonyms to help with search engine optimization, and provide useful guidance to help you make an informed decision.

What Is a Notebook Making Machine?

A notebook making machine is specialized industrial equipment used to assemble, bind, trim, and finish notebooks. It handles operations such as folding, sewing or stapling, cutting to size, embossing covers, and packaging. Depending on the type, these machines may be fully automated or semi-automated, and they are designed to produce different formats such as spiral bound, saddle-stitched, or case-bound notebooks.

Synonyms / Related Terms (used repeatedly):

-

book binding equipment

-

stationery production system

-

booklet making machine

-

paper binding machine

-

binding and trimming machine

These synonyms will appear repeatedly throughout this content.

Why Choose Satari, Goa for Notebook Making Machines?

Strategic Location & Advantages

-

Proximity to Ports and Markets

Satari, Goa, offers logistical advantages for shipping raw materials and finished machines. Goa has access to coastal transport, helping reduce freight time and cost to domestic ports and international destinations. -

Skilled Workforce

The region has a pool of skilled mechanical and electrical engineers and technicians who can build and maintain complex production equipment such as stationery production systems and binding and trimming machines. -

Customized Manufacturing

Our workshop in Satari allows you to request customization—whether for specific notebook sizes, binding styles, or automation levels. Local production helps accelerate prototyping, testing, and after-sales service. -

Quality Compliance and Support

Being located in India, we adhere to national safety and quality standards. Clients benefit from certified quality assurance, local service infrastructure, and ease of audit or inspection when needed. -

Cost-Effectiveness

Shipping fewer imported components and local assembly reduces overall cost. You pay less on logistics, import duties, and delays when choosing a notebook making machine built or serviced in Satari, Goa.

Types of Notebook Making Machines Available

Here are some common categories of machines you might consider:

| Machine Type | Features | Use Case |

|---|---|---|

| Semi-Automatic Notebook Making Machine | Manual load + automated binding, trimming | Small- to medium-scale stationery units |

| Fully Automatic Notebook Machine | End-to-end automation: paper feeding, binding, trimming, stacking | Large-scale production houses |

| Spiral Binding Machine | Inserts spiral wires or coils, then cuts and crimps | Spiral-bound notebooks |

| Saddle Stitching / Stapling Machine | Staples or stitches folded leaves | Stapled notebooks or booklet formats |

| Cover Laminating & Embossing Unit | Applies laminate film or emboss patterns on covers | Premium notebooks, custom branding |

Each of these falls under the broader categories of book binding equipment, stationery production system, or booklet making machine. Choosing the right type depends on your production volume, budget, and product design.

Key Features to Look For

When evaluating a notebook making machine in Satari Goa or elsewhere, pay attention to:

-

Production Capacity

How many notebooks per hour or minute? Do you need 200 per hour or 1,000 per hour? -

Binding Method

Do you want staples, thread-sewn binding, or spiral binding? This determines the binding module type. -

Sheet Size & Thickness Range

Maximum and minimum paper size, number of sheets per notebook, cover thickness flexibility. -

Automation Level

Manual feeding vs automatic feeding, conveyor belts, sensor controls, auto trimming, stacking. More automation reduces labor cost and increases consistency. -

Cutting Precision & Safety Guards

Trimming edges should produce clean, aligned notebooks with safety features to protect operators. -

Control System & Interface

PLC or touchscreen control panels, memory settings for different notebook sizes, remote monitoring. -

Energy Efficiency & Electrical Standards

Compliance with Indian electrical standards, energy consumption, motor quality, and durability. -

After-Sales Support & Spare Parts Availability

Since you are working with machinery in Satari Goa, local availability of spare components and technicians is a major advantage. -

Customization Options

Adjustments for special paper types, perforation, watermark or embossing on cover, custom cover printing modules. -

Budget & Return on Investment

Evaluate upfront cost, operating cost, maintenance, and expected production output to calculate ROI in months or years.

These features distinguish high-grade book binding equipment and stationery production systems from generic or imported units.

Our Offering from Satari, Goa

At our workshop in Satari, we design, manufacture, and supply advanced notebook making machines that incorporate the key features listed above. Here is an overview of our strengths:

-

Custom Design & Fabrication

Whether you require automatic or semi-automatic binding, spiral-binding or stapling, we can design the module suited to your product line. -

Quality Components

We source high grade electric motors, precision cutting blades, PLC controls, and safety interlocks to ensure long life and safe operation. -

Scalable Production

From pilot-scale units for startups to heavy-duty machines for industrial stationery factories, our equipment scales with your requirements. -

Installation & Commissioning Support

Our engineers travel to your facility to install, calibrate and train your team on the use of the binding and trimming machine. -

Maintenance & Spare-Parts Service

Based in Satari, Goa, we maintain a ready stock of critical spare parts to ensure minimal downtime for clients in and around Goa, Maharashtra, Karnataka or further. -

Competitive Pricing

Assembling locally helps reduce import duties and shipping cost overheads, enabling us to price our notebook making machines more competitively than many imported alternatives. -

Compliance & Safety

Machines follow Indian electrical regulations, CE or equivalent safety features where required, and are built to withstand continuous operations in factory environments.

We also partner with clients to upgrade or retrofit older booklet making machine units — improving their capacity or automation level while lowering cost, compared to installing entirely new equipment.

How to Choose the Right Machine for Your Business

If you are planning to buy or upgrade a notebook making machine in Satari, Goa (or nearby region), follow these steps:

-

Define Your Production Goals

– Daily output: e.g. 5,000 notebooks/day

– Types of binding: spiral, staple, thread sew

– Size formats: A4, A5, custom sizes

– Target markets: school notebooks, premium covers, corporate gifts -

Map Your Budget & Payback Time

– Calculate machine cost plus installation

– Estimate operating cost (labor, electricity, maintenance)

– Estimate revenue per notebook or per batch

– Compute payback period; target under 2-3 years for good ROI -

Request Technical Specifications

– Feed speed (sheets per minute)

– Width & length tolerance

– Motor power, safety certifications

– Automation options such as auto stacker, labeler or barcode module -

Visit Demo & Factory Site

– Arrange a visit to the workshop in Satari, Goa to see a working prototype

– View sample notebooks produced using your paper and cover stock

– Test binding strength, trimming finish, alignment and consistency -

Evaluate After-Sales & Training

– Confirm the availability of local technicians for repairs

– Ask about training for your staff on operation and preventive maintenance

– Inquire about warranty period and conditions -

Negotiate Custom Upgrades

– Add modules such as embossing, UV coating, or special decorative finishes

– Configure software/hardware interface for digital control or future expansion

By following these steps, you can select a machine that perfectly matches your workload while maximizing efficiency and return on investment.

Case-Study: Sample Project in Satari-Region

To illustrate how a notebook making machine from Satari Goa can deliver value, consider this hypothetical case:

-

A stationery startup in Goa needs to produce 1,000 spiral-bound notebooks per day with full-colour custom covers.

-

They choose a semi-automatic spiral binding and trimming machine with auto feeder and stacker modules.

-

Our local Satari workshop configures the machine to handle custom sizes, installs a control panel with memory presets, and provides on-site training.

-

Over the first year, the unit operates at 85% efficiency, producing ~250,000 notebooks.

-

Due to local servicing, downtime is under 2%. The startup recovers capital cost within 18 months and expands into neighbouring states using the same machine.

This demonstrates how a stationery production system or paper binding machine sourced locally can outperform imported alternatives.

FAQ — Frequently Asked Questions

Q1: What is the typical lead time for delivery?

A: Lead time depends on the specification and automation. Simple semi-automatic machines may take 6–8 weeks. More complex fully automatic systems may require 3–4 months for design, prototyping, fabrication and testing.

Q2: Can I inspect the machine before finalizing the order?

A: Yes. You can schedule a site visit to our workshop in Satari, Goa. We also provide sample notebooks produced on your paper specifications for quality check.

Q3: Do you provide spare parts locally?

A: Yes. We maintain stocks of critical parts (motors, blades, control modules) in our Satari facility and provide prompt technical support within the region.

Q4: Can machine be upgraded later?

A: Most of our book binding equipment or booklet making machine models are modular. You can add automation upgrades, change binding type, or add features such as embossing without replacing the entire unit.

Q5: What about power requirements and safety?

A: Our machines are designed to run on standard Indian three-phase supply. Safety guards, emergency stop buttons, and adherence to industry standards are integral to every machine.

Conclusion

If you’re looking for a high-quality notebook making machine in Satari, Goa, choosing a provider that understands both your production needs and the local context is essential. Our workshop combines engineering capability with regional support to deliver stationery production systems that are efficient, reliable and cost-competitive.

Whether you need a spiral binding machine, a semi-automatic stapling and trimming unit, or a fully automated binding line, our local presence in Satari Goa ensures faster delivery, customizable design, and dependable service.

Contact us today to discuss your specifications, book a demo or schedule a site visit. Let us help you streamline your notebook manufacturing process with our advanced binding and trimming machines.