Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

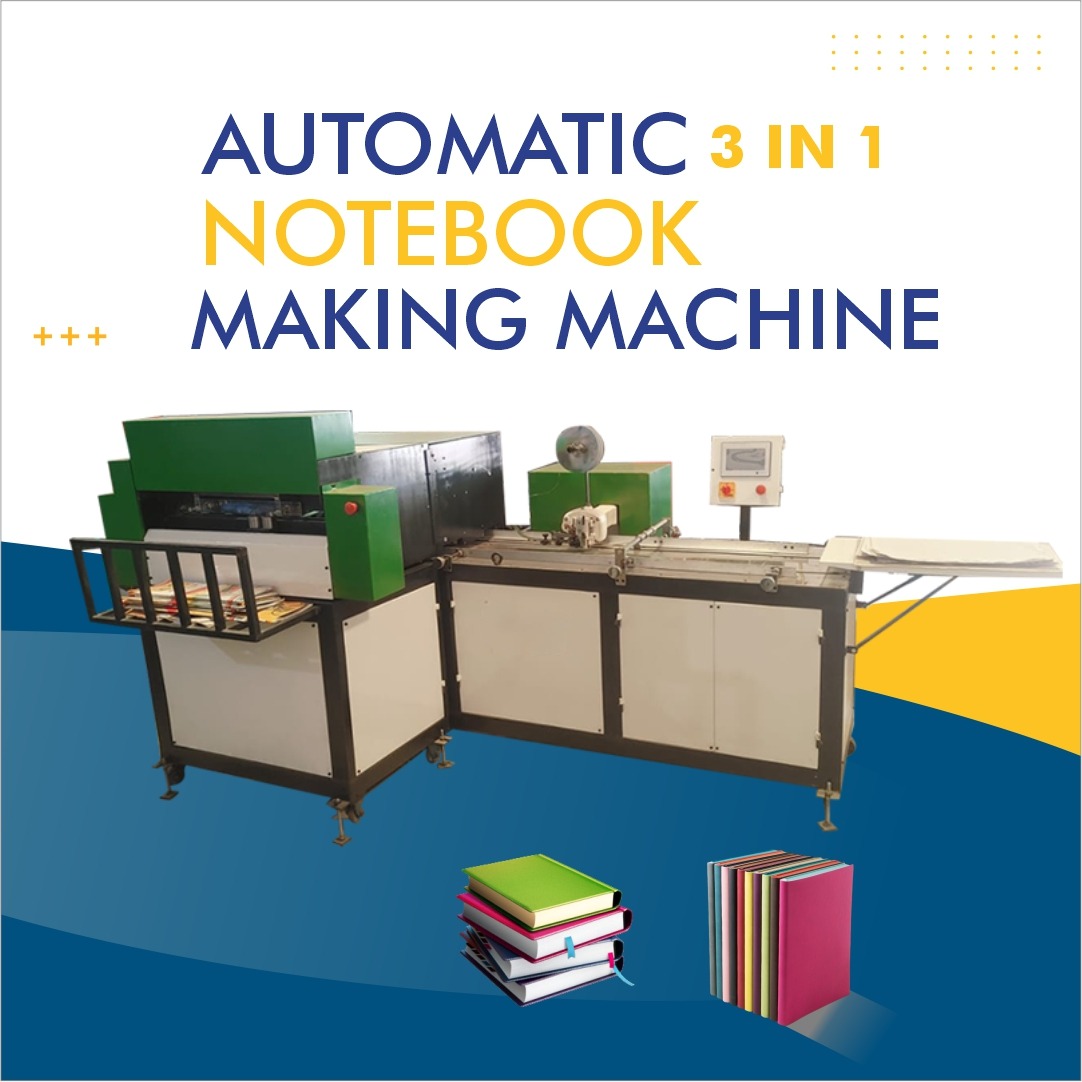

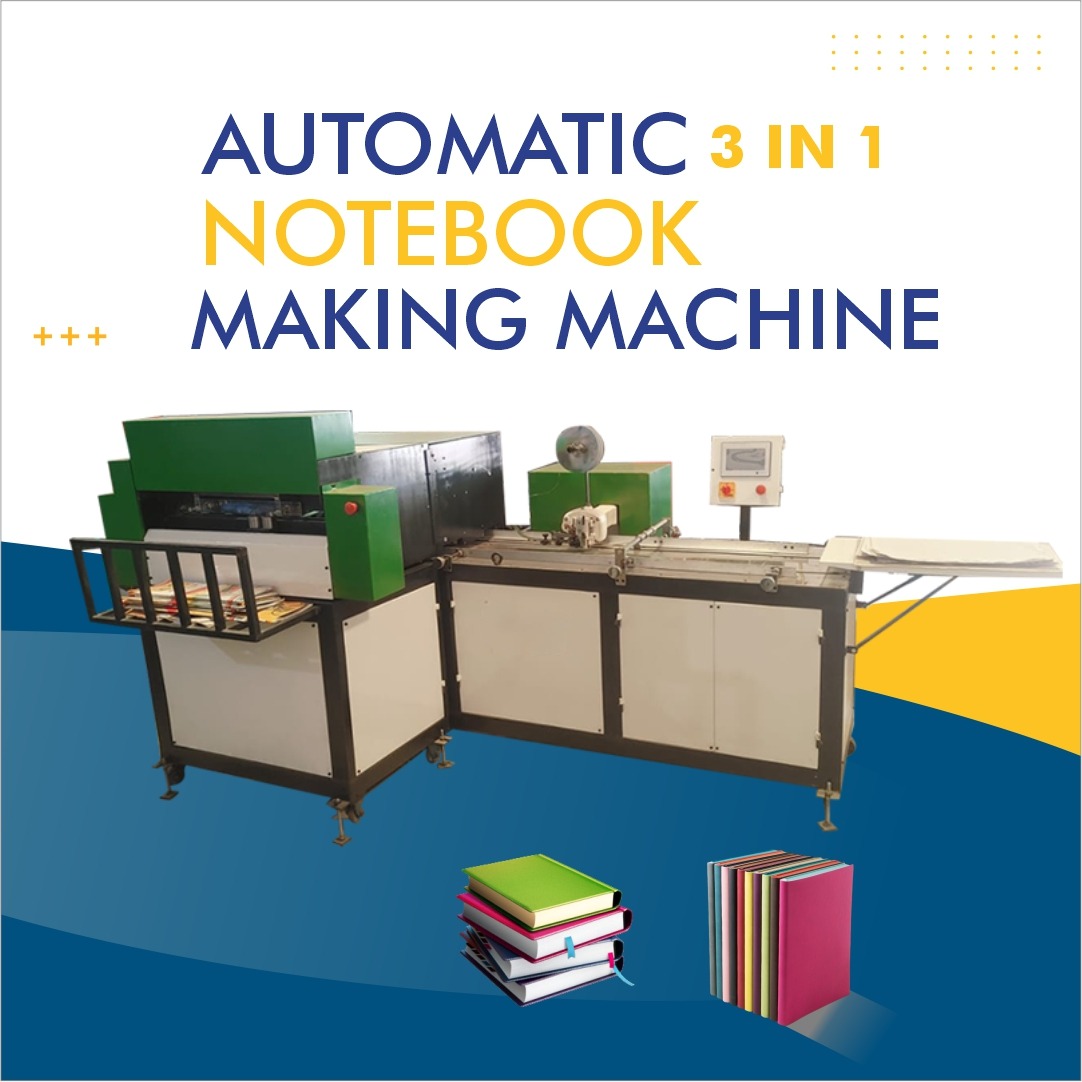

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Manufacturer & Supplier — Pernem Goa

Notebook Making Machine Pernem | Goa

If you are looking for a top-of-the-line notebook making machine in Pernem, Goa, you have come to the right place. Whether you run a stationery factory, school-stationery business or a packaging unit that wants to diversify into book production, investing in the right notebook making machine is crucial. This comprehensive guide walks you through key features, types, benefits, installation, maintenance, and how you can source the best equipment in Pernem.

Why Choose Notebook Making Machine in Pernem, Goa

Pernem is gaining recognition as a hub for light manufacturing in North Goa. Locating your notebook making machine nearby means faster logistics, easy service support, and reduced downtime. By selecting a local supplier or installer, you benefit from on-site demonstrations and quicker spare-parts delivery. Local vendors familiar with Goa regulations and power standards can help you install your notebook making machine with greater ease and compliance.

Types of Notebook Making Machines

Notebook making machines come in several variants depending on production scale, automation level, and binding style. Here are some common types:

-

Semi-automatic flat notebook making machine

This type lets you feed paper manually or semi-automatically, and performs cutting, binding (stitching or glue), and trimming. It is ideal for small to medium-scale notebook manufacturers. -

Fully automatic notebook maker

A high-capacity machine that performs all steps (cutting, binding, trimming, cover cutting) automatically with minimal human intervention. Suitable for larger operations. -

Wire–O binding or spiral binding machine

For notebooks that require spiral binding or wire binding instead of traditional stapled binding. Such machines may be add-on attachments or integrated modules. -

Blind-stitch / saddle-stitch binding machine

These machines stitch or staple the spine ‘plaint-style’. Useful for notebooks of moderate thickness. -

Custom or hybrid machines

Some notebook making machines combine features—e.g. detachable cover cutting, cover printing alignment, embossing modules or perforation units.

Each variant will differ in output speed (sheets per hour), paper size compatibility, maximum thickness (number of sheets), and ease of changeover.

Key Features to Look For

When evaluating notebook making equipment, consider:

-

Production Capacity: How many notebooks per hour or per shift. For example, a semi-automatic machine might produce a few hundred per hour, while a fully automatic model could reach thousands.

-

Paper Size & Format Compatibility: Ability to accommodate standard sizes (A4, A5, custom formats) and adjust margins.

-

Binding Method: Stitching (wire staples), glue binding, perfect binding or spiral binding. The binding type affects machine design.

-

Cutting Accuracy: Precision knife or guillotine cutters to trim edges uniformly.

-

Ease of Operation: User-friendly control panel, safety guards, error detection.

-

Materials & Durability: Quality steel frame, wear-resistant components, long-lasting blades or stitching heads.

-

Power Requirements & Energy Efficiency: Conformance to Goa / India power specifications and safe grounding.

-

Service & Maintenance Support: Local availability of technician support and spare parts in Pernem or nearby Goa cities like Mapusa or Panaji.

-

Flexibility & Scalability: Ability to upgrade modules later — for example adding spiral binder or embossing station.

Benefits of Installing a Notebook Making Machine

Investing in a notebook making machine yields several benefits:

-

Cost Efficiency

Manufacturing notebooks in-house drastically reduces procurement costs and improves margins. You avoid middle-man mark-ups, and you control raw-material usage more closely. -

Quality Control

You can monitor every step — paper cutting, binding, trimming — for defects or misalignment. That ensures your notebooks meet your quality standards consistently. -

Faster Turnaround

On-site production means you don’t have to wait days or weeks for external vendors. Especially useful if you handle bulk orders or seasonal demand (e.g. school term supplies). -

Customisation & Flexibility

You can adjust formats (size, cover design, thickness), use special paper or cover stock, or introduce custom binding styles without depending on third-party manufacturers. -

Revenue Diversification

A notebook machine can form the backbone of a stationery manufacturing line. Once you produce notebooks, you can scale to diaries, planners or customised booklets.

How to Source a Notebook Making Machine in Pernem

To acquire the right machine for your requirements in Pernem, follow these steps:

-

Requirement Assessment

Determine your annual or monthly production targets, the types of notebooks you want to produce (size, page count, binding style), and the level of automation you require. -

Vendor Shortlisting

Find suppliers who can deliver to Goa. Check for vendors who can show previous installations in Goa or nearby Maharashtra/Karnataka. Ask for references or site visits. -

Quotation & Comparison

Obtain detailed quotations that specify machine speed, accuracy, warranty terms, spare-parts availability, installation cost and power specifications. Compare upfront cost vs long-term operating cost. -

Site Visit & Demo

Request on-site demo of the machine (or video demonstration) to see sample notebooks produced. Insist on sample cutting margin errors, binding durability tests. -

Installation & Training

Ensure the supplier or technician will come to Pernem / Goa for installation, calibration, and staff training. Check lead times and shipping logistics. -

Compliance & Safety Certification

Ensure the machine adheres to Indian safety norms (e.g. electrical standards, mechanical safety guards). Check for CE-mark or BIS certifications if required. -

Maintenance Contract & Spare Parts

Negotiate a maintenance agreement. Ask for availability of consumables (blades, staples, glue cartridges) and preventive maintenance schedule.

Operating Steps of the Notebook Making Process

Below is a generic operation workflow when using a notebook making machine:

-

Paper Preparation

Sort and stack inner sheets and cover sheets as per size (for example A5 inner sheets). Align and feed into the cutter or stacking unit. -

Cutting / Trimming

The machine cuts the large paper roll or sheets into correct sizes for inner pages and covers. Precision trimming ensures no rough edges. -

Binding / Stitching

Bound either by wire-O / spiral / saddle stitching / glue. The binding unit applies staples or adhesive. The machine may punch holes or fold pages as needed. -

Cover Attachment / Lamination

Cover sheets (cardstock / printed cover) may be attached before or after binding. Some machines support lamination or UV coating of cover automatically. -

Final Trimming & Finishing

After binding, the notebooks pass through final trimming station to trim edges uniformly. Finishing modules may emboss logos, round corners or perforate pages. -

Inspection & Packaging

Each notebook is visually inspected. Faulty units are rejected or re-cut. Accepted notebooks are stacked or packed for dispatch.

Maintenance & Troubleshooting Tips

To keep your notebook making machine running smoothly in Goa’s humid climate (especially monsoon season), consider the following maintenance best practices:

-

Regular Cleaning

Remove paper dust, glue stains and cutting debris after every shift. Accumulation reduces cutting precision and may clog sensors. -

Lubrication

Apply manufacturer-recommended lubricants to bearings, guides, and moving parts. Check lubrication points monthly or as per machine manual. -

Blade / Cutter Replacement

Trimming blades dull over time. Schedule periodic inspection and replacement to maintain clean cuts. -

Stitching Head / Staple Cartridge Maintenance

If your machine uses staples or stitching heads, clean and inspect them for jamming. Replace worn components before they break mid-production. -

Moisture Control

Goa’s humidity can cause adhesive problems or slight paper deformation. Store stock materials in low-moisture-area. Ensure the machine is not placed in direct sunlight or damp corner. -

Electrical Checkups

Inspect wiring, safety interlocks, emergency-stop switches and sensors monthly. Make sure voltage fluctuations are controlled using stabilisers, as Goa may experience supply instability. -

Preventive Maintenance Schedule

Use a log book to record machines’ runtime hours, minor faults, and maintenance done. Schedule preventive maintenance quarterly with vendor or technician.

Case Study / Example Use Case

Suppose you operate a stationery business in Pernem or nearby Mapusa. You decide to install a semi-automatic notebook making machine with capacity of 500 notebooks/hour. After installation and staff training, you shifted from outsourcing production to in-house facility. Over one academic year, you saved approximately 30% on cost per unit compared to purchasing ready-made stock. You scaled up to offer customised notebooks for schools and printing houses in Goa. The local proximity of spare-part support ensured any minor downtime (say cutter misalignment) was fixed within 24 hours, thanks to technician visits from nearby Panaji.

This led you to expand your offerings to bound planners and diaries using the same machine with minor reconfiguration of the binding modules. The extra revenue offset the machine investment within 18–24 months.

Costs & Investment Estimate

While exact costs depend on model and features, you can expect the following approximate investment brackets:

| Tier | Machine Type | Approximate Investment* |

|---|---|---|

| Entry / Semi-automatic | Basic cutting + stitching model | ₹5,00,000 to ₹10,00,000 |

| Mid-level / Semi-automatic with trimming & adjustable formats | Higher speed & larger size range | ₹10,00,000 to ₹20,00,000 |

| Fully automatic notebook making line | High-speed production, automation modules | ₹20,00,000 to ₹50,00,000+ |

*Prices are indicative and depend on features such as binding method, automation level, brand, and freight / installation cost to Pernem, Goa.

Why Local Supplier Matters

Choosing a supplier who can deliver to Pernem Goa matters because:

-

Lower transport & freight cost

-

Local presence for urgent support & spare-part delivery

-

Easier installation and compliance with local power, safety, and environmental norms

-

Possibility of visiting a reference unit nearby to inspect real performance

How to Promote Your Notebook Business After Installing the Machine

Once your notebook making machine is up and running, here are ways to market your finished notebooks:

-

Target local schools, colleges and tuition centres in North Goa

-

Partner with local stationery stores to supply custom-printed notebooks

-

Offer personalized covers (Goa tourism-themed art, local language printing)

-

Set up an online order portal or tie-up with e-commerce platforms targeting Goa region

-

Exhibit at local trade fairs in Panaji or Mapusa to showcase your product quality

Conclusion

Investing in a notebook making machine at Pernem, Goa can be a game-changer for your stationery or printing business. It helps you control quality, reduce costs, scale production, and offer customised solutions. By carefully evaluating features, choosing the right automation level and securing local maintenance support, you can build a sustainable business with reliable production capacity.