Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

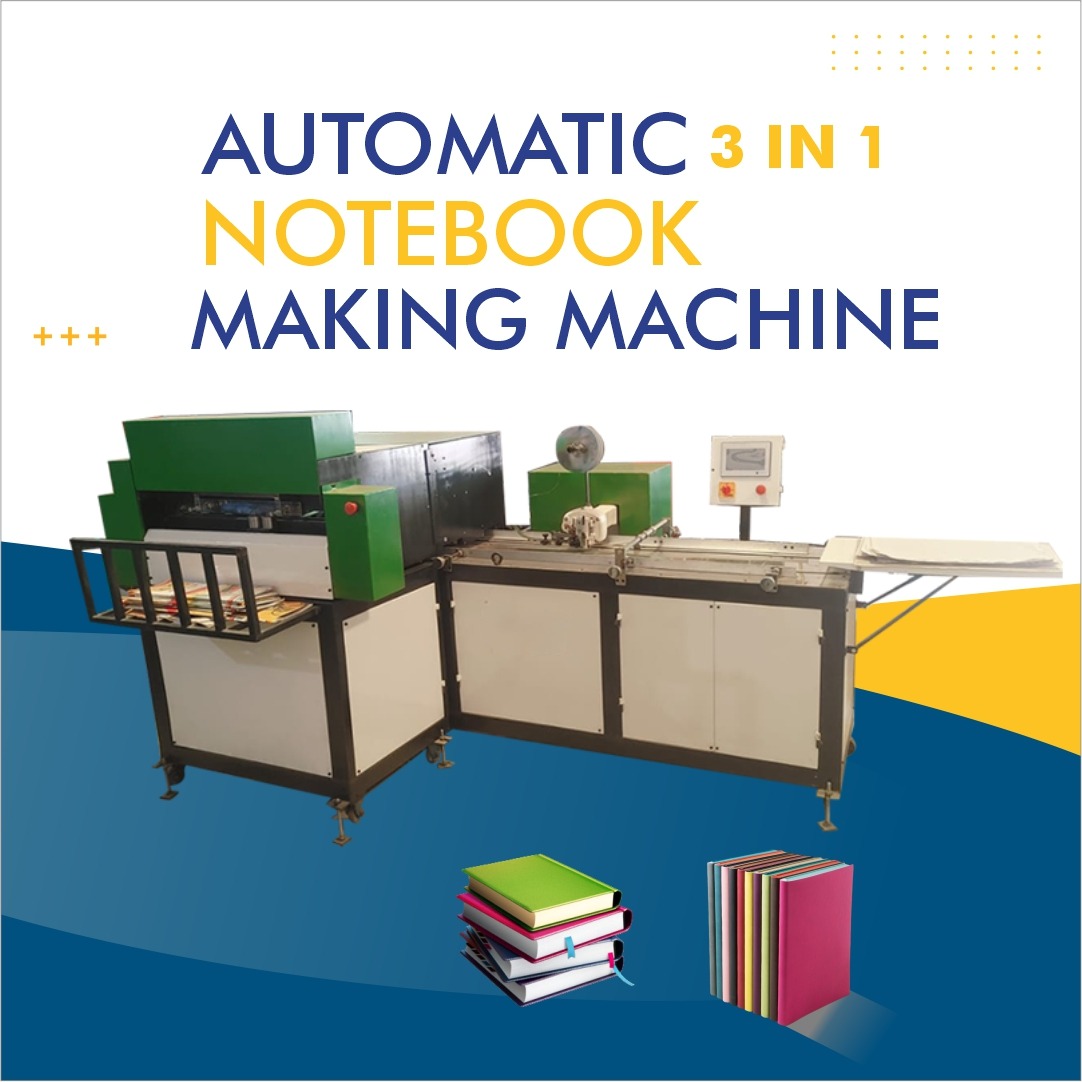

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine – Bandoda (Goa) | Supplier & Manufacturer

Notebook Making Machine – Bandoda | Goa

Welcome to our comprehensive guide on notebook making machines offered in Bandoda, Goa. Whether you are planning to establish a small-scale stationery workshop or scale up into full-scale notebook production, the right notebook manufacturing equipment is critical. In this article, we explain how to choose the best machine, types of machines, our local presence in Bandoda, the benefits of our equipment, technical specifications, and manufacturing considerations.

We also share how our stationery production equipment can help reduce costs, increase efficiency, and ensure consistent quality in notebook output.

Why Choose Bandoda, Goa for Your Notebook Making Machine Supplier

Strategic Location

Bandoda is a growing industrial area in Goa, with good transport connectivity that links to Goa’s ports, roads and supporting infrastructure. Setting up or procuring equipment here gives you logistical advantages for raw materials like paper, binding wire or coils, covers, and transporting finished notebooks.

Local Support & Service

Choosing a notebook making machine supplier near Bandoda ensures local after-sales service, prompt technical support, spare parts availability, and quicker installation times than sourcing from distant cities. We understand the regional business environment, compliance with state regulations, and local labor force.

Cost Advantages

Being locally based or sourcing locally reduces transportation cost, customs/import duties (if parts are pre-manufactured nearby), and allows you to respond swiftly to production demand. This is especially helpful for stationery businesses servicing Goa, Karwar, Mangalore, and neighboring regions.

Types of Notebook Making Machines & Equipment

Here are several types of notebook making machines commonly used in notebook manufacturing setups:

-

Automatic Book Binding Machine

A machine designed to bind sheets, attach covers, apply glue or stitching, and cut the edges to produce final notebooks. This reduces manual labor and improves consistency. -

Spiral Notebook Machine

Equipment specifically made to punch holes, insert and bind spiral coils or wires. Ideal for spiral-bound notebooks or planners. -

Writing Pad / Note Pad Making Machine

For stacking paper, cutting to size, binding at the top edge, and packaging writing pads. These machines often combine trimming, backing board attachment, and shrink-wrapping options. -

Stationery Production Equipment (Cutting / Trimming / Collating Units)

These units perform pre-binding tasks such as cutting paper to the right formats (A4, A5, custom shapes), collating pages in sequence, aligning cover pages, and quality-checking. -

Paper Product Machine (Folding / Laminating / Coating Units)

Supplementary machines that work with the main binding or cutting machine to laminate covers, coat pages, or fold inserts.

Each machine above may be purchased as a standalone unit or integrated into a production line.

Key Technical Parameters to Consider

When choosing a notebook making machine or notebook manufacturing equipment, consider the following features:

-

Capacity (units per hour or per minute): How many notebooks the machine can produce in one shift.

-

Binding Type: Glue binding, stitch binding, spiral binding, wire-O binding.

-

Paper Size Compatibility: Standard sizes (A4, A5, custom sizes).

-

Thickness and Page Count: Maximum number of pages or paper thickness the machine can handle.

-

Automation Level: Manual, semi-automatic, or fully automatic.

-

Precision & Tolerance: Tolerances for cutting edges, alignment of binding, hole-punch accuracy.

-

Materials Compatibility: Types of paper stock, cover board material, lamination or coating options.

-

Power & Energy Consumption: Electrical rating and compliance with local safety norms.

-

Footprint: Size of the machine and space required in your facility in Bandoda.

-

Safety Features & Certifications: Safety guards, emergency stop buttons, compliance with BIS (Bureau of Indian Standards) or CE markings (if relevant).

-

Maintenance & Spare Parts: Availability of spare parts locally in Goa; ease of servicing mechanical or electrical components.

By optimizing these parameters, you can ensure your stationery production equipment meets output, quality, and cost-efficiency goals.

Benefits of Investing in a Quality Notebook Making Machine

Investing in a high-performance notebook making machine offers several advantages:

-

Increased Productivity & Speed: Automation reduces manual handling and accelerates production cycles.

-

Improved Quality & Consistency: Machines deliver consistent binding, neat edges, and uniform cut lines across batches.

-

Lower Labor Costs: Fewer personnel needed for repetitive tasks like trimming, stamping, or binding.

-

Customization Flexibility: You can offer customized sizes, branded covers, or special formats (grid, ruled, plain pages) with the right equipment.

-

Scalability: When demand rises, your machinery can scale up – either by increasing shifts or upgrading modules.

-

Return on Investment: Though initial cost may be high, the increased throughput and reduced waste typically lead to ROI in a defined period (often months to a few years).

-

Competitive Advantage: Having efficient notebook manufacturing equipment gives you the capability to fulfill bulk orders quickly and deliver products reliably.

Our Services & Offering in Bandoda, Goa

If you choose us as your local notebook making machine provider, here’s what we offer:

-

Custom Machine Design & Supply: We can tailor specifications (size, capacity, binding type) to suit your production targets and workspace in Bandoda.

-

On-Site Installation & Commissioning: Our team visits your factory in Bandoda / nearby areas to install the machine, calibrate settings, and train your staff.

-

After-Sales Support & Maintenance: Local technicians available to repair, service, or upgrade your stationery production equipment.

-

Spare Parts & Consumables: We stock standard spares for binding heads, cutting blades, motor drives, and control panels within Goa.

-

Training & Process Optimization: We help you optimize feed rates, reduce paper waste, and ensure smooth operation right from day one.

Case Study: Local Notebook Production Setup at Goa

Consider a small-scale notebook manufacturer setting up in or near Bandoda. They require about 1,000 notebooks per day, sized A5 with 60 pages each, spiral bound, with laminated covers.

By selecting a mid-range spiral notebook machine, plus a trimming/cutting unit and a collating feeder, they can achieve output targets with minimal wastage.

A properly calibrated automatic binding machine can integrate with the trimming unit and reduce manual finishing work. Maintenance is handled by local technicians who respond within 24 hours. Over a year, this setup leads to consistent delivery to local schools and stationery retailers across Goa.

This real-life scenario illustrates how choosing the right local supplier in Bandoda, Goa for notebook manufacturing equipment delivers tangible benefits in cost-control, product quality and business scaling.

Cost Considerations & Budget Planning

When budgeting for a notebook making machine, consider the following factors:

-

Capital Cost: Price of the machine itself, including any custom modifications.

-

Installation & Shipping: Transportation cost to bring the machine to Bandoda, Goa; any taxes or freight charges.

-

Customs / Import Duties: If parts are imported, include applicable duties or compliance cost.

-

Operational Costs: Electricity, routine maintenance, consumables such as binding coils, glue, paper trimming blades.

-

Labor & Training: Staff time needed for operation and supervision; training fees for technicians.

-

Depreciation & Financing: How you amortize cost over useful life, or finance interest if you take a loan.

-

ROI Timeline: Estimate how long it will take to recover investment given your daily production volume, pricing of your finished notebooks, and material costs.

By planning carefully and working with a reliable notebook manufacturing equipment provider, you can ensure your investment yields profitable operation.

Tips for Optimising Your Notebook Production Workflow

Here are some practical tips to maximise output and minimise wastage using your notebook making machine:

-

Standardise Sizes & Templates: Use consistent paper size templates to minimise setup changes and reduce scrap paper.

-

Batch Processing: Produce in batches with identical specifications (page count, binding, cover design) so machine setups need fewer adjustment intervals.

-

Preventive Maintenance Scheduling: Establish regular cleaning, blade sharpening, lubrication, and machine calibration to avoid breakdowns.

-

Quality Checkpoints: Inspect first 10 units from each batch for alignment, binding strength, trimming accuracy, and maintain records to track performance over time.

-

Monitor Energy Consumption: Track power usage per 100 notebooks to identify inefficiencies or upgrades.

-

Raw Material Storage & Handling: Keep paper dry, flat, and within temperature control. Local humidity in Goa may affect glue setting or paper warping.

-

Staff Training Module: Ensure operators understand machine controls, safety features, emergency procedures, and daily cleaning routines.

These best practices help you leverage your automatic notebook machine or stationery production equipment efficiently.

Frequently Asked Questions

Q. Can the machine handle custom sizes?

Yes. We offer customisable binding heads and cutting dies to support non-standard sizes (such as square or pocket-size notebooks).

Q. What is the lead time for delivery to Bandoda, Goa?

Typical lead time depends on configuration and current order queue. For standard models, delivery within 4–8 weeks is common. Custom designs may take longer.

Q. Are spare parts available locally in Goa?

Yes. We maintain a stock of critical spare parts in or near Bandoda, including cutting blades, punch dies, control relays, motor spares, and wiring harnesses.

Q. Can you upgrade capacity later?

Absolutely. Many of our notebook making machine models are modular and allow capacity upgrades (e.g. adding parallel binding stations or faster motors).

Q. Is training provided?

Yes. We provide on-site training for operators and supervisors after installation to ensure smooth operation and safe usage.

Conclusion

Selecting the right notebook making machine is a key decision for any stationery manufacturer. When you source equipment locally at Bandoda, Goa, you benefit from proximity, service support, and cost-effectiveness.

Whether you’re producing wire-bound notebooks, spiral-bound planners, writing pads, or custom-bound books, the right notebook manufacturing equipment dramatically improves quality, productivity, and profitability.