Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

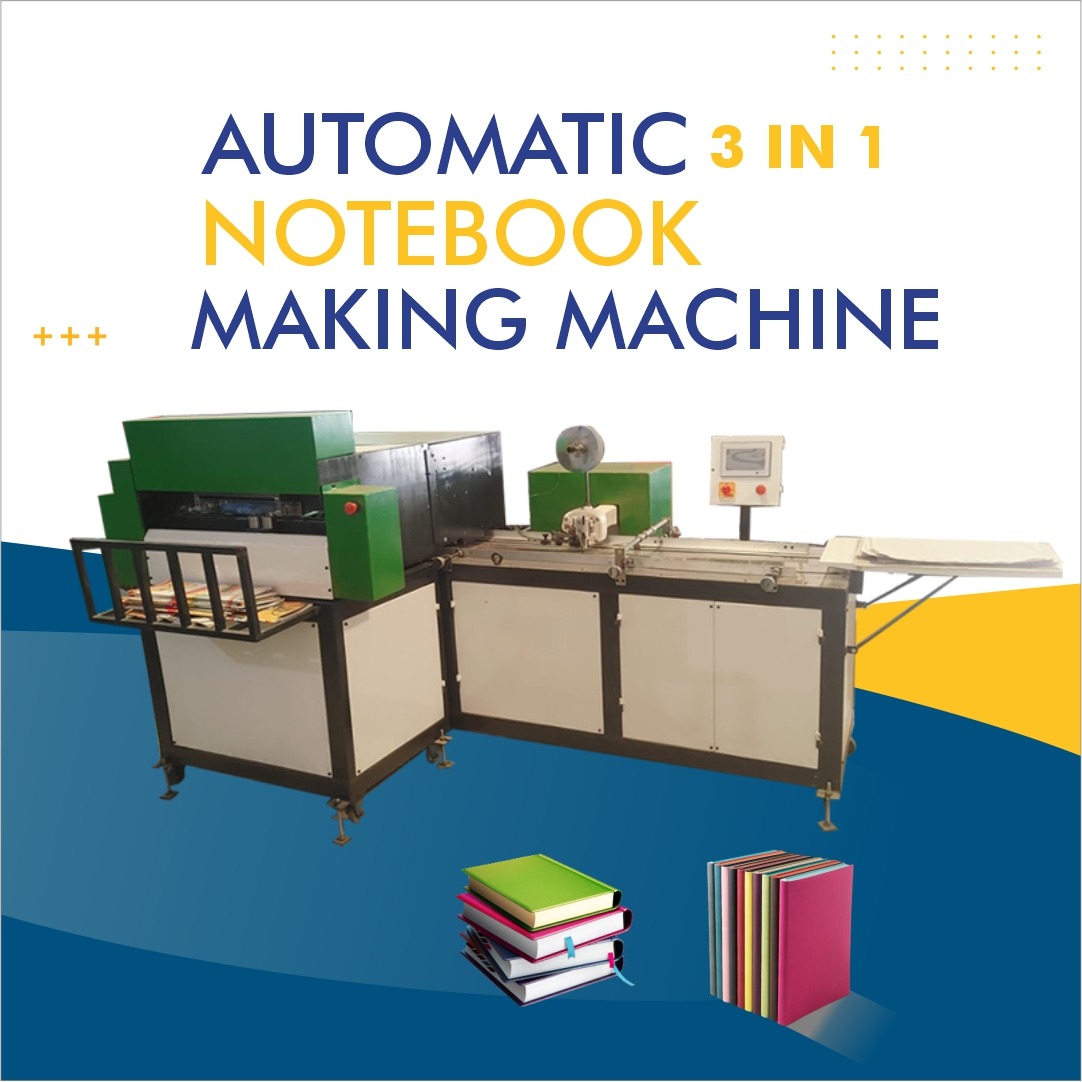

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier & Manufacturer – Tilda Newra, Chhattisgarh

Notebook Making Machine Tilda Newra | Chhattisgarh

Tilda Newra, in Chhattisgarh, is emerging as a promising location for small and medium-scale manufacturing units. Entrepreneurs invested in stationery production increasingly seek reliable notebook making machine solutions locally. Whether you are planning to set up a new unit in Tilda Newra or expand your existing facility, choosing the right notebook making machine is critical to your productivity, quality, and return on investment.

In this article, we will explore the types, features, benefits, cost considerations and sourcing tips for notebook manufacturing machine in and around Tilda Newra, Chhattisgarh. We also highlight why proximity to Chhattisgarh-based manufacturers matters, and how to evaluate your requirements before investing.

Why Choose a Notebook Making Machine in Tilda Newra / Chhattisgarh

-

Local access & support – Getting machines from suppliers in Chhattisgarh (Raipur / Bilaspur / Raigarh region) helps reduce delivery time, freight cost, and ensures faster installation and after-sales servicing. Laghu Udyog Bharat+2TradeIndia+2

-

Cost-effectiveness – Locally manufactured or supplied machines often have lower logistics overhead and better alignment with regional requirements.

-

Regulatory & compliance ease – Local suppliers are more likely to conform to Indian electrical and safety standards, plus India-based spare parts availability.

-

Scalability – As your production grows, you can coordinate with nearby suppliers to upgrade or customize your notebook making machine.

Given these advantages, sourcing a notebook making machine near Tilda Newra makes sense for both startups and established manufacturers.

Types of Notebook Making Machines

Before buying, it’s important to understand the different types of notebook making machine available. Each offers different levels of automation, capacity, and cost. Here are the main categories:

-

Manual Notebook Making Machine

-

Ideal for very small-scale production or startups.

-

Operator-driven processes: cutting sheets, pasting covers, stitching or binding by hand-assisted tools.

-

Lower upfront cost but slower output and more manual effort.

-

Example listings in Chhattisgarh (Bilaspur area) show manual types available via local suppliers. aajjo.com

-

-

Semi-Automatic Notebook Making Machine

-

Some steps automated (sheet cutting, binding alignment or stitching), while other tasks still require human intervention.

-

Balanced cost and productivity.

-

Useful for medium-volume production, where consistency and quality matter but full automation may not yet be justified.

-

-

Fully Automatic Notebook Making Machine

-

High level of automation: sheet feeding, cover pasting, trimming, binding, stitching or spiral binding automatically.

-

Higher throughput, lower reliance on manual labor, more consistent product quality.

-

Suitable for large-scale manufacturing units or industrial production.

-

Example: TradeIndia lists an automatic notebook making machine available in Raipur. TradeIndia

-

-

Spiral Notebook Making Machine

-

Specialized for spiral-bound notebooks. Includes punch-hole mechanisms, spiral insertion, trimming.

-

May be integrated into automatic or semi-automatic lines.

-

-

Cover Making / Binding Finishing Machines

-

Accessories or sub-modules which complement the main notebook making machine: cover pasting, laminating, edge finishing, embossing, or corner cutting.

-

Each type will suit different production volume, budget, and scale. Your selection must align with your business goals in Tilda Newra.

Key Features to Evaluate

When comparing different notebook manufacturing machine models, focus on features that affect output, quality and maintenance:

-

Production capacity / Output – e.g. number of notebooks per hour or per shift.

-

Machine speed & efficiency – throughput in sheets per minute, binding speed, trimming accuracy.

-

Binding type & flexibility – stitched binding, glue binding, spiral binding. Ability to handle different sizes (A4, A5, customized).

-

Automation level – how many steps require manual intervention vs automated controls.

-

Precision & finishing quality – alignment, trimming margins, cover overhang, corner cutting precision.

-

Material compatibility – paper thickness, cover board or laminated covers, various paper grades.

-

Power & energy consumption – electrical requirements, footprint, noise, safety compliance.

-

Spare parts / maintenance – availability of spare knives, binding wires, motors, belts etc.—local suppliers in Chhattisgarh can help reduce downtime.

-

Footprint & layout – floor space required, ease of integration into your facility in Tilda Newra.

-

Cost of ownership – not just purchase price, but installation, maintenance, energy cost, operator cost, downtime losses.

Cost Considerations & Pricing

When budgeting for a notebook making machine, consider the following:

-

Upfront Capital Cost

-

Manual machines will cost significantly less than automatic ones.

-

Fully automatic notebook making machines tend to have higher price tags reflecting motors, automation control system, safety systems, and more complex structure.

-

-

Operation & Maintenance Cost

-

Regular maintenance: lubrication, blade replacement, motor checks.

-

Spare parts procurement time and cost.

-

Electricity / power consumption based on usage hours.

-

-

Return on Investment (ROI)

-

Estimate number of units produced daily × profit margin per notebook.

-

Evaluate how machine speed improvements or reduced manual labor translate to cost savings.

-

-

Customization & Upgrades

-

If you require special features (e.g. custom sizes, multi-fold pages, premium cover finishing), customization may add to cost.

-

Future upgrades (adding modules for laminated covers, binding styles) should also be factored.

-

-

Logistics & Shipping

-

Proximity matters: sourcing from within Chhattisgarh or nearby reduces freight and handling cost.

-

Some vendors in Raipur or Bilaspur can deliver and install locally (see listings for Chhattisgarh notebook machine suppliers). Food Mart Agro+1

-

Sourcing Suppliers Near Tilda Newra

Although your exact location is Tilda Newra, which is likely rural or semi-urban in Chhattisgarh, the nearest hub for machinery supply is likely Raipur, Bilaspur, or other industrial towns in Chhattisgarh. Here are a few sources to begin with:

-

Laghu Udyog offers notebook making machinery across Chhattisgarh. Laghu Udyog Bharat

-

TradeIndia listings show notebook making machines in Raipur. TradeIndia

-

Food Mart Agro Engineering supplies machines in many towns of Chhattisgarh including Raipur, Bilaspur etc. Food Mart Agro

-

Justdial lists notebook making machine manufacturers in Raipur and Raigarh region. Justdial+1

When you contact these suppliers, you should provide them with your location (Tilda Newra), desired production capacity (e.g. units/day), binding type (spiral or stitched), and expected budget. Ask for site-visits or prior installations to validate performance.

Implementation & Setup in Tilda Newra

Once you’ve selected a suitable notebook making machine, here is a rough step-by-step to implement it successfully in your production unit:

-

Site preparation

-

Ensure your factory floor at Tilda Newra has proper leveled foundation, electrical supply (voltage/stabilization), ventilation, and access to maintenance staff.

-

Plan layout: space for raw paper feed, machine footprint, buffer area for finished notebooks, storage.

-

-

Installation & Commissioning

-

Coordinate with supplier to deliver, install and calibrate the machine.

-

Test run with actual materials (paper & cover stock you intend to use). Adjust alignment, trimming, binding tension etc.

-

-

Operator Training

-

Train operators or staff in using the control panel (for semi / fully automatic machines), maintenance routines, safety protocols.

-

-

Pilot Production Run

-

Run a small batch to check defects, finishing quality, consistency.

-

Measure metrics: wastage, binding errors, trimming tolerance, throughput vs expected production.

-

-

Quality Assurance & Maintenance Schedule

-

Define schedule for routine cleaning, lubrication, blade replacement, preventive checks.

-

Maintain log-book for machine usage hours, faults, downtime.

-

-

Scaling & Optimization

-

As your demand grows, monitor whether the machine meets capacity. If not, consider upgrade modules or adding another unit.

-

Negotiate with supplier for spare parts / upgrade support.

-

Benefits of Choosing Quality Notebook Manufacturing Machine

-

Improved Production Speed: Automatic or semi-automatic machines increase output per hour compared to fully manual processes.

-

Consistent Quality & Finish: Better alignment, trim accuracy, binding strength. Leads to fewer rejects and higher customer satisfaction.

-

Cost Efficiency Over Time: Though the initial investment may be higher, savings in labor, reduced wastage, and higher output deliver lower cost per unit in the long run.

-

Product Portfolio Expansion: With advanced machines, you can diversify binding types (spiral, stitched), cover finishing styles, sizes & formats which enhances your market offering.

-

Competitive Advantage: Offering premium-quality notebooks produced in Tilda Newra with reliable delivery can help you compete regionally.

Potential Challenges & Mitigation

While investing in a notebook making machine brings many benefits, there are some common challenges to watch out for:

-

Power Fluctuations: Rural areas may face voltage instability. You’ll need stable power backup or voltage regulators.

-

Skilled Operators: Semi / fully-automatic machines require trained staff. Plan for training, or hire experienced technician / operator.

-

Maintenance Downtime: Without local spare parts or service support, downtime leads to production loss. That’s why sourcing from Chhattisgarh vendors with local after-sales matters.

-

Material Handling: Paper supply, cover board quality, and raw material storage must match machine capability. Poor input quality reduces finished output quality.

-

Scaling Constraints: If demand suddenly grows, you must ensure your machine capacity or modular upgrade options can handle scale.

By preparing for these risks in advance (e.g. backup power, operator training, preventive maintenance), you can maximize uptime and productivity in your unit at Tilda Newra.

Conclusion

If you're planning to set up or upgrade your notebook production facility in Tilda Newra, Chhattisgarh, choosing the right notebook making machine is a foundational decision.

Here’s what you should do next:

-

Finalize your production goals: units/day, binding types, quality expectations.

-

Contact nearby machine suppliers in Chhattisgarh (Raipur / Bilaspur / trade-platforms) with your specifications.

-

Request quotations for manual / semi-automatic / fully automatic notebook making machines.

-

Compare not only price but features, after-sales support, spare-parts availability, delivery & installation timeline.

-

Plan the layout & site readiness in your facility at Tilda Newra.

-

Conduct pilot production run & quality checks.

-

Ensure you have operator training, maintenance schedule, and a growth / upgrade plan.