Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

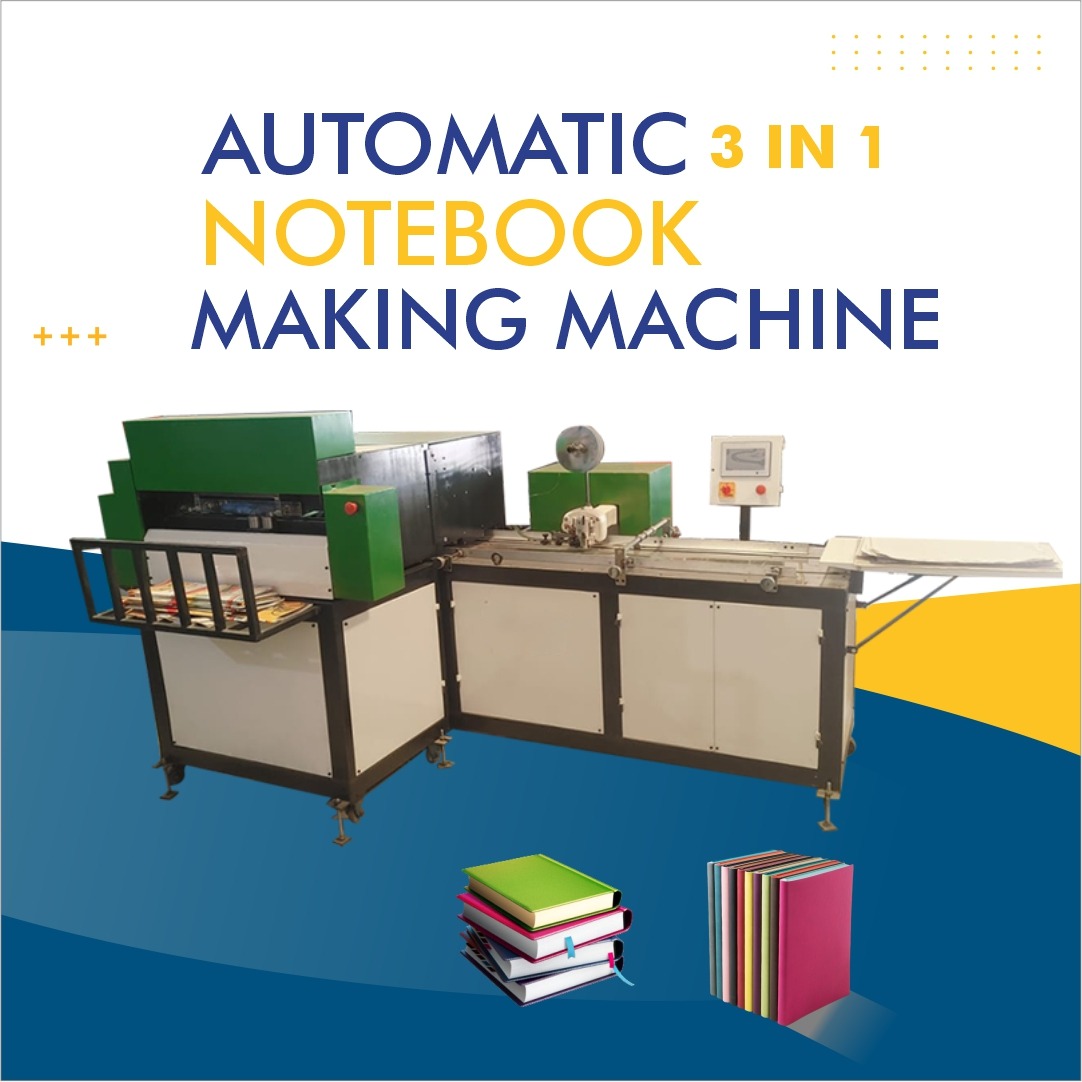

Notebook Making Machine in Simga, Chhattisgarh – Purchase Automatic & Semi-automatic Notebook Machines

Notebook Making Machine in Simga | Chhattisgarh

Simga is an emerging industrial locality near Raipur in Chhattisgarh, well-positioned for light manufacturing and small-scale production units. For entrepreneurs and small factories in and around Simga looking to set up or scale a notebook manufacturing line, selecting the right notebook making machine is critical. Whether you’re aiming for manual production, semi-automatic throughput, or fully-automatic operation, choosing the correct equipment affects cost, quality, and ongoing reliability.

This guide provides a comprehensive overview of notebook making machines — types, features, cost considerations, and why acquiring your machine in Simga, Chhattisgarh makes good business sense.

Why Choose a Notebook Making Machine in Simga, Chhattisgarh

-

Proximity to supplier networks: Chhattisgarh already has local dealers and manufacturers of notebook making machines (for example in Raipur). Justdial+2foodmartagro.com+2

-

Lower transportation and logistics cost compared to importing from distant states.

-

Local support and maintenance: Installation, service, spare-parts availability is easier when your machine is nearby rather than shipped from far.

-

Growing demand: With educational institutions, plus stationery demand in Central India, notebook production offers a stable business in the region.

Because Simga is close enough to Raipur and other industrial hubs, businesses can benefit from both rural-proximity (land, labor costs) and access to suppliers in Raipur / Bilaspur / Durg.

Types of Notebook Making Machine

When selecting a notebook making machine, you’ll typically come across the following types:

-

Manual Notebook Making Machine

-

Best for low-volume production or startups.

-

Requires more human labour (folding, stitching, binding done manually or semi-manual).

-

Lower capital cost; simpler to maintain.

-

Useful where workforce is available at lower cost.

-

-

Semi-Automatic Notebook Making Machine

-

Part of the process is automated (e.g. stitching, folding, trimming), while other parts require operator involvement.

-

Balanced option between cost and productivity.

-

Suitable for mid-scale production (hundreds to a few thousands of units per day).

-

-

Fully Automatic Notebook Making Machine

-

Automates multiple steps: paper cutting, folding, binding/stitching, edge-squaring, trimming.

-

Higher throughput capacity, lower labour per unit.

-

Higher initial cost; requires reliable power & maintenance.

-

Ideal for medium-to-large scale production.

-

-

3-in-1 Notebook Making Machine

-

Combines multiple operations (for example stitching, fold-edge-squaring) within one integrated machine module.

-

Saves floor-space, reduces handling between operations.

-

-

Spiral Binding / Specialty Notebook Making Machines (if you diversify)

-

If you plan spiral-bound notebooks, covers, or other binding formats, there may be additional attachments or models.

-

Each of these types corresponds to different price ranges, production speeds, automation levels, and maintenance needs.

Key Components & Features

When evaluating a notebook making machine, pay attention to these features:

-

Production Speed / Capacity

How many notebooks per hour (or per minute) the machine can produce. Fully automatic machines often measure speed in pieces/minute; manual / semi-automatic in units/hour. -

Size and Format Compatibility

What size of notebook paper (A4, A5, custom dimensions), number of pages, thickness, cover dimensions, binding type. -

Automation Grade

Manual, Semi-automatic, Fully automatic; whether binding/stitching is electric-driven, how much manual intervention required. -

Material & Build Quality

Whether frame is mild steel / stainless steel, durability under continuous use, whether safety features are included. -

Power Requirements

Voltage (220 V single phase or 3 phase 380 V), motor power, electrical safety. In Chhattisgarh, ensure compatibility with local supply. -

After-sales Service & Spare Parts

Availability of servicing personnel near Simga or Raipur, lead time for spare parts. -

Footprint & Floor Space

Does the machine require dedicated space, vibration isolation? Are there noise / safety enclosures? -

Brand & Warranty

Reputation of manufacturer, warranty period, user reviews.

Cost Estimates in Chhattisgarh Region

Here are some indicative cost references for notebook making machines in Chhattisgarh / nearby regions:

-

TradeIndia lists a notebook making machine around ₹ 4,50,000 near Raipur. TradeIndia

-

Some manual notebook making machines in Bilaspur are available at lower prices (e.g. ₹ 65,000). aajjo.com

-

Fully automatic models (3-in-1 stitch / fold / edge square) may cost several lakhs depending on speed & capacity. royalbusinessindustry.com+1

Keep in mind that cost includes not just the purchase price but also shipping, installation, electrical work, training, and potentially civil work (foundation etc.).

How to Choose the Right Machine for Simga Setup

To select the best notebook making machine for your facility in Simga, follow these steps:

-

Estimate your production requirement

For example, how many notebooks do you plan to manufacture daily or monthly? What page counts? What sizes? -

Decide level of automation

If labour is cheap and you plan small production, manual or semi-automatic may suffice. If you aim to scale, go for fully automatic. -

Assess site constraints

Space available, electrical supply (single-phase or three-phase), noise / ventilation requirements, operator skills. -

Compare multiple suppliers

Get quotations from machine suppliers in Raipur / Bilaspur / Chhattisgarh. Visit their existing installations if possible. -

Factor in running costs

Electricity consumption, maintenance, spare parts, downtime. More advanced machines may cost less per unit in labour but could have higher maintenance. -

Plan for future expansion

Choose a machine that can be upgraded or has optional modules for increased speed / capacity / binding formats. -

Check local compliance & duty / taxes

In Chhattisgarh / India, check whether GST, local transportation, installation taxes apply.

Benefits & ROI of Investing in a Notebook Making Machine

-

Increased Productivity

Automated or semi-automated machines reduce manual errors, speed up throughput, and allow consistent quality. -

Better Quality & Finish

Machines with edge-squaring, accurate stitching / binding, trim precision improve final product quality compared to purely manual. -

Lower Unit Cost Over Time

While initial investment is higher, machine-led production reduces labour cost per notebook, cuts wastage, and improves consistency. -

Scalability

Once your machine is in place, you can scale up operations without a proportional increase in workforce. -

Competitive Advantage

In markets such as schools, stationery shops, institutional supply in Chhattisgarh / nearby states, consistent quality & timely delivery gives you advantage.

Potential Challenges & Mitigation

-

Power Fluctuations

Rural / semi-urban areas like Simga may have voltage variations. Use stabilizers or surge protectors, and ensure machine supports required phase / voltage. -

Skilled Operators

Training is needed for machine operation, troubleshooting, safety protocols, especially for semi / fully automatic machines. -

Spare Parts Availability

Make sure supplier offers spare parts locally (Raipur or nearest city), or has reliable logistics. -

Maintenance Downtime

Plan preventive maintenance schedule; budget for regular servicing and downtime while securing buffer production capacity. -

Raw Material Quality

Paper cuttings, cover boards, stitching wire / thread quality can affect output. Ensure your raw material specifications align with what the machine expects.

Scenario: Setting Up a Small Notebook Factory at Simga

Suppose you plan to start producing 2,000 notebooks per day of size A5, average 80 pages, with stitched binding. You have a small warehouse in Simga, electricity supply with 3-phase connection, and you want to minimize manual labour while keeping investment under ₹ 5 lakh.

-

Select a semi-automatic or entry-level fully automatic 3-in-1 machine

-

Look for a model capable of stitching, edge-squaring & trimming.

-

Ask for quotations from Chhattisgarh-region suppliers (Raipur / Bilaspur) who deliver to Simga.

-

-

Space & Installation

-

Allocate floor area (say ~ 10 ft × 8 ft plus operator clearance), ensure ventilation, dust/ noise control.

-

-

Cost Breakdown

-

Machine cost: perhaps ₹ 3.5–4.5 lakh

-

Electrical & civil installation: ₹ 30,000

-

Training & commissioning: ₹ 20,000

-

Working capital for raw material (paper, cover boards): ₹ 1 lakh

-

-

Revenue & Payback

-

If you sell each notebook at a margin of ₹ 15 over cost, producing 2,000 per day yields margin ₹ 30,000/day.

-

Assuming 25 working days/month → ₹ 7.5 lakh margin/month. Even with operating cost, payback period could be under a year — depending on actual demand.

-

-

Scaling Up

-

Once demand grows, you may consider an upgraded faster machine, or parallel line.

-

This scenario underscores how buying a suitable notebook making machine in Simga / Chhattisgarh region can lead to a realistic business plan with good returns.

How to Find Reliable Notebook Making Machine Supplier Near Simga

-

Contact manufacturers listed in Raipur or nearby Chhattisgarh district directories. Justdial+1

-

Visit show-rooms or ask for machine demos or video references.

-

Check for companies offering installation & after-sales service in Raipur / Bilaspur / Durg. foodmartagro.com

-

Compare multiple quotations, and always ask for sample output (sample notebooks made by the machine).

Conclusion

If you’re planning notebook production in or around Simga, Chhattisgarh, investing in a good notebook making machine is a smart move. Choose the right type (manual / semi-automatic / fully automatic) based on your scale. Get multiple quotations, verify supplier support, and ensure proper installation/training.