Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

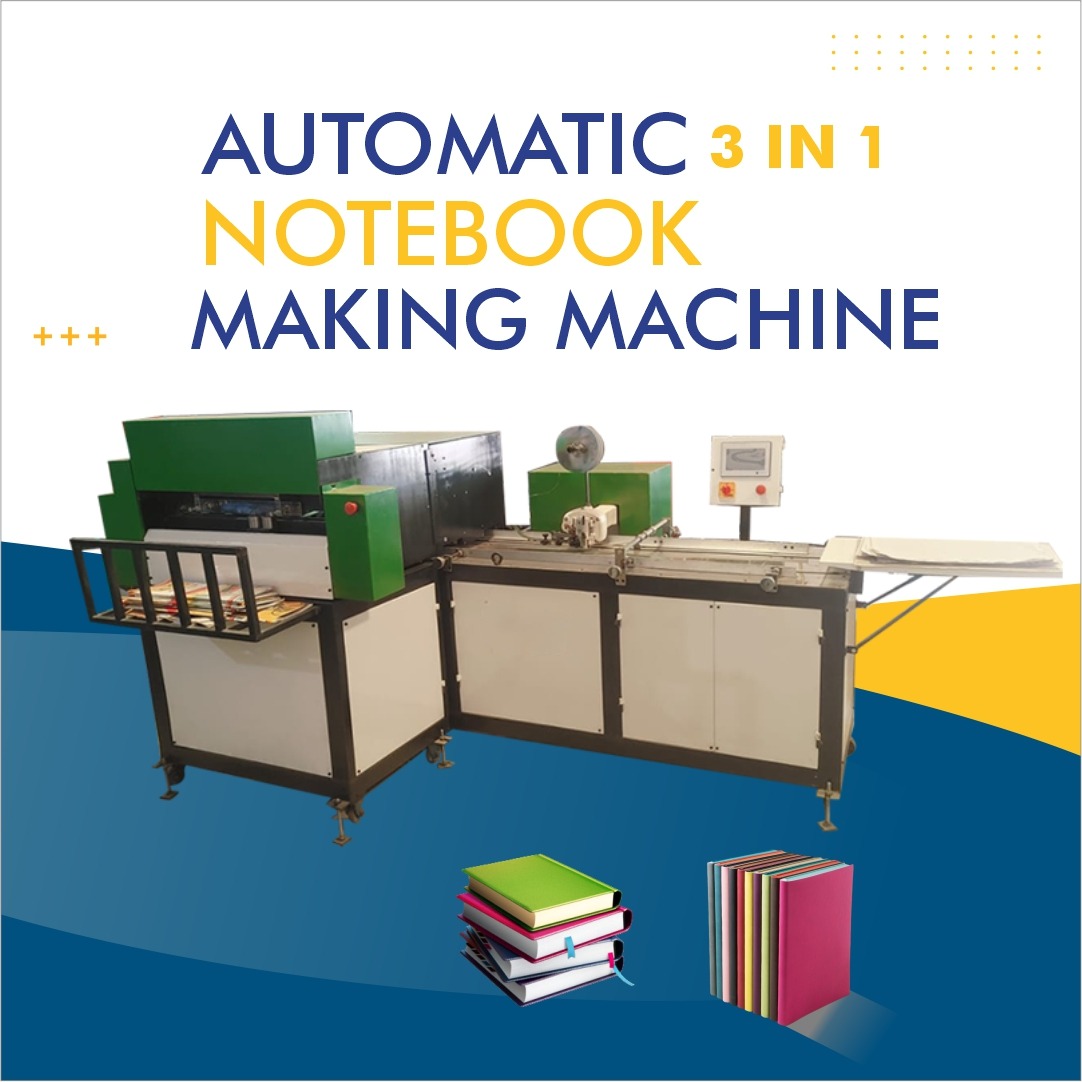

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Ratanpur, Chhattisgarh | Manufacturer & Supplier

Notebook Making Machine in Ratanpur | Chhattisgarh

In Ratanpur, Chhattisgarh — a township in Bilaspur district with growing industrial and educational demands Wikipedia — there is increasing requirement for reliable notebook making machine solutions. Whether you're planning a small-scale stationery business or expanding an existing unit, choosing the right notebook manufacturing machine is essential for productivity and quality. This article outlines everything you need to know about notebook making machines near Ratanpur: types, features, cost factors, suppliers, and best practices for maintenance.

Why Ratanpur is a Strategic Location

Ratanpur lies about 25 km from Bilaspur and forms part of Chhattisgarh’s growing industrial belt Wikipedia. Proximity to Bilaspur city enables access to raw material suppliers, transport logistics, and labor. By locating your notebook production or procurement efforts around Ratanpur, you can reduce freight cost, quicker servicing, and better coordination with local manufacturers of stationery equipment.

While many notebook making machine suppliers are based in Raipur, Raigarh or Bilaspur area, having operations or sourcing near Ratanpur can give you competitive advantage in lead times, installation, spare parts, and on-site servicing.

Types of Notebook Making Machines

When sourcing a notebook making machine in Ratanpur or nearby Chhattisgarh, you will encounter several types. It’s important to understand which suits your production volume, budget, and product type.

-

Manual Notebook Making Machine

-

Low investment option.

-

Operator-driven cutting, folding, page alignment and binding steps.

-

Suitable for small batch production, custom notebooks, or startups.

-

Offers a low-cost entry for new business.

-

-

Semi-Automatic Notebook Making Machine

-

Automates certain repetitive functions (like cutting or stitching) but still requires some manual intervention.

-

Balances cost and productivity.

-

Useful for medium scale production.

-

-

Fully Automatic Notebook Making Machine

-

Automates cutting, stitching or binding, trimming and cover finishing with minimal human interference.

-

High throughput, ideal for large volume production.

-

Higher procurement cost but delivers faster ROI if run continuously.

-

Example product listed by TradeIndia for Chhattisgarh area TradeIndia

-

-

Spiral / Coil-Bound Notebook Machine

-

Specialized for spiral binding (coil binding) rather than stitched or stapled binding.

-

Adds variety to your offerings (spiral-bound school notebooks, sketchbooks etc.).

-

-

Exercise-Book / Register Making Machine

-

Configured for larger page sizes or register format notebooks.

-

Sometimes manufacturers label these under “school notebook machine” lines.

-

Each of these types may come with optional features such as automatic cover pasting, lamination, trimming edges, counting pages, or stacking finished notebooks.

Key Features & Specifications to Evaluate

When evaluating a notebook manufacturing machine, consider the following specifications:

-

Cutting Capacity & Precision: Ability to cut paper stack thickness, blade quality, tolerances.

-

Binding / Stitching Mechanism: Single-stitch stapling, wire-stitched binding, spiral binding.

-

Production Speed: Number of notebooks per hour or per minute.

-

Size & Format: Supported paper sizes (A4, B5, custom school notebook size).

-

Cover Handling: Plain cover, printed cover, hard or soft cover finishing.

-

Automation Level: Manual feed vs automatic paper feeding, auto counting, auto trimming.

-

Power Source & Electrical Requirements: Compatibility with local supply, motor rating, safety standards.

-

Material Compatibility: Types of paper stock, thickness, margin of error.

-

Footprint / Floor Space: Physical size of machine, weight and installation space required.

-

After-Sales Support & Spare Parts: Accessibility of replacement parts, local repair services or technician availability.

-

Cost & ROI: Price of machine vs expected output, operating costs (electricity, labor, maintenance).

Cost & Budget Considerations

The cost of a notebook making machine depends on capacity, features, and automation level:

-

Manual machines typically cost much less up front, but require more labor per notebook.

-

Semi-automatic machines fall in the mid-range.

-

Fully automatic machines carry the highest price but fastest throughput.

-

Specialized machines (e.g. for spiral binding) or larger formats may cost more.

As a rough guideline, suppliers around Chhattisgarh list automatic notebook making machines in range of a few lakh rupees TradeIndia. Manual or semi-automatic machines may cost significantly less. However costs differ based on brand, specifications, and whether delivered new or as refurbished.

You should also factor in installation cost, transportation to Ratanpur, operator training, and maintenance contracts when calculating total cost of ownership.

Suppliers & Sources Near Ratanpur / Chhattisgarh

While there may not yet be a major established manufacturer in Ratanpur itself, you can source notebook making machines from nearby cities and companies servicing Chhattisgarh:

-

Laghu Udyog – offers notebook making machines in Chhattisgarh Laghu Udyog Bharat

-

Food Mart Agro Engineering – a supplier listing notebook making machines for this region foodmartagro.com

-

TradeIndia listings for notebook making machine in Raipur / Chhattisgarh region TradeIndia+1

-

Other manufacturers listed on Justdial near Raipur or Raigarh Justdial+1

If you set up a business in Ratanpur (Bilaspur district), you may request on-site demonstrations or factory visits to these supplier locations for better assessment.

How to Choose the Right Machine for Your Operation

Here’s a step-by-step guideline to help you select a suitable notebook making machine:

-

Assess Required Capacity

Estimate how many notebooks per day or month you intend to produce. Consider seasonal peaks (back-to-school period, exams etc.). -

Define Product Specifications

Decide notebook size, number of pages per notebook, binding type (stitched / spiral), cover finishing (printed / laminated), thickness of paper used. -

Budget & Financing

Determine your capital budget. Consider leasing options, loan finance or phased purchase if available in Chhattisgarh. -

Compare Suppliers & Quotes

Request detailed quotations from nearby suppliers (Raipur / Bilaspur area). Obtain sample videos or onsite visits. Compare technical specs, warranty terms, spare parts availability. -

Check Floor Space and Power Requirements

Ensure your production site near Ratanpur can accommodate size, has suitable electrical supply, and conforms to safety/regulations. -

Consider Maintenance & Training

Ask supplier for operator training, preventive maintenance schedule, and local technical support. Machines with higher automation often require periodic calibration. -

Evaluate Return on Investment (ROI)

Calculate per-unit cost including labor, power, consumables and maintenance. Compare that with sales price of notebooks to estimate payback period.

Operation & Maintenance Guidelines

To ensure longevity and efficient performance of your notebook making machine, follow these best practices:

-

Routine Cleaning: Dust, paper fibres and debris accumulate. Regular cleaning of blades and moving parts helps maintain quality.

-

Lubrication: Monthly or as per manufacturer guidelines, lubricate mechanical joints, cutting blades and moving gears.

-

Calibration: For precision cutting and alignment, periodic checks and adjustments are required.

-

Spare Parts Inventory: Keep consumables such as knives, staples or wire binding coils in stock locally to reduce downtime.

-

Operator Training: Ensure operators understand safety protocols, proper loading of paper stacks, and quality checks.

-

Service Contracts: If available, procure annual service or maintenance contract from your supplier. Because you’re close to Bilaspur / Raipur region, local technician visits may be economical.

Advantages of Setting Up in Ratanpur / Bilaspur Region

Starting a notebook manufacturing operation around Ratanpur offers several useful advantages:

-

Lower logistic cost for raw materials (paper, cover stock) via Bilaspur regional supply chain.

-

Access to local technical support and spare-part suppliers from nearby cities.

-

Availability of skilled operators familiar with stationery or light manufacturing work.

-

Potential market demand from schools, institutions, and stationery retailers in Bilaspur district and neighbouring regions.

-

Possibility to scale by upgrading from manual / semi-automatic to fully automatic machines as business grows.

Common Challenges & How to Mitigate Them

| Challenge | Mitigation Strategy |

|---|---|

| Initial capital cost for a good quality machine | Explore finance or leasing options; consider semi-automatic machines with potential upgrade path |

| Ensuring consistent paper supply | Establish relationships with local paper mills or wholesalers in Bilaspur / Raipur |

| Technical downtime due to machine breakdown | Choose a supplier offering prompt on-site maintenance; maintain basic spare-parts stock |

| Maintaining quality and uniformity | Set quality checks (page alignment, margin precision, binding strength) and operator training |

| Regulatory / electrical compliance | Ensure machine meets safety / electrical norms; check permits if required for installation in your unit |

Conclusion

If you are planning to set up or upgrade a notebook manufacturing facility near Ratanpur, Chhattisgarh, selecting the right notebook making machine is critical. By understanding types (manual / semi-automatic / automatic), evaluating specifications, obtaining quotes and considering maintenance, you can choose equipment that matches your production goals and budget. Use nearby suppliers in Bilaspur / Raipur region, inspect machines in person, and ensure support and after-sales services.

When you are ready to proceed, reach out to reliable suppliers in Chhattisgarh and request site visits or demo runs. Starting with a scalable solution will let your business grow from small batches to larger volume production without repeated machine upgrades.