Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

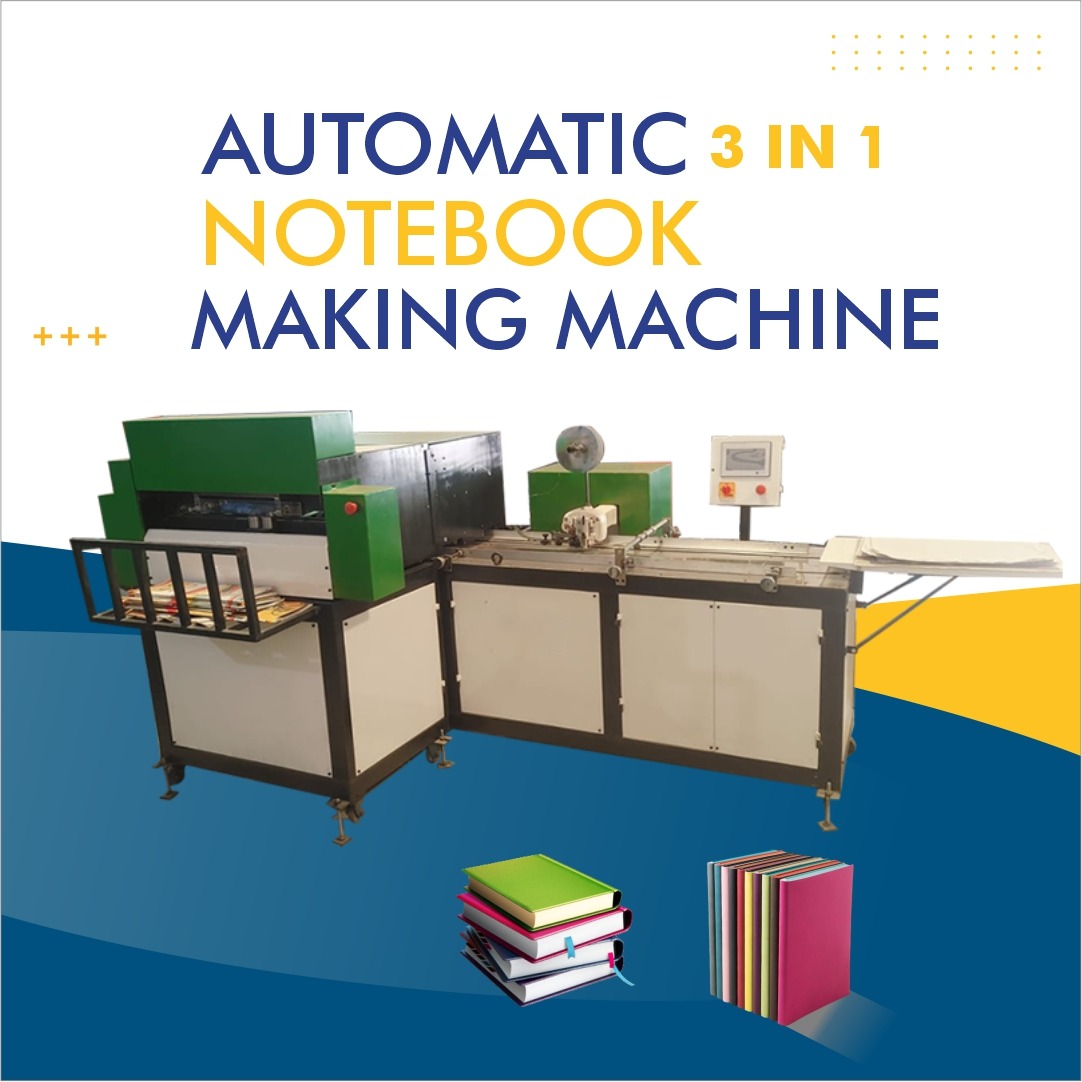

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Top Notebook Making Machine in Rajnandgaon – High-Efficiency Equipment Chhattisgarh

Notebook Making Machine in Rajnandgaon | Chhattisgarh

Rajnandgaon in Chhattisgarh has emerged as a growing industrial hub, and businesses seeking to set up stationary or paper-products manufacturing are increasingly looking for high-performance notebook making machine equipment in this region. Whether you are starting a brand-new notebook production unit or upgrading an existing facility, choosing the right notebook making machine is essential to ensure productivity, quality, and long-term profitability.

This article provides a comprehensive guide to the notebook manufacturing equipment available in Rajnandgaon, Chhattisgarh — including types of machines, features, suppliers, installation tips, and the key benefits of choosing local manufacturers over distant vendors.

2. Why Choose Notebook Manufacturing Equipment in Rajnandgaon

Strategical Location

Located in Chhattisgarh, Rajnandgaon offers logistical advantages for procurement of raw materials such as paper, binder board and packaging. Proximity to major road networks means reduced transportation costs for heavy machinery. Working with a notebook making machine provider in Rajnandgaon ensures faster installation and local support.

Cost-Effectiveness & Customization

Local vendors in Rajnandgaon can offer notebook manufacturing equipment at competitive rates and are more willing to customize machines – for sheet-size variations, binding styles, or production capacity. You avoid import duties, long shipping lead-times, and paperwork associated with out-of-state suppliers.

After-Sales Service & Maintenance

A manufacturer or supplier based in Rajnandgaon or nearby regions (such as Raipur or Bilaspur) offers on-site service, quick spare-parts supply, and faster technician visits. If your automatic notebook binder requires adjustment or maintenance, local support substantially reduces machine downtime.

Regulatory and Incentive Benefits

Operating in Chhattisgarh, you may benefit from state incentives for industrial units. Procuring notebook manufacturing equipment locally could streamline compliance with local regulations and encourage collaboration with regional auxiliary industries (sheet-paper suppliers, packaging vendors, etc.).

3. Types of Notebook Making Machines Available

When searching for a notebook making machine in Rajnandgaon, you can choose from multiple types of binding or assembly equipment. Below are the major categories you may consider:

3.1. Automatic Notebook Binder / Binding Machine

An automatic binder or automatic notebook binder is designed to stitch, glue or staple the pages and cover automatically. It increases production speed and consistency, making it ideal for medium to large scale notebook production. Some models include edge trimming, corner rounding, or cover alignment systems.

3.2. Spiral or Wire-O Binding Machine

If you prefer spiral-bound or wire-O style notebooks, a spiral binding machine or wire binding unit can punch holes and insert coils automatically or semi-automatically. These are often modular add-ons to a broader notebook production line.

3.3. Book Sewing Machine / Thread Sewing Notebook Machine

For premium quality, hard-cover notebooks or journals, book sewing/stitching machines offer durability and aesthetic appeal. This type of machine is often called a book sewing machine or sewing-stitch notebook machine and is used alongside trimming and binding modules.

3.4. Paper Cutting & Trimming Equipment

Before binding or stitching, notebook sheets and covers must be cut or trimmed to exact size. Paper cutting or trimming units complement your notebook manufacturing equipment and are often sourced from the same supplier for seamless integration.

3.5. Complete Notebook Production Line

For large-scale manufacturers, a fully integrated notebook production line may include feeders, collators, binding, trimming, cover insertion, and packing modules. Suppliers in Rajnandgaon may supply or retrofit these lines to meet your output targets.

3.6. Manual or Semi-Automatic Binder Units

If your production scale is moderate or you are testing new designs, semi-automatic or manual binding units are more cost-effective. These can still be upgraded later to automatic models as business grows.

4. Specifications & Features to Look For

To select the right notebook making machine for your facility in Rajnandgaon, consider the following technical specifications and features:

-

Production capacity: Number of notebooks per hour or per minute. Ensure the machine can meet your business forecast.

-

Sheet size compatibility: Standard sizes (A4, A5, custom sizes) and maximum dimensions.

-

Cover thickness: Ability to bind different cover weights or board thickness.

-

Binding type: Staple-binding, glue binding, thread sewing, spiral binding, etc.

-

Automation level: Manual, semi-automatic, or fully automatic.

-

Speed control & adjustment: Ability to adjust speed or pause for quality inspection.

-

Cutting / trimming features: Edge trimmer, corner trimmer, sheet alignment.

-

Electrical & safety compliance: Ensure the machine meets Indian standards (voltage, CE / BIS compliance if applicable).

-

Machine footprint & space requirement: Fit into your factory layout in Rajnandgaon.

-

Warranty & service support: Local availability of parts and technicians for your notebook manufacturing equipment.

5. How to Select a Supplier in Rajnandgaon, Chhattisgarh

Choosing a reliable supplier or manufacturer for your notebook making machine is critical. Here are some tips:

5.1. Local References & Testimonials

Visit existing notebook or stationery manufacturing units near Rajnandgaon and ask for referrals. Check whether their automatic notebook binder or binding machines have performed well over time.

5.2. On-Site Demonstrations

Request live demonstrations of the machine working. Ensure the machine can produce test notebooks in the size and binding style you need.

5.3. Technical Support & Training

Ensure the vendor provides training for your staff, regular maintenance schedules, and prompt spare-parts delivery. A book sewing machine or binder often needs periodic adjustment; local training helps reduce errors.

5.4. Price Breakdown & Customization Options

Get detailed quotations including installation, commissioning, shipping cost (if any), and customization scope. Compare cost of notebook production line components and see whether the vendor allows future upgrades.

5.5. Compliance & Certifications

Check if the machine meets safety standards and has certifications required in Chhattisgarh or India (such as BIS / IS standards). Suppliers based in or near Rajnandgaon may be more familiar with local compliance requirements.

6. Benefits of Investing in a Quality Machine

6.1. Improved Productivity & Efficiency

A high-speed notebook making machine reduces manual effort, speeds up production, and maintains consistent quality across batches. That improves overall output, lowers waste, and increases ROI.

6.2. Better Product Quality & Uniformity

Precision trimming, consistent binding pressure, and accurate alignment result in professional-grade notebooks. Whether you are producing school-notebooks, diaries, or premium journals, quality matters for brand reputation.

6.3. Scalability & Future-Proofing

If your business in Rajnandgaon grows, you can expand production capacity. Machines with modular architectures or upgrade-capability allow you to scale without full replacement.

6.4. Cost Savings Over Time

Although initial investment in notebook manufacturing equipment can be significant, reduced labor cost, lower error/waste rate, and efficient energy usage lead to long-term savings.

6.5. Competitive Advantage

Supplying notebooks to schools, corporates or retailers in Chhattisgarh and neighboring states demands reliability. Having a high-quality notebook making machine gives you faster turnaround times, better finish, and ability to fulfill bulk orders timely.

7. Case Study / Example Scenario

Suppose you plan to launch a notebook brand in Rajnandgaon with a daily capacity of 5,000 notebooks (A5 size, softcover with glue-binding). You evaluate two options:

-

Semi-automatic binder with manual trimming vs.

-

Automatic notebook binder with inline trimming and cover alignment module.

-

Option 1 may cost significantly less initially, but you will require more manual labor and might face variability.

-

Option 2 is costlier up front, but offers higher throughput (e.g. 500 notebooks/hour), uniform finish, and lower rejection rate.

If your supplier is based near Rajnandgaon, commissioning and maintenance costs drop, and you can negotiate custom trimming widths for your specific notebook format. Because of local sourcing advantages, your supply chain for raw materials (paper, cover board) is shorter too—reducing turnaround and logistic overheads.

8. Installation & Commissioning Tips

When your notebook production line arrives at your facility in Rajnandgaon:

-

Ensure foundation or flooring is level and strong enough to support the machine’s weight and vibration.

-

Coordinate with the supplier’s engineers for proper alignment, calibration, and trial runs.

-

Train operators on safety procedures, maintenance schedule, and quality inspection protocols.

-

Plan spare-parts inventory for glue heads, cutting blades, staples or binding coils.

-

Keep a logbook for machine run-hours and maintenance tasks to monitor performance over time.

9. Typical Cost & Return on Investment

While prices vary widely depending on capacity, automation level, and features, a mid-range automatic notebook binder could cost anywhere between a few lakhs to tens of lakhs of rupees.

When you calculate ROI, factor in:

-

Units produced per hour × working hours per day × selling price per notebook

-

Savings from reduced rejects or rework

-

Reduced manpower and error rate

-

Increased product consistency and client satisfaction

With well-specified equipment and reliable local maintenance, a notebook manufacturing setup in Rajnandgaon can achieve payback within a few years depending on production scale and market demand.

Conclusion

If you are considering setting up or upgrading a notebook production unit in or near Rajnandgaon, Chhattisgarh, selecting the right notebook making machine is vital. You benefit from reduced logistical complexity, lower installation time and faster maintenance when you work with a supplier familiar with this region. Whether you require an automatic binder, spiral binding module or a fully integrated notebook production line, local choices provide flexibility, cost effectiveness, and reliability.