Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

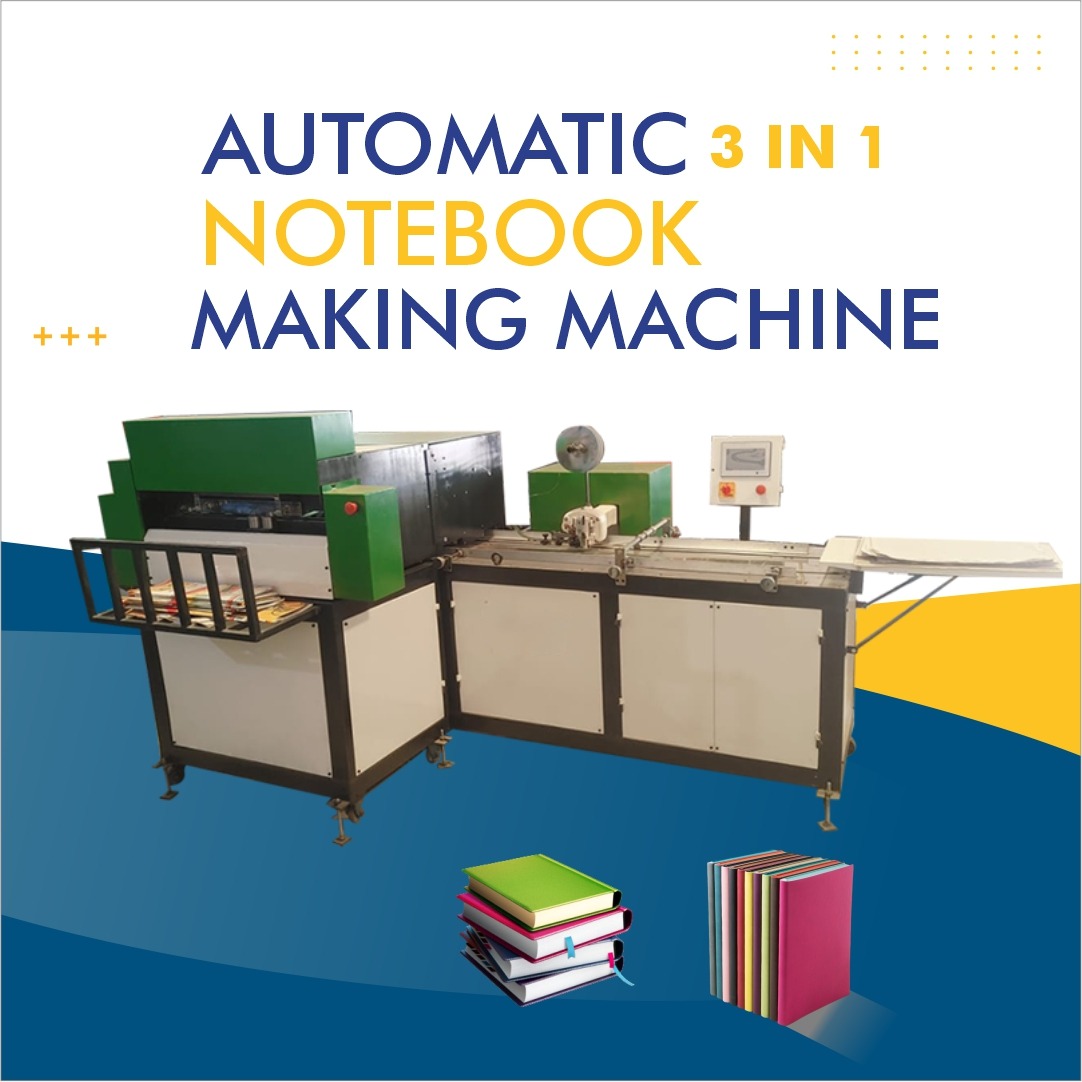

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier — Naya Baradwar, Chhattisgarh

Notebook Making Machine Naya Baradwar | Chhattisgarh

In the rapidly growing educational supplies sector of Chhattisgarh, investing in a high-performance notebook making machine can be a game changer. Especially in industrial hubs such as Naya Baradwar, setting up a production unit for notebooks requires reliable machinery that delivers consistent quality, supports scalability, and offers energy efficiency. This article explores the benefits, technical features, local manufacturing support, and practical considerations for acquiring a notebook making machine in Naya Baradwar, Chhattisgarh.

We will also discuss the kinds of notebook making machine types available (automatic and semi-automatic), how to select the right model based on your production targets, and what support you can expect locally.

Why Choose Naya Baradwar, Chhattisgarh for Notebook Making Machine Installation

-

Strategic Location & Logistics

Naya Baradwar is well-positioned within Chhattisgarh, offering good road connectivity to supply raw materials like paper sheets, binding covers, glue, and packaging materials. Proximity to neighboring districts helps with inbound and outbound logistics. -

Local Manufacturing Ecosystem

Chhattisgarh has been encouraging industrial units under state policy incentives. Local vendors for metal fabrication, spare-parts maintenance, and skilled labour are accessible near Naya Baradwar. This reduces downtime and maintenance costs for notebook making machine owners. -

Growing Demand for Notebooks

With increasing school enrolments and stationery usage in rural and urban Chhattisgarh, there’s sustained demand for school notebooks, exercise books, and other bound paper products. A resident manufacturer of notebook making machine equipment or a user in Naya Baradwar can cater to both local and interstate markets. -

State Incentive Schemes

Small and medium enterprises setting up manufacturing plants in Chhattisgarh may qualify for subsidies, net-metering support, or tax rebates. Installing a notebook making machine can be part of a value-addition strategy that benefits from such schemes.

Types of Notebook Making Machines

When considering a notebook making machine for Naya Baradwar, you should understand the available types, their advantages, and limitations.

| Machine Type | Description | Advantages | Considerations |

|---|---|---|---|

| Automatic Notebook Making Machine | Fully automated line that cuts paper, binds pages, applies covers, staples or stitches binding, and trims the finished product. | High throughput, consistent quality, low manual labour, ideal for large-volume production. | Higher upfront cost, requires stable power supply, regular maintenance. |

| Semi-Automatic Notebook Machine | Some processes (cutting, stitching or trimming) require manual intervention while other steps are machine-driven. | Lower cost upfront, flexibility to modify settings manually, easier maintenance by local technicians. | Slower than automatic machines, more labour intensive. |

| Compact Manual-Assisted Machine | Best for startups or small-scale production; major operations still handled manually with machine-assisted tools. | Very low capital investment, minimal maintenance cost. | Limited capacity, suitable only for small batches or trial runs. |

Key Technical Features to Evaluate

When selecting a notebook making machine in Naya Baradwar, consider the following technical specifications:

-

Production Capacity

Estimate the number of notebooks needed per day or month. Automatic machines may produce thousands of notebooks per hour; semi-automatic ones may be slower. Match capacity with demand projections to avoid under-utilization or over-investment. -

Binding Method

Choose between wire-stitching, stapling, or adhesive binding. The machine model must support the preferred method. Some machines offer interchangeable binding heads for different binding styles. -

Paper Size & Thickness Compatibility

The machine should handle various sheet sizes (A4, A5, custom sizes) and paper thickness (gsm). It should allow flexibility for notebook design variations. -

Operation Modes & Controls

Automatic machines often have PLC or digital control panels for speed adjustment, jam detection, safety interlocks, etc. Evaluate user-interface ergonomics, local language support, and maintenance ease. -

Power Consumption & Energy Efficiency

Given electricity costs and reliability in rural/semi-urban Chhattisgarh, machines with energy-efficient motors or the ability to run on variable supply may reduce operational cost and downtime. -

Safety & Compliance

Ensure the machine meets industrial safety standards (guards, emergency stops, CE or equivalent compliance). Also check noise levels and workplace ergonomics for operating staff. -

After-Sales Service & Local Support

Availability of spare parts, local technicians, prompt service is critical. A notebook making machine installed near Naya Baradwar should have maintenance support within reachable distance to minimize production halts. -

Upgradability & Customisation

If your product portfolio may expand (e.g. different sizes of notebooks, special covers), select a machine that supports modular upgrades or custom modifications by local fabricators or your supplier.

Benefits of Investing in a Notebook Making Machine

Increased Productivity

An automatic notebook making machine dramatically increases output compared to manual binding. This allows you to meet bulk orders from schools, agencies or wholesale buyers without delays.

Cost Efficiency

Machines reduce labour cost per unit. Over time, lower cost per notebook improves profit margins. Also, consistency in quality reduces wastage caused by manual errors or misalignment.

Quality & Consistency

Automation ensures accurate cuts, consistent binding alignment, and uniform trimming. This helps in achieving professional appearance, reducing returns or complaints from clients.

Scalability

With the right machine, scaling operations (adding shifts, increasing raw material supply, expanding market reach) becomes easier. The same equipment can support higher volumes without needing new solutions for each growth phase.

Competitive Edge

Having in-house machinery gives you control over production schedules, turnaround times, and pricing. You can respond quickly to custom orders (e.g. special sizes, binding styles). This flexibility strengthens your position versus vendors who outsource binding.

Local Employment & Brand Value

Setting up manufacturing units around Naya Baradwar creates local jobs (operators, technicians, maintenance staff). It also adds to your brand image as a local manufacturer of notebooks, possibly with “Made in Chhattisgarh” credentials.

Practical Considerations for Setting Up in Naya Baradwar

-

Site Requirements

Ensure your production facility has stable flooring (to support machine weight), adequate space for raw material staging, product stacking, loading/unloading docks. Plan layout to allow safe access and future expansion. -

Power & Utilities

Check electricity capacity, backup power (generator or UPS), and grounding. Consider ambient conditions (temperature, dust) and ventilation to maintain smooth machine operation. -

Raw Material Sourcing

Secure reliable suppliers for paper sheets, cover stock, staples or stitching wire, glue, binding boards, packaging boxes. Proximity to paper mills or stationery raw material traders in Chhattisgarh or neighbouring states helps reduce lead time and shipping cost. -

Staff Training

Operators require training for machine setup, troubleshooting, preventive maintenance, and safety protocols. Ensure documentation and local language manuals are available or provided by supplier. -

Regulatory Compliance

Register under local municipal or industrial regulations, comply with fire safety norms, labour laws and environmental guidelines (such as disposal of scrap paper or glue waste). -

Cost & Financing

Prepare a financial plan for capital investment, estimated ROI period. Investigate government grants or low-interest loans available in Chhattisgarh or central schemes for small-scale manufacturing units. -

Marketing & Distribution Strategy

Once production is operational, establish relationships with local schools, stationery wholesalers, retailers, and government tender agencies. Highlight your capacity, quality consistency, turnaround time, and custom design options.

Case Study Outline: Installing Automatic Notebook Making Machine near Naya Baradwar

Background

A stationery entrepreneur based near Naya Baradwar planned to scale up production of school exercise books for district-level distribution.

Requirements

-

Capacity: 3,000–5,000 notebooks per day

-

Binding: Double-wire stitch binding for 100-page A4 notebooks

-

Custom cover designs and variable thickness options

Solution

They selected an automatic notebook making machine equipped with dual stitching heads, PLC control panel, speed regulation, and programmable trimming. They also acquired a semi-automatic feeding station to handle manually pre-cut paper stacks.

Outcome

-

Daily production target achieved within first month

-

Labour cost per notebook fell by nearly 40 % compared to earlier manual process

-

Turnaround time improved; custom covers delivered within 48 hours

-

Prompt local maintenance support reduced downtime to less than 2 days per month

Lessons Learned

-

Importance of robust installation base (foundation, power supply quality)

-

Need for preventive maintenance schedule with local technician

-

Value of maintaining buffer inventory of staples, spare parts, and glue to avoid stoppages

Choosing Your Supplier

When you research suppliers of notebook making machine in Chhattisgarh or nearby states, ask these questions:

-

Does the supplier provide installation and commissioning service at your Naya Baradwar facility?

-

Are spare parts locally available or stock-maintained nearby?

-

What is the warranty period and terms for mechanical and electrical components?

-

Can the machine be customized to your production specifications (size, binding type, speed)?

-

Can training for operators and technicians be provided on-site?

-

Does the supplier assist in startup configuration, testing, and quality validation of first batches?

Conclusion

Investing in a reliable notebook making machine in Naya Baradwar, Chhattisgarh can transform a small stationery operation into a scalable manufacturing unit. By understanding technical requirements, local context, supply chain considerations, and supplier support, you can make an informed decision that maximises productivity, quality, and profitability.

Whether you choose an automatic or semi-automatic model, ensure your capital investment aligns with projected demand, maintenance planning, and long-term growth strategy. With the right machine in place, you will be well positioned to serve educational institutions, retailers, and wholesalers across Chhattisgarh and beyond.