Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

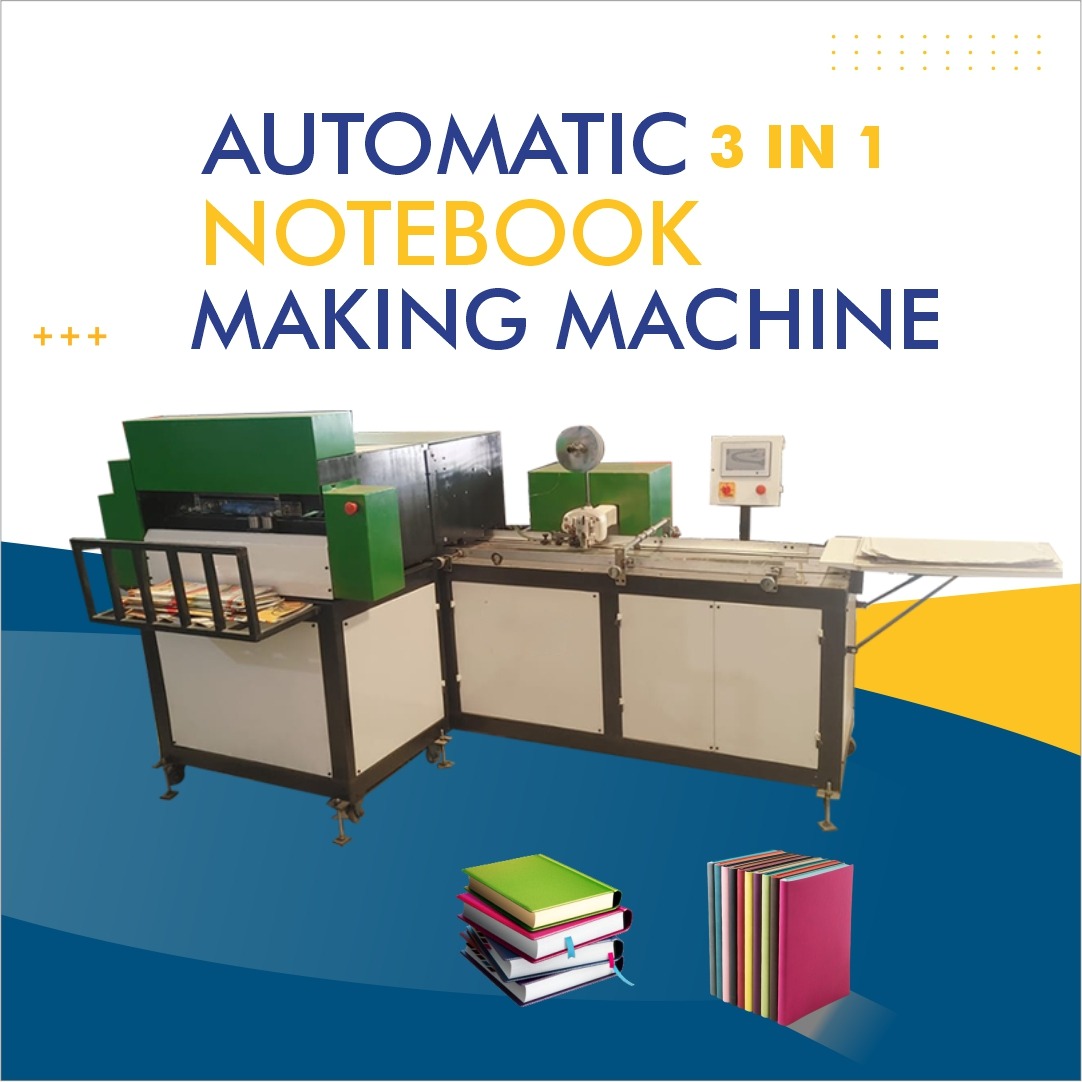

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier | Mungeli (Chhattisgarh) | Quality Stationery Equipment

Notebook Making Machine Mungeli | Chhattisgarh

Mungeli, located in the heart of Chhattisgarh, is emerging as a centre for small and medium-scale industrial units. Among these, stationery and paper-based manufacturing is seeing rapid growth. If you are planning to start notebook production or upgrade your existing facility, investing in a notebook making machine is one of the most critical decisions. In this article, we explore everything you need to know about acquiring a reliable notebook making machine in Mungeli, Chhattisgarh — from types and features to supplier considerations, cost factors, installation and after-sales service.

This comprehensive guide will help entrepreneurs, factory owners, and hobby manufacturers make an informed decision about notebook manufacturing equipment in this region. We cover synonyms such as notebook manufacturing equipment, automatic notebook maker, book-binding machine, paper binding equipment, and stationery production machine.

Why Choose Mungeli (Chhattisgarh) for Notebook Machine Installation

-

Strategic location: Mungeli is centrally located in Chhattisgarh, offering convenient road and rail logistics to nearby industrial hubs and raw-material sources.

-

Cost advantages: Land, power, and labor are relatively more economical than in large metro areas; this lowers the fixed costs of operating stationery production units in Mungeli.

-

Growing demand: Schools, colleges, coaching centres, and offices in the region present consistent demand for notebooks and stationery; setting up a local production unit meets local supply needs while saving transport cost.

-

State-level incentives: Government of Chhattisgarh offers certain incentives for MSMEs (Micro, Small and Medium Enterprises), including subsidy, power-ease, or simpler licensing processes. Locating the notebook making machine facility in Mungeli may allow you to avail such benefits.

Because of these factors, installing a high-quality notebook manufacturing equipment in Mungeli is a smart choice for both new ventures and expanding operations.

Types of Notebook Making Machines

When you're exploring options, you will encounter various types of notebook making machines. Below is an overview of types you might consider:

-

Automatic notebook making machine

These machines handle the entire notebook production cycle—cutting paper, stacking, binding (e.g. spiral, stitched, perfect binding), trimming, and finishing. If you have a high production target, automatic notebook makers offer speed, consistency, and less manual labour involvement. Keywords: automatic notebook maker, stationery production machine. -

Semi-automatic notebook machine

In these machines, specific steps (such as cutting or binding) might require manual intervention, while others are automated. Semi-automatic machines are ideal for medium-scale production where capital cost must be balanced with output volume. -

Manual or table-top binding machine / book binding machine

Best suited for low-volume production or custom notebooks. Although slower, such binding machines allow flexible binding styles and lower investment. -

Custom notebook manufacturing equipment

Some suppliers provide tailor-made machines based on your notebook size (A4, A5, custom), binding type (spiral, glue, thread sew), or special features (hard covers, embossing, perforation). This type of equipment may be more expensive but better suited for differentiated product lines. -

Hybrid model

A combination of mechanical and electrical components to perform multiple tasks with adjustable automation, suited for expansion or modular scaling.

Key Features to Evaluate

Before you purchase a notebook making machine in Mungeli, keep these features in mind to ensure good ROI and operational efficiency:

-

Production capacity & speed

The number of notebooks per hour / per minute the machine can produce. Higher capacity machines (automatic or semi-automatic) will have greater throughput, reducing your unit-cost. -

Notebook format and size flexibility

The machine should support the standard sizes you plan (for example A4, A5, custom sizes), both in terms of page dimensions and cover format. -

Binding type supported

Spiral binding, glue binding, stitched binding, perfect binding, or hybrid. Ensure your machine supports the binding style your target customers expect. -

Material handling

Paper stack thickness, cover stock (cardboard thickness), pre-cut or roll feed, trimming options, and finishing (round corners, embossing, varnishing). -

Precision and consistency

Accurate alignment, neat trimming, consistent binding strength and finish quality — very important to meet quality expectations. -

Ease of operation & maintenance

Look for machines with user-friendly controls, easy maintenance (available spare parts near Chhattisgarh), local electrical compatibility, and technical support. -

Energy consumption

Electricity capacity in Mungeli may be limited or costly during peak demand; low-power or energy-efficient machines reduce production costs long term. -

Safety features & compliance

Ensure the machine meets Indian safety regulations, has emergency stops, and follows industrial standards for electrical and mechanical safety. -

After-sales service

The supplier’s ability to deliver installation, training, spare parts and service support locally in Chhattisgarh or nearby regions.

Cost Factors & Investment Estimate

Investing in a notebook manufacturing equipment involves several cost components. Consider the following when budgeting:

-

Machine cost

Automatic notebook making machines typically cost more than semi-automatic or manual binding machines. Prices vary widely based on capacity, quality of build, brand, and customization. -

Import duty and taxes

If the machine is imported or includes imported components, you may have to pay customs duty, GST, shipping or handling charges. Locally manufactured machines may avoid some extra cost. -

Installation & commissioning

The vendor may charge for installation in your factory in Mungeli, training staff to use the equipment, and initial trial runs to calibrate the quality. -

Civil infrastructure

You may need reinforcement of factory flooring, electrical wiring upgrades, ventilation or workshop modifications to accommodate the machine’s footprint and weight. -

Utility charges

Ongoing electricity, water (if involved), and maintenance consumables (binding wire, glue, thread, cover stock) are part of operating expenses. -

Maintenance & spare parts

Budget for periodic maintenance, spare part replacement (knives, motors, sensors, belts etc.), and possibly service contracts with the supplier. -

Depreciation & financing

If you finance the machine via bank loan or internal capital, compute depreciation, interest and return on investment to ensure your business becomes profitable within your planning horizon.

As an approximate ballpark range, a semi-automatic notebook making machine may cost anywhere from INR 3 lakh to INR 10 lakh (depending on features), while high-speed automatic models could go beyond INR 15 lakh or more — depending on specifications. These figures vary based on brand, capacity, and customization.

Supplier & Vendor Considerations

When choosing a supplier for your notebook making / manufacturing equipment, consider:

-

Proximity to Chhattisgarh / Northern India

A vendor near Chhattisgarh reduces freight cost, improves ease of service calls, and ensures spare parts arrive faster. -

Track record & references

Ask to see installations in similar industry units — especially notebook or stationery manufacturers in nearby states (e.g. Madhya Pradesh, Uttar Pradesh, Maharashtra border areas). Visit references if possible. -

Warranty & support terms

Check warranty period, maintenance contract terms, training offerings, and if there is on-site commissioning at Mungeli or nearby cities. -

Customisation ability

Whether the vendor can adjust machine dimensions, add custom features (e.g. special cover cutting, embossing station, or variable thickness binding). -

Technology & automation level

Compare mechanical versus digital control interfaces, PLC controls, motor quality, sensor systems, and automation modules. Higher technology often yields better speed and less waste, improving profitability. -

Spare parts stock

Check if the supplier maintains parts inventory either locally in Chhattisgarh / neighbouring states, or delivers quickly via logistics. Downtime due to idle machine can cost production loss. -

User training & documentation

Operating complex notebook manufacturing equipment requires skilled staff. Ask if the vendor provides operational training, safety training, and user manuals (preferably in Hindi or English) suitable for your workforce.

Setting Up Operations in Mungeli

Once you acquire your notebook making machine, setting up the operation involves several steps:

-

Site selection & factory layout

Choose a workshop in Mungeli that has sufficient floor space, power load capacity, ventilation, and structural strength to support heavy machinery. Design production flow: raw paper storage → cutting / folding station → binding machine → finishing / trimming → packaging area. -

Utility connections

Ensure stable electricity supply, ideally three-phase power if needed. Evaluate backup or generator options, lighting, air circulation, and dust-control systems to maintain product quality and machine life. -

Raw material sourcing

Establish reliable suppliers of uncut paper sheets or rolls, binding wire or glue, cover stock, and packaging materials. Local sourcing within Chhattisgarh or neighbouring states reduces lead time and freight cost. -

Staff recruitment & training

Hire operators, technicians, quality-control personnel, and maintenance staff. Work with the equipment supplier to conduct hands-on training on machine operation, safety protocols, routine cleaning, and adjustment. -

Quality control & standards

Implement periodic inspection of notebook alignment, binding strength, margin consistency, trimming precision, and cover finishing. Maintain logs, set acceptable tolerances, and monitor defect rates. Good quality will help you compete with branded notebooks on shelf. -

Production planning & scaling

Plan your production cycles based on demand forecasts for schools, offices, or retail sales in Chhattisgarh. Start with moderate volumes to validate your workflow and gradually scale. Use your machine’s full capacity without overstressing it to maximize its lifespan. -

Marketing & sales strategy

Label your notebooks with “Made in Mungeli, Chhattisgarh” to emphasise local production. Tie-up with wholesale distributors, stationery shops in Bilaspur, Raipur, Janjgir-Champa, and other regional towns. Offer customised notebook sizes or covers to educational institutions or corporates in the region. -

Regulatory compliance

Obtain required local permits or trade licences for operating a manufacturing unit in Mungeli. Register under relevant departments (municipal corporation, pollution control board if required, MSME registration for subsidy eligibility, and GST registration).

Competitive Advantage & Growth Prospects

Operating a notebook manufacturing facility with modern equipment in Mungeli can give you competitive edge in several ways:

-

Lower logistics and delivery times

By manufacturing locally, you can respond faster to bulk purchase orders from schools or coaching centres in Chhattisgarh, reducing lead times compared to imported or distant manufacturers. -

Cost-competitive pricing

Reduced freight, lower labour cost, and more efficient machine utilisation can allow you to price your notebooks more aggressively while maintaining margin. -

Customization and flexibility

Possession of your own notebook making machine allows you to offer custom sizes, customised covers, or limited-edition prints — features that generic imported notebooks may not support. -

Expansion into related products

Once your core notebook production stabilizes, you can diversify into related items: exercise books, diaries, notepads, school stationery sets, or diaries with special binding and finishing. Your notebook manufacturing equipment could be adapted or upgraded to support these lines. -

Brand identity & local sourcing

Marketing your products as locally manufactured in Chhattisgarh or “Made in Mungeli” helps build customer loyalty in schools, retailers, offices and corporate gifts packaging markets. Alongside quality assurance, local presence boosts trust. -

Potential for export

If you scale up, there may be opportunities to supply notebooks to nearby states or even export regionally. With high-quality output and cost-effective production, your machine investment starts paying off through volume growth.

Maintenance & Best Practices

To ensure long life and optimal performance of your notebook manufacturing equipment:

-

Perform routine preventive maintenance (lubrication, motor inspection, alignment checks, cleaning).

-

Keep dust and paper residues cleared periodically from cutting and binding stations.

-

Monitor vibration, unusual noises or performance drops; these are early warning signs of misalignment or wear.

-

Use original spare parts or those recommended by the vendor to maintain binding strength and safety standards.

-

Maintain a logbook of machine usage hours, production volume, service intervals, and periodic calibration checks.

-

Schedule annual technical audits with service personnel to adjust for wear and tear, especially in binding mechanisms and cutting blades.

By applying these best practices, you further increase the ROI by extending the useful life of your notebook making machine, reducing downtime, and ensuring consistent product quality.

Conclusion

If you are serious about starting or upgrading your notebook production facility in Mungeli, Chhattisgarh, choosing the right notebook making machine is central to your success. By analysing types of machines, assessing features, planning costs, and ensuring proper installation and maintenance, you position your business to grow sustainably.

With the right notebook manufacturing equipment (such as an automatic notebook maker or semi-automatic notebook machine) and a well-planned operation in Mungeli, you can serve local markets efficiently, scale your output, maintain high quality, and build a brand advantage.