Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

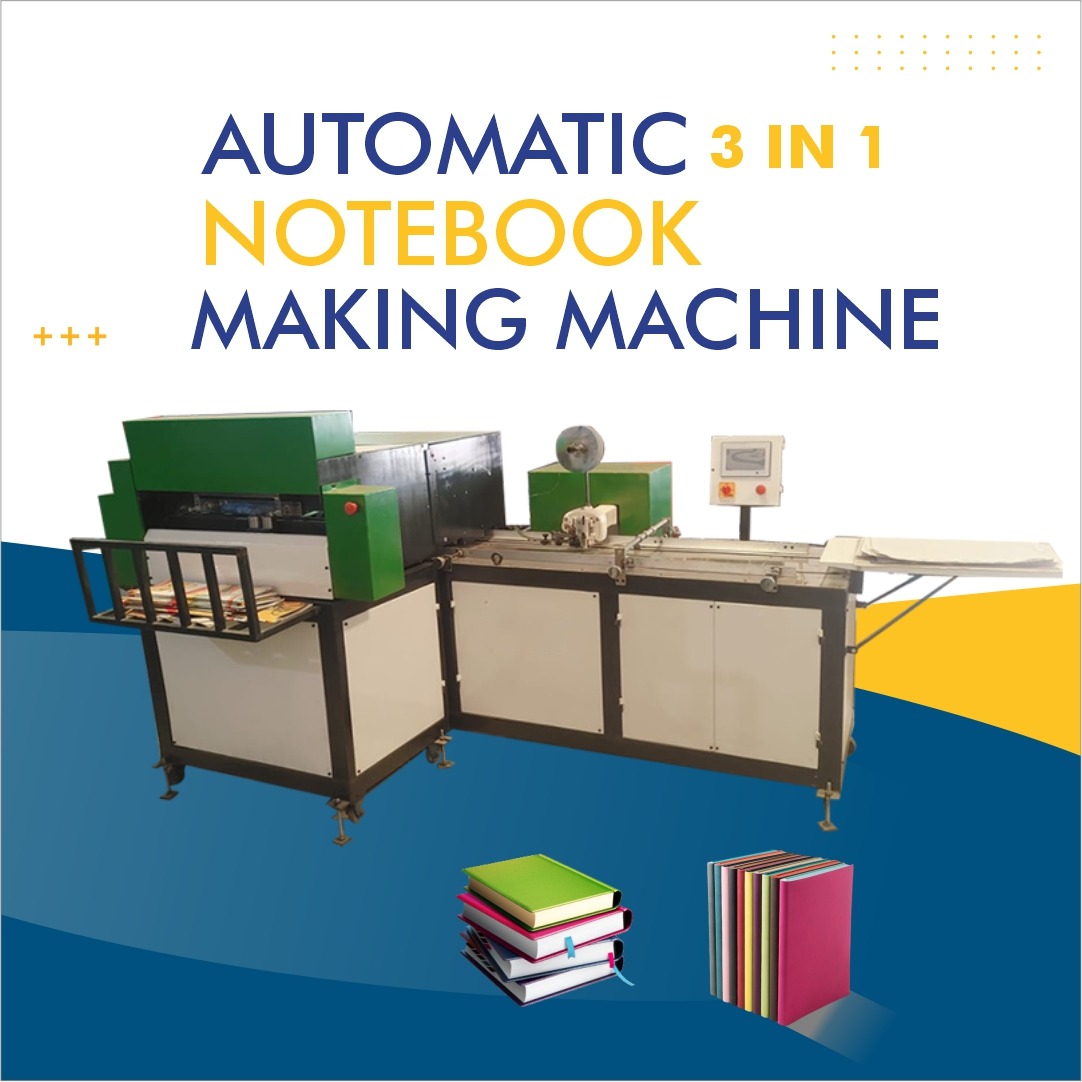

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Khamhria Chhattisgarh – Manufacturer & Supplier

Notebook Making Machine in Khamhria | Chhattisgarh

If you're planning to set up a notebook production unit in or around Khamhria, Chhattisgarh, your first step is selecting the right notebook making machine. A high-quality notebook manufacturing machine ensures consistent output, excellent binding quality, and long-term reliability. In this guide, we’ll walk you through the types of notebook making machines, the benefits of investing locally in Khamhria, key technical specifications, vendor selection tips, and maintenance guidelines.

2. Why Choose Notebook Manufacturing Machine in Khamhria, Chhattisgarh

-

Strategic Location: Khamhria (Raipur district region) offers access to raw materials (paper mills, blank sheets) and is well connected by road to major markets in Chhattisgarh and neighbouring states.

-

Cost Advantage: Lower freight and logistics cost compared to importing machines from far away. Local manufacturing or assembly reduces transportation expense and import duties.

-

Support & Service: Proximity allows quicker after-sales service, spare-parts supply, and installation support.

-

Regulatory & Industrial Policies: State incentives and subsidies for industrial units in Chhattisgarh can reduce the cost of setting up notebook production lines.

-

Customization: Local machine suppliers can better customize notebook making machine design to match the climate, voltage, and operational demand specific to your factory in Khamhria.

3. Types of Notebook Making Machines

Below are some common types of equipment you may require:

| Machine Type | Function |

|---|---|

| Paper Cutting & Trimming Machine | Cuts large paper sheets into correct notebook size. Critical for uniform edges. |

| Binding Machine (Stapling / Stitching) | Binds folded signature sheets into finished notebooks. Could be wire-stitch or saddle-stitch. |

| Spiral Binding Machine | For spiral bound notebooks – inserts coil binding and closes ends. |

| Cover Laminating / Slitting Machine | Applies laminated covers or trims laminated cover material. |

| Corner Rounding Machine | Rounds corners of notebooks to give professional finish. |

| Perforation & Punching Machine | Creates perforated pages or punched holes for rings. |

| Automatic Collating Machine | Aligns sheets, signatures, covers for accurate assembly. |

| High-Speed Notebook Production Line | Integrates cutting, folding, binding, trimming in a semi-automated or fully automated line. |

Each of these can be sold as a standalone machine or as part of a complete notebook manufacturing machine line.

4. Technical Specifications to Evaluate

When purchasing a notebook making machine, carefully check specifications such as:

-

Capacity (Sheets / Hour): How many notebooks can you produce per hour or per shift?

-

Maximum Size / Format: The maximum sheet size the cutting or trimming unit can handle (e.g. A4, A5, custom).

-

Binding Type Supported: Wire-stitch, saddle stitch, spiral coil binding, or glue binding.

-

Automation Level: Semi-automatic or fully automatic collating, stitching, trimming.

-

Power Requirements: Voltage, phase (e.g. 3-phase), power consumption.

-

Material Compatibility: Paper weight (GSM), cover thickness, laminated covers.

-

Accuracy & Tolerance: Cutting tolerance (± mm), binding alignment precision.

-

Safety Features: Guards, emergency stop buttons, operator safety mechanisms.

-

Maintenance Access: Ease of opening the machine for cleaning, blade replacement, lubrication points.

-

Warranty & Spare Parts: Local supplier must provide warranty terms, spare-parts availability.

5. Benefits of a Good Notebook Making Machine

Investing in a reliable notebook manufacturing machine offers multiple benefits:

-

Consistent Product Quality: Uniform cutting, accurate binding, and finishing results in professional-quality notebooks.

-

Higher Productivity: Faster cycle times and higher output per shift reduce unit cost.

-

Reduced Labor & Errors: Automation reduces manual handling, lowering error rates (misaligned pages, uneven cuts).

-

Cost Efficiency: Lower material wastage and energy consumption per unit helps profitability.

-

Scalability: Modular machines or a production line can be scaled up as demand grows.

-

Competitive Edge: Offering better binding, cutting finish, and turnaround times gives an edge in retail or institutional markets (schools, offices).

6. Setting Up a Notebook Production Line in Khamhria

Here’s how you can plan setting up a notebook production facility around the notebook making machine:

A. Site & Infrastructure

-

Ensure adequate floor area with vibration-free foundation for heavy machines.

-

Access to stable three-phase electricity and voltage regulation.

-

Proper ventilation and dust-extraction system to handle paper dust.

B. Raw Materials Sourcing

-

Paper sheets or jumbo rolls (sourced from nearby mills).

-

Covers — laminated sheets, thickness 200–300 GSM.

-

Binding wire, spiral coil, staples.

C. Labour & Training

-

Operators need training for machine setup, alignment, safety procedures, daily maintenance.

-

Supervisor or technician familiar with mechanical adjustments (blade alignment, stitch depth).

D. Workflow Design

Design workflow from cutting → collating → binding → trimming → finishing. Map floor plan to avoid bottlenecks and ensure smooth material flow.

E. Quality Control

Implement QC checks:

-

Page count accuracy per notebook.

-

Binding strength test.

-

Edge straightness and trimming precision.

-

Cover alignment and corner rounding consistency.

7. Choosing a Supplier in or Near Chhattisgarh

When selecting a supplier or manufacturer for your notebook manufacturing machine, consider:

-

Reputation & Reviews — ask for client references.

-

Local presence or service centre near Khamhria / Raipur.

-

Willingness to customize machine dimensions or functions.

-

Spare parts stock availability in Chhattisgarh.

-

Installation & commissioning support on-site.

-

Certification & compliance (electrical safety, CE / Indian BIS standards).

Request a detailed quote with breakdown: machine cost, freight to Khamhria, installation charges, commissioning support, and optional training.

8. Cost Considerations & Return on Investment

Calculate your investment and ROI by estimating:

-

Capital cost: cost of the notebook production line (cutting, binding, trimming etc.).

-

Operating cost: electricity, maintenance, labour per month.

-

Depreciation: useful life of machine (e.g. 8-10 years).

-

Output: number of notebooks per month × selling price per unit.

-

Break-even period: how many months until investment is recovered.

-

Profit margin: revenue minus cost / notebook and per month.

Example: If your machine produces 5,000 notebooks per day, and you sell at ₹10 per notebook, your monthly revenue could be ₹1.5 million (assuming 30 days). Subtract material, labour, electricity and you get gross margin. Then compare that with monthly amortised machine cost to compute payback period.

9. Maintenance & Safety Practices

To keep your notebook manufacturing machine in optimal condition, follow these practices:

-

Regular Cleaning: Daily removal of paper dust and debris around cutting blades and binding heads.

-

Scheduled Lubrication: Apply grease or oil at pivot points, slides, bearings as recommended.

-

Blade & Cutter Check: Inspect knives or trimming blades periodically for wear; replace when dull.

-

Electrical Inspection: Check wiring, switches, safety sensors regularly.

-

Operator Safety Training: Ensure that safety guards are in place. Emergency stop buttons should be tested monthly.

-

Spare-Parts Inventory: Keep critical spares (blades, binding staples, rollers) in stock to reduce downtime.

10. Case Study: Hypothetical Setup in Khamhria

Assume you invest in a high-speed notebook production line incorporating:

-

Automatic paper cutting & trimming machine

-

Collating & binding (wire-stitch) machine

-

Spiral binding module for optional run

-

Corner rounding & finishing unit

You install it at your factory near Khamhria, train two operators and one technician. After one month ramp-up, you reach output of 150,000 notebooks per month. At an average price of ₹10 per unit, your revenue becomes ₹1.5 million. Operating cost (power, labour, materials) is ₹800,000. Depreciation cost per month for machine capital is ₹50,000. That leaves gross margin of ₹650,000 before tax. You recover your capital investment in under 2 years.

This illustrates how the right notebook production equipment and site-advantage near Khamhria can deliver strong returns.

11. Synonyms & Keyword Use Summary

To optimize search-engine visibility for your business page, make sure to repeat synonyms such as:

-

notebook making machine

-

notebook manufacturing machine

-

paper binding equipment

-

binding machine Chhattisgarh

-

high-speed notebook machine

-

spiral binding machine

-

cutting and trimming machine

-

industrial notebook machine

-

notebook production equipment

-

binding equipment India

Each of these should appear naturally throughout your page content, in headings, alt text of images, and meta tags.

Conclusion

Choosing the right notebook making machine near Khamhria, Chhattisgarh is a strategic decision. By evaluating machine types, technical specifications, supplier capabilities, and ROI metrics, you can set up a productive and profitable notebook manufacturing business. Partner with local suppliers, ensure proper training and maintenance, and optimize workflow to maximize your investment.