Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

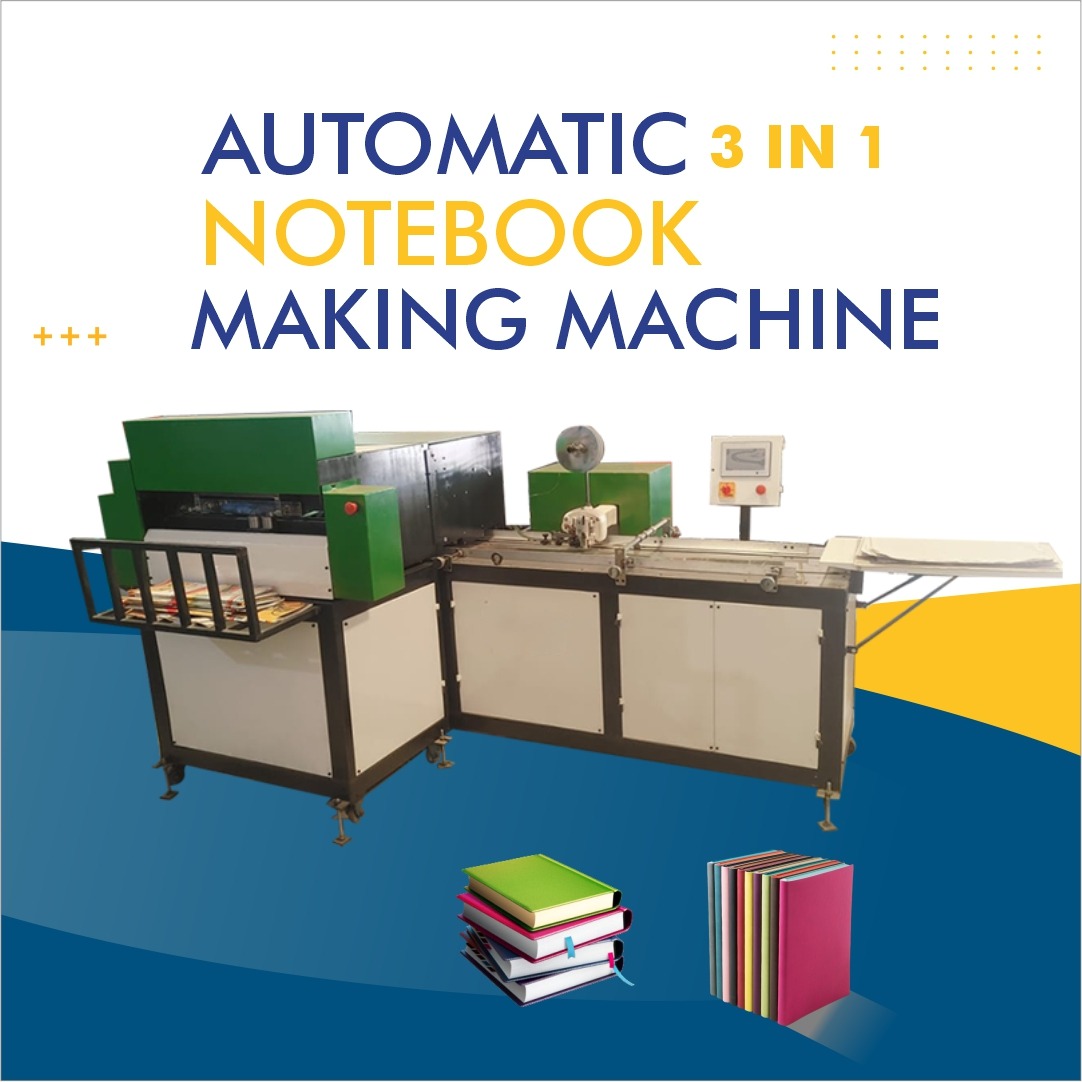

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Buy Notebook Making Machine in Katghora – Quality Machinery Supplier

Notebook Making Machine in Katghora | Chhattisgarh

Katghora is an emerging town in the Korba district of Chhattisgarh, India. Wikipedia+1 With its growing industrial base and proximity to major road networks (such as National Highway NH-130), Katghora is a promising location for setting up manufacturing and production units. A major opportunity lies in stationery manufacturing — especially in notebook production.

If you are looking to buy or install a notebook making machine in Katghora, Chhattisgarh, this guide will help you understand the types, benefits, specifications, and business potential in this region.

Why Katghora is a Good Location for Notebook Manufacturing

-

Industrial / Manufacturing Hub Proximity

Katghora has been listed among industrial & manufacturing hubs in Chhattisgarh. TradeIndia This indicates infrastructure and potential for access to workshops, labor, local materials, and machine servicing. -

Connectivity

Being on NH-130 and connected to Bilaspur, Korba, and neighboring regions, transport of raw materials (paper, glue, covers) and finished goods is viable. Wikipedia -

Lower Overheads Compared to Metro Areas

Setting up manufacturing in Katghora can offer lower land / labour cost compared to larger city or industrial zones. It can attract small-to-medium enterprises planning notebook production. -

Growing Industrial Ecosystem

There are other factories and engineering units around Katghora / Korba district, enabling access to ancillary services, maintenance, metal fabrication, and staff. Scribd+1

Given these advantages, installing a notebook making machine in Katghora is not only feasible but could be cost-effective and scalable for local or regional sales.

What is a Notebook Making Machine

A notebook making machine is an industrial equipment set that allows conversion of raw materials (paper sheets, cover boards, binding material) into finished notebooks. It may integrate various stages:

-

Paper cutting

-

Folding

-

Stitching or binding

-

Cover pasting or lamination

-

Trimming / polishing edges

-

Packaging

Depending on level of automation, you may find manual, semi-automatic, or fully automatic notebook making machines.

Synonyms:

-

notebook production machine

-

notebook fabrication equipment

-

notebook assembly machine

-

book binding machine

-

notebook manufacturing system

These synonyms can help you target related search queries.

Types & Specifications

Here are typical variants you may consider when sourcing machinery for your notebook production in Katghora or nearby.

| Type | Description | Typical Capacity | Notes |

|---|---|---|---|

| Manual Notebook Making Machine | Operator-driven functions such as manual sheet feeding, cutting, folding, stitching. Lower cost base. | e.g. ~3,000 pcs/day | Suitable for small scale operations. sbsmachine.com |

| Semi-Automatic Notebook Making Machine | Some functions like cutting, binding or trimming automated; rest manually managed. | Several thousand pcs/day | Popular for mid-scale production. asveng.com+1 |

| Fully Automatic Notebook Making Machine | All or most processes automated: sheet feeding, binding, trimming, finishing. | Thousands to tens of thousands daily | Best suited for high volume operations. kolkatamachineryimportexport.com+1 |

Other specification parameters to evaluate:

-

Automation grade (manual / semi-automatic / automatic)

-

Production capacity (e.g. notebooks per day or per hour)

-

Size compatibility (A4, A5, custom sizes)

-

Power requirements (voltage, phases, KW)

-

Material and build quality (mild steel, frame strength)

-

After-sales service, spare parts availability

Benefits of Using a Notebook Making Machine in Katghora

-

Local Production & Faster Turnaround

Instead of outsourcing production to distant cities, having your own notebook manufacturing system near Katghora means you can respond quickly to orders, reduce transportation cost and improve quality control. -

Cost Savings on Logistics

Raw material suppliers for paper, covers, adhesives may be sourced from nearby or regional markets. Local end customers (schools, stationary vendors around Chhattisgarh) can be served with lower delivery cost. -

Employment & Skill Development

Setting up a notebook fabrication equipment setup employs local labor. You can train staff in operation & maintenance of the notebook manufacturing system, boosting local employment. -

Scalability

Starting with a manual or semi-automatic notebook making machine allows you to experiment with small batches. Later you can upgrade or add additional capacity or move to fully automatic notebook making machine as demand grows. -

Profit Margins & Business Potential

Stationery demand is stable year-round (schools, colleges, local administration). Margins can be good if you control production cost. Also scope to customize notebooks (size, cover design, binding style) for niche segments.

Setting Up Your Notebook Manufacturing Unit — Steps & Considerations

If you plan to establish a notebook production unit in Katghora using a notebook production machine or notebook fabrication equipment, consider following steps:

1. Market Research & Demand Estimation

-

Survey local schools, colleges in Katghora / Korba / Bilaspur for their stationery requirements.

-

Check volume needed per month, design/customization needs.

-

Evaluate competitor notebooks (quality, price).

2. Choice of Machine & Supplier

-

Decide whether to start with manual / semi-automatic / fully automatic depending on budget & demand.

-

Compare suppliers (manufacturers in India) for notebook making machine variants.

-

Ask for capacity, warranty, spare parts, and training support.

3. Place & Infrastructure

-

Identify premises in Katghora (industrial area or non-residential zone).

-

Ensure supply of electricity (single / three phase as per machine), floor strength, ventilation, safety.

-

Plan storage for paper rolls / sheets, finished inventory, raw material handling.

4. Staffing & Training

-

Hire machine operators, helpers, quality controllers.

-

Train them for machine operation, maintenance, safety procedures (especially for semi / fully automatic systems).

5. Raw Material Procurement

-

Paper sheets or reels, cover boards, binding wires or staple wires, glue or adhesives, cover lamination / printing services.

-

Ensure reliable supply in or near Chhattisgarh to reduce lead times.

6. Quality & Customization

-

Provide options for size (A4, A5, custom), cover finishing, binding style.

-

Ensure consistent trimming, edge finishing, binding strength.

7. Legal & Regulatory Compliance

-

Register your business legally. Obtain local licenses if required.

-

Comply with power / environmental norms.

-

Consider GST / tax implications for selling stationery.

8. Marketing & Sales Channels

-

Sell notebooks locally (schools, stationery shops), regional (Bilaspur or Korba), or online (e-commerce).

-

Highlight “Made in Katghora / Chhattisgarh” as a local-brand advantage.

9. Scaling & Upgradation

-

As demand grows, you may add additional notebook assembly machine units, upgrade to fully automatic notebook manufacture machine, or diversify into registers / diaries.

Challenges & Risk Mitigation

-

Initial Capital Investment

Manual or semi-automatic machines are less expensive but have lower throughput. Fully automatic systems cost more. Plan capital budgeting carefully. -

Machine Maintenance

Being in Katghora, ensure that maintenance support / spare parts availability is addressed at contract stage. Choose suppliers that serve Chhattisgarh or have nearby service centers. -

Supply Chain Disruptions

Paper or other inputs may have price fluctuations. Strengthen relationships with multiple suppliers. -

Competition

There may be competing notebook manufacturers in other areas. Focus on quality, customization, timely delivery, and cost advantage. -

Regulatory & Power Supply Issues

Power interruptions, licensing delays or taxation changes (like GST norms) can affect production. Ensure backup plans or contingency reserves.

Case Scenario / Sample Business Model

Suppose you set up a small-scale notebook manufacturing unit in Katghora using a semi-automatic notebook making machine with capacity of 5,000 notebooks per day:

-

Monthly Output (assume 26 working days): ~130,000 notebooks

-

Costing: Raw material cost (paper, cover, binding), labor, utilities, machine maintenance

-

Revenue: Selling rate per notebook (e.g. small custom notebook for schools)

-

Profit margin: after fixed & variable costs

With efficient operations, you could break-even within months and expand capacity gradually by acquiring another notebook production machine or upgrading to an automatic notebook manufacturing system.

You may also supply bulk orders to schools, publishers, or stationery wholesalers in Korba / Bilaspur / Raipur.

How to Choose the Right Supplier / Vendor

When shopping for a notebook making machine supplier for your Katghora project:

-

Request technical datasheets for notebook making machines (manual, semi-automatic, automatic).

-

Compare capacity & productivity metrics.

-

Ask for site visits or video demos if possible.

-

Check warranty & spare parts availability in Chhattisgarh or nearest state.

-

Evaluate training & installation support included in the purchase.

-

Consider energy consumption and power compatibility (single / three phase).

Also ask for references from other units in Chhattisgarh or neighbouring states which operate similar notebook manufacturing machinery.

Conclusion

Investing in a notebook making machine in Katghora, Chhattisgarh offers you an excellent opportunity to build a stationery production business with localized advantage. With the right choice among manual, semi-automatic or automatic notebook making machines, proper planning, market understanding, and operational discipline, you can build a profitable unit serving schools, colleges, and retail channels in the region