Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

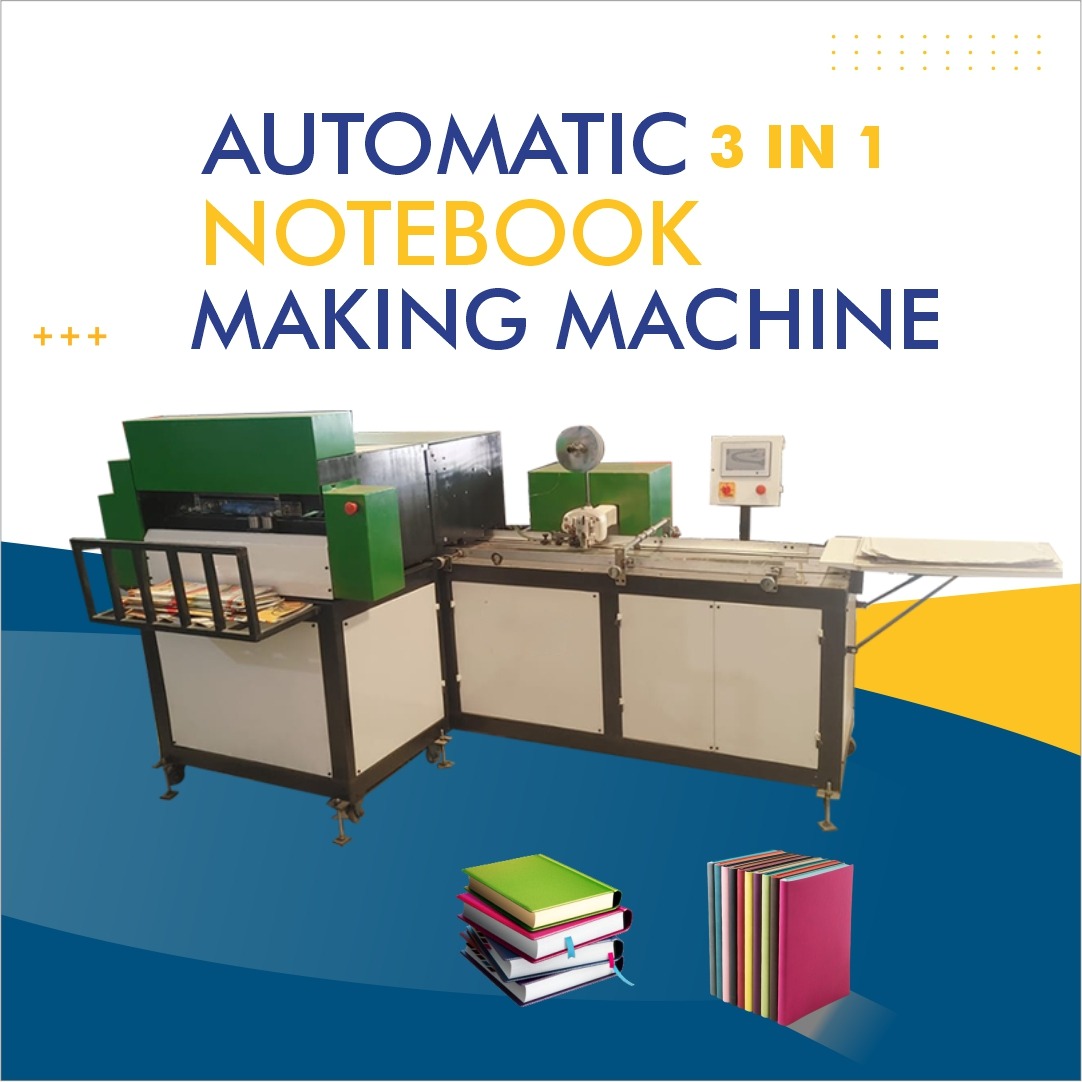

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Jagdalpur, Chhattisgarh | Buy & Install | Service & Parts

Notebook Making Machine in Jagdalpur | Chhattisgarh

Jagdalpur (Bastar district) is emerging as a promising location for small-scale manufacturing and MSME industries in Chhattisgarh. Wikipedia If you are planning to start or expand a notebook manufacturing business in or around Jagdalpur, investing in a quality notebook making machine is one of the most critical steps. This guide explains what to look for, types of machines, costs, installation, and business potential in Jagdalpur / Bastar region.

2. Why Notebook Making Machine Business in Jagdalpur

-

Growing educational & institutional demand: Schools, colleges, coaching centres in Bastar region require exercise books, registers, diaries. Local production reduces transport costs and lead time.

-

Proximity to raw material sources & markets: While Jagdalpur is not a paper-mill hub, being in Chhattisgarh with road connectivity (and future infrastructure improvements) helps in supply chain.

-

Development push for Bastar region: Government and private investments in Bastar are increasing. Though not specific to stationery, such infrastructure development improves ease of doing business. The Times of India

-

SME friendly environment: Local workshops, training institutes (e.g. Government Engineering College, Jagdalpur Wikipedia) can provide technical manpower support and local servicing.

Because of these factors, setting up a notebook manufacturing unit with own notebook making machine can be a viable micro / small industry in Jagdalpur / Bastar region.

3. Types of Notebook Making Machines

When choosing a notebook making machine, you must consider:

| Type | Advantages | Considerations |

|---|---|---|

| Manual / Semi-automatic machine | Lower investment, simple parts, easier maintenance | Lower capacity, more manual labour needed |

| Fully automatic machine | Higher throughput, consistency, reduced labour cost | Higher capital cost, power supply, maintenance complexity |

| Hybrid models | Mix of automation for some stages (e.g. folding, binding) while manual feeding in others | Good for mid-scale venture |

Some examples of machines available in India:

-

A Fully Automatic 3-in-1 Notebook Making Machine with A4 size support, capable of 1500-2000 books/hr. namibind.com

-

A Single Head Automatic Notebook Making Machine from a manufacturer using servo-control for stitching precision. endurancemachinery.com

-

Semi-automatic vs fully automatic variants offered by Indian firms such as Bhartiya Machine Works. bhartiyamachineworks.com

4. Key Specifications to Evaluate

When you evaluate a notebook making machine for your unit in Jagdalpur, consider the following:

-

Production Capacity: Number of notebooks per hour (e.g. 800, 1,500, 2,000 etc.)

-

Automation Level: Manual / Semi-automatic / Fully automatic

-

Notebook Size Support: A4, A5, other custom sizes

-

Thickness / Number of Pages per notebook (binding thickness)

-

Functions Included: Ruling, cutting, stitching, folding, edge squaring, packing

-

Power Requirements: Phase (single / three), voltage, motor power

-

Control System: PLC-based programming, servo control, pin-programming etc.

-

Warranty & After-Sales Service: Important for maintenance & uptime

-

Footprint & Layout: Space required in your factory / shed in Jagdalpur

-

Local Serviceability: Spare parts supply / Technical support nearer to Jagdalpur / Raipur region

5. Cost & Investment Estimation

Based on Indian market data:

-

Semi-automatic machines typically cost less, suitable for startup scale.

-

Fully automatic machines cost more, but yield higher throughput and lower labour cost per notebook. For example, several models in India range from ₹5-6 lakh upwards for automatic machines. bhartiyamachineworks.com+1

You should budget for:

-

Machinery purchase price

-

Shipping / Transportation costs to Jagdalpur

-

Installation & commissioning charges

-

Power connection (may require industrial meter / phase conversion)

-

Shed / workshop setup (flooring, space, ventilation)

-

Operator training & maintenance tools

-

Raw material (paper, cover board, binding wire / thread)

-

Working capital for first few months

Make a financial model with expected output (books per day), sales price per notebook, raw-material cost, labour & electricity, to estimate payback period.

6. Installation & After-Sales Service

Having a local or regional supplier can greatly reduce downtime. For Jagdalpur / Bastar region, you may:

-

Order machine from manufacturers who offer nationwide delivery / support

-

Ensure warranty / spare parts availability

-

Train local technicians or operators

-

Arrange periodic maintenance visits

Because power supply or technical skills may be limited in remote areas, plan for backup support, spare parts arrival time, and preventive maintenance schedule.

7. Finding a Supplier & Vendor

To procure a notebook making machine for Jagdalpur, you can:

-

Contact Indian manufacturers such as Bhartiya Machine Works (for semi / fully automatic models) bhartiyamachineworks.com

-

Approach machinery vendors like “Sujata Machines” or similar firms offering automatic notebook making machines with required capacity. sujatamachines.in

-

Request quotes from multiple vendors, check delivery lead time (including freight to Jagdalpur), check installation responsibility

-

Compare technical features (stitch head, folding, edge squaring, speed, PLC / servo control)

You may also explore vendors listed on India-Mart or similar industrial directories for printing / binding / packaging machinery.

8. Setting Up Your Notebook Manufacturing Unit in Jagdalpur

Here’s a sample plan to start:

-

Location & Infrastructure

-

Rent or build a small workshop facility near Jagdalpur town or industrial area.

-

Ensure enough floor area for the machine, storage for raw paper and finished notebooks.

-

Arrange three-phase power connection if required.

-

-

Procurement

-

Select appropriate machine: semi or fully automatic based on your budget and planned production capacity.

-

Order machine, coordinate delivery to Jagdalpur (freight transport via road).

-

-

Installation & Training

-

Get installation by vendor or trained technician.

-

Train one or two operators on machine operation, safety, maintenance.

-

-

Raw Material & Suppliers

-

Arrange supplier for paper sheets / boards / binding wire / cover material. Perhaps from Raipur or other nearby supply bases.

-

Negotiate rates once your monthly volumes are known.

-

-

Production & Quality Control

-

Set daily / weekly production targets (e.g. 500 notebooks per day, or higher).

-

Ensure quality: correct ruling, clean stitching, proper trimming, neat edge finishing.

-

-

Sales & Distribution

-

Approach local schools, coaching institutes, office-stationery shops in Jagdalpur & Bastar districts.

-

Explore neighbouring districts as well (Kondagaon, Dantewada etc.).

-

Price competitively considering cost & competition.

-

-

Scaling & Growth

-

Once initial orders steady, reinvest profits to increase capacity (e.g. add another shift or buy second machine).

-

Expand into related products: registers, diaries, spiral bound notebooks, customised covers.

-

9. Challenges & Risk Mitigation

-

Power supply reliability: Ensure stable electricity; perhaps a backup or stabilizer if voltage fluctuations.

-

Skilled operator availability: Training may be needed for local workers.

-

Logistics & transport: Delivery of paper or dispatch of finished notebooks may face higher transport costs from Jagdalpur – factor that into pricing.

-

Competition from established stationery brands: You must ensure your quality & delivery time compete well.

-

Regulatory / Licensing: Check local municipal regulations, GST registration, business licence for manufacturing unit in Chhattisgarh.

Conclusion

If you run the numbers correctly, a well-chosen notebook making machine with moderate capacity (say 1,000 to 2,000 notebooks per day) can deliver a good return on investment over 12-24 months, provided you manage inputs, maintain quality, and secure steady orders.

Because Jagdalpur / Bastar is underserved for local stationery manufacturing (much is imported / brought from outside), your local production offers advantages: faster delivery, lower freight cost, ability to customize covers / sizes quickly, and plan for local schools and institutional tenders.