Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

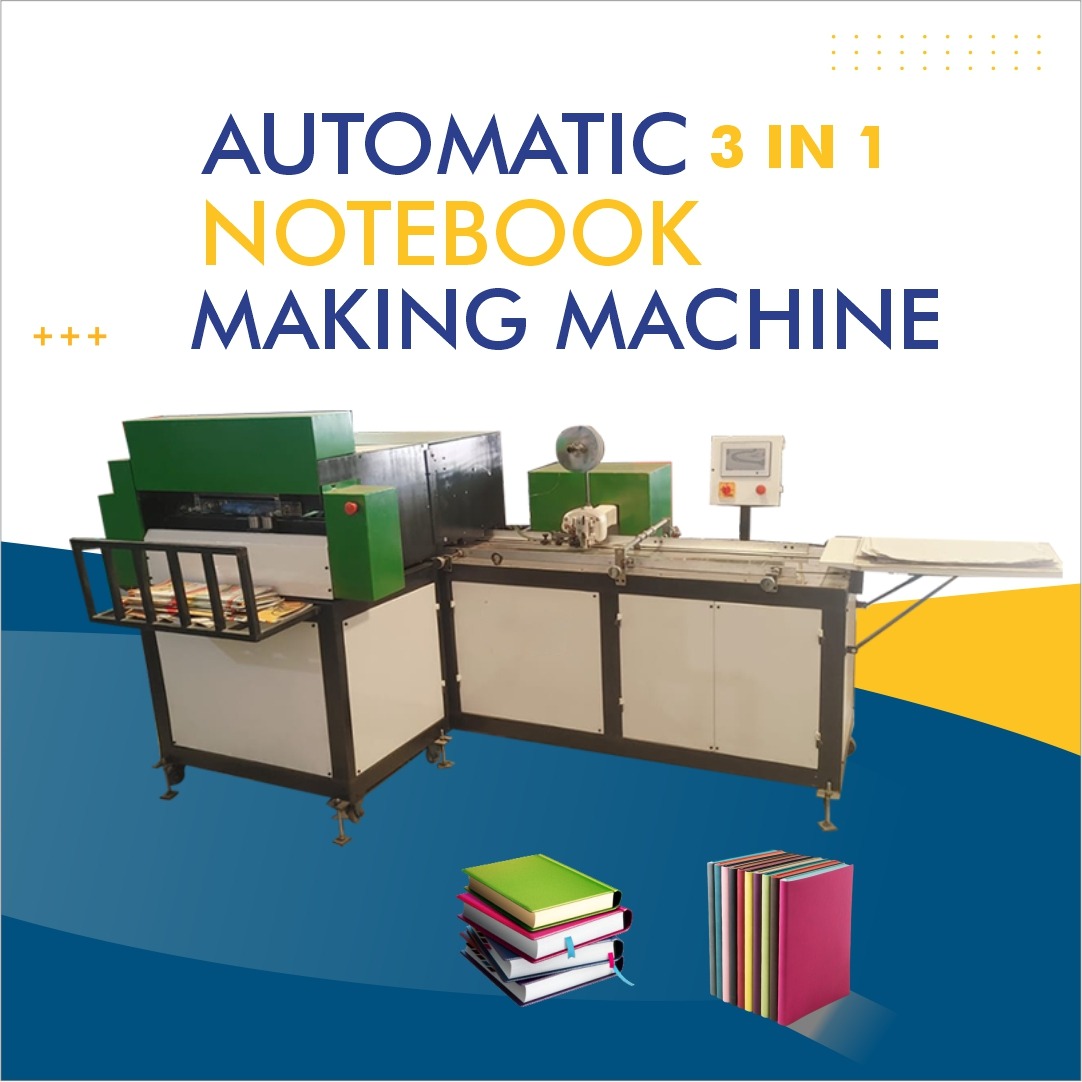

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine – Gobra Chhattisgarh Manufacturer & Supplier

Notebook Making Machine Gobra | Chhattisgarh

Gobra in Chhattisgarh has emerged as a growing hub for industrial machinery manufacturing. Among the key equipment produced here, the notebook making machine holds a prominent place. Businesses involved in stationery production rely on such machines to create high-quality notebooks in large volumes. Whether you are setting up a new production line or upgrading your existing facility, choosing the right notebook making machine from a reputable manufacturer in Gobra ensures dependable quality, local support, and cost-effectiveness.

This page provides an in-depth guide to notebook making machines — their types, features, benefits, and why Gobra Chhattisgarh is becoming a preferred location for purchasing one.

What is a Notebook Making Machine?

A notebook making machine is industrial equipment used to assemble, bind, trim, and finish notebooks. It is composed of modules such as paper feeder, stitching or gluing section, trimming unit, binding and packing module. These machines can be semi-automatic or fully automatic, depending on the scale of production.

Different options include:

-

Automatic stitching/sewing binding

-

Glued binding

-

Edge trimming and cover lamination

-

Paper cutting and stacker module

These features ensure that produced notebooks meet quality standards for pages alignment, edge finish and cover durability.

Why Choose a Notebook Making Machine from Gobra, Chhattisgarh

Local Manufacturing Expertise

Gobra hosts manufacturers experienced in stationery machinery production. By choosing a machine built here, you gain the advantage of local engineering talent familiar with regional materials, voltage & power supply standards, and after-sales service support.

Cost-Effective Solutions

Local manufacturing in Chhattisgarh typically offers lower costs compared to imported equipment — reduced logistics cost, lower customs duties, and faster installation support.

Customization & Support

Gobra-based manufacturers often offer customization: you can specify paper sizes, trim style, binding method (stitching or gluing), speed (notebooks per minute), and automation level. On-site installation, operator-training and spare parts availability are easier when the machine is manufactured nearby.

Quality & Standards

Many local companies follow industrial standards for mechanical design, electrical safety, and machine durability. Proper assembly line machines ensure operational reliability and consistent product quality.

Types of Notebook Making Machines

Below are common categories of notebook making machines:

-

Automatic Notebook Making Machine

Fully automated equipment that takes raw paper piles, folds or arranges pages, binds them (by stitching or gluing), trims edges, and delivers finished notebooks. Ideal for large-scale production units. -

Semi-Automatic Notebook Machine

Requires some manual input for feeding or changeovers, while parts of the process such as trimming or binding are automated. Good for small to medium production volumes. -

Paper Binding and Stitching Machine

Specifically for the binding stage: stitching wires, staples or threads. Often integrated in a more comprehensive notebook production line. -

Glued Edge Binding Machine

Uses adhesive on one edge to bind sheets. This is suitable for soft-cover notebooks or diaries where stitching is not preferred. -

Cutting / Trimming Module

A separate or integrated module to trim edges of pages and covers to uniform dimensions. Important for finish quality. -

Cover Laminating or Lamination-Ready Machine Add-ons

Some machines allow you to laminate or apply protective coating to the cover for durability and premium look.

Key Features to Look For

When evaluating a notebook making machine—or comparing offers from suppliers in Gobra or elsewhere—you should pay attention to the following features:

-

Production Speed: Measured in notebooks per hour or minute. Higher throughput reduces cost per unit.

-

Paper Size Handling: Standard sizes (A4, A5, custom) and maximum thickness or number of sheets per notebook.

-

Binding Method: Stitch-binding capacity (wire, thread), glue binding strength, or combined options.

-

Trimming Accuracy: Edge finish tolerance in millimetres. Straight and clean edges enhance appearance.

-

Automation Level: Fully automatic lines have fewer manual touch points; semi-automatic ones may require manual feeding or stacking.

-

Energy Consumption & Safety: Compliant electrical design, safety guards, and efficient motors to minimize running costs.

-

Ease of Maintenance: Spare parts availability, ease of access, modular design to replace components.

-

Footprint & Layout: Floor space requirement, alignment with your factory layout and material flow.

-

After-Sales Services & Training: Local servicing, maintenance support, operator training to ensure minimal downtime.

The Notebook Manufacturing Process Flow

Below is a typical sequence in a notebook production line using a modern machine:

-

Paper Loading / Feeding — raw paper sheets sorted and stacked in feeder.

-

Page Collation — assembling the inner pages in the correct order.

-

Binding — stitching or gluing the stacked pages to the spine or cover.

-

Trimming — cutting edges of pages and cover to uniform dimensions.

-

Cover Attachment — adding front/back cover and affixing it properly (with adhesive, lamination, or stitching).

-

Finishing & Stacking — stacking the finished notebooks, possibly shrink-wrapping or packing.

-

Quality Check — verifying weight, page count, binding strength, and finish consistency.

Each step can be performed by dedicated modules within the notebook making machine, or by auxiliary equipment integrated into the production line.

Benefits of Owning a Notebook Making Machine

-

Increased Production Capacity – You can manufacture hundreds to thousands of notebooks per hour depending on the machine specifications.

-

Reduced Labor Cost – Automation reduces manual labor, increases consistency, and lowers error rate.

-

Improved Quality & Uniformity – Finely adjusted trimming and binding control produces professional finish.

-

Scalability – Machines can be upgraded or extended with add-on modules (e.g. lamination unit, additional trimming heads).

-

Competitive Edge – Owning advanced machinery helps meet bulk orders, ensure timely delivery, and win institutional or wholesale contracts.

-

Return on Investment – While initial capital cost is significant, efficient, high-speed machines pay back via lower per-unit cost and higher throughput.

Why Gobra, Chhattisgarh Is a Strategic Location

Infrastructure & Connectivity

Gobra enjoys proximity to road networks, power supply infrastructure, and access to raw materials such as paper and binding wire. That helps reduce lead times and cost for shipping raw materials and finished machines.

Industrial Ecosystem

Being near other manufacturing clusters in Chhattisgarh and neighbouring states helps coordinate backups for parts suppliers, skilled workforce, and engineering vendors.

Supportive Local Policies

Sometimes state or local industrial development authorities offer incentives, land-use benefits or support for machinery manufacturing units. Partnering with a local manufacturer might ease regulatory approvals and installation timelines.

Reduced Delivery Times

When the manufacturer is in Gobra, it is easier to coordinate installation visits, training sessions, and maintenance follow-ups compared to sourcing from distant cities.

How to Choose a Supplier in Gobra, Chhattisgarh

To select the right notebook machine manufacturer in Gobra, consider the following steps:

-

Assess Your Production Needs

Estimate your required volume (notebooks per day), sheet sizes, binding types and trimming specifications. -

Request Machine Specifications

Ask for datasheets: speed, power consumption, dimensions, accuracy tolerances, and warranty terms. -

Compare Quotes

Get multiple offers from local manufacturers. Compare cost, training package, installation lead time, and spare parts coverage. -

Visit the Factory

If feasible, visit the manufacturer’s plant in Gobra to see prototype or demo machines in operation. -

Check References

Ask for testimonials or case studies of other clients who bought similar machines and their performance. -

Negotiate Terms

Payment schedule, after-sales support, maintenance contract and delivery schedule should all be clarified before signing.

Maintenance Tips & Lifespan

-

Routine Inspection – Lubrication of moving parts, checking binding heads and trimming blades periodically.

-

Blade Sharpening or Replacement – Trimming knives or cutters should be kept sharp for clean edges.

-

Electrical Checks – Periodically inspect wiring, safety interlocks, and control panels.

-

Spare-Parts Stocking – Maintain stock of critical parts: adhesives, binding wires, blade sets, belts, sensors.

-

Operator Training – Trained operators minimize downtime and machine misuse.

With prudent maintenance and usage, a quality notebook making machine can serve reliably for many years, delivering consistent output with reduced breakdowns.

Case Study Example (Hypothetical)

Suppose StationeryCo Pvt. Ltd. located near Bilaspur chose a fully automatic notebook making machine built in Gobra:

-

Daily production: 10,000 A5 notebooks

-

Binding type: wire-stitch binding with edge trimming

-

Payback period: approximately 18 months due to high throughput and reduced labor cost

-

Quality result: uniform cuts within ±0.5 mm tolerance, minimal rejects

This kind of performance showcases how a locally built machine can deliver industrial-grade output with reliable service support and ROI.

Conclusion

If you are planning to set up or upgrade a notebook production unit, investing in a notebook making machine from Gobra Chhattisgarh can provide significant advantages — from cost savings and customization to local maintenance support. By carefully evaluating features like speed, binding method, trimming accuracy, service availability and supplier reputation, you can select the right equipment for your business goals.

Contact a reputable manufacturer in Gobra today to discuss your requirements, request a quote, and arrange a site-visit. With the right machine in place, you can scale your production, improve product quality, and grow your stationery business.