Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

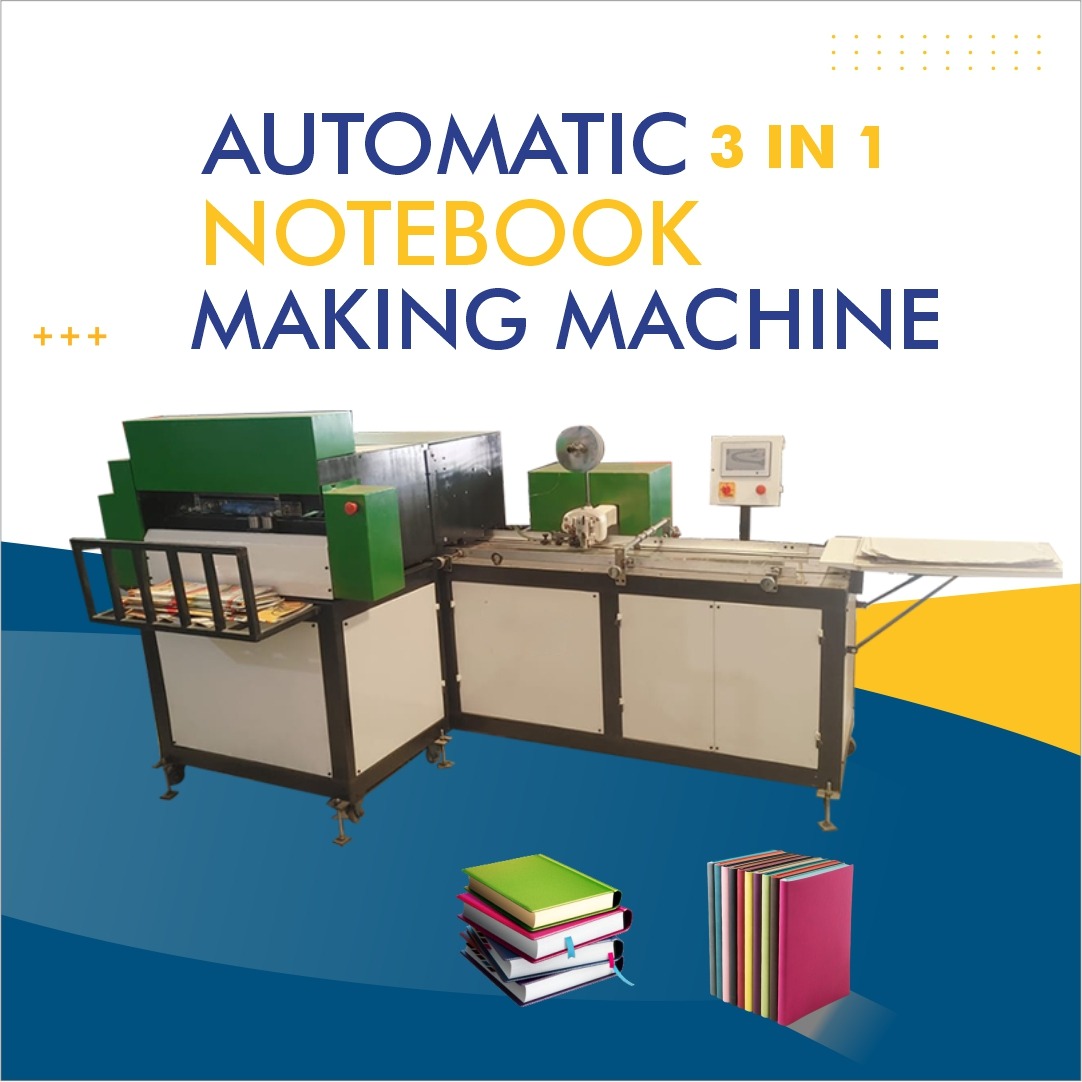

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Buy Notebook Making Machine in Gharghoda Chhattisgarh | Reliable Supplier

Notebook Making Machine in Gharghoda | Chhattisgarh

If you're planning to start or expand a notebook production business in Chhattisgarh, a quality notebook making machine is essential. At Gharghoda, Chhattisgarh, you can source durable and efficient notebook machines that suit your production scale — from small artisanal units to large-scale school-grade notebook manufacturers. In this article, we explain what features to look for, why Gharghoda is a good location, the types of machines available, and how to choose the right model for your needs.

Why Choose Gharghoda, Chhattisgarh for Notebook Making Machine Purchase

Gharghoda is emerging as a hub for small and medium scale manufacturing in Chhattisgarh. The advantages include:

-

Proximity to raw material sources: Many paper suppliers, binders and packaging material vendors are accessible within regional supply chains.

-

Lower transportation cost: Being located in Chhattisgarh reduces logistics cost if your target market includes adjoining districts and nearby states.

-

Local expertise: Technicians and operators familiar with notebook binding and machine maintenance are available locally.

-

Support for regional industries: Government incentives or ease of local customs / clearances may apply for a manufacturing unit operating out of Gharghoda or surrounding region.

By selecting a notebook making machine from a supplier based in or servicing Gharghoda, you benefit from quick service support, timely spare part replacement, and lower lead times.

Key Features to Consider in a Notebook Making Machine

Whether you are buying a manual, semi-automatic or fully automatic notebook making machine, certain specifications are critical. Here’s what to evaluate:

-

Production Capacity

How many notebooks per hour or per minute? Small operations may require ~50-200 notebooks/hour; larger units may need 500+ notebooks/hour. -

Binding Method

Choices include perfect binding, saddle stitch, staple binding or spiral binding. For school notebooks, staple-type or sewn binding are common. -

Sheet & Cover Size Compatibility

Machines must support standard sizes: A4, A5, letter-size, or custom sizes depending on your customer base. -

Automation Level

-

Manual: Requires more human effort but lower initial cost.

-

Semi-automatic: Motor-driven components with manual feeding or loading.

-

Fully Automatic: Material feeding, cutting, binding and trimming all under programmed control.

-

-

Build Quality & Durability

Stainless steel or industrial-grade framing ensures longevity. Precision rollers, cutters, adhesives or staple mechanisms should be robust and serviceable. -

Changeover Time & Flexibility

Ability to switch between sizes or binding types with minimal downtime. Useful if you produce different notebook formats. -

Maintenance & Spare Parts

Choose a supplier offering spare parts within Chhattisgarh or the region. Local availability from Gharghoda or nearby makes it easier to maintain uptime. -

Cost & ROI

Consider initial investment, operating cost (electricity, labor, consumables), and projected sales revenue. A good notebook making machine should deliver payback in reasonable timeframe.

Types of Notebook Making Machines

Here are some common types available to notebook producers:

-

Manual / Semi-automatic Stapled Notebook Machine

Suitable for small volumes; operator assembles pages and staples binding manually or semi-automatically. -

Spiral Notebook Making Machine

For spiral binding notebooks; includes coil insertion, punching holes and trimming edges. -

Perfect Binding / Glue-Binding Machine

Useful for premium notebooks with glued spines rather than staples. -

Fully Automatic Production Line

Integrated machine that takes paper feed, cuts pages, assembles signatures, covers, binds, trims and stacks finished notebooks automatically. -

Edge-Glued Hardback Notebook Equipment

For notebooks with hard covers and glued edges; usually higher cost but premium finish.

Benefits of Installing Notebook Making Machine in Gharghoda

Installing or buying a notebook making machine in this geographic location can offer multiple advantages:

-

Lower Delivery Lead Time: Proximity means you can receive the machine faster and reduce idle waiting.

-

On-site Technical Support: Local technicians from or near Gharghoda can provide faster repair and calibration.

-

Cost-effective Training: The operator training and servicing can be done locally without high travel or accommodation costs.

-

Adaptation to Local Paper Grades: Machines can be calibrated for paper types commonly used in Chhattisgarh, adjusting for humidity, thickness or local standards.

-

Compliance with Regional Regulations: Being based nearby helps ensure compliance with industrial regulations, power utility norms, safety standards, and any statutory inspections in Chhattisgarh.

How to Select the Right Vendor

When searching for a supplier or manufacturer of notebook making machines near Gharghoda, consider:

-

Experience & Track Record

Ask for references of similar installations, especially in Chhattisgarh or nearby states. -

Customization Capability

Whether the manufacturer can adjust binding specifications, speed, size format, or power options suitable for your operation. -

After-sales Service

Does the supplier offer preventive maintenance, spare parts inventory nearby, and remote or onsite support? -

Quality Certifications

Look for certifications such as ISO, electrical safety compliance, CE marking (if relevant), or equivalent local regulatory approvals. -

Payment Terms & Warranty

Clarify warranty duration, terms of service visits, payment schedule and whether training for operators is included.

Case Example: Small-Scale Notebook Unit in Gharghoda

Suppose you run a small educational stationery business in Gharghoda. You invest in a semi-automatic notebook making machine capable of producing 150 notebooks/hour with staple binding. Within one year your sales to schools in adjoining districts grow, you recover your investment through volume sales. Because you sourced your machine locally, you receive timely spare-part replacement and the supplier sends a technician monthly for calibration — minimizing downtime. Production scalability allows you to upgrade to a fully automatic machine later without relocating.

Maintenance & Safety Tips

To keep your machine running smoothly:

-

Regularly clean cutting knives, rollers and binding heads from paper dust and adhesive residue.

-

Ensure lubrication of moving parts as per manufacturer’s guidelines.

-

Train operators in safe handling of sharp edges and electrical safety.

-

Monitor electrical load, earthing and stability (especially in rural areas with voltage fluctuations).

-

Schedule periodic inspections from the supplier for calibration or alignment.

Cost Estimate & Financing Options

Depending on capacity, automation level and features, a notebook making machine’s cost may range from modest budget versions to premium production lines. Local banks or regional industrial finance schemes may offer small-business loans in Chhattisgarh. Be sure to prepare a detailed business plan including projected output, raw material cost, pricing to schools & stationery shops, and payback period.

Future Trends

The stationery industry is evolving. Some future-proofing suggestions:

-

Integration of computerized controls or PLC-based automation for precision and remote monitoring.

-

Use of eco-friendly adhesives or recycled paper supplies.

-

Modular upgrade paths—start with semi-automatic model and expand to full automation later.

-

Energy-efficient components to reduce electricity consumption (important in rural or semi-urban areas of Chhattisgarh).

-

Custom branding / embossing modules to produce branded notebooks for schools or corporate clients.

Conclusion

Selecting the right notebook making machine in Gharghoda, Chhattisgarh is a critical decision for any stationery or school-notebook manufacturer. By evaluating production capacity, binding method, automation level, build quality and local support, you can invest wisely and ensure steady output with minimal downtime. Whether you’re launching a new unit or upgrading an existing facility, choosing a locally supported supplier will give you the advantage of timely service, tailored customization, and more sustainable operations.