Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

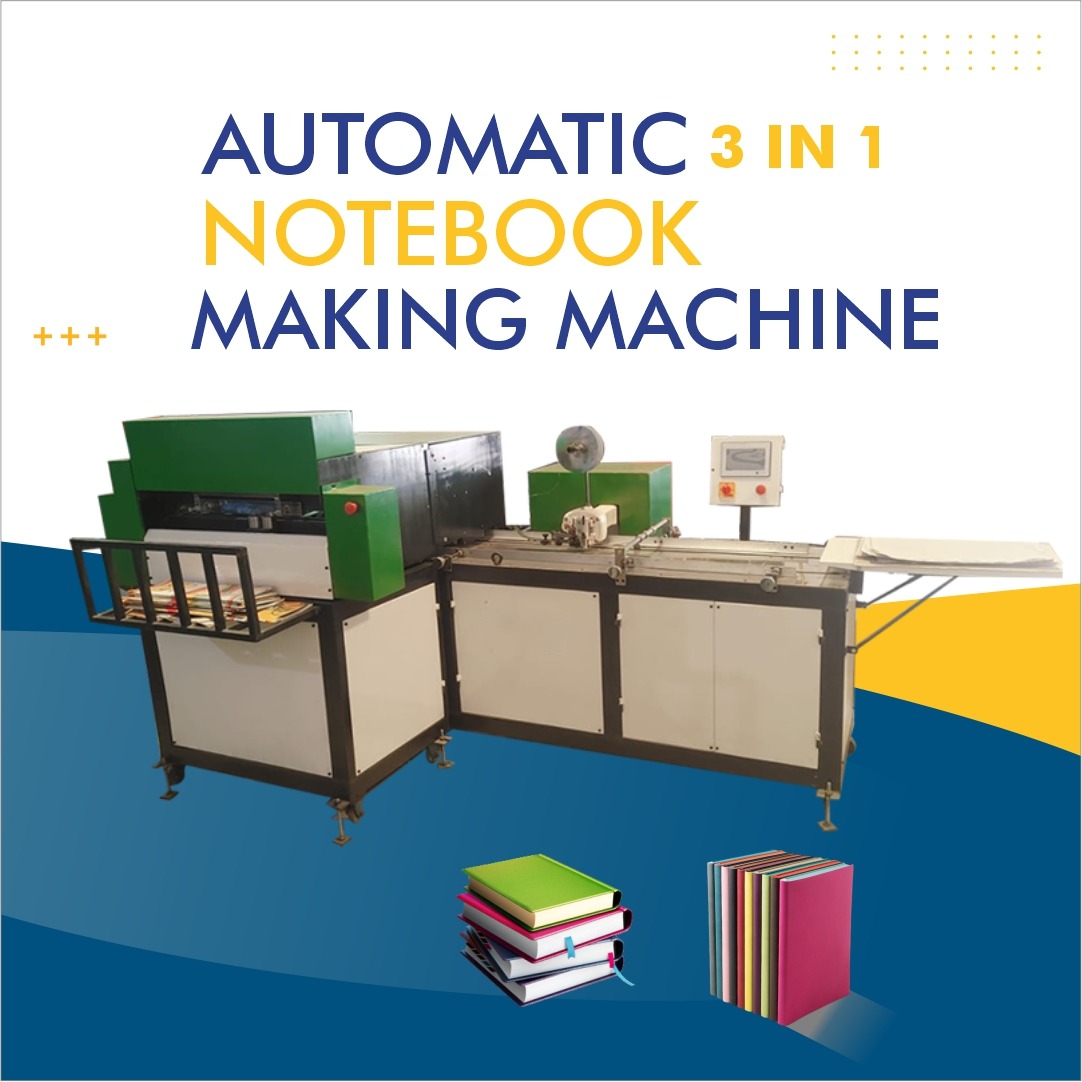

Notebook Making Machine in Dhamtari | Best Quality & Affordable Prices

Notebook Making Machine in Dhamtari | Chhattisgarh

If you are looking for a reliable notebook making machine in Dhamtari, Chhattisgarh, you have come to the right place. With rising demand for notebooks for educational institutions, corporate branding, and stationery wholesalers, having a well-designed notebook production setup has become essential. Whether you need a manual, semi-automatic, or fully automatic notebook making machine, selecting the right equipment can significantly improve productivity, reduce wastage, and maintain consistent product quality.

This article will guide you through how to choose a notebook making machine in Dhamtari, what features to look for, approximate pricing, installation factors, maintenance considerations, and how your investment can generate a good return over time.

Why Choose a Local Manufacturer in Dhamtari?

-

Reduced logistic cost: Procuring a machine from a local or regional manufacturer means you save on transportation, customs delays, and freight.

-

After-sales support: Maintenance, service visits, spare parts supply are easier when the supplier is nearby.

-

Customization: Local manufacturers often provide customization options suited to local power supply, material type, or size variations.

-

Faster turnaround: From inquiry to installation, local presence can significantly reduce delays.

Some listings show nearby locations such as Raipur or other Chhattisgarh cities, but Dhamtari-based or nearby workshop availability can give you the advantage of proximity. For example, there is a listing for "Small Business Solution" as a manufacturer of notebook making machines & paper plate machines in Dhamtari, Chhattisgarh. smallbusinessolution.com

Types of Notebook Making Machines

Before purchasing, it’s important to understand different types of machines available. Each type has trade-offs between cost, speed, automation, and labor requirement.

-

Manual Notebook Making Machine

-

Suitable for small-scale production or startups with limited budget.

-

Operator feeds paper sheets, folds, stacks, binds manually or semi-manually.

-

Lower speed, greater labor input but lower capital cost.

-

-

Semi-Automatic Notebook Making Machine

-

Some steps automated (cutting, stitching or binding), others manual.

-

Good compromise between cost and production rate.

-

Often used by medium-scale manufacturers who want higher throughput without full automation.

-

-

Fully Automatic Notebook Making Machine

-

End-to-end automation: sheet feeding, trimming, stitching or binding, cover folding, cutting, and packaging.

-

High speed, lower manual labor, consistent quality.

-

Higher initial investment cost but better for larger volumes.

-

-

Specialised Variants

-

Exercise Book Machine (ruled pages, specific binding style)

-

Spiral-Bound Notebook Machine

-

Hard-Cover / Soft-Cover binding machine

-

Custom size notebook machines (e.g. A4, A5, local Indian standard sizes)

-

Each variant may have different technical specs such as sheet size capacity, binding type, stitching style, number of pages, speed (books per hour), and material thickness.

Key Features to Look For

When choosing a notebook making machine, evaluate the following parameters:

-

Production Capacity & Speed: Books per hour/day; for example 2000-5000 notebooks/day vs higher volume.

-

Page Size & Format: Support for A4, A5, customized sizes; rule type (single-line, four-line, unruled).

-

Binding Type: Stapling / stitching binding, glue binding, spiral binding.

-

Automation Level: Manual feeding vs motorised feed or conveyor, sensor-based alignment.

-

Power Requirements: Single-phase or three-phase supply; local voltage stability in Dhamtari area.

-

Durability & Build Quality: Frame strength, quality of cutting blades, stitching or stapling heads.

-

Safety and Standards: Safety guards, compliance with local safety norms.

-

Spare Parts & Serviceability: Availability of replacements (blades, motors, gearboxes) locally.

-

Customisation Options: Flexible design for different page counts, cover styles, thickness.

-

Operating Cost & Energy Efficiency: Motor power rating, energy consumption per unit output, maintenance cost.

Approximate Pricing / Investment

Pricing for notebook making machines varies widely depending on automation and capacity:

| Type | Approximate Price Range (India) | Notes |

|---|---|---|

| Manual notebook making machine | Low | Suitable for small batches or pilot production |

| Semi-automatic notebook machine | Mid-range | Moderate output, some automation features |

| Fully automatic notebook making machine | High | High speed, for large scale production |

To give an example, a semi-automatic notebook making machine listed in Raipur is priced around ₹4,50,000 per unit. TradeIndia

If you are sourcing from Dhamtari, cost may vary depending on customization, shipping, installation, and commissioning. It’s always best to request a detailed quotation including installation, warranty and commissioning.

How to Evaluate Suppliers in Dhamtari / Nearby

To select a reliable supplier in or near Dhamtari, follow these steps:

-

Check Local Listings

Use directories like Justdial to search “notebook making machine manufacturers Dhamtari”. Although direct listings for Dhamtari may be limited, look at nearby areas too, or suppliers who deliver to Dhamtari. Justdial+2Justdial+2 -

Request Technical Brochures

Ask for specifications: machine layout, speed chart, sample output quality (notebook samples made on the machine). -

Site Visit / Demo

If possible, visit the manufacturer’s workshop to see a machine in operation. This helps check build quality, noise levels, ease of operation. -

After-Sales & Training

Confirm whether they provide installation & training for your staff, as well as spare parts support in or near Dhamtari. -

Warranty & Maintenance Terms

Check warranty duration, maintenance schedules, availability of consumables (blades, staples/stitching wire, adhesives if used), downtime response time. -

Payment & Delivery Terms

Clarify payment schedule (advance, on-delivery), lead time, delivery cost to your factory premises in Dhamtari, and commissioning charges.

Case Study / Use Scenario

Let’s assume you wish to produce school / exercise notebooks for local schools around Dhamtari and Raipur districts. Suppose your target production is 3,000 notebooks per day. You evaluate two options:

-

Option A: Semi-automatic notebook making machine installed near Dhamtari (local supplier).

-

Lower freight cost, reduced downtime for service visits.

-

Moderate capital expense; labor needed for feeding material.

-

Suitable if you have staff available and want initial scale without very large investment.

-

-

Option B: Fully automatic notebook making machine imported / sourced from outside the state.

-

Higher capacity, reduced labor, faster ROI if you scale to tens of thousands of notebooks monthly.

-

But you must account for higher installation cost, longer shipping time, possibly higher cost of spare parts or maintenance delays.

-

Comparing the two, if your volume is moderate and you expect to scale gradually, Option A via a local Dhamtari-area supplier may give you better risk profile.

You would calculate your expected revenue per notebook, subtract material cost, labor cost, and run machine hours per day to estimate break-even period. A well-chosen machine should pay for itself within 12-24 months depending on utilization.

Maintenance & Troubleshooting Tips

Once your notebook making machine is installed, good maintenance practices will help you avoid downtime:

-

Routine maintenance schedule: Lubrication of moving parts, periodic adjustment of cutting blades or stitching heads.

-

Spare parts inventory: Keep critical parts like blades, guide rails, alignment rollers, stitching wire or staples in stock near your facility in Dhamtari.

-

Operator training: Ensure your staff is trained for cleaning, alignment adjustment, minor repairs, and safety procedures.

-

Monitoring output quality: Set up regular quality audits (page alignment, binding strength, cutting accuracy) to reduce wastage early.

-

Local technical support: Prefer suppliers who send field engineers or who have contacts near Dhamtari or Raipur to minimize wait times for assistance.

Conclusion

If you are planning to set up or upgrade your notebook production facility in Dhamtari, Chhattisgarh, investing in the right notebook making machine is critical. Focus on balancing capacity, automation level, cost, and service support.

By choosing a trusted supplier (preferably local or regional) and evaluating technical specifications carefully, you can optimize your investment, enhance production quality, and meet growing demand from schools, corporate clients, or distributors.