Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

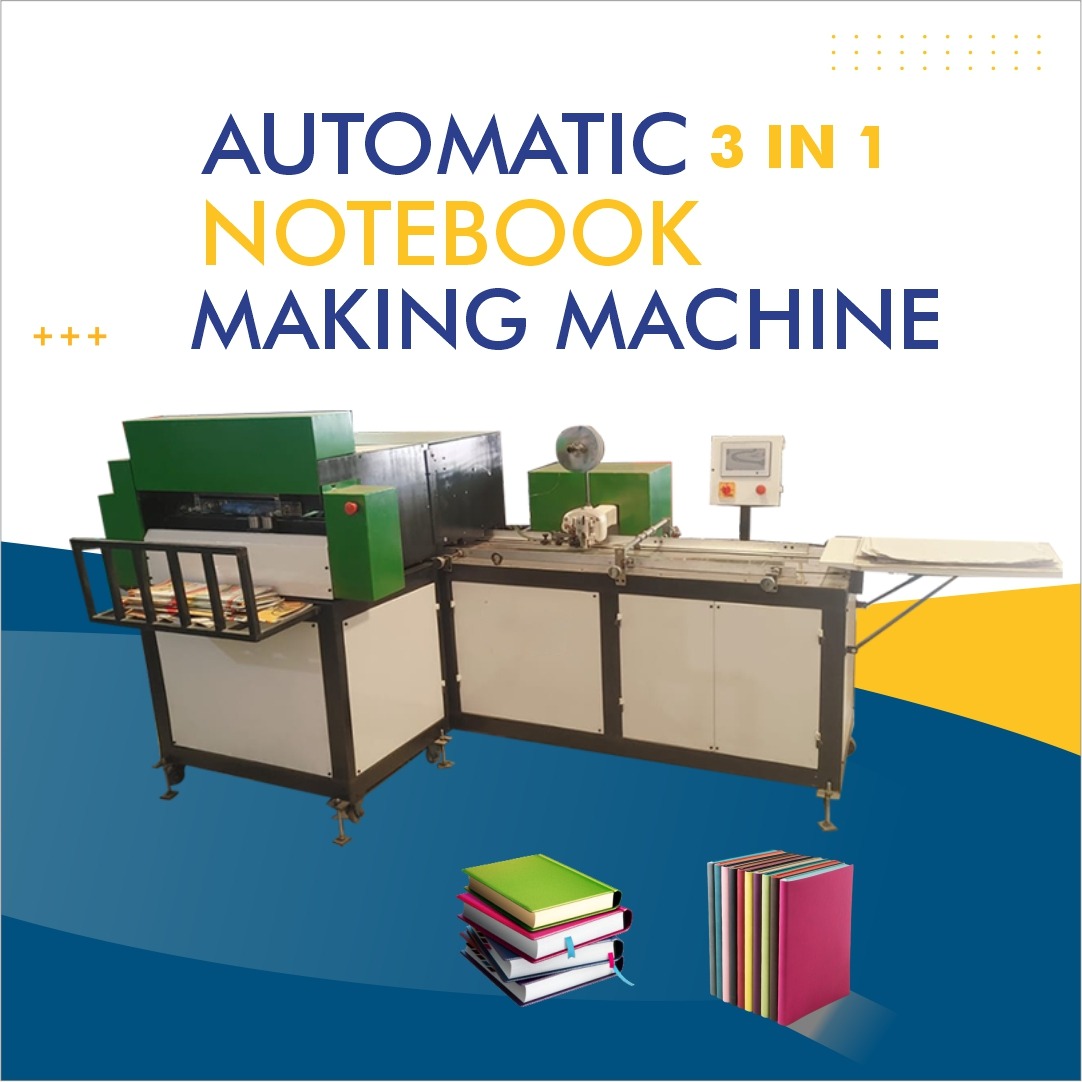

Notebook Making Machine – Dalli Rajhara Chhattisgarh | High-Quality Notebook Production Equipment

Notebook Making Machine Dalli Rajhara | Chhattisgarh

If you are searching for a notebook making machine in Dalli Rajhara, Chhattisgarh, you’ve landed at the right place. Whether you plan to launch a small-scale stationery factory or upgrade your existing production line, choosing the right notebook manufacturing equipment is crucial for quality, efficiency, and profitability. In this comprehensive guide you will find everything from machine features, benefits, local support options, and key specifications to help you make an informed decision.

In this article we will cover:

-

What is a notebook making machine

-

Why Dalli Rajhara, Chhattisgarh is a good location for notebook production

-

Key features and specifications to look for in a machine

-

Types of notebook production machines

-

Synonyms and related terms to help you find the right equipment

-

Local suppliers, installation, and after-sales support

-

Cost factors, ROI, and operational considerations

-

Frequently asked question

What Is a Notebook Making Machine?

A notebook making machine is specialized industrial equipment used to assemble sheets of paper, bind them, attach covers, and finish notebooks. This machine may include functions such as paper cutting, folding, stitching, gluing, trimming and binding. It automates key steps to increase productivity, reduce waste, and ensure consistency across all units.

Synonymously, such machines may also be called notebook production equipment, stationery manufacturing machine, or notebook binder machine. Regardless of terminology, their purpose remains the same—to enable high-volume, quality-assured notebook output.

Why Choose Dalli Rajhara, Chhattisgarh?

1. Strategic Location & Raw Material Access

Dalli Rajhara is a town in Chhattisgarh known for industrial activity and accessibility. Being within Chhattisgarh, it offers reasonable proximity to paper mills, skilled labor, and transport routes to major markets (such as Raipur, Bilaspur, and even neighboring states).

2. Cost Advantage & Local Incentives

Operating in Dalli Rajhara may afford you lower facility rental, affordable labor costs, and possibly state-level industrial incentives under Chhattisgarh’s industrial development policy. This can reduce your overall investment for procurement of notebook production equipment and its operation.

3. Skilled Workforce & Logistics

Chhattisgarh has a growing skilled workforce able to operate commercial notebook machinery and perform maintenance. In addition, proximity to larger cities ensures logistic connectivity for spare-parts delivery, servicing, and technical support.

4. Demand for Stationery Products

India’s growing education sector continues to drive demand for notebooks. Setting up your notebook manufacturing unit with the right paper binding machine near Dalli Rajhara allows you to serve regional schools and wholesalers with reduced lead times and competitive pricing.

Key Features & Specifications to Consider

When evaluating a notebook making machine, you should examine specifications under these headings:

| Feature | Why It Matters |

|---|---|

| Production Speed | Number of notebooks per minute/hour determines your output. Higher speed leads to better throughput—especially important for notebook production equipment. |

| Binding Method | Options include wire-spiral binding, stitched binding, glued binding or staple binding. Choose based on product type and cost. |

| Paper Size Flexibility | Ability to handle different formats (A4, A5, custom sizes). Useful for school or custom orders. |

| Cover Material Handling | Whether the machine supports card covers, PVC transparent covers, or decorative laminated cardboard. |

| Precision & Finish Quality | Clean trimming, accurate alignment, strong binding strength—features typical of advanced stationery manufacturing machine. |

| Automation Level | Semi-automatic vs full-automatic machines. Automating folding, stacking, trimming reduces manual labor. |

| Maintenance & Spare Parts | Local availability of spare parts, ease of servicing by technicians familiar with notebook binder machine brands. |

| Energy Efficiency | Machines with lower power consumption help reduce recurring expenses and improve profitability. |

| Safety & Compliance | Ensuring the equipment meets Indian industrial safety standards and has CE or equivalent certifications. |

These factors significantly influence your return on investment, product quality, and operational reliability.

Types of Notebook Production Machines

There are various kinds of notebook making machine categories you may evaluate:

-

Single-Station Manual or Semi-Automatic Machines

-

Ideal for startups or small-scale production units.

-

Typically includes basic folding, stacking, and manual binding steps.

-

-

Fully Automatic Notebook Manufacturing Equipment

-

Best suited for medium to large-scale production.

-

Automates cutting, folding, stitching, trimming, and binding in continuous lines.

-

Offers higher speed and uniform output.

-

-

Wire-Spiral Binding Machines

-

Perfect for spiral-bound notebooks used in academic or professional settings.

-

Requires wire coil insertion, closing mechanism, and trimming.

-

-

Stitched & Stapled Notebook Binder Machines

-

Uses staples or thread to bind sheets.

-

Offers durable binding suited for standard school notebooks or professional diaries.

-

-

Customized Notebook Machinery

-

Machines tailored to your choice of paper weight, cover thickness, size variations.

-

May include additional features such as foil stamping, embossing, or lamination for premium notebooks.

-

Each type should be evaluated carefully based on your target market segment and production volume.

Local Suppliers, Installation & Support in Dalli Rajhara

When seeking a notebook making machine near Dalli Rajhara, Chhattisgarh, consider the following:

-

Reach out to equipment manufacturers or vendors in Chhattisgarh or neighbouring states such as Madhya Pradesh, Maharashtra, or Jharkhand.

-

Ask for onsite demonstrations in or around Dalli Rajhara or ask for video walkthroughs.

-

Ensure installation services include local technicians who understand your regional power supply, floor layout, and compliance regulations.

-

Request training for your staff to operate the stationery manufacturing machine safely and efficiently.

-

Confirm warranty terms and availability of spare parts for your notebook production equipment within Chhattisgarh or nearby industrial areas.

Some vendors may offer customization of commercial notebook machinery to suit your binding style, speed requirements, and budget.

Cost Factors, ROI & Operational Considerations

Before finalising purchase of a notebook making machine, assess:

-

Capital Investment: Cost depends on automation level, capacity, binding method (spiral, stitched, glued), and optional features such as embossing or lamination.

-

Running Costs: Electricity charges, consumables (binding wire, glue, card stock), labor wages, periodic maintenance, and spare-part replacement.

-

Output & Capacity Planning: Estimate average monthly production (e.g. number of notebooks per day) to calculate cost per unit and profitability margin.

-

Break-even Period: Use production volume, selling price per notebook, and total cost to determine how many months it will take to recover the investment.

-

Quality Control: Ensure your paper binding machine yields consistent binding strength, minimal wastage, and professional finish to satisfy customers.

-

Scale-Up Potential: Choose modular or upgradeable notebook binder machine models so you can expand when demand increases.

-

Regulatory Compliance: Register under local industry licensing, ensure fire safety norms, labour law compliance, and environmental clearances if applicable.

By carefully analysing these factors you can optimise your investment in reliable book-binding equipment and achieve sustainable profitability.

Frequently Asked Questions (FAQ)

Q. Can I get after-sales service for a notebook making machine near Dalli Rajhara?

A. Yes — several vendors provide regional or onsite service in Chhattisgarh. Always confirm their service network before purchase of your notebook manufacturing equipment.

Q. What is the typical speed of a small-scale notebook production equipment?

A. Entry-level semi-automatic machines may produce 200–500 notebooks per hour, while fully automatic lines can achieve much higher throughput depending on size and binding type.

Q. Are customized binding styles possible?

A. Yes. Many suppliers of commercial notebook machinery offer customization for cover types, paper thickness, binding method (spiral, stitched, glued), sizes (A4, A5, customised), and finishing options.

Q. How much space is needed for installation?

A. Space requirement depends on the machine model and footprint. A typical small-to-medium notebook binder machine may require 200–500 sq. ft including feeding, stacking, and trimming zones. Larger automated lines demand more floor area. Always request a layout drawing from the supplier.

Q. Can I export notebooks manufactured in Dalli Rajhara?

A. Yes, if you adhere to quality standards and packaging norms. With good quality output from your stationery manufacturing machine, you may supply notebooks beyond your local region, and potentially to other states or for institutional contracts.

Conclusion

Investing in a notebook making machine at Dalli Rajhara, Chhattisgarh offers numerous advantages — strategic location, cost-effective workforce, local demand, and the ability to scale production. By carefully evaluating notebook production equipment, choosing the right binding method, and ensuring reliable after-sales support, your notebook manufacturing business can thrive.

To get started, shortlist a few vendors or manufacturers of stationery manufacturing machine, compare quotes, request demos, and verify local support. Take into account production speed, machine type (semi-automatic or fully automatic), binding options, and cost of ownership.

If you want help shortlisting specific suppliers or accessing technical specifications for machines near Dalli Rajhara, let me know—I can assist you further in identifying reliable manufacturers and estimating costs.