Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

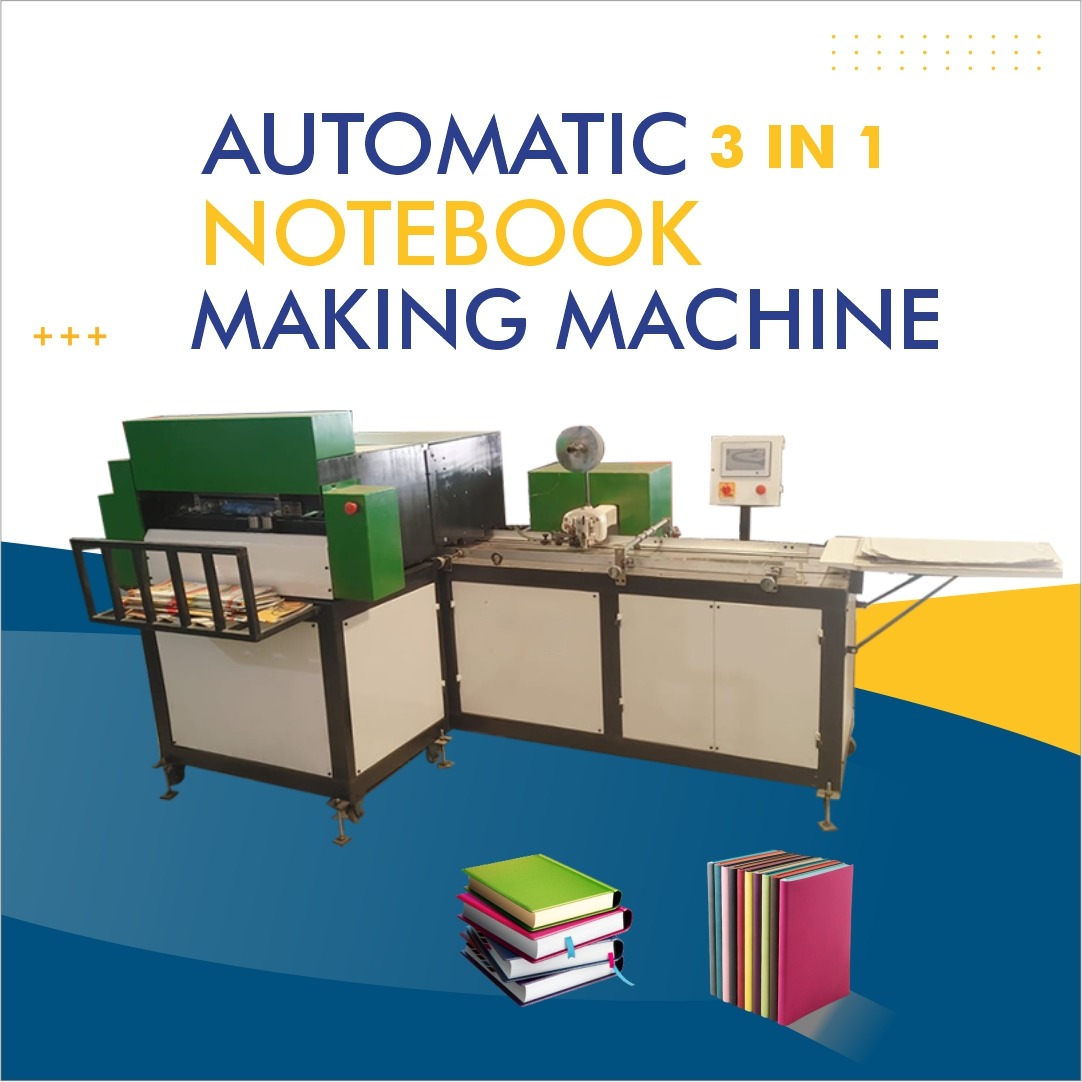

Notebook Making Machine in Chirimiri Chhattisgarh - Buy Automatic & Semi-Automatic Notebook Machines

Notebook Making Machine in Chirimiri | Chhattisgarh

If you are planning to establish a notebook manufacturing unit in Chirimiri, Chhattisgarh, or want to upgrade your existing setup, investing in a high-quality notebook making machine is crucial. Whether you choose an automatic or semi-automatic model, the right machinery can dramatically improve output, quality, and profitability. This page provides everything you need to know — machine types, features, costs, benefits, and local context for Chirimiri and its nearby regions.

In recent years, Chhattisgarh has emerged as an interesting zone for small to medium scale manufacturing units, owing to improving infrastructure, relatively affordable land and labor, and demand for educational stationery. A well-placed notebook production facility using proper notebook making machine can tap local demand (schools, stationery market) and also serve nearby districts.

This guide aims to help entrepreneurs in and around Chirimiri to understand how to choose, procure, install, and operate a notebook making machine, and what to expect in terms of cost, maintenance, and returns.

2. Why Choose Chirimiri, Chhattisgarh for Notebook Manufacturing

-

Location advantages: Chirimiri is in the northern part of Chhattisgarh, where raw materials like paper sheets, cover boards, binding threads / stitching supplies may be procured from regional markets. Transport connectivity to nearby towns facilitates distribution of finished notebooks.

-

Cost factors: Labor costs, electricity, and real estate may be more affordable compared to metro or large industrial hubs. This reduces operational overhead.

-

Growing demand: Educational institutions, schools, coaching centres all require notebooks. There is potential for supplying local markets and scaling to nearby districts.

-

Support infrastructure: Chhattisgarh has several machinery manufacturers / suppliers in Raipur and surrounding regions offering notebook-machinery and spare parts support. For example, Raipur-based manufacturers supply automatic notebook making machines. TradeIndia+2Creation Technology+2

-

Customization and service: Local suppliers can more easily provide installation, maintenance, training and spare parts than remote vendors.

Thus Chirimiri can be a strategic location for a notebook manufacturing plant using modern notebook making machine setups.

3. Types of Notebook Making Machines

When we talk about notebook making machines, you’ll find several types. Choosing the right one depends on your scale of production, budget, labor availability, and desired automation level. Here are the main categories:

| Type | Description |

|---|---|

| Manual Notebook Making Machine | Minimal automation. Some steps like cutting, folding or stitching may require manual intervention. Suitable for very small scale or startup operations. |

| Semi-Automatic Notebook Making Machine | Certain steps are automated (folding, cutting, stitching), but others may require manual feeding or supervision. Balanced cost vs productivity. For example, units offering capacity of ~1,500-5,000 notebooks/hour. TradeIndia+1 |

| Fully Automatic / Automatic Notebook Making Machine | Complete or nearly-complete automation — cutting, binding, trimming, pressing, sometimes even cover attachment. Best for higher volume production and consistent quality. Example models priced around INR 3-4 lakh in Chhattisgarh region. TradeIndia |

| Specialised Notebook Machines | e.g. spiral-bound notebook machines, edge-squaring, cover-attaching modules or hybrid setups combining multiple machines. These may be needed for premium or custom notebook formats. |

Each machine type has trade-offs in capital cost, speed, maintenance, and manpower requirements.

4. Key Features & Specifications to Consider

When choosing a notebook making machine, pay attention to the following:

-

Production capacity / Speed

How many notebooks per hour (or per day) you want to produce. Automatic machines often give higher throughput with consistency. -

Automation grade

Fully-automatic vs semi-automatic. More automation reduces manual labor but increases upfront cost. -

Size & Format compatibility

Support for various sizes (A4, A5, custom sizes), thickness of sheets, cover type, binding style (stitched, glued, spiral etc.). -

Power requirements

Voltage, phase (single / three), horsepower rating, energy consumption. Chhattisgarh electricity supply & cost should be factored. -

Material & Build Quality

Bodies made of steel, precision cutting blades, durable binding heads etc. Reliable materials reduce downtime and maintenance cost. -

Cutting / stitching / binding / trimming precision

Quality matters especially for binding lines, aligned cuts, uniform trims. This affects final notebook appearance and durability. -

Maintenance & Spare Parts Availability

Choose a machine for which spare parts & service engineers are available near Chirimiri / Raipur region. -

Cost & Warranty

Compare OPEX vs CAPEX. Some machines may come with warranty, installation support, training by supplier. -

Compliance & Safety

Ensure machine meets safety standards (electrical isolation, guards around cutting areas etc.), and operate in compliance with local regulations.

5. Cost Estimates

Here are approximate price ranges for machines in/around Chhattisgarh (for guidance):

-

Semi-Automatic Notebook Making Machine — approx ₹ 1 lakh to ₹ 4 lakh depending on capacity & features. TradeIndia

-

Fully Automatic Notebook Making Machine in Chhattisgarh (e.g. Raipur supplier) — around ₹ 3.75 lakh for certain models. TradeIndia

-

Custom or premium versions (larger capacity / premium build) may cost more.

-

Additional costs to consider: freight / transport to Chirimiri, installation charges, civil works (foundation / flooring), commissioning, staff training, running cost (electricity, maintenance).

To calculate return on investment (ROI), you must combine machine cost with expected monthly output, cost of raw materials (paper, cover board, binding wire/thread), labor cost, overheads (rent / building), and sale price of notebooks.

6. Setting Up Notebook Production in Chirimiri

Here’s a step-by-step outline to set up a small notebook manufacturing plant in Chirimiri using a notebook making machine:

-

Market survey & demand estimation

-

Check demand in Chirimiri area (schools, retail stationery shops, nearby towns).

-

Estimate order volumes (e.g. monthly notebooks required).

-

-

Business plan & machine selection

-

Determine your target production capacity.

-

Select whether to use an automatic or semi-automatic notebook making machine based on volume & budget.

-

Request quotes from suppliers near Chhattisgarh / Raipur region.

-

-

Procurement

-

Contact nearby manufacturers / suppliers (e.g. those listed in Raipur / Chhattisgarh). Creation Technology+2Creation Technology+2

-

Confirm shipping / delivery time to Chirimiri, installation service, spare-part availability.

-

-

Site preparation

-

Choose a workshop / factory floor with enough space, sturdy floor, stable electricity, ventilation.

-

Provide proper power supply (phase, wiring, earthing etc.).

-

-

Installation & Commissioning

-

Supplier installs & tests the notebook making machine. Train local staff on operation, safety, maintenance.

-

-

Raw material sourcing

-

Paper sheets, cover board, printing (if you have printed covers), binding thread / staples / glue as required.

-

Local vendors or delivery from nearest paper / stationery wholesalers.

-

-

Production & Quality Control

-

Set up process flow: cutting → folding / ruling → stacking → stitching or binding → trimming / pressing → cover attachment → final inspection.

-

Implement quality checks for alignment, binding strength, finishing edges.

-

-

Marketing & Distribution

-

Sell to local stationery shops, schools, coaching centres, or wholesale to nearby towns.

-

Establish pricing model (per notebook cost + margin).

-

-

Maintenance & Scaling Up

-

Regular maintenance schedule for machine to avoid breakdown.

-

Monitor production data; once demand increases, consider scaling by adding another notebook making machine or upgrading to fully automatic model.

-

7. Benefits of Investing in a Good Notebook Making Machine

-

Higher productivity: Automated machines reduce manual labor, increase throughput.

-

Consistency & quality: Uniform cutting, binding, finishing yields more professional notebooks.

-

Cost savings over time: While initial cost may be high, per-unit cost drops with volume.

-

Scalability: Ability to increase output without proportional increase in labor.

-

Competitive Edge: Better finished product helps you compete with imported / branded notebooks in appearance and durability.

-

Local advantage: Serving nearby market from Chirimiri (lower transport cost, faster delivery) strengthens your brand & reputation.

8. Challenges & Mitigation

Setting up a notebook manufacturing unit is promising, but there are challenges you should plan for:

| Challenge | Mitigation |

|---|---|

| Initial capital investment | Explore financing options or subsidies for MSMEs in Chhattisgarh. Spread investment using semi-automatic before upgrading. |

| Raw material price fluctuations | Lock in suppliers for paper & binding materials; negotiate bulk discounts. |

| Technical downtime / machine failure | Choose supplier with good service record & local presence; maintain preventive maintenance. |

| Skilled operator availability | Train local staff; work with supplier to provide initial training. |

| Market competition | Differentiate via quality, timely delivery, customised sizes / cover designs. |

9. Why Your Business Should Choose Us / Our Value-Proposition

(If you are the seller or manufacturer setting this content for your website, you can include this section tailored to your company. Example below.)

-

We supply both automatic notebook making machine and semi-automatic notebook machine tailored for small & medium manufacturers in Chirimiri and surrounding regions.

-

Our machines are built with industrial-grade materials, reliable motors, safety features, and local support service.

-

We assist you with selection, installation & running-in of the machine at your site.

-

Spare parts & technical assistance available via our network in Chhattisgarh (Raipur / Bilaspur areas).

-

You can scale production as your business grows.

Contact us for a free consultation and machine demo near Chirimiri, Chhattisgarh.

Conclusion

A well-chosen notebook making machine can transform a small startup into a profitable manufacturing business in Chirimiri, Chhattisgarh. By understanding machine types, cost estimates, location-specific considerations, and operational best practices, you can reduce risk and maximize returns. Whether you start with a semi-automatic model and later upgrade to fully automatic machinery, the key is a structured approach: assess demand, choose reliable equipment, invest wisely, train staff, and monitor performance.