Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

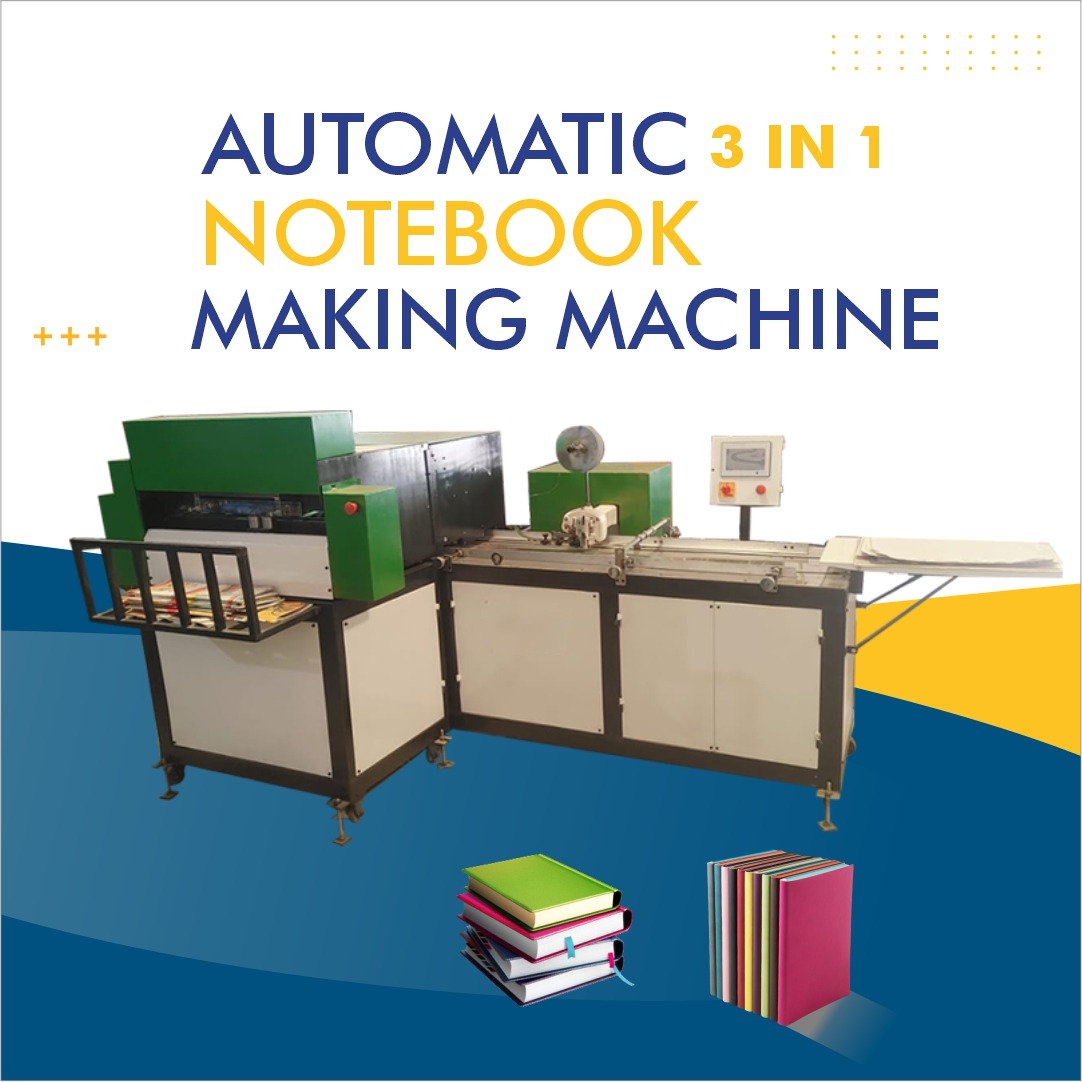

Notebook Making Machine Supplier in Chhuikhadan, Chhattisgarh | Best Quality & Price

Notebook Making Machine in Chhuikhadan | Chhattisgarh

Notebook making is a critical part of the stationery and paper product industry. For businesses and manufacturers in Chhuikhadan, Chhattisgarh, having the right Notebook Making Machine can significantly improve production efficiency, reduce labor costs, and ensure consistent product quality. In this comprehensive guide, we explore everything about notebook making machines, their types, benefits, maintenance, and why they are essential for stationery manufacturers.

1. Introduction to Notebook Making Machines

A Notebook Making Machine is a specialized equipment designed to produce notebooks efficiently, from binding the pages to finishing the cover. These machines are widely used in schools, colleges, corporate offices, and stationery manufacturing units. The adoption of automated and semi-automated notebook machines has revolutionized the paper product industry by reducing production time and labor dependency.

2. Types of Notebook Making Machines

Understanding the types of machines available in the market is essential before investing in one. The primary types include:

a. Manual Notebook Making Machines

Manual machines require human intervention for each step of the notebook assembly. They are suitable for small-scale production and offer affordability but have lower output compared to automatic machines.

b. Semi-Automatic Notebook Making Machines

These machines combine manual and automatic processes. They are ideal for medium-scale businesses, providing a balance between efficiency and cost.

c. Fully Automatic Notebook Making Machines

Automatic notebook machines are designed for large-scale production. They handle cutting, folding, binding, and cover placement with minimal human intervention. This type ensures high-quality notebooks and rapid production.

d. Specialized Paper Binding Machines

Some machines focus solely on paper binding, which is a critical step in notebook production. These machines ensure strong binding and long-lasting notebooks.

3. Key Features of Notebook Making Machines

Modern Notebook Making Machines come with features that enhance productivity and quality. Some key features include:

-

High-Speed Production: Capable of producing hundreds of notebooks per hour.

-

Adjustable Sizes: Machines can handle different notebook sizes and page counts.

-

Durable Construction: Made from high-quality steel for long-term use.

-

Automatic Feeding System: Reduces manual labor and increases efficiency.

-

Precision Cutting & Binding: Ensures professional finish for every notebook.

-

Energy Efficiency: Machines are designed to reduce electricity consumption.

By investing in a high-quality notebook making machine, businesses in Chhuikhadan, Chhattisgarh can significantly improve production output and product quality.

4. Benefits of Investing in a Notebook Making Machine

Investing in a Notebook Making Machine provides multiple advantages for manufacturers and stationery businesses. These include:

-

Enhanced Productivity: Automatic machines can produce large volumes in a short time, ideal for bulk orders.

-

Consistent Quality: Machines ensure uniformity in binding and cutting, giving professional-grade notebooks.

-

Cost-Effective: Reduces manual labor, minimizes wastage, and ensures efficient resource utilization.

-

Customizable Production: Machines allow different notebook sizes, covers, and binding types.

-

Durability: Modern machines are robust and built for long-term industrial use.

5. Notebook Making Process

The process of notebook manufacturing using a Notebook Making Machine includes several steps:

-

Paper Cutting: The paper sheets are cut to the desired size.

-

Folding: Folded sheets are prepared for binding.

-

Binding: Pages are bound using glue, staples, or stitching depending on machine type.

-

Cover Attachment: Covers are aligned and attached to the bound pages.

-

Finishing & Quality Check: The final product is checked for quality and precision.

This structured process ensures notebooks produced in Chhuikhadan, Chhattisgarh meet both industrial and commercial standards.

6. Choosing the Right Notebook Making Machine

When selecting a Notebook Making Machine in Chhuikhadan, consider these factors:

-

Production Capacity: Determine daily notebook requirements.

-

Type of Binding: Choose between stapling, spiral, or stitched binding.

-

Automation Level: Decide whether a manual, semi-automatic, or fully automatic machine suits your business.

-

Durability: Ensure machines are built with high-grade materials.

-

Maintenance Support: Look for suppliers offering after-sales support and maintenance.

A well-chosen notebook making machine reduces downtime and increases overall efficiency.

7. Applications of Notebook Making Machines

The versatility of Notebook Making Machines allows their use in:

-

Educational institutions producing their own notebooks

-

Small and medium stationery manufacturing units

-

Corporate offices for customized notebooks

-

Industrial-scale production for commercial distribution

By implementing these machines, businesses in Chhuikhadan, Chhattisgarh can expand their product range and meet customer demands effectively.

8. Synonyms & Related Terms for SEO Optimization

To maximize SEO impact, we can include multiple keyword variations:

-

Automatic Notebook Making Machine

-

Paper Binding Machine

-

Stationery Manufacturing Equipment

-

Notebook Production Machine

-

School Notebook Machine

-

Industrial Notebook Maker

-

Notebook Manufacturing Equipment

-

Notebook Assembly Machine

Using these keywords repeatedly in content improves search engine visibility and attracts local traffic in Chhattisgarh.

9. Maintenance and Safety Tips

Proper maintenance ensures longevity and smooth operation of notebook making machines:

-

Regular Lubrication: Keeps moving parts functional and prevents wear.

-

Cleaning: Dust and paper residue can hinder performance; clean frequently.

-

Periodic Inspection: Check for loose parts, electrical issues, or blade dullness.

-

Operator Training: Ensure operators are trained to handle machines safely.

-

Proper Storage: Store machines in dry areas to prevent rust and corrosion.

10. Cost and Investment Consideration

The cost of a notebook making machine in Chhuikhadan, Chhattisgarh varies depending on type and features:

-

Manual machines: Cost-effective for startups.

-

Semi-automatic machines: Moderate investment with higher efficiency.

-

Fully automatic machines: Higher initial cost but maximum productivity.

Investing in a durable, high-quality machine ensures long-term savings and faster ROI for manufacturers.

11. Leading Suppliers in Chhuikhadan, Chhattisgarh

Local suppliers in Chhattisgarh offer a range of notebook making machines suited for small to industrial-scale production. Choosing a reliable supplier ensures:

-

Genuine spare parts

-

Timely delivery

-

After-sales support

-

Expert guidance for installation and operation

12. Conclusion

A Notebook Making Machine is an essential investment for stationery manufacturers in Chhuikhadan, Chhattisgarh. From small-scale operations to industrial production, these machines streamline production, improve quality, and increase profitability. By choosing the right type, maintaining it properly, and leveraging automation, businesses can establish themselves as leading notebook suppliers in the region.