Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

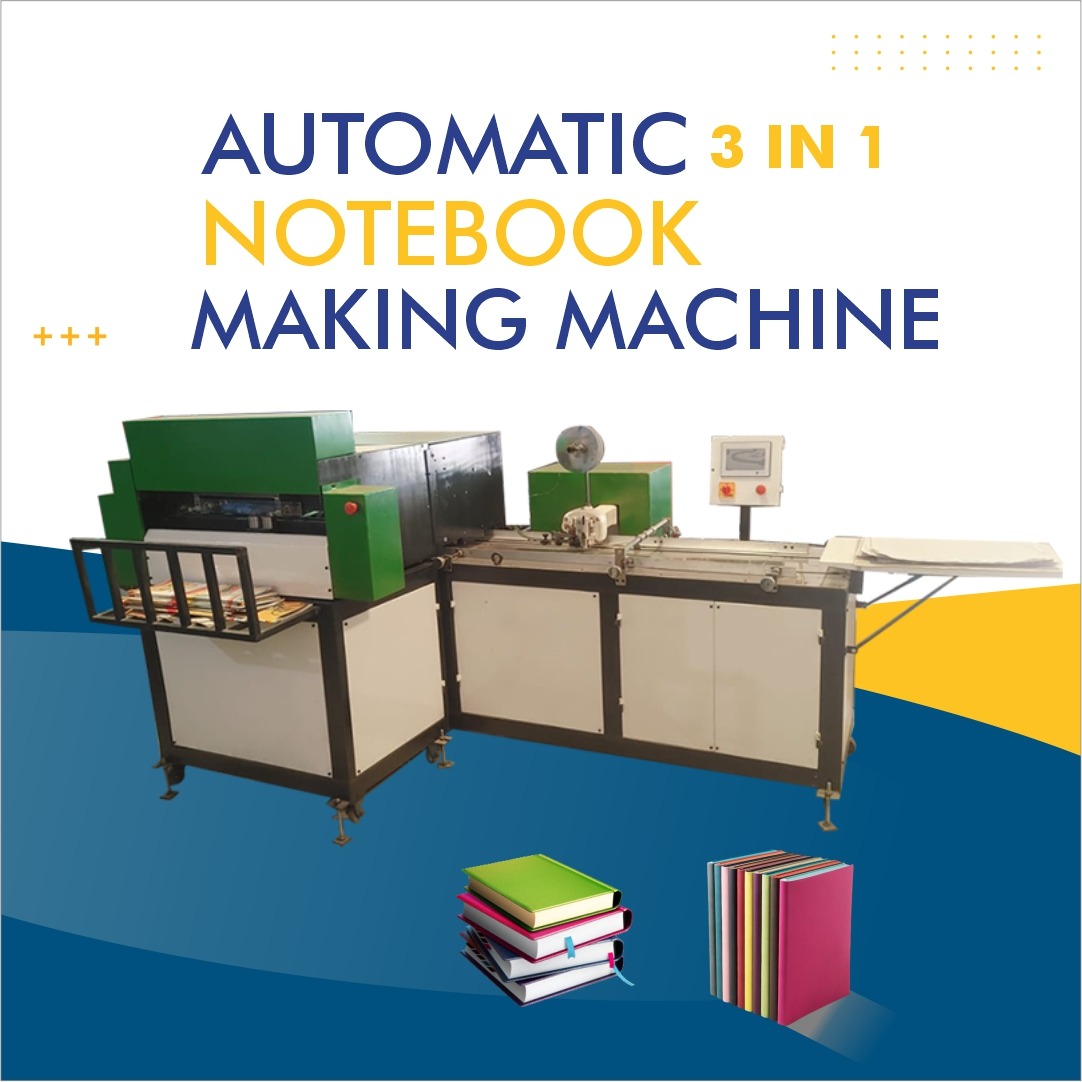

Notebook Making Machine in Champa, Chhattisgarh – Semi & Fully Automatic Notebook Maker

Notebook Making Machine in Champa | Chhattisgarh

Champa (Chhattisgarh) is emerging as a promising location for industrial units and small-scale manufacturing enterprises. If you are planning to start or expand a notebook manufacturing business in Champa, acquiring a quality notebook making machine is crucial. In this article we explain the benefits, types, features, investment considerations, local support, and why you should choose Champa for your notebook manufacturing setup.

We will repeat relevant synonyms such as notebook making machine, notebook manufacturing machine, automatic notebook maker, semi-automatic notebook making machine, notebook production equipment, etc—ensuring SEO reach for eight to ten keywords.

Why Choose Champa, Chhattisgarh for Notebook Manufacturing

-

Strategic Location & Infrastructure

Champa being in Chhattisgarh enjoys proximity to raw material sources, relatively lower land cost compared to big cities, and accessibility to major transportation links. State policy initiatives (such as industrial promotion and ease-of-doing-business schemes) have made Chhattisgarh more favorable to manufacturing enterprise setups. -

Favourable Business Policies

The state government of Chhattisgarh has introduced initiatives to promote industrial investment. For example, “one-click single window” industrial approvals are part of its efforts. (source: Chhattisgarh government industrial policy) — this improves license, approval and setup time in the region. -

Availability of Labour & Utilities

Experienced labour for mechanical operations, combined with availability of electricity, water and other utilities, make Champa attractive for setting up machine-driven production lines such as notebook making machine units. -

Local Market & Demand

Demand for notebooks, registers, exercise books is steady due to schools, colleges and institutional needs not only in Chhattisgarh but in neighbouring states. Local production reduces freight cost, ensures quicker supply, and allows customization (size, cover design, binding strength).

Types of Notebook Making Machines

When selecting a machine, you should understand the types and their capabilities. Below are typical variants:

-

Semi-Automatic Notebook Making Machine

This version requires some operator intervention in processes such as paper feeding, alignment, or manual changeovers. Ideal for small to medium-scale production capacity. Useful when you want lower initial investment but still decent output. -

Fully Automatic Notebook Making Machine

This model handles more steps automatically (cutting, stitching, folding, edge squaring etc.). Higher productivity, consistent quality, less dependency on manual labour. Best for scaling production, reducing operator error, and increasing throughput. -

Three-in-One / Multi Function Notebook Making Machine

Some machines integrate multiple operations such as stitching, folding, trimming, edge squaring in a single automated line. For instance, a fully automatic 3-in-1 notebook making machine may deliver thousands of notebooks per hour. namibind.com -

Single-Head Automatic Notebook Making Machine

For moderate throughput with higher precision, machines such as single-head automatic notebook making machines are available. endurancemachinery.com

Key Features to Look For

When selecting a notebook making machine, consider the following attributes:

-

Production Capacity

How many notebooks per hour can the machine produce? For example some automatic machines offer capacities like 800–1200 notebooks/hour. sujatamachines.in -

Automation Grade

Whether it is semi-automatic or fully automatic; presence of PLC programming, servo control, or integrated feeders. -

Machine Functions

The machine should support tasks such as cutting, stitching (wire/staple binding), folding, edge squaring / trimming. For example automatic stitching-folding-edge squaring machines exist. printekengineers.in -

Size & Thickness Range

Max/min notebook size (width, length) and spine thickness it can handle. A flexible machine supports multiple SKUs (sizes of notebook). sujatamachines.in+1 -

Electrical & Mechanical Specifications

Power supply (single/three phase), motor power, frame material, sensors, safety. For example some machines require 220 V or 440 V three-phase input. sujatamachines.in -

After-Sales Support & Warranty

Does the vendor provide on-site installation, lifetime support, training of operators, spare parts, etc. -

Cost & Return on Investment (ROI)

Initial capital cost, cost of raw material (paper, covers), labour cost, utilities, maintenance and projected sales margins. Consider local sales price of notebooks, competition, and break-even volume.

How to Source a Notebook Making Machine in Champa

-

Local & National Machine Manufacturers

Identify vendors in India who supply notebook making machines. Examples include Bhartiya Machine Works which offers both semi-automatic & fully-automatic versions. bhartiyamachineworks.com

Also other manufacturers such as Sujata Machines offer automatic notebook machines with stitching-folding-edge squaring capability. sujatamachines.in -

Import vs Domestic Supply

Domestic machines often have support service inside India; shipping/trucking to Champa may incur lower logistics cost. Evaluate delivery time and customs (if imported). -

Site Visit & Inspection

Request a demo, inspect machine build quality, check sample outputs (notebook finish quality, margin consistency, binding strength), and evaluate ease of maintenance. -

Regulation & Permits

Ensure that your factory setup in Champa complies with local municipal regulations, factory licensing, power load approvals, and safety standards.

Setting up Your Notebook Production Unit

Once you have the machine in place, other factors will determine your success:

-

Raw Materials

Paper sheets, covers (cardboard, coloured boards), binding wire or staples, glue & lamination materials (if any). Sourcing raw paper locally or via suppliers nearby reduces cost. -

Space & Layout

Allocate space for machine placement, material feed-in, output stacking, trimming & finishing, packing area. Ensure good workflow from raw intake → machine output → packaging → dispatch. -

Workforce & Training

Operators who can run the notebook making machine, adjust settings for different notebook sizes, monitor output quality, perform minor maintenance, repair jams, change knives or blades. -

Quality Control

Inspect sample notebooks for page alignment, margin straightness, binding durability, and aesthetic finish. Automatic machines often reduce errors—but still require monitoring and periodic calibration. -

Packaging & Branding

Design cover artwork, branding label, package the finished notebooks properly. Packaging may include shrink-wrap, sealing or bundling units together. -

Sales & Distribution

Target local schools, stationery stores, institutional clients in Champa and neighbouring areas. Leverage cost advantage of local production vs imported or distant-supplied notebooks. -

Maintenance & Spare Parts

Regularly service the machine. Keep spare blades/knives, check lubrication, clean sensors. Ensure you have vendor contact for troubleshooting.

Advantages of Investing in a Good Notebook Making Machine

-

High Productivity & Efficiency

An automatic or semi-automatic machine boosts output per operator, reduces wastage, and ensures uniform quality. -

Cost Savings

Faster turnaround, reduced manual labour cost, reduced rejects. Local manufacturing reduces transportation cost for finished goods. -

Flexibility in Customization

You can produce different sizes, different cover styles, varied binding/spine thickness, quickly respond to custom orders. -

Scalability

As demand grows (for instance from schools, institutes, or corporate clients), you can scale by adding more machines or upgrading capacity.

Typical Investment & ROI Example (Hypothetical)

| Item | Approximate Cost / Detail |

|---|---|

| Machine Cost (automatic / semi) | ₹ L-Lakhs (depending on model & capacity) |

| Utility & Power Setup | Electricity connection, wiring, load approval |

| Raw Material (paper, binding wire, cover board) | Depends on specification & volume |

| Labor & Operation Cost | Wages for machine operators, quality-check staff |

| Sales Price per Notebook | Set according to local market or negotiated institutional rates |

| Break-Even Volume | Depends on margin per unit and production capacity per day |

By calculating your daily output capacity (say 800–1,200 notebooks/day), subtracting raw & operational costs, you can estimate how many notebooks you must sell per month to recover the machine cost within 12 to 24 months.

Challenges & Mitigation

-

Power interruptions or fluctuations

Use stabilisers, UPS or surge protection. Ensure your notebook manufacturing machine is safeguarded against voltage variation. -

Raw Paper Supply Fluctuations

Maintain buffer inventory or contract periodically with a supplier to avoid downtime. -

Machine Downtime

Keep spare parts and consumables, train staff for minor repairs, ensure regular maintenance schedule. -

Competition & Pricing Pressure

Differentiate with quality finish, custom-size notebooks, or branded packaging to avoid competing purely on price.

Conclusion

Setting up a notebook production business in Champa, Chhattisgarh using a quality notebook making machine can be a viable and profitable venture provided you choose the right equipment, plan the workflow, and build relationships with buyers. Whether you choose a semi-automatic or fully-automatic notebook manufacturing machine, your success will depend on quality, cost management, and timely delivery.

If you’re ready to move forward, contact reputable machine suppliers for quotes, compare models on capacity/quality/reliability, inspect previous installations, and prepare a business plan specific to your target market in Champa or nearby districts.