Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

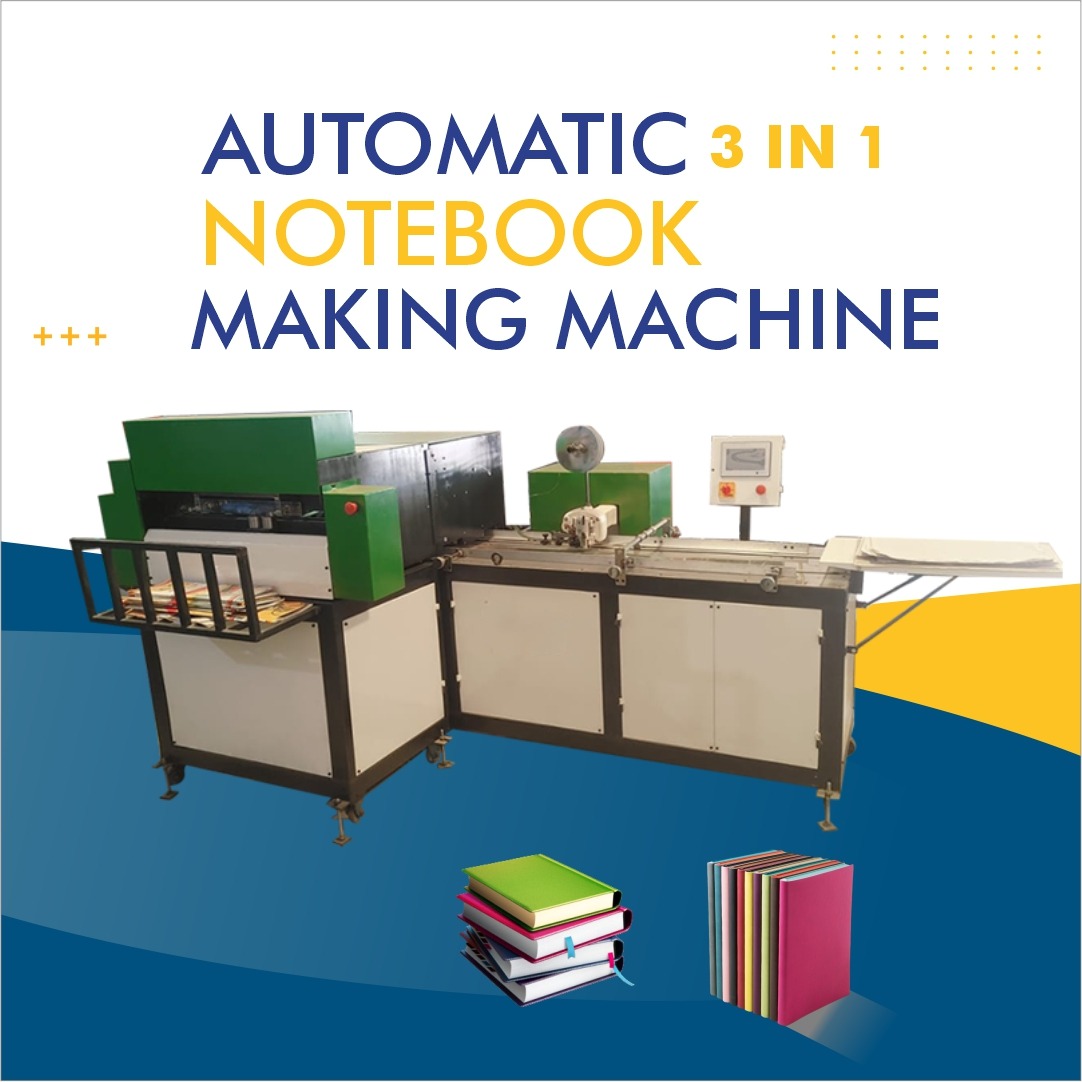

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Bhatapara, Chhattisgarh | Reliable Supplier & Service Provider

Notebook Making Machine in Bhatapara | Chhattisgarh

Located in Bhatapara, Chhattisgarh, our company specializes in supplying notebook making machines for small, medium and large-scale stationery and paper-products manufacturers. We are committed to delivering durable, efficient and cost-effective machinery tailored to the needs of the local market across Chhattisgarh and surrounding states.

We understand that notebook production requires precision in cutting, folding, binding and finishing. Our expertise in mechanical design, electrical automation and on-site support ensures you get a turnkey solution for notebook manufacturing machine and related equipment.

Why Choose Our Notebook Making Machine in Bhatapara

-

Local Presence & Service

Being based in Bhatapara, we can deliver and install machinery quickly across Chhattisgarh — Raipur, Bilaspur, Durg, and Korba. On-site service reduces downtime and helps you maintain continuous production. -

Customizable Designs

We design machines suited to your output volume. Whether you want low-volume or high-speed production, we offer models that can be adapted — thickness, paper size, binding style. -

High Efficiency & Reliability

Our high-speed notebook machine models include features such as servo motor drive, auto-detection of paper jams, and precision cutting & trimming to maintain quality at high throughput. -

After-Sales & Spare Parts Support

We supply genuine spare parts, offer preventive maintenance and immediate service calls in the region. This ensures your notebook manufacturing machine remains operational with minimal downtime. -

Cost-Effective & Scalable

Investment in our machinery offers good ROI. You can start with smaller capacity and scale up as demand grows. We assist in production layout, workflow optimization, and worker training.

Our Product Range

We provide a wide variety of equipment to support full production of notebooks, from raw paper to finished product:

-

Automatic Paper Cutting & Trimming Unit

Precisely cuts large sheets into inner pages and covers. -

Folding & Gathering Section

Aligns and stacks pages in correct order before binding. -

Binding / Stitching / Wire-O Binding Module

Options for saddle-stitch, wire binding or stitching your choice of finishing style. -

Cover Lamination or UV-Coating Unit (optional)

Improves durability and appearance of finished notebook covers. -

Edge-Trimming & Corner-Rounder

Ensures smooth edges and uniform shape. -

Numbering / Perforation / Serial-Labeling Module

For customized numbering or perforation features. -

Automatic Cutting & Guillotine Section

For final trimming after binding to ensure consistent size and neat finish. -

Packaging & Wrapping Module

Optional section for shrink-wrapping or bundle packing notebooks for dispatch.

Each component is engineered for reliability, ease of maintenance, and compatibility with Indian utilities and paper-stock standards.

Technical Specifications

| Parameter | Typical Value or Option |

|---|---|

| Maximum Sheet Size | A3 / A4 / Custom Dimensions |

| Throughput Rate | Up to 3,000 notebooks/hour (depending on model) |

| Paper Thickness Supported | 60 gsm to 300 gsm (inner) / 250 gsm cover |

| Binding Style | Saddle-stitch / Wire-O / Spiral / Stitching |

| Electrical Supply | 415 V, 50 Hz 3-phase (customizable) |

| Machine Footprint | Varies by model, approx. 5 m × 3 m to 10 m × 5 m |

| Control System | PLC / HMI interface with speed adjustment |

| Safety Features | Emergency stop switches, safety guards |

These specifications can be tailored to your requirements — contact us with your production targets and paper sizes.

Applications & Use Cases

Our notebook making machine is ideal for:

-

Stationery manufacturers in Chhattisgarh seeking in-house production rather than outsourcing.

-

Educational institutions or publishers wanting branded notebooks.

-

Small-scale entrepreneurs starting a notebook business.

-

Packaging units combining notebook production with custom printing and finishing.

By installing this machinery locally in Bhatapara, you save on logistics costs, import duties, and delays associated with outsourced finishing.

Installation & Support Services

We offer a comprehensive service package for all notebook manufacturing systems:

-

Site Assessment & Custom Layout Design

Our engineers visit your facility in or near Bhatapara / Bilaspur to assess space, electricity, workflow and safety. Based on that, we propose optimal layout. -

Installation & Commissioning

We handle delivery, on-site installation, and calibration so that the notebook manufacturing machine runs smoothly from day one. -

Training for Operators & Technicians

We conduct hands-on training for your staff on operation, safety, preventive maintenance, and basic troubleshooting. -

Preventive Maintenance Contracts

Regular check-ups, replacement of consumables and wear-parts, lubrication, performance tuning. -

Spare Parts Supply

Fast delivery of critical components such as blades, stitching wire, rollers, belts and electric components within Chhattisgarh region. -

Remote Support & Upgrades

Software or controller updates, capacity upgrades, or retrofit of modules as production needs evolve.

Cost & Financing Options

We understand that investing in industrial machinery can require capital planning. We can help you with:

-

Quotation Based on Your Requirements

Submit your production volume, notebook size, binding style and finish. We will prepare a detailed quote with itemized costs. -

Flexible Payment Terms

Partial advance, phased payments, or staggered delivery as machinery is installed in sections. -

Local Incentives & Subsidies

As you are based in Chhattisgarh, you may be eligible for government incentives, MSME subsidies or regional industrial support — we can guide you on documentation & eligibility. -

Return on Investment (ROI) Analysis

Based on your output per hour, revenue per notebook, and operational costs, we help you calculate the pay-back period so you can make an informed decision.

Why Bhatapara is a Strategic Location

Bhatapara offers key advantages for machinery manufacturers and stationery producers:

-

Proximity to raw-material suppliers including paper mills and packaging vendors in Chhattisgarh.

-

Good road network connecting to Bilaspur, Raipur and other industrial hubs.

-

Competitive labor cost and availability of skilled technicians in the region.

-

Permission and industrial-zone policies favorable to MSMEs located close to Tier-II towns.

By choosing a supplier located in Bhatapara, you benefit from reduced lead-times, faster service, and local regulatory familiarity.

How to Place an Order

To move forward with your notebook making machine purchase:

-

Share your production requirements: notebook size (length × width), number of notebooks per day / hour, binding type, finishing options.

-

Receive a preliminary layout design and machinery specification.

-

Review quote including cost of machine, installation, service contract, spare-parts plan.

-

Schedule installation & commissioning date.

-

Begin production with operator-training and initial test runs.

Contact us by phone, email or visit our office in Bhatapara for a site visit. We also offer a virtual consultation if you prefer.

Frequently Asked Questions (FAQ)

Q: What is the minimum order / capacity for your notebook making machine?

A: We offer entry-level units for small-scale production (e.g. several hundred notebooks per hour) up to high-speed models producing thousands per hour. Please specify your target output.

Q: Can I get a customized size for notebooks (e.g. non-standard dimensions)?

A: Yes. Our design team can develop machines to your required dimensions, binding style or finishing features.

Q: What maintenance is required and how often?

A: Consumable parts such as blades, belts and stitching wire wear depending on usage. A periodic preventive check every 3-6 months is recommended. We can provide a maintenance contract.

Q: Do you provide spare parts locally in Chhattisgarh?

A: Yes. Our facility stocks critical spare components and can dispatch them quickly to your factory anywhere in Chhattisgarh.

Q: What is the expected pay-back period?

A: It depends on your production volume, selling price per notebook, and operating hours. Typically customers recover their investment in 12-36 months. We assist with ROI analysis.

Conclusion

If you are looking for a notebook manufacturing machine in Bhatapara, Chhattisgarh, you’ve come to the right place. We combine local presence with international-quality machinery, customizable design, excellent service and competitive cost. Reach out to us today and we will help you select the ideal system, plan installation, train your staff, and keep your production running smoothly for years to come.