Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

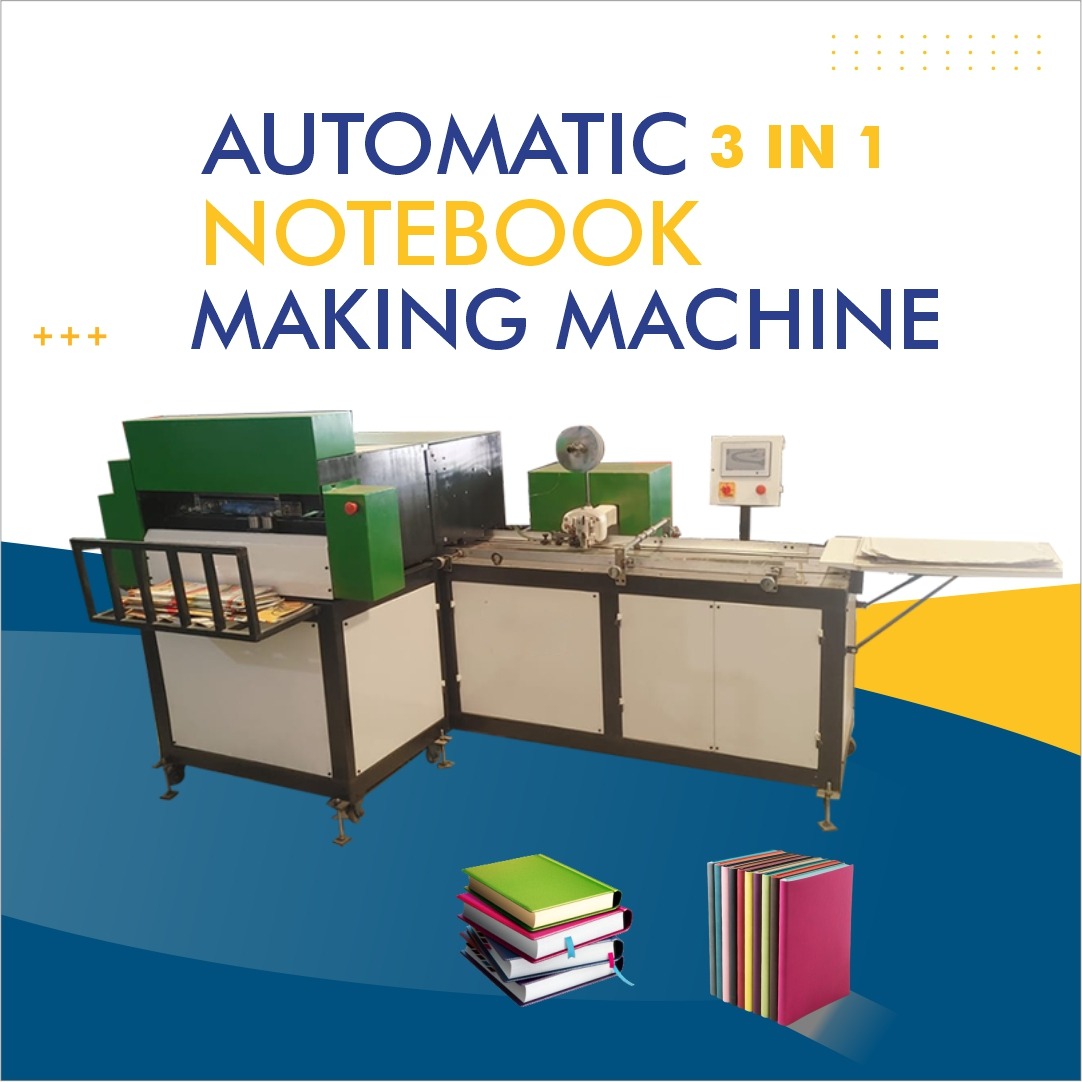

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Bemetara – Industrial Automatic Notebook Maker in Chhattisgarh

Notebook Making Machine Bemetara | Chhattisgarh

If you are exploring solutions to establish or upgrade a notebook making machine facility in Bemetara, Chhattisgarh, you’ve come to the right place. In this detailed guide, we cover everything from selecting the right automatic notebook machine to installation, operation, and maintenance. Whether you are a new investor or an existing school-supply manufacturer, this page will help you make informed decisions about notebook production equipment in Bemetara.

Why Choose Bemetara, Chhattisgarh for Notebook Production

-

Strategic Location: Bemetara is well-connected via road networks to major supply routes in Chhattisgarh. Setting up your factory here reduces transport cost and ensures easy logistics for raw materials and finished notebooks.

-

Local Demand: With increasing demand for stationery and notebooks across schools and colleges in the region, the local market offers opportunities for growth.

-

Supportive State Policies: Chhattisgarh government encourages small and medium enterprises in manufacturing. Incentives, electricity tariffs and industrial partnerships may benefit your project.

-

Lower Labour Costs: Compared to large metros, Bemetara offers lower operational costs for labour, power, lease and local compliance.

Because of these advantages, investing in a high-grade notebook making machine in Bemetara makes business sense.

What Is a Notebook Making Machine?

A notebook making machine is manufacturing equipment used to cut paper, fold leaves, bind them (often using glue or staple), attach covers, trim edges and deliver finished notebooks. Such equipment can be fully automatic or semi-automatic.

Key features include:

-

Paper feeding trays for inner sheets and cover sheets

-

Binding mechanism (e.g. adhesive, spiral, staple)

-

Cutting and trimming tools to ensure clean edges

-

Control panel for sizing, speed, and number of pages

-

Output conveyor or stacking section

When you choose an automatic notebook machine, you get higher throughput, lower manual labour, more consistent quality, and scalable production capacity.

Types of Notebook Making Machines

When sourcing equipment for notebook production in Bemetara or elsewhere, consider various types:

-

Semi-Automatic Notebook Machine

-

Manual feed for paper and cover

-

Operator intervenes at several steps

-

Lower cost initial investment, suitable for small-volume production

-

-

Fully Automatic Notebook Making Machine

-

Minimal human intervention

-

Automatic paper feed, binding, trimming, stacking

-

High output capacity (e.g. hundreds of notebooks per hour)

-

Ideal for industrial-scale production

-

-

Spiral / Wire-O Binding Machine

-

For spiral-bound style notebooks

-

Binding wire insertion, punching or drilling holes

-

Useful for notebooks requiring lay-flat design

-

-

Glue Binding Notebook Machine

-

Hot melt glue binding or cold glue

-

Typical for soft-cover stitched or glued notebooks

-

-

Cutting-Only & Trimming Equipment

-

Additional module to trim edges to perfection

-

Works in tandem with binding module

-

Each of these types can be customized based on the number of pages, paper size, cover thickness, and intended production volume.

Key Specifications to Consider

When evaluating machines for your notebook manufacturing setup in Bemetara, keep these parameters under focus:

| Specification | Why It Matters |

|---|---|

| Speed (notebooks/hour) | Determines your output capacity and ability to meet demand |

| Page-count Range | Machine must support minimum and maximum pages per notebook |

| Paper Size & Format | e.g., A4, A5, custom sizes; machine should adjust accordingly |

| Binding Type | Glue-binding, stapler, spiral bind — choose based on product line |

| Power Consumption | Important for electricity cost prognoses in Chhattisgarh region |

| Footprint & Layout | Floor space in your factory in Bemetara matters for planning |

| Operator Training & Safety | Compliance with safety norms and ease-of-use for staff |

Reviewing these factors helps you select the best-fit paper binding machine for your operation.

Benefits of Installing an Automatic Notebook Machine

-

Higher Productivity: Fully automatic operation delivers hundreds of finished notebooks per hour with consistent quality.

-

Reduced Waste: Precision trimming and binding reduce waste of raw paper and materials.

-

Cost Efficiency: Over time, labour cost and material waste savings compensate for initial investment.

-

Scalability: You can expand your product portfolio (diaries, custom covers) using the same machine platform.

-

Quality Consistency: Automated binding and trimming ensure uniform output across all notebooks.

Because of these benefits, investing in a proper industrial notebook maker is key to keeping your competitive edge in stationery production.

How to Source a Notebook Making Machine in Bemetara

Here’s a step-by-step plan to acquire and commission your equipment locally:

-

Market Survey and Vendor Short-listing

-

Search for manufacturers of notebook making machines in India.

-

Check if they have prior installations in Chhattisgarh or neighboring states.

-

Request case studies or site visits.

-

-

Request for Quotation (RFQ)

-

Prepare specifications: speed, page-range, binding type, size formats.

-

Include delivery to Bemetara, installation charges, training, spare parts.

-

-

Factory Visit & Demonstration

-

Ask vendor for working demo of the same model.

-

Evaluate build quality, ease of operation, maintenance demands.

-

-

Customisation & Local Adaptation

-

Voltage compatibility (India standard supply).

-

Spare-parts availability in or near Bemetara.

-

Local after-sales support and maintenance contract.

-

-

Installation, Testing & Training

-

Vendor should send technician(s) to oversee commissioning at your site.

-

Train your operators in safe machine handling, preventative maintenance, speed adjustment, and troubleshooting.

-

-

Regulatory & Safety Compliance

-

Ensure machine meets Indian safety regulations (e.g. electrical safety, worker protection).

-

Acquire any required factory inspections or approvals under Chhattisgarh state industrial norms.

-

-

Planning Operation Schedule

-

Estimate raw-paper inventory, production planning for schools season peaks.

-

Factor in maintenance downtime windows.

-

Following this structured approach helps ensure your investment in a custom notebook manufacturing operation functions smoothly from day one.

Cost Breakdown & Financial Considerations

While exact prices depend on model and features, here is a typical cost-breakdown overview for a medium-capacity automatic notebook machine installed in Bemetara:

| Item | Approximate Cost (Indicative) |

|---|---|

| Base Machine (Automatic) | ₹8-15 lakh* |

| Shipping & Local Delivery to Bemetara | ₹50,000 – ₹2 lakh (depending on distance & packaging) |

| Installation & Operator Training | ₹30,000 – ₹1 lakh |

| Extended Warranty & Annual Maintenance Contract | Varies by vendor, ~5-10% of machine cost per year |

| Spare Parts Starter Kit | ₹20,000 – ₹50,000 |

* Figures are indicative. Contact vendors for formal quotations. Factor in customs/customs-duty if imported parts involved.

Return-on-Investment (ROI) depends on your production volume, sale price per notebook, and running costs (paper, power, labour). A well-utilised machine typically recovers cost in 18 to 36 months.

Maintenance & After-Sales Support

To keep your notebook production equipment running reliably over years, ensure the following:

-

Scheduled Maintenance: Regular lubrication, belt tensioning, cutter blade re-sharpening, sensor checks.

-

Spare-Parts Availability: Common wear-parts like blades, belts, electrical sensors must be procurable locally or through your vendor.

-

Technical Support: Vendor should provide phone / remote assistance initially, and on-site maintenance visits periodically.

-

Upgrades & Retrofitting: As your business grows, your notebook production equipment may need enhancements (e.g. faster feeders, larger size capacity). Choose a vendor that offers retrofit options.

-

Operator Training Refreshers: Periodic retraining for staff ensures safety and consistent output quality.

Use Cases & Applications

Here are some common applications of a notebook making machine in Bemetara context:

-

School & College Notebooks: Standard ruled notebooks in A5 or A4 size for the local market.

-

Custom Promotional Notebooks: For businesses, events, or institutions around Raipur / Bilaspur region.

-

Corporate Diaries & Planners: Seasonal orders requiring different designs.

-

Export Orders: Supply to stationery brands across India or for export (subject to compliance with export-ready quality).

-

Spiral / Customized Binding: If you choose spiral binding module, you can diversify into sketchbooks or premium notebooks.

Each use case benefits from selecting the correct configuration of binding type, speed, and format.

Why Our Offering Is Ideal for Bemetara

We understand the challenges faced by notebook manufacturers in semi-urban or rural industrial zones like Bemetara:

-

We provide full turn-key installation at your site in Bemetara, Chhattisgarh.

-

Local technicians are available for on-site commissioning and preventive maintenance.

-

Our machines are designed for Indian electricity standards and suitable for medium voltage fluctuations.

-

Spare-part supply network extends across Chhattisgarh and neighbouring states.

-

Competitive pricing with transparent quotation including freight, taxes, and installation cost.

With our solution, you get a robust industrial notebook maker that can scale as your demand grows, while keeping your operating cost competitive.

Conclusion

Deploying a reliable notebook making machine in Bemetara, Chhattisgarh can significantly enhance your capability to serve the regional stationery market. From student notebooks to corporate diaries, the demand is rising. Choosing the right automatic notebook machine ensures high productivity, quality consistency, and long-term savings.

If you are serious about establishing or upgrading your notebook production line in Bemetara, Chhattisgarh, contact us today. We’ll help you choose the right paper binding machine, provide quotation, installation timeline, training plan, and post-sale support.

Start your journey towards efficient, scalable notebook manufacturing — request a proposal now.