Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

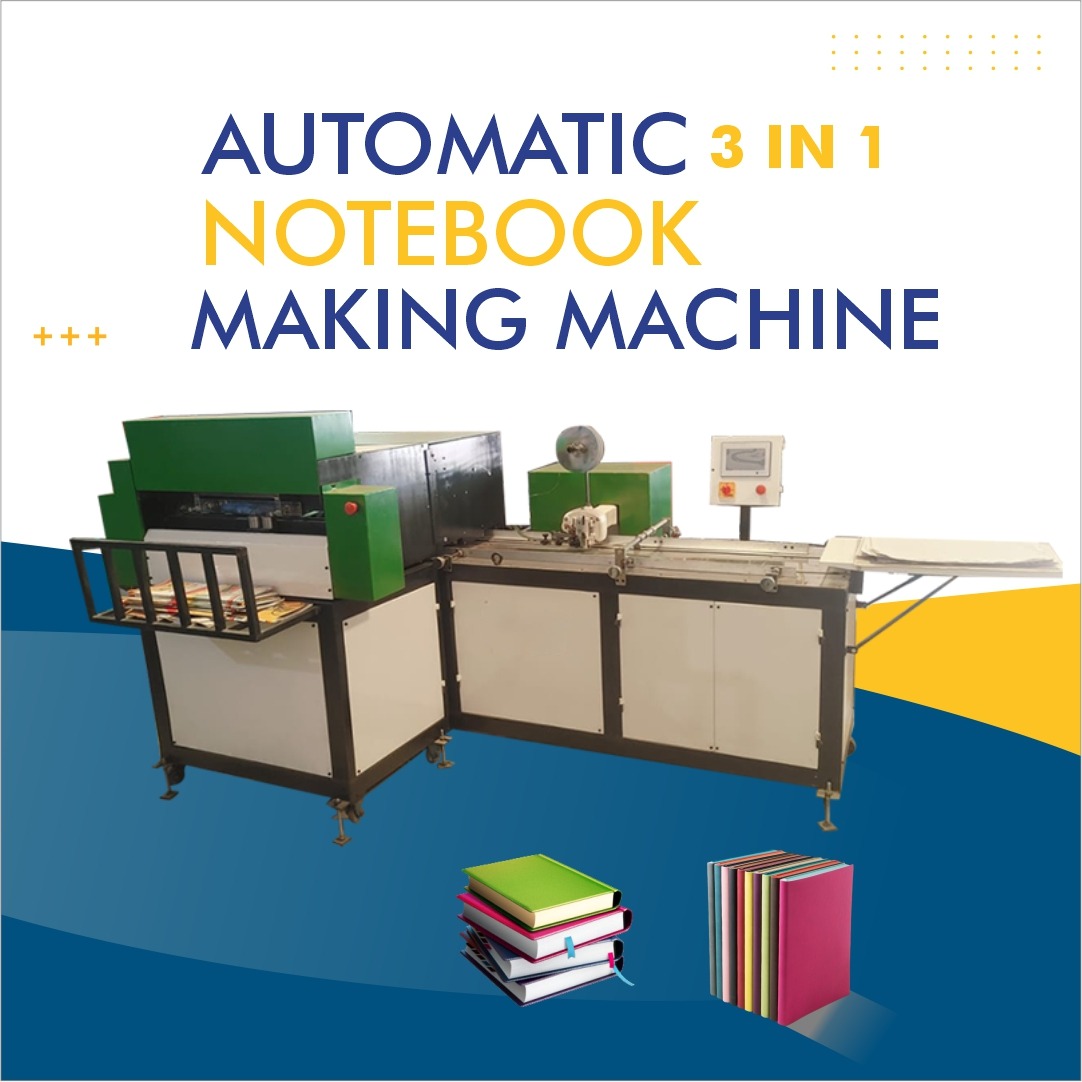

Notebook Making Machine in Baloda Bazar | Buy / Install in Chhattisgarh

Notebook Making Machine in Baloda Bazar | Chhattisgarh

Baloda Bazar is emerging as an industrially active district in Chhattisgarh. Wikipedia+1 With increasing demand for stationery products across schools, colleges, offices and retail outlets throughout Central India, notebook manufacturing has become a promising small-to-medium scale industry opportunity. If you are planning to start or expand a notebook production business in Baloda Bazar, Chhattisgarh, investing in the right notebook making machine is critical.

This article explains everything you need to know — from machine types to features, local considerations in Baloda Bazar, benefits of automation, cost factors, installation, maintenance, and how to select the right notebook making machine for your venture.

Why Choose Baloda Bazar for Notebook Machine Setup

-

Strategic Location: Baloda Bazar-Bhatapara district lies within Raipur division, and is well connected to other industrial districts. Wikipedia+1

-

Industrial Ecosystem: While cement plants dominate, the district also supports SMEs and manufacturing units. Skills Intelligence Platform+1

-

Cost Advantages: Land, labour, utilities may be more affordable compared to metro-areas; suitable for semi-automated or automated plant setup.

-

Growing Demand: Demand for notebooks remains steady (schools/offices), and local/regional distribution to nearby districts is feasible.

Thus Baloda Bazar can be a good location to install or source a notebook making machine or even establish a small-scale notebook manufacturing unit.

Types of Notebook Making Machines

To select the best machine for your purpose, you should consider various types:

-

Manual / Semi-Automatic Notebook Making Machine

These machines require some human intervention for feeding, binding, folding, or stitching. They are suited for small-scale production with moderate investment. -

Fully Automatic 3-in-1 Notebook Making Machine

These combine cutting, folding/edge squaring, stitching (wire binding), collecting output. Higher throughput, less manual labor. For example, some models offer up to 1,500–2,000 books per hour or similar. namibind.com -

Single-Head Automatic Notebook Making Machine

A simpler automatic model focused on stitching, folding and binding functionality. Good for moderate output operations. endurancemachinery.com -

Full Set Machines with Combining Stages

Machines that include cutting, trimming, stitching, folding and packaging support. Useful for setting up a more integrated notebook manufacturing plant. smallbusinessolution.com+1

Each machine type has its pros and cons in terms of investment, throughput, workforce needed, quality, and flexibility in notebook sizes.

Key Specifications & Features to Evaluate

When comparing machines, these parameters matter:

-

Production Capacity: How many notebooks per hour / per shift.

-

Automation Grade: Manual / Semi-Automatic / Fully Automatic.

-

Notebook Size Range: A4, custom sizes, length & width limits.

-

Maximum Notebook Thickness: Defines number of pages / sheets you can bind.

-

Binding / Stitching Type: Wire binding, center stitch, folding & edge squaring.

-

Material & Build Quality: Mild steel frames, PLC control, servo motors.

-

Power Supply & Phase: Many machines need 3-phase power, depending on model.

-

Warranty & After-Sales Service: Important for uptime and maintenance.

-

Footprint & Layout Requirements: Floor area, electrical load, noise, raw material feed area.

-

Cost & ROI: Capital cost, raw material cost (paper, binding wire / staples), labor, maintenance, and expected revenue from notebook sales.

Advantages of Automatic / High-Grade Machines

Investing in a high-quality automatic notebook making machine can bring multiple benefits:

-

Higher Throughput & Efficiency: Less manual work, consistent quality, faster output. Useful if you aim to supply schools, offices or wholesale buyers.

-

Consistency & Quality: Automatic folding, edge squaring and stitching reduce human error; finished notebooks look more professional.

-

Labour Savings: Reduced manual handling reduces staffing needs and operational errors.

-

Scalability: As demand grows, you can upgrade or run multiple shifts with automatic line.

-

Competitive Edge: With high-precision machines, you can compete on quality (less margin slippage, fewer rejects).

However, the upfront cost is higher and you’ll need trained operators, reliable electricity supply (especially 3-phase), and local maintenance support.

Cost Considerations & Investment

When planning to procure a notebook making machine in Baloda Bazar, evaluate:

-

Capital Cost of Machine: Prices vary widely depending on specifications. For example, semi-automatic machines may cost a few lakhs INR; fully automatic machines may cost several lakhs to over ₹8-10 lakhs. Bhartiya Machine Works+1

-

Installation & Shipping: If you import or transport from other cities / states to Baloda Bazar, consider freight, unloading & setup charges.

-

Power & Utilities: Ensure your facility has sufficient power load (possibly three-phase), stable electricity. Utility costs (electricity / compressor if needed).

-

Raw Materials: Paper sheets, binding wire/stitches or staples, covers, glue or adhesives.

-

Labour & Operations: Operators, training, supervision, routine maintenance.

-

Maintenance & Spare Parts: Availability of spare parts locally or through supplier. Warranty terms.

-

ROI Estimation: Estimate monthly production, unit cost per notebook, sale price per notebook, break-even duration.

You may prepare a simple profit forecast:

-

Estimate max production (say daily / monthly notebooks)

-

Deduct material cost, labor, electricity, packaging

-

Compare against expected sales revenue per notebook

-

Calculate months to break-even on your investment in the machine

Local Regulatory & Business Set Up Factors

Starting a small manufacturing setup in Baloda Bazar, Chhattisgarh, you should also consider:

-

Industrial Approvals & Permits: Factory / workshop licenses / compliance with local government norms.

-

Electricity Connections & Load Approvals: For heavy machinery, you may need approvals for higher electrical load / safety inspections.

-

Skill / Labour Availability: Hiring trained or semi-skilled labour to operate and monitor machines. Training may be required.

-

Transportation & Logistics: For delivering finished notebooks to markets (nearby districts, schools or wholesalers).

-

GST / Tax & Accounting: Compliance with GST / local tax regime for manufactures of stationery items.

You might check district-level industrial details; for Baloda Bazar district there are listings of industries in government databases. OCMMS

Suggested Steps to Source / Install a Notebook Making Machine in Baloda Bazar

Here is a practical roadmap:

-

Define Your Production Goal

How many notebooks per month / per shift you intend to produce. Determine sizes (A4 / custom), binding type, thickness. -

Select Machine Type

Based on budget & goal, choose semi-automatic or fully automatic model. Compare brands & features. -

Get Supplier Quotes

Contact machine manufacturers / distributors in India. Request quotations for shipping to Baloda Bazar, installation & training costs. -

Check Power & Infrastructure

Ensure your facility has required floor space, power supply (especially if 3-phase), compressed air (if needed), safety compliance. -

Plan Finances

Finalize investment budget, expected ROI timeline, raw material sourcing, labor costs, and break-even analysis. -

Procure Permits / Licenses

Register your business entity, ensure compliance with local laws, safety, environmental norms (if applicable), trade license. -

Install & Commission

After delivery of the machine, installation by supplier, calibration, trial runs, operator training. -

Start Production & Quality Monitoring

Monitor output daily, manage wastes / defects, ensure consistent quality and timely delivery to customers. -

Scale Up / Maintenance

Implement regular maintenance schedule, plan spare parts sourcing, consider future capacity expansion or additional units.

Case Uses & Business Potential

-

Small-scale stationery business can start with a semi-automatic machine and supply notebooks to local schools, coaching centres and retail shops in Baloda Bazar and nearby towns.

-

Mid-scale manufacturing using automatic or integrated machines can supply to districts around Chhattisgarh, tapping demand in Raipur, Bilaspur, Mahasamund, etc.

-

Custom notebooks & diaries (different cover design, binding styles) can be offered as value-added products, increasing profit margin.

-

OEM / Private-Label Supply: Supply notebooks to educational institutions or government stationery supply contracts.

With proper planning, good quality machinery and efficient operations, a notebook making business with the right machine in Baloda Bazar has the potential for stable revenue and growth.

Conclusion

If you are considering acquiring a notebook making machine in Baloda Bazar, Chhattisgarh, your decision should balance your production target, budget, automation level, and local infrastructure. Choosing a reliable machine with suitable capacity, ensuring proper site setup, and planning your finances carefully will help you establish a successful notebook manufacturing unit.

Whether you select a semi-automatic or fully automatic machine, the key is compatibility with your goals — scale-up potential, product quality, cost efficiency, and after-sales support. With the right approach, Baloda Bazar can be a good base for your stationery manufacturing business.