Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

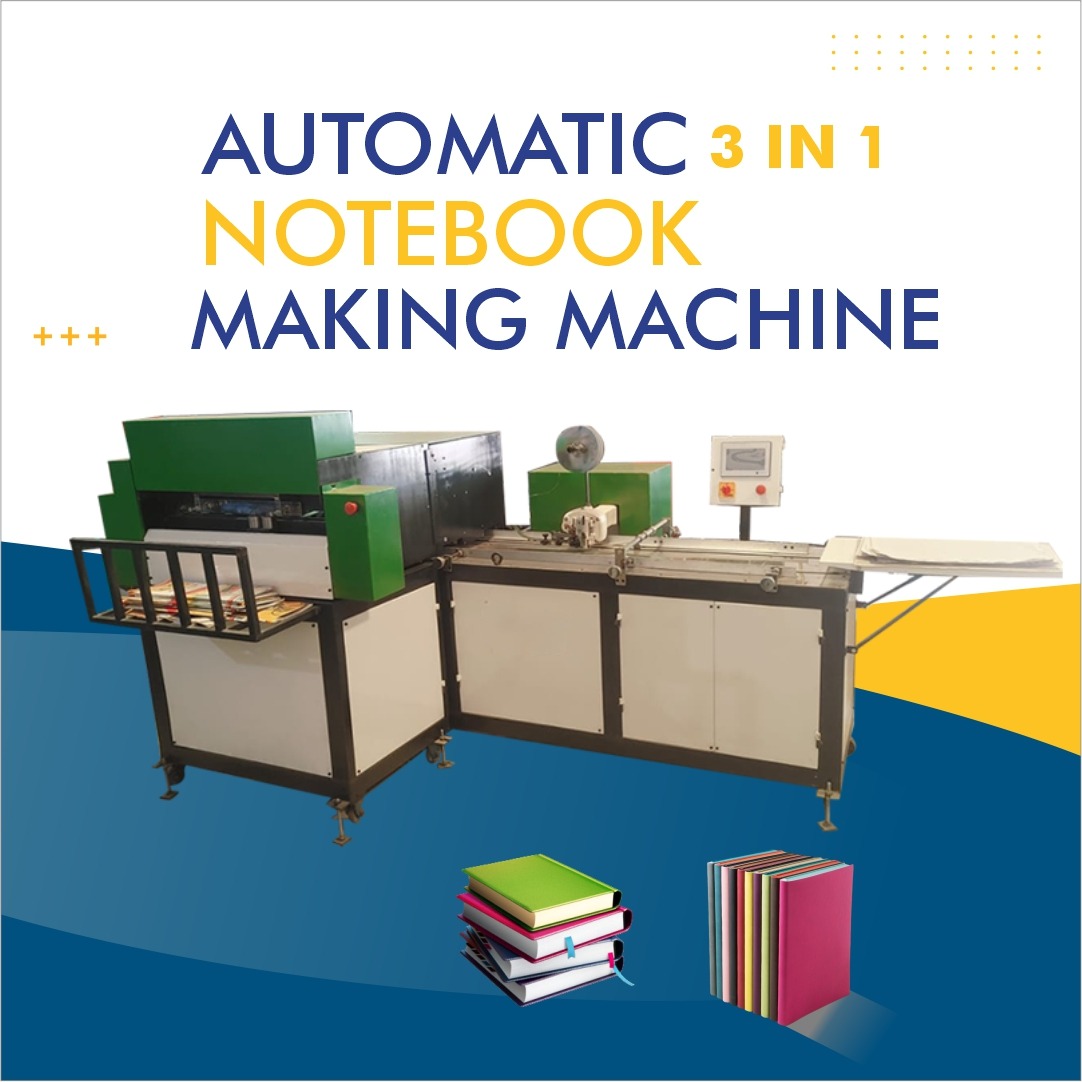

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine Supplier | Baikunthpur, Chhattisgarh

Notebook Making Machine in Baikunthpur | Chhattisgarh

If you are planning to set up a notebook manufacturing unit in Baikunthpur (Chhattisgarh), choosing the right notebook making machine is critical. Whether you want an automatic notebook maker or a semi-automatic system, the correct equipment improves efficiency, reduces waste, and boosts profitability. In this guide, we discuss everything you need to know about notebook making machines, their types, advantages, and how to choose one in Baikunthpur, Chhattisgarh.

1. What Is a Notebook Making Machine?

A notebook making machine is industrial equipment used to produce notebooks by automating processes such as cutting paper sheets, folding, collating pages, binding, and trimming edges. These machines reduce manual labor, improve production speed, and enhance consistency in final products.

Synonyms you may find for the same category include: notebook manufacturing machine, paper binding machinery, notebook production system, book-binding equipment, and stationery manufacturing machine. We will use these interchangeably throughout this article to emphasize relevance.

2. Types of Notebook Making Machines

Automatic Notebook Making Machines

An automatic notebook maker integrates several sub-processes into one continuous workflow. It cuts, folds, staples or binds, trims, and delivers finished units with minimal human intervention. Ideal for medium to large scale production.

Semi-Automatic Notebook Making Machines

Semi-automatic models require some manual action at certain steps (for example loading stack or removing finished product), but automate the core cutting, binding, and trimming operations. These can be more affordable and suitable for small to medium manufacturing units.

Manual or Simple Binding Equipment

If you are starting with smaller capacity or limited budget, manual binding equipment or simpler collating and stapling machines are an option. However, production rate and consistency will be lower.

Customized Machinery

Many manufacturers offer custom notebook making machines designed to your desired specifications (sheet size, binding type, paper capacity, binding method such as stitching or perfect binding).

3. Key Components & Features to Consider

When selecting a notebook making machine in Baikunthpur, you should evaluate the following features:

-

Production Capacity: Number of notebooks per hour/day. Automatic machines may produce hundreds of units per hour.

-

Sheet Size Compatibility: Standard sizes (A4, A5, customized sizes).

-

Binding Method: Saddle stitch, wire-binding, glue binding, stapling.

-

Cutting & Trimming Mechanism: Quality of paper cutting blades, trimming tolerance.

-

Speed & Accuracy: Precision in registration, alignment, speed of operation.

-

Automation Level: Fully automatic, semi-automatic, or manual intervention at steps.

-

Power Supply & Energy Consumption: Availability of electricity infrastructure in Baikunthpur and cost implications.

-

After-Sales Service & Spare Parts: Local support near Baikunthpur, Chhattisgarh for maintenance, spare blades, belts, motors.

-

Machine Footprint & Installation Space: Floor space available in your manufacturing unit.

-

Operator Skill Requirement: Ease of training local staff to run and maintain the equipment.

4. Advantages of Using a Notebook Making Machine

Using a professional notebook making machine offers multiple benefits:

-

Improved Productivity: Automatic or semi-automatic notebook production machinery speeds up production and reduces manual delays.

-

Consistent Quality: Uniform trimming, binding, and finishing, leading to customer satisfaction.

-

Reduced Material Waste: Precise cutting and binding reduces paper waste and mis-aligned sheets.

-

Lower Labour Costs: Automation means fewer manual labour hours, which is helpful in Baikunthpur where labour cost may be moderate, but quality control is critical.

-

Scalability: As your demand increases in Chhattisgarh or nearby states, you can scale up by adding more machines or upgrading to higher-capacity models.

-

Return on Investment: Though capital cost may be high initially, savings in labour, speed, and waste reduction often justify the investment within months to a few years, depending on production volume.

5. Market Demand for Notebooks in Baikunthpur & Chhattisgarh

Baikunthpur is located in the North-Chhattisgarh region. Demand for stationery products such as notebooks remains high due to schools, colleges, coaching centres, and residential population. Local manufacturers servicing Chhattisgarh, Madhya Pradesh, and neighbouring states can benefit from proximity to raw material suppliers and lower logistics costs.

Factors affecting demand include:

-

Academic calendar & school enrolments

-

Government procurement tenders

-

Seasonal demand (new academic year)

-

Local distribution network to retailers

To capitalize on this demand, using a reliable notebook machine supplier located close to your operation base (such as in or near Baikunthpur) helps reduce lead time and ensure timely maintenance.

6. Supplier & Installation in Baikunthpur, Chhattisgarh

When looking for a notebook machine supplier in Baikunthpur or the broader region of Chhattisgarh, consider the following steps:

-

Find local or regional manufacturers: Search for equipment makers in Chhattisgarh, Madhya Pradesh or nearby metro cities (e.g. Raipur, Bilaspur).

-

Inspect working units: Request a demo or visit an existing notebook production factory nearby that uses the machine.

-

Compare automatic vs. semi-automatic options: Evaluate initial cost, expected throughput, and long-term maintenance.

-

Negotiate warranty and spare-parts provision: Ensure the supplier can deliver replacement parts locally and support servicing.

-

Training & commissioning: Confirm that the supplier will provide on-site training of operators in Baikunthpur after installation.

-

After-installation support: Check availability of technicians and ease of ordering consumables such as blades, staples, binding wire, glue.

By choosing a notebook machine supplier with experience in Chhattisgarh and who understands power conditions, freight charges, and regulatory compliance, you reduce risk and downtime.

7. Cost Estimation & Financing

Approximate cost of a new notebook making machine depends on type and capacity:

-

A semi-automatic notebook machine might cost less initially (equipment price range varies based on supplier, model, and features).

-

A fully automatic notebook production machine generally has higher capital investment but lower labour cost per unit and higher output.

-

Import duties, freight charges to Baikunthpur, and installation charges may add to the base price. Local suppliers may offer easier terms or finance options.

You may explore bank financing or small-scale industry (MSME) subsidies for setting up stationery manufacturing in Chhattisgarh. Government schemes may support machinery purchases under industrial policy.

8. Setting Up Your Notebook Production Line

To set up an efficient notebook production line with a notebook making machine in Baikunthpur, follow these steps:

-

Locate a workshop or factory space with sufficient flooring area, power lines (electricity supply), ventilation and safety.

-

Procure raw materials (paper sheets, cover stock, binding wire or staples, glue).

-

Install the notebook making machine and ancillary equipment (paper cutter, stacking tables, conveyors).

-

Train staff in machine operation, safety protocols, and routine maintenance.

-

Establish quality control procedures — check page alignment, binding strength, trimming accuracy.

-

Plan your production process to match seasonal demand: ramp up before the start of the academic year.

-

Develop packaging and branding for final notebooks: covers, printing, lamination, bundling.

-

Set up local distribution to stationery stores, schools or online sales channels.

9. Common Challenges & Troubleshooting

When running a notebook machine in Baikunthpur, you may face these issues:

-

Power Fluctuations: Rural or semi-urban areas may have voltage fluctuation. Choose equipment with voltage stabilizers or built-in protection.

-

Maintenance Delays: If spare parts are not readily available locally, downtime can disrupt your production.

-

Wear & Tear of Cutting Blades: Frequent replacement or sharpening may be required; quality of spare parts matters.

-

Raw Material Quality Variance: Paper stock may vary in thickness or moisture content; ensure consistent supply.

-

Skilled Operator Turnover: Training new operators in binding accuracy and machine safety is necessary for consistent quality.

To mitigate challenges, maintain service contracts with your supplier, keep safety stock of consumables and spare parts, and conduct scheduled preventive maintenance.

10. Choosing Your Keywords & SEO Strategy

To attract customers searching for “notebook making machine” in Baikunthpur or Chhattisgarh online, you should optimize your website pages and content with the following keyword phrases:

-

notebook making machine

-

notebook machine supplier

-

automatic notebook maker

-

semi-automatic notebook machine

-

paper binding equipment

-

Baikunthpur notebook machine

-

Chhattisgarh notebook manufacturing

-

notebook production machinery

-

stationery machinery Chhattisgarh

-

binding equipment supplier Baikunthpur

Repeat these terms naturally across headings, paragraphs, alt-text for images (if any), and page metadata to enhance SEO relevance.

11. Why Buy in Baikunthpur — Local Advantages

Purchasing or installing a notebook maker machine locally in Baikunthpur or nearby regions of Chhattisgarh offers these local advantages:

-

Reduced logistics and shipping cost compared to buying from far-off locations

-

Easier coordination for installation, commissioning and periodic maintenance

-

Lower lead time for spare-part delivery

-

Better understanding of local environmental conditions (humidity, electricity supply) by local suppliers

-

Access to regional subsidies or incentives for industrial units in Chhattisgarh

These factors can improve your return on investment and streamline your operations.

12. Case Study: Hypothetical Notebook Unit in Baikunthpur

Imagine you establish a small-scale notebook factory in Baikunthpur with a semi-automatic notebook making machine. You install a model that produces 500 notebooks per hour. With three shifts per day, you could generate up to 10,000 units daily. At a margin of ₹5 per unit, that translates to ₹50,000 daily gross profit (before raw-material cost). Over a month, that’s over ₹1.5 million in revenue. If your machine paid for itself via reduced labour costs and increased consistency within 12-18 months, you will have long-term profitability with scope to upgrade to an automatic notebook maker in future.

Conclusion

-

Choosing the right notebook making machine (automatic or semi-automatic) is essential for scaling your notebook manufacturing.

-

Prioritize features such as capacity, binding method, spare-parts availability, and local support in Baikunthpur / Chhattisgarh.

-

Use appropriate SEO-ready keywords on your website or product pages to attract customers searching for notebook making machine or related terms in Baikunthpur.

-

Inspect suppliers, evaluate cost versus throughput, and consider power-supply or maintenance issues in your local area.

-

Plan for raw materials, staffing, quality control, and seasonal demand cycles