Paper Plate Machines

- Double Die Paper Plate Machine

- Fully Automatic Paper Plate Machine

- Hydraulic Paper Plate Machine

- Paper Plate Making Machines

- Single Die Paper Plate Making Machine

Notebook Making Machine

- Notebook Cutting Machine

- Notebook Edge Squaring Machine

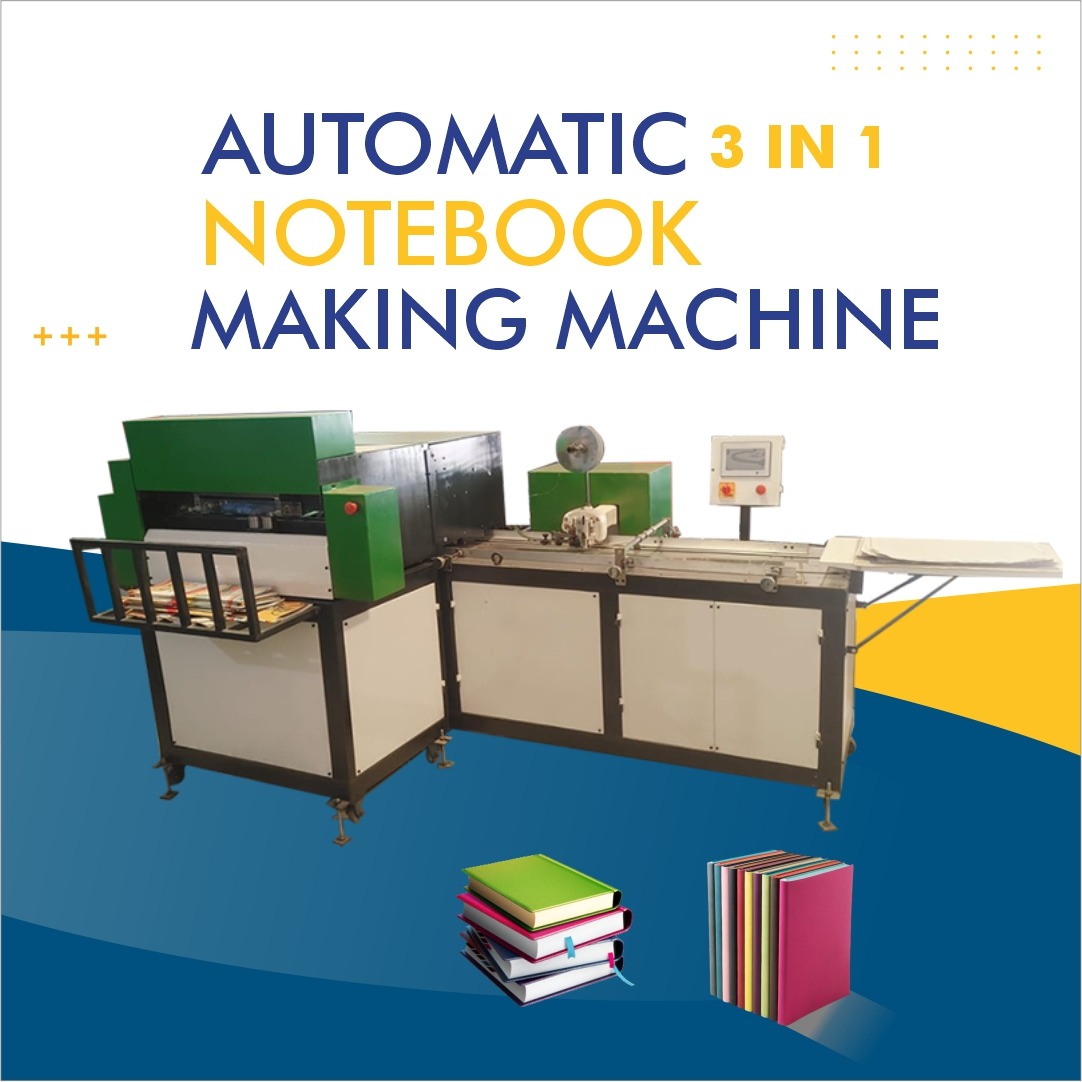

- Notebook Making Machine

- Notebook Spiral Binding Machine

- Notebook Stitching And Folding Machine

- Notebook Stitching Machine

Incense Making Machines

- Automatic agarbatti making machine

- Camphor Tablet Making Machine

- Dhoopbatti Making Machine

- Manual agarbatti making machine

Food Processing Machine

- BREAD SLICER MACHINE

- 4 BOLT OIL EXPELLER MACHINE

- 6 bolt oil expeller machine

- 9 BOLT OIL EXPELLER MACHINE

- Atta Chakki Machine

- Automatic paneer press machine

- Automatic rice mill with polisher

- Besan Making Machine

- Cattle feed machine

- Centrifugal chalna seperator

- Chapati Making Machine

- COLD PRESS OIL EXPELLER MACHINE

- Cotton Candy Making Machine

- Dal dryer machine

- Dal polisher machine

- Fully automatic noodles making machine

- Khoya Making Machine

- Kurkure Making Machine

- Kurkure roaster machine

- Laddu making machine

- Malli machine

- Masala coating machine

- Masala Making Machine

- Mini oil expeller machine

- Mini Rice Mill Machine

- Momos Making Machine

- Mustard Oil Expeller Machine

- Namkeen making machine

- Noodles Making Machine

- Oil And Hydro Dryer Machine

- OIL FILTER MACHINE

- Paneer press machine

- Pani Puri Making Machine

- Papad making machine

- Pasta Making Machine

- Planetary mixer machine

- Popcorn making machine

- Potato peeler machine

- Potato slicer machine

- RASGULLA MAKING MACHINE

- Soda vending machine

- Sugarcane juice machine

- Tomato Sauce Making Machine

Other Machines

- Concrete Vibrating Machine

- Automatic slipper machine

- Concrete Mixing Machine

- Cotton Wick Machine

- Hydraulic Press Brick Making Machine

- Ladies Bindi Making Machine

- Manual slipper machine

- Mini chaff cutter machine

- Paper cup making machine

- Sambrani cup making machine

- Sanitary Pad Making Machine

- Tissue Paper Making Machine

- Wire nail grinder machine

- Wire Nail Making Machine

- Wire nail polishing machine

Packing Machines

Detergent Making Machines

Rotary Oven Machine

- 12 tray rotary oven

- 18 tray rotary oven

- 24 tray rotary oven

- 36 tray rotary oven

- 42 tray rotary oven

- 84 tray rotary oven

Notebook Making Machine in Arang, Chhattisgarh | Reliable Manufacturer & Supplier

Notebook Making Machine in Arang | Chhattisgarh

In the ever-growing stationery manufacturing sector of Chhattisgarh, the demand for efficient and durable notebook making machines has increased dramatically. Businesses in Arang are seeking robust notebook making machines to produce high-quality notebooks at competitive cost. Whether it’s a small-scale factory or a large production house, choosing the right notebook making machine can determine the product quality, production speed, and long-term profitability.

This article explores everything you need to know about notebook making machines located or available in Arang, Chhattisgarh — from features, types, technical specifications, advantages, and local manufacturer insights to buying considerations and maintenance tips.

What is a Notebook Making Machine?

A notebook making machine is a specialized industrial device used to automate the tasks of cutting, folding, pasting, sewing, binding, trimming, and finishing notebooks. It can integrate several operations like page assembly, binding edge gluing, spiral binding or stitch binding, and cover attachment. The goal is to reduce manual labor, improve precision, increase throughput, and maintain consistency in finished notebooks.

Types of notebook making machines include:

-

Automatic sheet cutting and trimming machines

-

Binder feeding and binding machines

-

Edge glue pasting systems

-

Stitch-binding or staple binding units

-

Cover lamination and finishing devices

-

Spiral wire binding attachments

These machines vary from semi-automatic to fully automatic, depending on production requirements.

Why Choose a Notebook Making Machine in Arang, Chhattisgarh?

Strategic Location & Local Support

Arang is strategically located with good connectivity to Raipur and other industrial hubs in Chhattisgarh. Choosing a local notebook making machine manufacturer in Arang means you benefit from shorter lead times, better installation support, and localized after-sales service.

Cost Efficiency

Purchasing machinery locally reduces shipping cost, import duties, and handling overheads. Also, local vendors often understand state-level incentives, taxes, and provide on-site training.

Customisation & Adaptability

A machine manufactured or assembled in Arang can be customized to the local paper sizes, binding types, and production scales common in Chhattisgarh. You can request specifications best suited to your production line — for example, adjusting cutting rollers to standard paper sizes used in your factory.

Skilled Workforce & Proximity to Raw Materials

Arang and nearby areas have an accessible workforce skilled in mechanical trades. For producing notebook making machines — especially components like rollers, frames, feeder systems, and electrical modules — local suppliers and workshops are available. That gives an advantage in spare-parts availability and faster turnaround for repairs or upgrades.

Key Features to Look for in a Notebook Making Machine

When selecting a notebook making machine in Arang or nearby, consider the following features:

-

Production Capacity

Estimate how many notebooks you intend to produce per hour or per day. Machines with higher throughput may cost more, but reduce per-unit cost. -

Automation Level

Decide on manual, semi-automatic, or fully automatic. Fully automatic machines integrate cutting, feeding, binding, and trimming with minimal human intervention. -

Binding Type

Choose between stitch binding, staple binding, glue binding, or spiral binding. Some hybrid machines support multiple binding methods. Ensure the machine supports your chosen binding style. -

Paper Size & Thickness

Verify compatibility with standard notebook sizes (A4, A5, custom sizes). Also check maximum paper thickness or number of pages per binding operation. -

Cutting & Trimming Quality

Precision blade quality, trimming mechanisms, and safety features matter. Accurate trimming ensures neat edges and consistent product appearance. -

Controls & Interface

Modern notebook machines may feature PLC panels, touch-screen controls, automated fault detection, and recipe memory for switching between product models. -

Power Consumption & Safety Standards

Machines should comply with Indian electrical standards, have overload protection, emergency stop buttons, and safety guards around moving parts. -

After-Sales & Spare Parts Availability

Local manufacturer presence in Arang ensures easier service visits, faster repairs, and genuine spare parts supply.

Types of Notebook Making Machines You Can Find in Arang

Below is a summary of different varieties you might encounter or request from a manufacturer in Arang:

| Type | Description |

|---|---|

| Semi-Automatic Notebook Maker | Requires manual feeding or loading of pages or covers; binding and trimming are automated. |

| Fully Automatic Notebook Making Line | From paper cutting, feeding, binding, trimming, to finishing — all stages automated. Ideal for high-volume production. |

| Glue-Binding Machine | Applies adhesive to spine; suited for soft-cover notebooks, glue binding on the spine. |

| Stitch / Staple Binding Machine | Uses stitching or stapling units to bind folded pages; commonly used for notebooks with central spine staples. |

| Spiral or Wire Binding Attachment | Adds spiral binding capability; popular for diaries or engineering notebooks. |

| Trimming & Perforation Module | After binding, trims edges to exact dimensions and can perforate sheets for tear-off features. |

Manufacturers in Arang may offer modular systems so you can upgrade from a basic binding unit to a more advanced finishing line over time.

Benefits of Investing in a Notebook Making Machine in Arang

-

Improved Production Speed

Automation dramatically reduces manual labor time per notebook. This helps you scale production to meet higher demand during school seasons and festivals. -

Enhanced Quality & Consistency

Machines maintain uniform binding strength, precise trimming, and consistent finishing. This leads to better product quality and fewer defects or rejects. -

Lower Operational Costs

Though initial investment may be substantial, the per-unit cost of notebooks drops when you amortize capital cost across large production runs. -

Competitive Edge

With updated machinery you can introduce new styles (e.g. custom sizes, wire binding, laminated covers) and differentiate your notebooks in the market. -

Scalability

Starting with one machine, you can later augment capacity by adding modules (cutters, feeders, laminators) as your business grows. -

Regulatory & Safety Compliance

Modern machines comply with workplace safety regulations and reduce human exposure to hazardous cutting or trimming operations.

Buying Guide for Notebook Making Machines in Arang

Here are steps and recommendations to guide your purchase:

-

Define Your Requirements

-

How many notebooks per hour?

-

What sizes and formats?

-

Which binding styles?

-

Will you need customization or modular upgrade?

-

-

Request Quotes from Local Manufacturers

Ask for detailed technical specifications, layout drawings, electrical diagrams, and video demonstrations if available. -

Check References & Customer Feedback

Ask the manufacturer for references of existing clients in Chhattisgarh. Visit their facility in Arang if feasible. -

Visit Factory (if possible)

See a working demo machine under load. Verify build quality, alignment, feed accuracy, and finishing quality first-hand. -

Negotiate Warranty & After-Sales Service

Ensure warranty terms include parts and service. Ask about response times for maintenance calls within Raipur-Arang region. -

Consider Financing & Incentives

Check any state government support for small or medium-scale industries in Chhattisgarh. Sometimes capital equipment purchases are eligible for subsidies or low-interest loans. -

Installation & Training

Clarify whether the machine price includes installation, operator training, and start-up assistance. Local support means you can request hands-on training. -

Spare-Parts & Maintenance Contracts

Choose suppliers who stock critical parts locally. A maintenance contract can reduce downtime and ensure sustained production.

Maintenance Tips for Notebook Making Machines

To keep your machine productive and long-lasting, follow these maintenance practices:

-

Regular Lubrication & Cleaning

Moving parts like cutting blades, rollers, and bindings units require scheduled lubrication to prevent wear. -

Blade Sharpening & Replacement

Inspect cutting blades for dullness. Replace or sharpen blades periodically to maintain clean trimming edges. -

Alignment Calibration

Ensure page feeders and binding alignment sensors are calibrated every few weeks, especially after heavy usage. -

Electrical & Sensor Checks

Inspect motors, sensors, and safety switches regularly. Loose wiring or misaligned sensors can cause misfeeds or machine halts. -

Operator Training Refresher

Even after initial training, periodic refresher sessions help ensure correct setup, reduce errors, and extend machine life. -

Spare-Parts Stocking

Keep critical spare items on hand (belts, fuses, adhesives, binding staples or wires) for immediate replacement to avoid downtime.

Case Study: Hypothetical Notebook Factory Near Arang

Imagine a small-scale notebook factory near Arang that invested in a semi-automatic notebook making machine. Before installation, they were binding manually — around 500 notebooks per day. After installing the machine, their capacity rose to 2,500 notebooks daily. Quality control improved (fewer misaligned pages or trimming errors), waste was reduced by over 15 percent, and labor costs fell by one additional staff member. Within twelve months, the machine paid for itself through productivity gains and increased order volumes during school season.

Expanding further, they added a trimming & perforation module from the same Arang-based manufacturer, enabling them to offer tear-off notebooks and custom designs. Their sales contracts in Raipur schools increased by 30 percent due to improved finish and reliable delivery times.

Challenges & Solutions

Challenge: Power Fluctuations

In some parts of Chhattisgarh, voltage fluctuations or unstable supply can affect electrical equipment. Solution: Ensure the machine has built-in voltage stabiliser or request an external UPS unit. Confirm that your local provider offers suitable power protection devices.

Challenge: Raw Paper Quality Variation

Paper quality supplied locally may vary in thickness or finish. Solution: Work with your manufacturer to adjust feeder pressure settings, calibrate sensors, or upgrade feeding rollers for your paper grade.

Challenge: Operator Skill Levels

Operators may not have prior experience with industrial machinery. Solution: Ask the manufacturer to provide hands-on training, operation manual in local language, and safety guidelines. Consider on-site refresher sessions after six months.

How to Search for a Good Supplier in Arang

-

Use local business directories and industry forums for machinery suppliers in Raipur-Arang corridor.

-

Attend industrial trade fairs in Chhattisgarh or nearby states focusing on stationery or packaging machinery.

-

Seek recommendations from established notebook-making businesses in Raipur, Bilaspur or Bhilai who may have purchased machines locally.

-

Check for engineering workshops in Arang that specialise in metal fabrication and mechanical assemblies; they may build or refurbish machines or parts under contract.

Conclusion

For any stationery manufacturing business in Chhattisgarh, investing in a high-quality notebook making machine with local support from Arang can offer tangible benefits: better productivity, superior quality, lower long-term cost, and scalability for future growth. By carefully evaluating features, verifying supplier credibility, negotiating support and maintenance, and planning for training and spare-part management, you can ensure that your notebook production line is robust, efficient and competitive.